Photoelectrochemical Versus Photocatalytic Approaches Compared

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEC and PC Technologies Background and Objectives

Photoelectrochemical (PEC) and photocatalytic (PC) technologies represent two distinct yet interconnected approaches to harnessing solar energy for chemical transformations. These technologies have evolved significantly since the pioneering work of Fujishima and Honda in 1972, who demonstrated the photoelectrochemical splitting of water using titanium dioxide electrodes. This breakthrough laid the foundation for both fields, which have since developed along parallel but distinct technological trajectories.

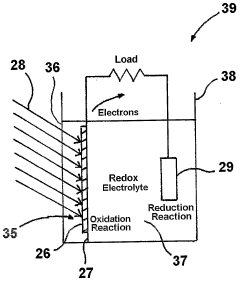

The fundamental principle underlying both approaches is the utilization of semiconductor materials that can absorb photons to generate electron-hole pairs. However, the key distinction lies in their operational mechanisms. PEC systems employ an external circuit to separate and transport charge carriers, typically incorporating dedicated electrodes immersed in an electrolyte solution. In contrast, PC systems function without external electrical connections, with reactions occurring directly on the surface of photocatalyst particles suspended in solution.

The evolution of these technologies has been driven by advances in materials science, nanotechnology, and surface engineering. Early research focused primarily on metal oxide semiconductors such as TiO2, while recent developments have expanded to include complex heterostructures, quantum dots, plasmonic materials, and organic-inorganic hybrid systems. This diversification reflects the ongoing quest to overcome efficiency limitations and expand the range of practical applications.

Current technological objectives for both PEC and PC approaches center on addressing several critical challenges. These include extending light absorption into the visible spectrum, improving charge separation and transport efficiency, enhancing reaction selectivity, and developing stable materials that can withstand harsh operational conditions. Additionally, there is growing emphasis on scalability and cost-effectiveness to facilitate commercial viability.

The potential applications of these technologies extend far beyond water splitting to include carbon dioxide reduction, nitrogen fixation, environmental remediation, and selective organic transformations. This versatility has attracted interest from diverse sectors including renewable energy, environmental protection, chemical manufacturing, and pharmaceutical production.

Looking forward, the technological trajectory is increasingly focused on integrated systems that combine the advantages of both approaches. Hybrid PEC-PC systems, tandem configurations, and artificial photosynthetic assemblies represent promising directions for maximizing solar energy conversion efficiency while maintaining practical applicability. The ultimate goal remains the development of sustainable, efficient processes that can effectively convert abundant solar energy into valuable chemical products or fuels.

The fundamental principle underlying both approaches is the utilization of semiconductor materials that can absorb photons to generate electron-hole pairs. However, the key distinction lies in their operational mechanisms. PEC systems employ an external circuit to separate and transport charge carriers, typically incorporating dedicated electrodes immersed in an electrolyte solution. In contrast, PC systems function without external electrical connections, with reactions occurring directly on the surface of photocatalyst particles suspended in solution.

The evolution of these technologies has been driven by advances in materials science, nanotechnology, and surface engineering. Early research focused primarily on metal oxide semiconductors such as TiO2, while recent developments have expanded to include complex heterostructures, quantum dots, plasmonic materials, and organic-inorganic hybrid systems. This diversification reflects the ongoing quest to overcome efficiency limitations and expand the range of practical applications.

Current technological objectives for both PEC and PC approaches center on addressing several critical challenges. These include extending light absorption into the visible spectrum, improving charge separation and transport efficiency, enhancing reaction selectivity, and developing stable materials that can withstand harsh operational conditions. Additionally, there is growing emphasis on scalability and cost-effectiveness to facilitate commercial viability.

The potential applications of these technologies extend far beyond water splitting to include carbon dioxide reduction, nitrogen fixation, environmental remediation, and selective organic transformations. This versatility has attracted interest from diverse sectors including renewable energy, environmental protection, chemical manufacturing, and pharmaceutical production.

Looking forward, the technological trajectory is increasingly focused on integrated systems that combine the advantages of both approaches. Hybrid PEC-PC systems, tandem configurations, and artificial photosynthetic assemblies represent promising directions for maximizing solar energy conversion efficiency while maintaining practical applicability. The ultimate goal remains the development of sustainable, efficient processes that can effectively convert abundant solar energy into valuable chemical products or fuels.

