Design Of Experiments For Photocatalyst Composition Screening

SEP 2, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocatalyst Screening Background and Objectives

Photocatalysis has emerged as a promising technology for addressing global environmental and energy challenges through the conversion of solar energy into chemical energy. The field has evolved significantly since the pioneering work of Fujishima and Honda in 1972, who demonstrated the photocatalytic splitting of water using titanium dioxide electrodes. Over the past five decades, research in photocatalysis has expanded exponentially, driven by its potential applications in water purification, air remediation, hydrogen production, and CO2 reduction.

The evolution of photocatalyst materials has progressed from simple metal oxides to complex multicomponent systems, including doped semiconductors, heterojunctions, plasmonic materials, and quantum dots. This complexity presents both opportunities and challenges for materials discovery and optimization. Traditional trial-and-error approaches to catalyst development have proven inefficient for navigating the vast compositional space of potential photocatalysts, necessitating more systematic and efficient screening methodologies.

Design of Experiments (DOE) for photocatalyst composition screening represents a critical approach to accelerate the discovery and optimization of high-performance photocatalytic materials. This methodology employs statistical principles to systematically explore the relationship between material composition variables and photocatalytic performance metrics, enabling researchers to identify optimal formulations with minimal experimental effort.

The primary objectives of photocatalyst composition screening include identifying materials with enhanced light absorption across the solar spectrum, improved charge separation and transport properties, optimized surface reaction kinetics, and increased stability under operational conditions. Additionally, modern screening approaches aim to discover materials that utilize earth-abundant elements, minimize environmental impact, and offer scalable synthesis routes for industrial implementation.

Recent technological advances have significantly enhanced the capabilities of high-throughput experimentation in photocatalysis, including automated synthesis platforms, rapid characterization techniques, and in-situ/operando analysis methods. These developments, coupled with computational tools such as machine learning and artificial intelligence, have created unprecedented opportunities for accelerating the discovery of next-generation photocatalysts.

The global research landscape in photocatalyst development shows intense activity across academic institutions, national laboratories, and industrial R&D centers, with notable concentrations in Asia, North America, and Europe. Bibliometric analysis reveals exponential growth in publications related to photocatalyst screening methodologies over the past decade, indicating the increasing recognition of systematic approaches to materials discovery in this field.

This technical research report aims to comprehensively examine the current state of DOE methodologies for photocatalyst composition screening, evaluate their effectiveness, and identify promising directions for future development that could significantly accelerate the discovery of high-performance photocatalytic materials for sustainable energy and environmental applications.

The evolution of photocatalyst materials has progressed from simple metal oxides to complex multicomponent systems, including doped semiconductors, heterojunctions, plasmonic materials, and quantum dots. This complexity presents both opportunities and challenges for materials discovery and optimization. Traditional trial-and-error approaches to catalyst development have proven inefficient for navigating the vast compositional space of potential photocatalysts, necessitating more systematic and efficient screening methodologies.

Design of Experiments (DOE) for photocatalyst composition screening represents a critical approach to accelerate the discovery and optimization of high-performance photocatalytic materials. This methodology employs statistical principles to systematically explore the relationship between material composition variables and photocatalytic performance metrics, enabling researchers to identify optimal formulations with minimal experimental effort.

The primary objectives of photocatalyst composition screening include identifying materials with enhanced light absorption across the solar spectrum, improved charge separation and transport properties, optimized surface reaction kinetics, and increased stability under operational conditions. Additionally, modern screening approaches aim to discover materials that utilize earth-abundant elements, minimize environmental impact, and offer scalable synthesis routes for industrial implementation.

Recent technological advances have significantly enhanced the capabilities of high-throughput experimentation in photocatalysis, including automated synthesis platforms, rapid characterization techniques, and in-situ/operando analysis methods. These developments, coupled with computational tools such as machine learning and artificial intelligence, have created unprecedented opportunities for accelerating the discovery of next-generation photocatalysts.

