Catalyst Support Engineering To Optimize Adsorption Energetics

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Catalyst Support Engineering Background and Objectives

Catalyst support engineering has evolved significantly over the past decades, transitioning from simple inert carriers to sophisticated materials that actively participate in catalytic processes. The field emerged in the early 20th century with the development of industrial catalysts for petroleum refining and chemical synthesis, where supports primarily served to disperse active metal components and provide mechanical stability. By the 1970s, researchers began recognizing the critical role supports play in modifying electronic properties of catalytic sites, leading to the concept of strong metal-support interactions (SMSI).

The advancement of surface science techniques in the 1980s and 1990s enabled deeper understanding of support effects on adsorption energetics, revealing how support materials can fundamentally alter the binding strength of reactants and intermediates at active sites. This knowledge has driven the field toward rational design approaches rather than empirical optimization. Recent developments in computational chemistry and in-situ characterization methods have further accelerated progress by allowing researchers to predict and observe support-adsorbate interactions at atomic scales.

Current technological trends focus on precise engineering of support properties including surface acidity/basicity, defect structures, oxygen vacancy concentration, and interfacial electronic states. The emergence of 2D materials, metal-organic frameworks, and single-atom catalysts has expanded the design space for support engineering, offering unprecedented control over adsorption energetics. Additionally, the growing emphasis on sustainable catalysis for renewable energy applications has intensified research on support materials that can operate effectively under diverse and often harsh reaction conditions.

The primary objective of catalyst support engineering is to develop methodologies for tailoring adsorption energetics to achieve optimal catalytic performance. This involves establishing structure-property relationships that connect support characteristics to adsorption behavior and catalytic outcomes. Specific goals include enhancing activity by optimizing binding strengths according to the Sabatier principle, improving selectivity through preferential adsorption of desired intermediates, and extending catalyst lifetime by mitigating deactivation mechanisms related to strong adsorption of poisons or coking precursors.

Another critical objective is to develop universal design principles that can be applied across different catalytic systems, moving beyond case-by-case optimization. This includes creating predictive models that correlate support properties with adsorption energetics and establishing high-throughput experimental protocols for rapid screening of support materials. The ultimate aim is to enable precise engineering of the catalytic microenvironment at the molecular level, allowing for customized adsorption properties that maximize efficiency, selectivity, and stability across diverse chemical transformations.

The advancement of surface science techniques in the 1980s and 1990s enabled deeper understanding of support effects on adsorption energetics, revealing how support materials can fundamentally alter the binding strength of reactants and intermediates at active sites. This knowledge has driven the field toward rational design approaches rather than empirical optimization. Recent developments in computational chemistry and in-situ characterization methods have further accelerated progress by allowing researchers to predict and observe support-adsorbate interactions at atomic scales.

Current technological trends focus on precise engineering of support properties including surface acidity/basicity, defect structures, oxygen vacancy concentration, and interfacial electronic states. The emergence of 2D materials, metal-organic frameworks, and single-atom catalysts has expanded the design space for support engineering, offering unprecedented control over adsorption energetics. Additionally, the growing emphasis on sustainable catalysis for renewable energy applications has intensified research on support materials that can operate effectively under diverse and often harsh reaction conditions.

The primary objective of catalyst support engineering is to develop methodologies for tailoring adsorption energetics to achieve optimal catalytic performance. This involves establishing structure-property relationships that connect support characteristics to adsorption behavior and catalytic outcomes. Specific goals include enhancing activity by optimizing binding strengths according to the Sabatier principle, improving selectivity through preferential adsorption of desired intermediates, and extending catalyst lifetime by mitigating deactivation mechanisms related to strong adsorption of poisons or coking precursors.

Another critical objective is to develop universal design principles that can be applied across different catalytic systems, moving beyond case-by-case optimization. This includes creating predictive models that correlate support properties with adsorption energetics and establishing high-throughput experimental protocols for rapid screening of support materials. The ultimate aim is to enable precise engineering of the catalytic microenvironment at the molecular level, allowing for customized adsorption properties that maximize efficiency, selectivity, and stability across diverse chemical transformations.