Market Applications and Demand Analysis

The global market for photoelectrochemical (PEC) and photocatalytic technologies has witnessed significant growth in recent years, driven by increasing environmental concerns and the push for sustainable solutions. The combined market value for these technologies reached approximately $3.2 billion in 2022 and is projected to grow at a CAGR of 8.7% through 2028, reflecting strong demand across multiple sectors.

Water treatment represents the largest application segment, accounting for nearly 40% of the current market. The demand for efficient water purification systems that can degrade organic pollutants, remove heavy metals, and eliminate pathogens continues to rise, particularly in regions facing severe water scarcity. Photocatalytic systems have gained particular traction in this sector due to their lower implementation costs and simpler operational requirements compared to PEC systems.

The energy sector presents another significant market opportunity, particularly for photoelectrochemical approaches. The global hydrogen economy is expanding rapidly, with green hydrogen production becoming a priority for many nations. PEC water splitting for hydrogen generation is attracting substantial investment, with market analysts predicting this segment could grow at over 12% annually through 2030, outpacing the overall market growth rate.

Environmental remediation applications have also shown robust demand growth, with both technologies finding applications in air purification systems and soil decontamination projects. The construction industry has embraced photocatalytic self-cleaning surfaces and air-purifying materials, creating a specialized market niche estimated at $450 million globally.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 42% share, led by China, Japan, and South Korea, where government initiatives supporting clean technology development have accelerated adoption. North America and Europe follow with 28% and 24% market shares respectively, with particularly strong growth in solar fuel applications.

Industry surveys indicate that end-users prioritize different attributes when selecting between PEC and photocatalytic approaches. For industrial applications, efficiency and scalability rank as the top considerations, favoring PEC systems in energy applications. For consumer and commercial building applications, cost-effectiveness and ease of maintenance are paramount, giving photocatalytic solutions a competitive edge.

The market is increasingly segmented between high-performance, higher-cost PEC systems targeting industrial and energy applications, and more affordable photocatalytic solutions addressing environmental remediation and consumer markets. This bifurcation is expected to continue, with specialized applications driving innovation in both technological approaches to address specific market needs.

Water treatment represents the largest application segment, accounting for nearly 40% of the current market. The demand for efficient water purification systems that can degrade organic pollutants, remove heavy metals, and eliminate pathogens continues to rise, particularly in regions facing severe water scarcity. Photocatalytic systems have gained particular traction in this sector due to their lower implementation costs and simpler operational requirements compared to PEC systems.

The energy sector presents another significant market opportunity, particularly for photoelectrochemical approaches. The global hydrogen economy is expanding rapidly, with green hydrogen production becoming a priority for many nations. PEC water splitting for hydrogen generation is attracting substantial investment, with market analysts predicting this segment could grow at over 12% annually through 2030, outpacing the overall market growth rate.

Environmental remediation applications have also shown robust demand growth, with both technologies finding applications in air purification systems and soil decontamination projects. The construction industry has embraced photocatalytic self-cleaning surfaces and air-purifying materials, creating a specialized market niche estimated at $450 million globally.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 42% share, led by China, Japan, and South Korea, where government initiatives supporting clean technology development have accelerated adoption. North America and Europe follow with 28% and 24% market shares respectively, with particularly strong growth in solar fuel applications.

Industry surveys indicate that end-users prioritize different attributes when selecting between PEC and photocatalytic approaches. For industrial applications, efficiency and scalability rank as the top considerations, favoring PEC systems in energy applications. For consumer and commercial building applications, cost-effectiveness and ease of maintenance are paramount, giving photocatalytic solutions a competitive edge.

The market is increasingly segmented between high-performance, higher-cost PEC systems targeting industrial and energy applications, and more affordable photocatalytic solutions addressing environmental remediation and consumer markets. This bifurcation is expected to continue, with specialized applications driving innovation in both technological approaches to address specific market needs.

Current State and Technical Challenges

The global landscape of photoelectrochemical (PEC) and photocatalytic technologies has evolved significantly over the past decade, with both approaches showing promising advancements in solar energy conversion and environmental remediation applications. Currently, photocatalytic systems have achieved wider commercial deployment, particularly in self-cleaning surfaces, air purification, and water treatment, while PEC systems remain predominantly at the research and development stage with limited industrial implementation.