The global research landscape in photocatalyst development shows intense activity across academic institutions, national laboratories, and industrial R&D centers, with notable concentrations in Asia, North America, and Europe. Bibliometric analysis reveals exponential growth in publications related to photocatalyst screening methodologies over the past decade, indicating the increasing recognition of systematic approaches to materials discovery in this field.

This technical research report aims to comprehensively examine the current state of DOE methodologies for photocatalyst composition screening, evaluate their effectiveness, and identify promising directions for future development that could significantly accelerate the discovery of high-performance photocatalytic materials for sustainable energy and environmental applications.

Market Analysis for Advanced Photocatalytic Materials

The global market for advanced photocatalytic materials is experiencing significant growth, driven by increasing environmental concerns and stringent regulations regarding water and air purification. The market was valued at approximately $2.1 billion in 2022 and is projected to reach $4.5 billion by 2028, representing a compound annual growth rate (CAGR) of 13.5%. This robust growth trajectory underscores the expanding commercial potential for innovative photocatalyst compositions.

Environmental applications currently dominate the market landscape, accounting for nearly 45% of total demand. Water treatment represents the largest segment, followed by air purification and self-cleaning surfaces. The construction industry has emerged as a major consumer of photocatalytic materials, incorporating them into building materials for pollution-reducing facades and interior air quality improvement.

Regionally, Asia-Pacific leads the market with approximately 40% share, primarily due to severe air pollution challenges in countries like China and India, coupled with substantial government investments in environmental remediation technologies. North America and Europe follow with 25% and 22% market shares respectively, where demand is primarily driven by stringent environmental regulations and growing consumer awareness regarding sustainable technologies.

The industrial sector presents substantial growth opportunities, particularly in developing economies where rapid industrialization has exacerbated pollution concerns. Photocatalytic materials capable of operating under visible light rather than solely UV light are witnessing accelerated demand, as they offer greater practical utility and energy efficiency.

Customer requirements are increasingly focused on photocatalyst durability, efficiency under varied conditions, and cost-effectiveness. The market shows particular interest in composite photocatalysts that demonstrate enhanced performance characteristics compared to traditional titanium dioxide-based materials. This trend aligns perfectly with the need for systematic composition screening methodologies.

Market analysis reveals a significant gap between laboratory research and commercial implementation, creating opportunities for companies that can effectively bridge this divide through scalable manufacturing processes and application-specific formulations. The development of high-throughput experimental design methodologies for photocatalyst composition screening could substantially accelerate market penetration by reducing development cycles and optimization timeframes.

Pricing trends indicate that while premium pricing exists for high-performance photocatalysts, there is increasing pressure to reduce costs to facilitate broader market adoption. This economic reality underscores the importance of efficient experimental design approaches that can identify optimal compositions while minimizing resource expenditure.

Environmental applications currently dominate the market landscape, accounting for nearly 45% of total demand. Water treatment represents the largest segment, followed by air purification and self-cleaning surfaces. The construction industry has emerged as a major consumer of photocatalytic materials, incorporating them into building materials for pollution-reducing facades and interior air quality improvement.

Regionally, Asia-Pacific leads the market with approximately 40% share, primarily due to severe air pollution challenges in countries like China and India, coupled with substantial government investments in environmental remediation technologies. North America and Europe follow with 25% and 22% market shares respectively, where demand is primarily driven by stringent environmental regulations and growing consumer awareness regarding sustainable technologies.

The industrial sector presents substantial growth opportunities, particularly in developing economies where rapid industrialization has exacerbated pollution concerns. Photocatalytic materials capable of operating under visible light rather than solely UV light are witnessing accelerated demand, as they offer greater practical utility and energy efficiency.

Customer requirements are increasingly focused on photocatalyst durability, efficiency under varied conditions, and cost-effectiveness. The market shows particular interest in composite photocatalysts that demonstrate enhanced performance characteristics compared to traditional titanium dioxide-based materials. This trend aligns perfectly with the need for systematic composition screening methodologies.