Market Analysis for Advanced Catalyst Support Technologies

The global market for advanced catalyst support technologies is experiencing robust growth, driven primarily by increasing demand for more efficient and sustainable catalytic processes across multiple industries. Current market valuation stands at approximately $6.2 billion, with projections indicating a compound annual growth rate of 5.8% through 2028. This growth trajectory is particularly evident in regions with strong industrial bases such as North America, Europe, and rapidly industrializing Asian economies, especially China and India.

The petroleum refining sector remains the largest consumer of advanced catalyst supports, accounting for roughly 42% of the total market share. This dominance stems from the industry's continuous need to process increasingly heavy and sour crude oil feedstocks while meeting stringent environmental regulations. The chemical synthesis industry follows closely, representing about 28% of market demand, with particular emphasis on fine chemicals and pharmaceutical intermediates production.

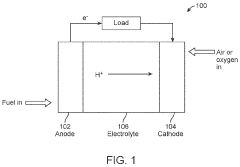

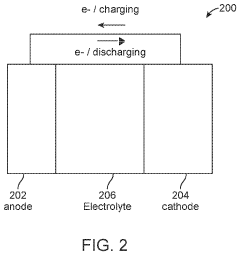

Environmental applications, especially emission control technologies, constitute the fastest-growing segment with a growth rate exceeding 7.5% annually. This acceleration is directly linked to tightening global emission standards and the increasing adoption of catalytic converters in automotive applications. Additionally, the renewable energy sector is emerging as a significant market driver, particularly in hydrogen production and fuel cell technologies where optimized adsorption energetics play a crucial role.

Market analysis reveals a clear shift toward engineered supports that offer precise control over adsorption energetics. Customers are increasingly willing to pay premium prices for supports that demonstrate superior selectivity, stability, and activity. This trend is reflected in the growing market share of advanced materials such as hierarchical zeolites, metal-organic frameworks (MOFs), and graphene-based supports, which collectively account for approximately 23% of the market value despite representing only 11% of volume sales.

Regional market dynamics show interesting patterns, with North America and Europe focusing on innovation and high-performance applications, while Asian markets emphasize cost-effective scaling and manufacturing optimization. The Middle East region is rapidly expanding its catalyst support manufacturing capabilities, leveraging its petrochemical industry advantages.

Customer segmentation analysis indicates that large multinational corporations dominate procurement volumes, but small and medium enterprises represent a growing customer base, particularly for specialized applications requiring customized adsorption properties. This diversification presents significant opportunities for targeted product development and specialized market entry strategies focused on optimizing adsorption energetics for specific catalytic processes.

The petroleum refining sector remains the largest consumer of advanced catalyst supports, accounting for roughly 42% of the total market share. This dominance stems from the industry's continuous need to process increasingly heavy and sour crude oil feedstocks while meeting stringent environmental regulations. The chemical synthesis industry follows closely, representing about 28% of market demand, with particular emphasis on fine chemicals and pharmaceutical intermediates production.

Environmental applications, especially emission control technologies, constitute the fastest-growing segment with a growth rate exceeding 7.5% annually. This acceleration is directly linked to tightening global emission standards and the increasing adoption of catalytic converters in automotive applications. Additionally, the renewable energy sector is emerging as a significant market driver, particularly in hydrogen production and fuel cell technologies where optimized adsorption energetics play a crucial role.

Market analysis reveals a clear shift toward engineered supports that offer precise control over adsorption energetics. Customers are increasingly willing to pay premium prices for supports that demonstrate superior selectivity, stability, and activity. This trend is reflected in the growing market share of advanced materials such as hierarchical zeolites, metal-organic frameworks (MOFs), and graphene-based supports, which collectively account for approximately 23% of the market value despite representing only 11% of volume sales.

Regional market dynamics show interesting patterns, with North America and Europe focusing on innovation and high-performance applications, while Asian markets emphasize cost-effective scaling and manufacturing optimization. The Middle East region is rapidly expanding its catalyst support manufacturing capabilities, leveraging its petrochemical industry advantages.