Photocatalytic technologies have reached efficiency levels of 10-15% for specific applications, with TiO2-based materials dominating the commercial market. However, these systems face persistent challenges in visible light utilization, with most conventional photocatalysts only able to harness UV radiation (approximately 4-5% of the solar spectrum). This fundamental limitation restricts their practical energy conversion capabilities in real-world settings.

PEC approaches demonstrate theoretical advantages in charge separation and collection efficiency, with laboratory-scale devices achieving solar-to-hydrogen conversion efficiencies of up to 19% under optimized conditions. Nevertheless, these systems struggle with stability issues, particularly in the harsh electrochemical environments required for water splitting or CO2 reduction. Most high-performance PEC materials degrade significantly within hours or days of operation, presenting a major barrier to commercialization.

The geographical distribution of research expertise shows distinct patterns, with East Asian countries (particularly China, Japan, and South Korea) leading in photocatalytic research output and patent filings. Meanwhile, North American and European institutions maintain strong positions in fundamental PEC research and advanced material development. This regional specialization has created knowledge silos that sometimes impede cross-fertilization between the two technological approaches.

A critical technical challenge shared by both approaches is the development of earth-abundant, non-toxic materials that can effectively harvest visible light. Current high-performance systems often rely on rare elements like platinum, ruthenium, or iridium, raising concerns about scalability and sustainability. Additionally, the complex interplay between material properties, interface engineering, and reaction kinetics remains incompletely understood, hampering rational design strategies.

Manufacturing scalability presents another significant hurdle, particularly for PEC systems that require precise fabrication of complex multilayer structures. While photocatalytic materials can often be produced through relatively straightforward solution-based methods, achieving consistent performance across large-scale production batches remains challenging. The integration of these technologies into existing industrial processes or energy infrastructure also requires substantial engineering innovation that has yet to be fully realized.

Photocatalytic technologies have reached efficiency levels of 10-15% for specific applications, with TiO2-based materials dominating the commercial market. However, these systems face persistent challenges in visible light utilization, with most conventional photocatalysts only able to harness UV radiation (approximately 4-5% of the solar spectrum). This fundamental limitation restricts their practical energy conversion capabilities in real-world settings.

PEC approaches demonstrate theoretical advantages in charge separation and collection efficiency, with laboratory-scale devices achieving solar-to-hydrogen conversion efficiencies of up to 19% under optimized conditions. Nevertheless, these systems struggle with stability issues, particularly in the harsh electrochemical environments required for water splitting or CO2 reduction. Most high-performance PEC materials degrade significantly within hours or days of operation, presenting a major barrier to commercialization.

The geographical distribution of research expertise shows distinct patterns, with East Asian countries (particularly China, Japan, and South Korea) leading in photocatalytic research output and patent filings. Meanwhile, North American and European institutions maintain strong positions in fundamental PEC research and advanced material development. This regional specialization has created knowledge silos that sometimes impede cross-fertilization between the two technological approaches.

A critical technical challenge shared by both approaches is the development of earth-abundant, non-toxic materials that can effectively harvest visible light. Current high-performance systems often rely on rare elements like platinum, ruthenium, or iridium, raising concerns about scalability and sustainability. Additionally, the complex interplay between material properties, interface engineering, and reaction kinetics remains incompletely understood, hampering rational design strategies.

Manufacturing scalability presents another significant hurdle, particularly for PEC systems that require precise fabrication of complex multilayer structures. While photocatalytic materials can often be produced through relatively straightforward solution-based methods, achieving consistent performance across large-scale production batches remains challenging. The integration of these technologies into existing industrial processes or energy infrastructure also requires substantial engineering innovation that has yet to be fully realized.

Comparative Analysis of Current Technical Solutions

01 Photocatalytic materials for enhanced efficiency

Advanced photocatalytic materials have been developed to improve conversion efficiency in photoelectrochemical systems. These materials include modified titanium dioxide, metal oxides, and composite semiconductors that exhibit enhanced light absorption across broader spectral ranges. The incorporation of dopants and nanostructuring techniques allows for improved charge separation and reduced recombination rates, leading to significantly higher quantum yields in photocatalytic reactions.- Semiconductor materials for enhanced photoelectrochemical efficiency: Various semiconductor materials can be engineered to improve photoelectrochemical efficiency and conversion rates. These materials include modified titanium dioxide, doped zinc oxide, and novel composite semiconductors that exhibit improved light absorption across broader spectral ranges. The band gap engineering of these materials allows for better utilization of solar energy, resulting in higher quantum efficiency and improved conversion rates in photocatalytic and photoelectrochemical applications.