Market analysis reveals a significant gap between laboratory research and commercial implementation, creating opportunities for companies that can effectively bridge this divide through scalable manufacturing processes and application-specific formulations. The development of high-throughput experimental design methodologies for photocatalyst composition screening could substantially accelerate market penetration by reducing development cycles and optimization timeframes.

Pricing trends indicate that while premium pricing exists for high-performance photocatalysts, there is increasing pressure to reduce costs to facilitate broader market adoption. This economic reality underscores the importance of efficient experimental design approaches that can identify optimal compositions while minimizing resource expenditure.

Current Challenges in Photocatalyst Composition Screening

Despite significant advancements in photocatalyst development, the field faces substantial challenges in composition screening methodologies. Traditional trial-and-error approaches remain prevalent but are inherently inefficient, requiring extensive laboratory resources and time investments. A single photocatalyst composition evaluation can take days to weeks, creating a significant bottleneck in the discovery pipeline. This inefficiency severely limits the exploration of the vast compositional space available for novel photocatalyst formulations.

High-throughput experimentation (HTE) methods have emerged as potential solutions but face implementation barriers in photocatalyst research. The complex reaction conditions required for accurate photocatalytic performance assessment—including precise light sources, reaction vessels, and analytical techniques—make standardization across multiple parallel experiments challenging. Furthermore, miniaturization of photocatalytic reactions often leads to inconsistent results compared to bench-scale experiments, raising questions about data reliability.

Data reproducibility presents another critical challenge. Environmental factors such as humidity, temperature fluctuations, and light source stability significantly impact photocatalytic performance measurements. Many research groups report inconsistent results even when using identical catalyst compositions, highlighting the need for standardized testing protocols and more robust experimental designs.

The multidimensional parameter space in photocatalyst development compounds these challenges. Beyond elemental composition, factors such as crystallinity, surface area, morphology, and defect concentration all influence catalytic activity. Current experimental design approaches struggle to efficiently navigate this complex parameter landscape, often focusing on one variable while holding others constant—an approach that misses potential synergistic effects.

Analytical bottlenecks further complicate screening efforts. Real-time monitoring of photocatalytic reactions remains difficult, particularly for gas-phase products. Most screening protocols rely on end-point measurements rather than kinetic data, potentially overlooking promising candidates with unique reaction profiles. Advanced analytical techniques like mass spectrometry and chromatography require significant time for sample preparation and analysis, limiting throughput.

The disconnect between laboratory screening conditions and real-world application environments represents another significant challenge. Many promising photocatalysts identified under idealized laboratory conditions fail to perform when exposed to actual environmental conditions, including variable light intensities, presence of competing substrates, and water quality variations. This gap necessitates more sophisticated experimental designs that incorporate realistic operating conditions earlier in the screening process.

Machine learning and artificial intelligence approaches offer promising solutions but are hampered by insufficient high-quality experimental data. The photocatalysis community lacks standardized, accessible databases of composition-performance relationships, limiting the effectiveness of predictive modeling approaches that could otherwise accelerate discovery.

High-throughput experimentation (HTE) methods have emerged as potential solutions but face implementation barriers in photocatalyst research. The complex reaction conditions required for accurate photocatalytic performance assessment—including precise light sources, reaction vessels, and analytical techniques—make standardization across multiple parallel experiments challenging. Furthermore, miniaturization of photocatalytic reactions often leads to inconsistent results compared to bench-scale experiments, raising questions about data reliability.

Data reproducibility presents another critical challenge. Environmental factors such as humidity, temperature fluctuations, and light source stability significantly impact photocatalytic performance measurements. Many research groups report inconsistent results even when using identical catalyst compositions, highlighting the need for standardized testing protocols and more robust experimental designs.