Customer segmentation analysis indicates that large multinational corporations dominate procurement volumes, but small and medium enterprises represent a growing customer base, particularly for specialized applications requiring customized adsorption properties. This diversification presents significant opportunities for targeted product development and specialized market entry strategies focused on optimizing adsorption energetics for specific catalytic processes.

Current Challenges in Adsorption Energetics Optimization

Despite significant advancements in catalyst design, optimizing adsorption energetics remains one of the most challenging aspects in heterogeneous catalysis. The fundamental challenge lies in achieving the delicate balance described by the Sabatier principle – adsorption energies must be neither too strong nor too weak to maximize catalytic activity. Current computational methods, while powerful, still struggle with accurately predicting adsorption energetics for complex catalyst systems, particularly when dealing with multimetallic surfaces or complex support interactions.

Material stability presents another significant challenge, as high-temperature reactions and harsh chemical environments can lead to catalyst degradation, sintering, and deactivation. The dynamic nature of catalyst surfaces under reaction conditions further complicates matters, as surface reconstructions and adsorbate-induced modifications can dramatically alter adsorption properties during operation.

Support-metal interactions, while offering opportunities for tuning adsorption energetics, introduce complexity that is difficult to characterize and control precisely. The electronic effects at these interfaces remain incompletely understood, limiting rational design approaches. Additionally, the presence of multiple active sites with varying adsorption properties on real catalyst surfaces creates heterogeneity that is challenging to account for in both theoretical models and experimental characterizations.

Scale-up issues persist as laboratory-optimized catalysts often perform differently at industrial scales due to mass transfer limitations, heat management challenges, and support material constraints. The gap between fundamental surface science studies on well-defined systems and practical catalysts with complex morphologies and compositions remains substantial.

Characterization limitations further impede progress, as in-situ and operando techniques capable of monitoring adsorption energetics under reaction conditions are still developing. The spatial and temporal resolution needed to capture the dynamic behavior of adsorption sites during catalysis exceeds the capabilities of many current analytical methods.

Economic and sustainability constraints add another layer of complexity, as industry increasingly demands catalysts that not only optimize adsorption energetics but also minimize the use of precious metals, demonstrate long-term stability, and enable environmentally benign processes. The trade-offs between performance, cost, and sustainability often necessitate compromises in adsorption energy optimization.

Addressing these challenges requires interdisciplinary approaches combining advanced computational modeling, novel synthesis methods, cutting-edge characterization techniques, and innovative reactor designs. The development of machine learning algorithms to predict adsorption properties and high-throughput experimental methods to rapidly screen catalyst formulations represents promising directions for overcoming current limitations.

Material stability presents another significant challenge, as high-temperature reactions and harsh chemical environments can lead to catalyst degradation, sintering, and deactivation. The dynamic nature of catalyst surfaces under reaction conditions further complicates matters, as surface reconstructions and adsorbate-induced modifications can dramatically alter adsorption properties during operation.

Support-metal interactions, while offering opportunities for tuning adsorption energetics, introduce complexity that is difficult to characterize and control precisely. The electronic effects at these interfaces remain incompletely understood, limiting rational design approaches. Additionally, the presence of multiple active sites with varying adsorption properties on real catalyst surfaces creates heterogeneity that is challenging to account for in both theoretical models and experimental characterizations.

Scale-up issues persist as laboratory-optimized catalysts often perform differently at industrial scales due to mass transfer limitations, heat management challenges, and support material constraints. The gap between fundamental surface science studies on well-defined systems and practical catalysts with complex morphologies and compositions remains substantial.

Characterization limitations further impede progress, as in-situ and operando techniques capable of monitoring adsorption energetics under reaction conditions are still developing. The spatial and temporal resolution needed to capture the dynamic behavior of adsorption sites during catalysis exceeds the capabilities of many current analytical methods.

Economic and sustainability constraints add another layer of complexity, as industry increasingly demands catalysts that not only optimize adsorption energetics but also minimize the use of precious metals, demonstrate long-term stability, and enable environmentally benign processes. The trade-offs between performance, cost, and sustainability often necessitate compromises in adsorption energy optimization.