- Nanostructured catalysts for photocatalytic performance: Nanostructured catalysts significantly enhance photocatalytic performance through increased surface area and improved charge carrier dynamics. These include metal nanoparticles, core-shell structures, and hierarchical nanostructures that facilitate efficient charge separation and transfer. The nanoscale architecture reduces recombination rates of electron-hole pairs, leading to higher quantum yields and improved conversion efficiency in photocatalytic reactions such as water splitting and CO2 reduction.

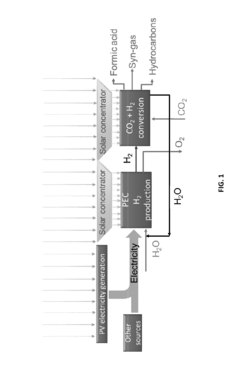

- Hybrid systems for improved conversion rates: Hybrid photoelectrochemical systems combine different technologies to overcome limitations of single-component systems. These include tandem cell configurations, Z-scheme systems, and integrated photoelectrochemical-photovoltaic devices. By strategically combining materials with complementary properties, these hybrid systems achieve synergistic effects that enhance light harvesting, charge separation, and catalytic activity, resulting in significantly improved solar-to-fuel or solar-to-electricity conversion rates.

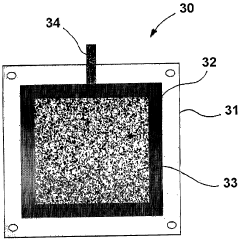

- Novel electrode designs for enhanced photoelectrochemical performance: Advanced electrode designs play a crucial role in improving photoelectrochemical efficiency. These include structured photoelectrodes, transparent conductive substrates with optimized morphologies, and multi-junction architectures. Innovations in electrode design focus on maximizing light absorption, facilitating efficient charge transport, and providing abundant active sites for reactions, thereby enhancing overall conversion efficiency and stability of photoelectrochemical systems.

- Process optimization techniques for maximizing efficiency: Various process optimization techniques can significantly improve the efficiency of photoelectrochemical and photocatalytic systems. These include reaction condition optimization (pH, temperature, electrolyte composition), light management strategies (concentration, wavelength filtering), and reactor design innovations. Advanced characterization and modeling approaches enable systematic optimization of these parameters, leading to substantial improvements in quantum efficiency, reaction rates, and overall conversion efficiency of photoelectrochemical and photocatalytic processes.

02 Photoelectrochemical cell design optimization

Innovative cell architectures have been developed to maximize photoelectrochemical conversion rates. These designs focus on optimizing electrode configurations, electrolyte composition, and membrane technologies to reduce internal resistance and enhance mass transport. Advanced cell designs incorporate features such as tandem structures, microfluidic channels, and specialized light management systems that collectively improve energy conversion efficiency and operational stability under various conditions.Expand Specific Solutions03 Nanostructured electrodes for improved performance

Nanostructured electrodes represent a significant advancement in photoelectrochemical technology, offering increased surface area and enhanced charge transport properties. These electrodes utilize various morphologies including nanowires, nanotubes, and hierarchical structures to optimize light harvesting and catalytic activity. The controlled synthesis of these nanostructures enables precise tuning of bandgaps and interfacial properties, resulting in substantial improvements in conversion efficiency and reaction selectivity.Expand Specific Solutions04 Novel catalysts for accelerated reaction kinetics

Innovative catalyst systems have been developed to address kinetic limitations in photoelectrochemical and photocatalytic processes. These catalysts include noble metal nanoparticles, non-precious metal complexes, and biomimetic structures that significantly lower activation energies for critical reactions. Advanced co-catalyst combinations and strategic catalyst positioning on photoactive surfaces enable more efficient charge utilization, resulting in higher quantum efficiencies and improved conversion rates under practical operating conditions.Expand Specific Solutions05 Integrated systems for practical applications