The multidimensional parameter space in photocatalyst development compounds these challenges. Beyond elemental composition, factors such as crystallinity, surface area, morphology, and defect concentration all influence catalytic activity. Current experimental design approaches struggle to efficiently navigate this complex parameter landscape, often focusing on one variable while holding others constant—an approach that misses potential synergistic effects.

Analytical bottlenecks further complicate screening efforts. Real-time monitoring of photocatalytic reactions remains difficult, particularly for gas-phase products. Most screening protocols rely on end-point measurements rather than kinetic data, potentially overlooking promising candidates with unique reaction profiles. Advanced analytical techniques like mass spectrometry and chromatography require significant time for sample preparation and analysis, limiting throughput.

The disconnect between laboratory screening conditions and real-world application environments represents another significant challenge. Many promising photocatalysts identified under idealized laboratory conditions fail to perform when exposed to actual environmental conditions, including variable light intensities, presence of competing substrates, and water quality variations. This gap necessitates more sophisticated experimental designs that incorporate realistic operating conditions earlier in the screening process.

Machine learning and artificial intelligence approaches offer promising solutions but are hampered by insufficient high-quality experimental data. The photocatalysis community lacks standardized, accessible databases of composition-performance relationships, limiting the effectiveness of predictive modeling approaches that could otherwise accelerate discovery.

Current DoE Methodologies for Photocatalyst Screening

01 Titanium dioxide-based photocatalyst compositions

Titanium dioxide (TiO2) is widely used as a base material for photocatalysts due to its excellent photocatalytic properties. These compositions often include TiO2 in various crystalline forms such as anatase or rutile, sometimes doped or modified with other elements to enhance their photocatalytic activity. The compositions can be used for environmental applications such as air and water purification, self-cleaning surfaces, and antimicrobial applications.- Titanium dioxide-based photocatalyst compositions: Titanium dioxide (TiO2) is widely used as a base material for photocatalyst compositions due to its excellent photocatalytic properties. These compositions often include TiO2 in various crystalline forms such as anatase or rutile, sometimes doped with other elements to enhance their photocatalytic activity. The compositions can be applied as coatings on various surfaces to provide self-cleaning, air purification, and antibacterial properties when exposed to light.

- Metal-doped photocatalyst compositions: Photocatalyst compositions can be enhanced by doping with various metals such as silver, platinum, palladium, or transition metals. These metal dopants improve the photocatalytic efficiency by reducing electron-hole recombination rates and extending the light absorption range into the visible spectrum. Metal-doped photocatalysts show improved performance in environmental applications such as water purification, air cleaning, and degradation of organic pollutants.

- Composite photocatalyst materials: Composite photocatalyst materials combine different semiconductors or incorporate supporting materials to enhance photocatalytic activity. These compositions often include combinations such as TiO2/ZnO, TiO2/carbon materials (graphene, carbon nanotubes), or TiO2/clay minerals. The synergistic effects between the components result in improved charge separation, increased surface area, and enhanced light absorption, leading to superior photocatalytic performance for environmental remediation and energy applications.

- Visible light-responsive photocatalyst compositions: Conventional photocatalysts like pure TiO2 are primarily active under UV light. Visible light-responsive photocatalyst compositions are designed to utilize a broader spectrum of solar radiation by incorporating nitrogen, sulfur, carbon, or other non-metal dopants, or by sensitizing with dyes. These modified compositions can effectively function under indoor lighting or natural sunlight, making them more practical for everyday applications such as self-cleaning surfaces, air purifiers, and antimicrobial coatings.

- Photocatalyst formulations for specific applications: Specialized photocatalyst formulations are developed for specific applications such as water treatment, air purification, self-cleaning surfaces, and antimicrobial coatings. These formulations often include additives like binders, dispersants, and stabilizers to enhance adhesion to substrates, improve durability, and maintain photocatalytic activity over extended periods. The compositions may be tailored in terms of particle size, morphology, and surface properties to optimize performance for the intended application environment.