Addressing these challenges requires interdisciplinary approaches combining advanced computational modeling, novel synthesis methods, cutting-edge characterization techniques, and innovative reactor designs. The development of machine learning algorithms to predict adsorption properties and high-throughput experimental methods to rapidly screen catalyst formulations represents promising directions for overcoming current limitations.

State-of-the-Art Support Engineering Methodologies

01 Metal-support interactions for optimized adsorption energetics

Engineering the interface between metal catalysts and their supports can significantly alter adsorption energetics. By controlling the electronic properties at this interface, the binding strength of reactants and intermediates can be tuned to optimize catalytic performance. These interactions can be manipulated through various preparation methods, including controlled deposition techniques and post-synthesis treatments, resulting in enhanced catalytic activity and selectivity.- Metal-support interactions for optimized adsorption energetics: Engineering catalyst supports to optimize metal-support interactions can significantly influence adsorption energetics. By controlling the electronic properties at the interface between the metal catalyst and support material, the binding energy of reactants can be tuned. This approach allows for enhanced catalytic activity and selectivity by modifying the adsorption strength of key intermediates, leading to improved reaction pathways and reduced energy barriers.

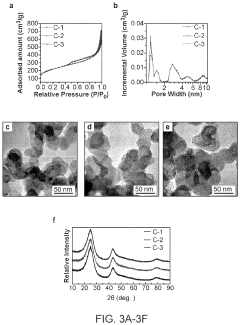

- Porous support structures for controlled adsorption: Developing porous catalyst supports with engineered pore architectures enables precise control over adsorption energetics. These structures provide high surface area, controlled diffusion pathways, and specific adsorption sites that can be tailored for target reactions. By manipulating pore size distribution, interconnectivity, and surface chemistry, the adsorption behavior of reactants and intermediates can be optimized to enhance catalytic performance and stability.

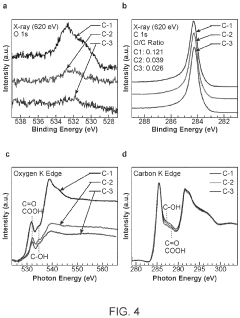

- Surface functionalization for tuning adsorption properties: Functionalizing catalyst support surfaces with specific chemical groups allows for precise tuning of adsorption energetics. These functional groups can alter the electronic properties of the support surface, creating preferential binding sites with optimized adsorption energies for target molecules. This approach enables the design of catalysts with enhanced selectivity, activity, and resistance to poisoning by controlling the strength and nature of adsorbate-surface interactions.

- Composite and hybrid support materials for enhanced adsorption control: Developing composite or hybrid catalyst supports by combining multiple materials creates synergistic effects that can optimize adsorption energetics. These engineered supports integrate the beneficial properties of different materials, such as combining the high surface area of one component with the electronic properties of another. The resulting hybrid structures offer unique adsorption sites with tailored energetics that cannot be achieved with single-component supports.

- Computational modeling for adsorption energetics prediction: Utilizing computational modeling and simulation techniques to predict and optimize adsorption energetics on catalyst supports. These approaches include density functional theory calculations, molecular dynamics simulations, and machine learning methods to understand the fundamental interactions between adsorbates and support surfaces. By computationally screening different support materials and structures, researchers can design catalysts with precisely engineered adsorption properties before experimental validation.

02 Porous support structures for enhanced adsorption properties

Catalyst supports with engineered porosity provide increased surface area and controlled adsorption sites. These porous structures can be designed with specific pore sizes, distributions, and interconnectivity to enhance mass transport and optimize reactant adsorption energetics. Various synthesis methods, including templating approaches and controlled crystallization, enable the creation of supports with tailored porosity for specific catalytic applications.Expand Specific Solutions03 Surface functionalization for tailored adsorption energetics

Chemical modification of catalyst support surfaces through functionalization can precisely tune adsorption energetics. By introducing specific functional groups, the electronic properties and binding characteristics of the support can be altered to achieve optimal interaction with reactants. These modifications can include grafting organic moieties, creating oxygen vacancies, or incorporating heteroatoms to adjust the local electronic environment and adsorption behavior.Expand Specific Solutions04 Composite and hybrid support materials for controlled energetics