Integrated photoelectrochemical and photocatalytic systems have been designed to address real-world implementation challenges. These systems combine multiple technologies including solar concentration, thermal management, and product separation to achieve commercially viable conversion rates. Modular designs allow for scalability while maintaining efficiency, and hybrid approaches that combine photoelectrochemical processes with conventional technologies enable continuous operation under variable conditions. Advanced control systems optimize performance parameters in response to changing environmental factors.Expand Specific Solutions

Leading Research Groups and Industrial Players

Photoelectrochemical and photocatalytic technologies are currently in a transitional phase from early development to commercial application, with a global market expected to reach $4-5 billion by 2025. The competitive landscape features established industrial players like Toshiba, BASF, and FUJIFILM focusing on scalable applications, while research institutions such as Rutgers, Shanghai Normal University, and Commissariat à l'énergie atomique are advancing fundamental science. Technology maturity varies significantly across applications, with water treatment and air purification systems reaching commercial viability while solar fuel production remains largely experimental. Companies like Repsol and GTI Energy are investing in photoelectrochemical approaches for renewable energy applications, while academic-industrial partnerships are accelerating technology transfer, particularly in Asia where Zhejiang University and Central South University collaborate with regional manufacturers.

BASF Corp.

Technical Solution: BASF has developed advanced photocatalytic systems focused on practical industrial applications, emphasizing scalability and cost-effectiveness. Their approach centers on heterogeneous photocatalysts that can operate in suspension or fixed-bed configurations without external electrical bias. BASF has engineered composite photocatalyst materials that combine titanium dioxide with visible-light-responsive components, extending the usable solar spectrum beyond UV light. Their technology incorporates carbon-based sensitizers and noble metal nanoparticles as co-catalysts to enhance charge separation and surface reaction kinetics. BASF's systems are designed for environmental applications including water purification and air treatment, as well as selective organic transformations for fine chemical synthesis. Their recent innovations include the development of magnetically recoverable photocatalysts that facilitate catalyst separation and reuse in industrial settings, addressing one of the key challenges in practical photocatalytic applications.

Strengths: Simpler system design without electrical components; lower implementation costs; easier scale-up potential for distributed applications; ability to function in various media (gas, liquid). Weaknesses: Generally lower quantum efficiencies; challenges in product separation; limited control over reaction selectivity; potential for catalyst deactivation.

The Regents of the University of California

Technical Solution: The University of California has developed advanced photoelectrochemical (PEC) systems that integrate semiconductor materials with electrocatalysts to directly convert solar energy into chemical fuels. Their approach focuses on tandem photoelectrode architectures that utilize multiple bandgap materials to maximize solar spectrum absorption and achieve higher solar-to-hydrogen conversion efficiencies. Their research has demonstrated solar-to-hydrogen efficiencies exceeding 10% using III-V semiconductor materials coupled with earth-abundant catalysts. The university has pioneered protective coating strategies to enhance the stability of photoelectrodes in harsh electrolyte environments, significantly extending device lifetimes from hours to months. Their recent innovations include the development of integrated PEC devices that combine light absorption, charge separation, and catalytic functions in monolithic structures, reducing interface losses and improving overall system performance.

Strengths: Superior solar-to-hydrogen conversion efficiencies compared to traditional photocatalytic systems; better control over reaction pathways through applied bias; ability to physically separate reduction and oxidation products. Weaknesses: Higher system complexity requiring electrical components; typically higher implementation costs; more challenging scale-up compared to particulate photocatalytic systems.

Key Scientific Breakthroughs and Patents

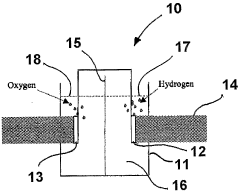

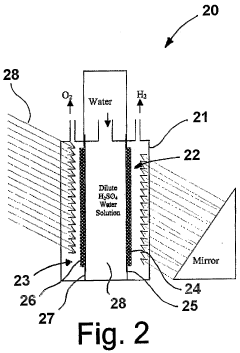

Photoelectrolysis of water using proton exchange membranes

PatentWO2005008806A2

Innovation

- A photoelectrochemical cell design with a light transmissive enclosure and semiconductor photoanode and photocathode separated by a thin electrolyte layer, utilizing a proton exchange membrane like NAFION for gas separation, water containment, and electron transport, minimizing electrolyte thickness and surface tension to enhance solar energy efficiency and gas release.