02 Metal-doped photocatalyst compositions

Incorporating metal dopants into photocatalyst compositions can significantly enhance their photocatalytic activity and extend their light absorption range. Common metal dopants include noble metals (platinum, silver, gold), transition metals (iron, copper, nickel), and rare earth elements. These doped photocatalysts show improved performance in various applications including pollutant degradation, hydrogen production, and antimicrobial activities.Expand Specific Solutions03 Composite photocatalyst materials

Composite photocatalyst materials combine different semiconductors or incorporate supporting materials to create synergistic effects and enhance photocatalytic performance. These composites often include combinations of TiO2 with other semiconductors like ZnO, WO3, or carbon-based materials such as graphene and carbon nanotubes. The composite structure helps to reduce electron-hole recombination rates and improve charge separation, resulting in higher photocatalytic efficiency.Expand Specific Solutions04 Visible light-responsive photocatalyst compositions

Traditional photocatalysts like pure TiO2 are primarily active under UV light. Visible light-responsive photocatalyst compositions are designed to utilize a broader spectrum of solar radiation by incorporating nitrogen, sulfur, carbon, or other non-metal dopants, or by creating heterojunctions with narrow band gap semiconductors. These compositions are particularly valuable for indoor applications or environments with limited UV exposure.Expand Specific Solutions05 Application-specific photocatalyst formulations

Specialized photocatalyst formulations are developed for specific applications such as water treatment, air purification, self-cleaning surfaces, or antimicrobial coatings. These formulations often include additives like binders, dispersants, or stabilizers to enhance their performance in the target application. The compositions may be optimized for specific contaminants, environmental conditions, or substrate compatibility, and can be formulated as powders, suspensions, or incorporated into various matrices.Expand Specific Solutions

Leading Research Groups and Industrial Players

Photocatalyst composition screening using Design of Experiments (DOE) is currently in a growth phase, with the market expanding as renewable energy and environmental applications gain traction. The global photocatalysis market is projected to reach significant scale due to increasing environmental regulations and sustainability initiatives. Technologically, this field shows varying maturity levels across different players. Academic institutions like California Institute of Technology, Northwestern University, and National University of Singapore are advancing fundamental research, while industrial leaders including Dow Global Technologies, Samsung Electronics, and FUJIFILM Corp. are developing commercial applications. Pharmaceutical companies such as Pfizer, Genentech, and F. Hoffmann-La Roche are exploring photocatalytic processes for green chemistry applications, indicating cross-industry adoption of this technology for more efficient and sustainable chemical synthesis methods.

Dow Global Technologies LLC

Technical Solution: Dow has developed a comprehensive Design of Experiments (DOE) approach for photocatalyst composition screening that integrates high-throughput experimentation with advanced statistical modeling. Their methodology employs parallel reactor systems capable of testing multiple catalyst compositions simultaneously under controlled conditions. The company utilizes response surface methodology (RSM) to optimize photocatalyst formulations by systematically varying metal dopants, support materials, and preparation methods. Dow's platform incorporates in-situ spectroscopic analysis to monitor reaction kinetics in real-time, allowing for rapid assessment of photocatalytic activity. Their approach also includes machine learning algorithms that analyze historical experimental data to predict promising catalyst compositions, significantly reducing the experimental space that needs to be explored physically. This integrated system enables Dow to screen hundreds of photocatalyst compositions weekly, accelerating the discovery of novel materials for environmental remediation and renewable energy applications.

Strengths: Dow's approach combines industrial-scale capabilities with sophisticated data analytics, allowing for rapid screening of complex catalyst systems. Their established manufacturing infrastructure enables quick scale-up of promising candidates. Weaknesses: The system may prioritize commercially viable formulations over scientifically novel compositions, potentially missing breakthrough materials that require longer development timelines.