Combining different materials to create composite or hybrid catalyst supports enables precise control over adsorption energetics. These engineered supports leverage the complementary properties of multiple components to achieve synergistic effects. By carefully selecting and integrating materials with different electronic, structural, and chemical properties, the resulting composite supports can offer unique adsorption characteristics that are not achievable with single-component materials.Expand Specific Solutions05 Computational modeling for adsorption energetics optimization

Advanced computational methods are employed to predict and optimize adsorption energetics in catalyst support engineering. Density functional theory calculations, molecular dynamics simulations, and machine learning approaches enable the rational design of catalyst supports with targeted adsorption properties. These computational tools help identify promising support materials and modifications by providing insights into the fundamental interactions governing adsorption behavior at the atomic and molecular levels.Expand Specific Solutions

Leading Research Groups and Industrial Players

The catalyst support engineering market for optimizing adsorption energetics is currently in a growth phase, characterized by significant R&D investments across petrochemical and energy sectors. The global market size is expanding rapidly, driven by increasing demand for efficient catalytic processes in refining and chemical production. Technical maturity varies across applications, with companies like PetroChina, Sinopec, and W.R. Grace leading commercial implementations. Research institutions such as Sinopec Research Institute and Toyota Central R&D Labs are advancing fundamental understanding of support-catalyst interactions. Axens, BASF, and Clariant are developing proprietary support materials with enhanced stability and selectivity. The competitive landscape features collaboration between major oil companies and specialized catalyst manufacturers, with increasing focus on sustainable catalyst supports for renewable energy applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed comprehensive catalyst support engineering technologies focused on optimizing adsorption energetics for petroleum refining and petrochemical processes. Their approach integrates computational modeling with advanced material synthesis to create supports with tailored surface properties and controlled adsorption behavior. Sinopec's "AdEnergy" platform employs density functional theory calculations to predict metal-support interactions and optimize binding energies for specific reactions. Their synthesis methodology includes hydrothermal techniques with precise pH and temperature control to engineer supports with defined crystallinity, surface area, and pore structures. Sinopec has pioneered composite supports combining multiple oxide phases to create synergistic effects that enhance catalytic performance through modified adsorption energetics. Their technology has shown particular success in fluid catalytic cracking (FCC) and hydrocracking applications, where optimized supports have demonstrated up to 25% higher conversion rates and improved selectivity to valuable products compared to conventional materials.

Strengths: Massive production capacity enables rapid scaling of new catalyst technologies; vertical integration allows comprehensive testing from laboratory to commercial scale. Weaknesses: Research sometimes prioritizes incremental improvements over breakthrough innovations; international intellectual property protection may be less comprehensive than Western competitors.

Sinopec Research Institute of Petroleum Processing

Technical Solution: Sinopec Research Institute of Petroleum Processing (RIPP) has developed sophisticated catalyst support engineering technologies specifically targeting adsorption energetics optimization for petroleum refining processes. Their approach combines experimental and theoretical methods to design supports with precisely controlled surface properties and pore structures. RIPP's "EnerSorp" technology platform utilizes advanced characterization techniques including microcalorimetry and temperature-programmed desorption to quantitatively measure adsorption energies and correlate them with catalytic performance. Their synthesis methodology incorporates template-assisted techniques to create hierarchical pore structures that optimize mass transfer while maintaining high surface area. RIPP has pioneered the development of modified alumina and silica-alumina supports with engineered acid site distributions and strengths to control adsorption behavior of different hydrocarbon species. Their technology has demonstrated particular success in hydrodesulfurization catalysts, where optimized supports have achieved up to 40% higher activity and significantly improved sulfur tolerance through precise control of adsorption energetics for sulfur compounds and hydrogen.

Strengths: Specialized focus on petroleum processing provides deep expertise in relevant catalytic processes; strong integration with Sinopec's commercial operations enables rapid technology validation. Weaknesses: Research portfolio heavily concentrated on fossil fuel applications with less emphasis on emerging sustainable technologies; some advanced characterization capabilities may lag behind leading international research institutions.