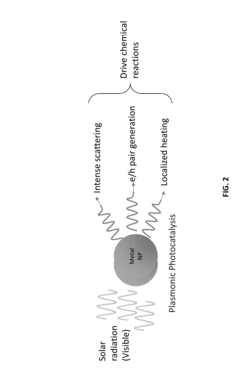

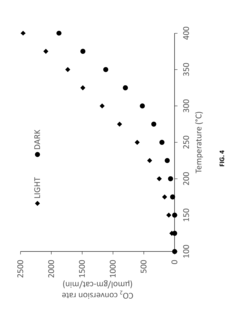

Method to reduce co2 to co using plasmon-enhanced photocatalysis

PatentActiveUS20150291434A1

Innovation

- A method using plasmonic photocatalysts with metallic nanoparticles and semiconductor materials exposed to visible light to enhance the reduction of CO2 to CO, achieving increased reaction rates and efficiencies through surface plasmon resonance.

Energy Conversion Efficiency Benchmarking

Energy conversion efficiency represents a critical metric for comparing photoelectrochemical (PEC) and photocatalytic systems. When benchmarking these approaches, PEC systems typically demonstrate higher solar-to-hydrogen (STH) conversion efficiencies, with leading systems achieving 10-15% efficiency under laboratory conditions. In contrast, conventional photocatalytic systems generally exhibit lower efficiencies, typically below 5% STH, due to inherent limitations in charge separation and transport mechanisms.

The efficiency gap stems from fundamental differences in system architecture. PEC systems benefit from directed electron flow through external circuits and the application of bias potentials, which significantly enhance charge separation. Additionally, the use of specialized electrodes with optimized band structures contributes to more efficient light harvesting across broader spectral ranges.

Standardized testing protocols reveal that PEC systems maintain relatively stable efficiency under varying light intensities, while photocatalytic approaches often show diminishing returns at higher irradiance levels due to increased recombination rates. This performance differential becomes particularly pronounced when considering practical deployment scenarios with fluctuating solar conditions.

Recent advancements in tandem PEC cells have pushed theoretical efficiency limits closer to 30%, though practical implementations remain considerably lower. Meanwhile, photocatalytic systems have seen incremental improvements through strategies such as co-catalyst loading and Z-scheme configurations, yet still lag behind their PEC counterparts in absolute efficiency terms.

When evaluating real-world applications, the efficiency-stability relationship emerges as a crucial consideration. While PEC systems demonstrate superior initial conversion rates, their complex components often suffer from degradation mechanisms that compromise long-term performance. Photocatalytic approaches, despite lower absolute efficiencies, frequently exhibit better stability profiles over extended operation periods, particularly in challenging environmental conditions.

Economic analysis of energy return on investment (EROI) indicates that despite higher initial efficiencies, PEC systems currently face challenges in achieving favorable energy payback periods due to more complex manufacturing requirements and shorter operational lifetimes. This creates a nuanced efficiency landscape where the technically superior approach may not always represent the most economically viable solution for specific deployment scenarios.

The efficiency gap stems from fundamental differences in system architecture. PEC systems benefit from directed electron flow through external circuits and the application of bias potentials, which significantly enhance charge separation. Additionally, the use of specialized electrodes with optimized band structures contributes to more efficient light harvesting across broader spectral ranges.

Standardized testing protocols reveal that PEC systems maintain relatively stable efficiency under varying light intensities, while photocatalytic approaches often show diminishing returns at higher irradiance levels due to increased recombination rates. This performance differential becomes particularly pronounced when considering practical deployment scenarios with fluctuating solar conditions.

Recent advancements in tandem PEC cells have pushed theoretical efficiency limits closer to 30%, though practical implementations remain considerably lower. Meanwhile, photocatalytic systems have seen incremental improvements through strategies such as co-catalyst loading and Z-scheme configurations, yet still lag behind their PEC counterparts in absolute efficiency terms.

When evaluating real-world applications, the efficiency-stability relationship emerges as a crucial consideration. While PEC systems demonstrate superior initial conversion rates, their complex components often suffer from degradation mechanisms that compromise long-term performance. Photocatalytic approaches, despite lower absolute efficiencies, frequently exhibit better stability profiles over extended operation periods, particularly in challenging environmental conditions.