California Institute of Technology

Technical Solution: Caltech has pioneered an advanced DOE framework for photocatalyst screening that combines combinatorial synthesis methods with high-throughput characterization techniques. Their approach utilizes automated robotic systems to prepare gradient libraries of photocatalyst compositions across multiple metal oxide systems. The institute has developed specialized parallel photoreactors equipped with fiber-optic spectrometers that enable simultaneous evaluation of quantum efficiency and reaction rates across different wavelengths. Caltech's methodology incorporates Bayesian optimization algorithms that adaptively suggest new experimental conditions based on previous results, efficiently navigating the vast compositional space. Their platform also integrates rapid materials characterization techniques including XRD, XPS, and SEM with automated data processing to correlate structural properties with photocatalytic performance. This comprehensive approach allows researchers to identify structure-property relationships and mechanistic insights that guide rational catalyst design beyond simple screening.

Strengths: Caltech's approach excels in fundamental scientific understanding, providing mechanistic insights alongside performance data. Their advanced characterization capabilities enable detailed structure-property correlations. Weaknesses: The sophisticated analytical techniques may limit throughput compared to more industrialized screening platforms, and the academic focus may result in less emphasis on manufacturing scalability.

Key Innovations in High-Throughput Screening Technologies

A method for screening photosensitive compound

PatentWO2006090259A2

Innovation

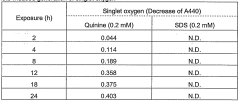

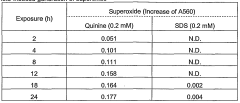

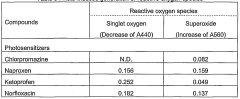

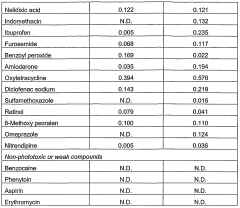

- A method involving the addition of test compounds and reactive oxygen species to a reaction container, followed by photo-irradiation and monitoring of reactive oxygen species generation, which allows for the evaluation of photosensitivity by comparing the results with known photosensitive compounds, and includes the use of plasmid DNA for photogenotoxicity assessment.

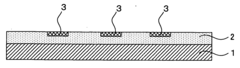

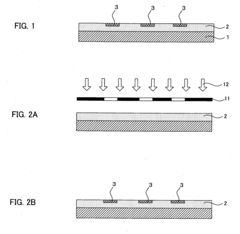

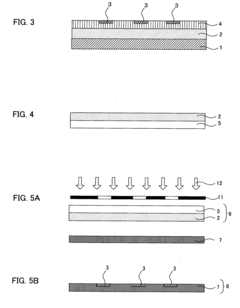

Photocatalyst composition and photocatalyst containing layer

PatentInactiveUS20060223699A1

Innovation

- A photocatalyst composition with high electron spin resonance signal intensity from hydroxy radicals, increasing 1,000 times or more within 600 seconds, enhancing active oxygen species generation efficiency and enabling rapid, precise pattern formation without the need for developing solutions.

Sustainability Impact of Improved Photocatalysts

The advancement of photocatalyst technology through optimized composition screening represents a significant opportunity for enhancing global sustainability efforts. Improved photocatalysts directly contribute to reducing environmental footprints across multiple sectors by enabling more efficient solar energy utilization and pollutant degradation processes.

Enhanced photocatalytic materials can dramatically improve renewable energy systems, particularly in solar-to-hydrogen conversion efficiency. Current water-splitting technologies using photocatalysts typically achieve 5-15% efficiency, but optimized compositions identified through systematic experimental design could potentially double these rates. This improvement would significantly reduce the carbon footprint associated with hydrogen production, currently dominated by fossil fuel-based methods that generate 9-12 kg CO2 per kg hydrogen.

In environmental remediation applications, advanced photocatalysts offer substantial benefits for water treatment systems. Optimized photocatalytic materials can accelerate the degradation of persistent organic pollutants by 30-50% compared to conventional treatments, while simultaneously reducing energy requirements and chemical additives. This translates to lower operational costs and minimized secondary pollution in water treatment facilities.