Key Innovations in Adsorption Energy Tuning

Novel supported catalyst systems

PatentWO2004069406A1

Innovation

- The development of supported catalyst systems with modified inorganic oxide supports featuring Rio groups such as -CH2OH, -CH(OH)2, and -CH2CH2OH, which minimize surface charge and hydrophobic interactions, allowing for the attachment of catalytic species like enzymes or organometallic complexes via linkers, thereby preventing non-specific binding and maintaining high catalytic activity.

High performance platinum-based catalyst combined with carbon support engineering

PatentPendingUS20220336822A1

Innovation

- A manufacturing method involving reductive treatment of a catalyst support and reacting Pt-containing and N-containing precursors to form PtN or PtNM nanostructures affixed to the support, which are then annealed and exposed to acid, creating a high-performance Pt-based electrocatalyst with reduced Pt usage and improved stability.

Sustainability Impact of Optimized Catalytic Systems

Optimized catalytic systems offer significant sustainability benefits across multiple environmental dimensions. The reduction in energy requirements for chemical processes represents one of the most immediate impacts, as catalysts lower activation energy barriers, enabling reactions to occur at lower temperatures and pressures. This translates directly into reduced fossil fuel consumption and greenhouse gas emissions across industrial applications. For instance, advanced catalyst support engineering has demonstrated potential energy savings of 20-40% in petroleum refining operations compared to conventional methods.

Water conservation emerges as another critical sustainability advantage. Catalytic processes typically require less water for cooling and separation steps than traditional chemical manufacturing routes. In pharmaceutical production, optimized adsorption energetics have been shown to reduce water usage by up to 30% while maintaining or improving product yields. This is particularly valuable in water-stressed regions where industrial operations compete with agricultural and municipal demands.

The enhanced selectivity of engineered catalyst supports significantly reduces waste generation throughout chemical value chains. By promoting desired reaction pathways while suppressing side reactions, these systems minimize the formation of byproducts that would otherwise require energy-intensive separation or disposal. Studies indicate that optimized catalytic systems can reduce waste streams by 15-25% in fine chemical manufacturing, substantially decreasing the environmental footprint of these operations.

Resource efficiency represents another sustainability dimension, as catalysts with engineered supports often demonstrate longer operational lifetimes and improved regeneration capabilities. The extended service periods reduce the frequency of catalyst replacement, conserving the often rare and precious metals used in catalyst formulations. Recent advances in support engineering have achieved up to 50% increases in catalyst longevity for certain hydrogenation processes.

From a circular economy perspective, optimized catalytic systems facilitate the transformation of waste materials into valuable products. Catalysts supported on engineered materials can convert agricultural residues, plastic waste, and industrial byproducts into fuels, chemicals, and materials. This waste valorization approach not only diverts materials from landfills but also reduces dependence on virgin resource extraction.

The cumulative sustainability impact extends to improved air and water quality in communities surrounding industrial facilities. By enabling more efficient and cleaner chemical processes, these catalytic systems reduce emissions of criteria pollutants and hazardous air pollutants, contributing to public health benefits beyond their direct environmental advantages.

Water conservation emerges as another critical sustainability advantage. Catalytic processes typically require less water for cooling and separation steps than traditional chemical manufacturing routes. In pharmaceutical production, optimized adsorption energetics have been shown to reduce water usage by up to 30% while maintaining or improving product yields. This is particularly valuable in water-stressed regions where industrial operations compete with agricultural and municipal demands.

The enhanced selectivity of engineered catalyst supports significantly reduces waste generation throughout chemical value chains. By promoting desired reaction pathways while suppressing side reactions, these systems minimize the formation of byproducts that would otherwise require energy-intensive separation or disposal. Studies indicate that optimized catalytic systems can reduce waste streams by 15-25% in fine chemical manufacturing, substantially decreasing the environmental footprint of these operations.

Resource efficiency represents another sustainability dimension, as catalysts with engineered supports often demonstrate longer operational lifetimes and improved regeneration capabilities. The extended service periods reduce the frequency of catalyst replacement, conserving the often rare and precious metals used in catalyst formulations. Recent advances in support engineering have achieved up to 50% increases in catalyst longevity for certain hydrogenation processes.