Economic analysis of energy return on investment (EROI) indicates that despite higher initial efficiencies, PEC systems currently face challenges in achieving favorable energy payback periods due to more complex manufacturing requirements and shorter operational lifetimes. This creates a nuanced efficiency landscape where the technically superior approach may not always represent the most economically viable solution for specific deployment scenarios.

Environmental Impact and Sustainability Assessment

The environmental impact assessment of photoelectrochemical (PEC) and photocatalytic approaches reveals significant differences in their sustainability profiles. PEC systems generally demonstrate higher energy conversion efficiencies, potentially reducing the overall environmental footprint per unit of hydrogen or chemical product generated. This efficiency advantage translates to smaller land area requirements for equivalent output compared to traditional photocatalytic systems, which is particularly valuable in regions with limited space availability.

Water consumption patterns differ markedly between these technologies. PEC systems typically require continuous water flow for both reaction medium and cooling purposes, whereas photocatalytic approaches often utilize water primarily as a reaction medium. This distinction becomes critical in water-stressed regions where resource management is paramount for sustainable implementation.

Life cycle assessments indicate that PEC systems generally involve more complex manufacturing processes and specialized materials, including rare earth elements and precious metals for electrodes and membranes. These materials present challenges regarding resource depletion and end-of-life management. Conversely, photocatalytic systems can often be designed with more abundant materials, though high-performance catalysts may still require critical raw materials.

Waste generation profiles also differ substantially. PEC systems produce concentrated waste streams that may contain metal ions from electrode degradation, requiring specialized treatment protocols. Photocatalytic approaches typically generate more diffuse waste products, which may be less concentrated but potentially more challenging to capture and process effectively.

Carbon footprint calculations favor PEC systems during operational phases due to their higher efficiencies, but manufacturing emissions are typically higher compared to simpler photocatalytic setups. The break-even point for carbon neutrality varies significantly based on system design, geographical location, and energy mix used during manufacturing.

Scalability considerations reveal that photocatalytic systems often demonstrate advantages in modular deployment and distributed applications, while PEC systems may benefit from economies of scale in centralized installations. This distinction influences their respective environmental impacts when deployed at industrial scales.

Regulatory compliance frameworks increasingly recognize these differential environmental impacts, with emerging standards specifically addressing the unique sustainability challenges of each approach. Forward-looking environmental regulations are beginning to incorporate specific provisions for water usage efficiency, critical materials management, and end-of-life considerations for both technologies.

Water consumption patterns differ markedly between these technologies. PEC systems typically require continuous water flow for both reaction medium and cooling purposes, whereas photocatalytic approaches often utilize water primarily as a reaction medium. This distinction becomes critical in water-stressed regions where resource management is paramount for sustainable implementation.

Life cycle assessments indicate that PEC systems generally involve more complex manufacturing processes and specialized materials, including rare earth elements and precious metals for electrodes and membranes. These materials present challenges regarding resource depletion and end-of-life management. Conversely, photocatalytic systems can often be designed with more abundant materials, though high-performance catalysts may still require critical raw materials.

Waste generation profiles also differ substantially. PEC systems produce concentrated waste streams that may contain metal ions from electrode degradation, requiring specialized treatment protocols. Photocatalytic approaches typically generate more diffuse waste products, which may be less concentrated but potentially more challenging to capture and process effectively.

Carbon footprint calculations favor PEC systems during operational phases due to their higher efficiencies, but manufacturing emissions are typically higher compared to simpler photocatalytic setups. The break-even point for carbon neutrality varies significantly based on system design, geographical location, and energy mix used during manufacturing.

Scalability considerations reveal that photocatalytic systems often demonstrate advantages in modular deployment and distributed applications, while PEC systems may benefit from economies of scale in centralized installations. This distinction influences their respective environmental impacts when deployed at industrial scales.

Regulatory compliance frameworks increasingly recognize these differential environmental impacts, with emerging standards specifically addressing the unique sustainability challenges of each approach. Forward-looking environmental regulations are beginning to incorporate specific provisions for water usage efficiency, critical materials management, and end-of-life considerations for both technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!