The carbon reduction potential of improved photocatalysts extends to industrial processes as well. By replacing energy-intensive chemical synthesis routes with photocatalytic alternatives, carbon emissions could be reduced by an estimated 15-25% in specific chemical manufacturing processes. Life cycle assessments indicate that photocatalyst-based production methods can decrease the overall environmental impact by 30-40% compared to conventional approaches.

Resource conservation represents another critical sustainability dimension. Systematic composition screening enables the identification of photocatalysts that utilize earth-abundant elements rather than rare or precious metals. This shift reduces supply chain vulnerabilities and extraction-related environmental damage while promoting circular economy principles through the potential use of recovered materials in catalyst formulations.

From a socioeconomic perspective, improved photocatalysts contribute to sustainability by enabling decentralized environmental solutions. Small-scale, solar-powered water purification systems utilizing advanced photocatalysts can provide clean water access in remote or underserved communities, addressing UN Sustainable Development Goal 6 (Clean Water and Sanitation) while reducing reliance on energy-intensive centralized infrastructure.

The cumulative sustainability impact of optimized photocatalysts could be transformative over the next decade, with potential greenhouse gas reductions estimated at 0.5-1.2 gigatons CO2-equivalent annually if widely implemented across energy, environmental, and industrial applications. This represents a significant contribution to global climate mitigation efforts while simultaneously addressing multiple environmental challenges.

Enhanced photocatalytic materials can dramatically improve renewable energy systems, particularly in solar-to-hydrogen conversion efficiency. Current water-splitting technologies using photocatalysts typically achieve 5-15% efficiency, but optimized compositions identified through systematic experimental design could potentially double these rates. This improvement would significantly reduce the carbon footprint associated with hydrogen production, currently dominated by fossil fuel-based methods that generate 9-12 kg CO2 per kg hydrogen.

In environmental remediation applications, advanced photocatalysts offer substantial benefits for water treatment systems. Optimized photocatalytic materials can accelerate the degradation of persistent organic pollutants by 30-50% compared to conventional treatments, while simultaneously reducing energy requirements and chemical additives. This translates to lower operational costs and minimized secondary pollution in water treatment facilities.

The carbon reduction potential of improved photocatalysts extends to industrial processes as well. By replacing energy-intensive chemical synthesis routes with photocatalytic alternatives, carbon emissions could be reduced by an estimated 15-25% in specific chemical manufacturing processes. Life cycle assessments indicate that photocatalyst-based production methods can decrease the overall environmental impact by 30-40% compared to conventional approaches.

Resource conservation represents another critical sustainability dimension. Systematic composition screening enables the identification of photocatalysts that utilize earth-abundant elements rather than rare or precious metals. This shift reduces supply chain vulnerabilities and extraction-related environmental damage while promoting circular economy principles through the potential use of recovered materials in catalyst formulations.

From a socioeconomic perspective, improved photocatalysts contribute to sustainability by enabling decentralized environmental solutions. Small-scale, solar-powered water purification systems utilizing advanced photocatalysts can provide clean water access in remote or underserved communities, addressing UN Sustainable Development Goal 6 (Clean Water and Sanitation) while reducing reliance on energy-intensive centralized infrastructure.

The cumulative sustainability impact of optimized photocatalysts could be transformative over the next decade, with potential greenhouse gas reductions estimated at 0.5-1.2 gigatons CO2-equivalent annually if widely implemented across energy, environmental, and industrial applications. This represents a significant contribution to global climate mitigation efforts while simultaneously addressing multiple environmental challenges.

Scale-up Considerations for Promising Candidates

Scaling up photocatalyst compositions from laboratory experiments to industrial applications represents a critical transition phase that demands careful consideration of multiple factors. When promising photocatalyst candidates emerge from composition screening experiments, their commercial viability hinges on successful scale-up strategies.