From a circular economy perspective, optimized catalytic systems facilitate the transformation of waste materials into valuable products. Catalysts supported on engineered materials can convert agricultural residues, plastic waste, and industrial byproducts into fuels, chemicals, and materials. This waste valorization approach not only diverts materials from landfills but also reduces dependence on virgin resource extraction.

The cumulative sustainability impact extends to improved air and water quality in communities surrounding industrial facilities. By enabling more efficient and cleaner chemical processes, these catalytic systems reduce emissions of criteria pollutants and hazardous air pollutants, contributing to public health benefits beyond their direct environmental advantages.

Scalability and Industrial Implementation Considerations

The transition from laboratory-scale catalyst support engineering to industrial implementation presents significant challenges that must be addressed systematically. Current industrial catalytic processes require supports that maintain optimal adsorption energetics while accommodating tonnage-scale production demands. Manufacturing scalability necessitates standardized production protocols that can consistently reproduce the precise surface characteristics achieved in research settings. Notably, industrial implementation often requires adaptation of laboratory synthesis methods to utilize commercially available precursors and equipment compatible with existing manufacturing infrastructure.

Economic feasibility represents a critical consideration in scaling catalyst support technologies. The cost-benefit analysis must account for not only raw material expenses but also energy requirements, specialized equipment investments, and potential process modifications. Advanced support materials offering superior adsorption energetics must demonstrate sufficient performance advantages to justify implementation costs, particularly when replacing established catalyst systems in existing industrial operations.

Quality control mechanisms become increasingly vital at industrial scale, requiring robust analytical techniques capable of rapidly assessing support properties across large production batches. Inline monitoring systems that can detect deviations in surface characteristics, porosity, and adsorption behavior are essential for maintaining consistent catalyst performance. The development of accelerated aging protocols that can reliably predict long-term stability under industrial conditions represents another crucial aspect of implementation planning.

Environmental and safety considerations must be integrated into scalability assessments, particularly regarding the handling of nanomaterials or chemically modified supports. Sustainable manufacturing approaches that minimize waste generation and energy consumption align with both regulatory requirements and corporate sustainability initiatives. Recovery and recycling strategies for spent catalyst supports further enhance the economic and environmental profile of advanced materials.

Collaboration between academic researchers, material suppliers, and end-users is essential for successful industrial implementation. Knowledge transfer mechanisms must effectively communicate the fundamental science of adsorption energetics to process engineers responsible for implementation. Pilot-scale demonstration projects serve as critical intermediate steps, allowing for identification and resolution of scale-dependent challenges before full industrial deployment. These collaborative efforts ultimately determine whether theoretically promising catalyst support technologies can deliver practical value in commercial applications.

Economic feasibility represents a critical consideration in scaling catalyst support technologies. The cost-benefit analysis must account for not only raw material expenses but also energy requirements, specialized equipment investments, and potential process modifications. Advanced support materials offering superior adsorption energetics must demonstrate sufficient performance advantages to justify implementation costs, particularly when replacing established catalyst systems in existing industrial operations.

Quality control mechanisms become increasingly vital at industrial scale, requiring robust analytical techniques capable of rapidly assessing support properties across large production batches. Inline monitoring systems that can detect deviations in surface characteristics, porosity, and adsorption behavior are essential for maintaining consistent catalyst performance. The development of accelerated aging protocols that can reliably predict long-term stability under industrial conditions represents another crucial aspect of implementation planning.

Environmental and safety considerations must be integrated into scalability assessments, particularly regarding the handling of nanomaterials or chemically modified supports. Sustainable manufacturing approaches that minimize waste generation and energy consumption align with both regulatory requirements and corporate sustainability initiatives. Recovery and recycling strategies for spent catalyst supports further enhance the economic and environmental profile of advanced materials.

Collaboration between academic researchers, material suppliers, and end-users is essential for successful industrial implementation. Knowledge transfer mechanisms must effectively communicate the fundamental science of adsorption energetics to process engineers responsible for implementation. Pilot-scale demonstration projects serve as critical intermediate steps, allowing for identification and resolution of scale-dependent challenges before full industrial deployment. These collaborative efforts ultimately determine whether theoretically promising catalyst support technologies can deliver practical value in commercial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!