The reactor design becomes paramount when scaling photocatalyst applications. Laboratory-scale batch reactors must evolve into continuous flow systems for industrial implementation. This transition necessitates reconfiguration of light penetration dynamics, as the optical path length increases significantly with reactor size. Innovative reactor designs such as thin-film reactors, microreactors with high surface-to-volume ratios, or fluidized bed photoreactors may offer solutions to maintain photon efficiency at larger scales.

Material synthesis protocols require substantial modification during scale-up. Laboratory methods often employ precise but commercially impractical techniques like sol-gel processes or hydrothermal synthesis. Industrial production demands more economical approaches such as precipitation methods, spray pyrolysis, or mechanochemical processing. The challenge lies in preserving the critical physicochemical properties—crystallinity, surface area, and active site distribution—while adapting synthesis routes.

Economic feasibility analysis becomes increasingly important as scale increases. Promising photocatalysts containing precious metals (platinum, palladium) or rare earth elements may face prohibitive cost barriers at industrial scale. Substitution strategies using earth-abundant elements or dramatic reduction in catalyst loading must be explored without compromising performance metrics.

Quality control protocols must evolve with scale. Batch-to-batch consistency becomes more challenging yet more critical at industrial scale. Implementation of in-line monitoring techniques, such as spectroscopic methods for real-time assessment of photocatalyst properties and performance, becomes essential for maintaining product specifications.

Environmental impact considerations intensify during scale-up. Life cycle assessment should evaluate the sustainability of large-scale photocatalyst production, including energy requirements, waste generation, and potential environmental releases. Recycling strategies for spent photocatalysts must be developed concurrently with scale-up efforts to ensure circular economy principles are integrated from the outset.

Regulatory compliance frameworks differ substantially between laboratory research and commercial implementation. Scale-up planning must incorporate relevant environmental, health, and safety regulations governing chemical manufacturing processes, particularly for novel nanomaterials with potentially unknown environmental impacts.

The reactor design becomes paramount when scaling photocatalyst applications. Laboratory-scale batch reactors must evolve into continuous flow systems for industrial implementation. This transition necessitates reconfiguration of light penetration dynamics, as the optical path length increases significantly with reactor size. Innovative reactor designs such as thin-film reactors, microreactors with high surface-to-volume ratios, or fluidized bed photoreactors may offer solutions to maintain photon efficiency at larger scales.

Material synthesis protocols require substantial modification during scale-up. Laboratory methods often employ precise but commercially impractical techniques like sol-gel processes or hydrothermal synthesis. Industrial production demands more economical approaches such as precipitation methods, spray pyrolysis, or mechanochemical processing. The challenge lies in preserving the critical physicochemical properties—crystallinity, surface area, and active site distribution—while adapting synthesis routes.

Economic feasibility analysis becomes increasingly important as scale increases. Promising photocatalysts containing precious metals (platinum, palladium) or rare earth elements may face prohibitive cost barriers at industrial scale. Substitution strategies using earth-abundant elements or dramatic reduction in catalyst loading must be explored without compromising performance metrics.

Quality control protocols must evolve with scale. Batch-to-batch consistency becomes more challenging yet more critical at industrial scale. Implementation of in-line monitoring techniques, such as spectroscopic methods for real-time assessment of photocatalyst properties and performance, becomes essential for maintaining product specifications.

Environmental impact considerations intensify during scale-up. Life cycle assessment should evaluate the sustainability of large-scale photocatalyst production, including energy requirements, waste generation, and potential environmental releases. Recycling strategies for spent photocatalysts must be developed concurrently with scale-up efforts to ensure circular economy principles are integrated from the outset.

Regulatory compliance frameworks differ substantially between laboratory research and commercial implementation. Scale-up planning must incorporate relevant environmental, health, and safety regulations governing chemical manufacturing processes, particularly for novel nanomaterials with potentially unknown environmental impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!