Photocatalytic Reactor Optical Path Optimization Methods

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocatalytic Reactor Optical Path Development and Objectives

Photocatalytic reactor technology has evolved significantly over the past several decades, transitioning from simple batch reactors to sophisticated systems with optimized optical paths. The development trajectory began in the 1970s with pioneering work by Fujishima and Honda on photocatalytic water splitting, which laid the foundation for subsequent reactor designs. Early reactors featured basic configurations with limited light utilization efficiency, typically below 10%.

The 1990s marked a turning point with the introduction of slurry reactors that improved surface area exposure but suffered from light penetration limitations due to the "inner filter effect." By the early 2000s, fixed-bed reactors emerged, offering better light distribution but presenting challenges in catalyst loading and mass transfer. The past decade has witnessed remarkable advancements in optical path engineering, including the development of optical fibers, light-guiding elements, and reflective surfaces that have pushed photon utilization efficiencies above 40% in laboratory settings.

Current technological trends focus on maximizing the interaction between photons and catalyst surfaces while minimizing energy losses. This includes the development of multi-dimensional light distribution systems, plasmonic enhancement techniques, and quantum dot sensitization to extend the spectral response range. Computational fluid dynamics (CFD) coupled with radiation transfer equations (RTE) have become essential tools for reactor design optimization, enabling precise modeling of light distribution patterns within complex geometries.

The primary objective of photocatalytic reactor optical path optimization is to achieve uniform light distribution throughout the reactor volume while maximizing photon absorption by the catalyst. Secondary goals include minimizing energy consumption, reducing hotspots that can lead to catalyst deactivation, and enabling scalable designs suitable for industrial implementation. Quantitative targets include achieving photon utilization efficiencies exceeding 60%, reducing energy consumption by 30% compared to conventional designs, and maintaining performance stability over extended operation periods.

Future development aims to integrate advanced materials science with precision optical engineering to create next-generation reactors capable of addressing global challenges in environmental remediation and renewable energy production. This includes the development of solar-driven systems with concentrated light harvesting capabilities, microstructured reactors with optimized light paths, and hybrid systems that combine photocatalysis with other advanced oxidation processes. The ultimate goal is to create economically viable photocatalytic systems with predictable performance across varying scales and operating conditions.

The 1990s marked a turning point with the introduction of slurry reactors that improved surface area exposure but suffered from light penetration limitations due to the "inner filter effect." By the early 2000s, fixed-bed reactors emerged, offering better light distribution but presenting challenges in catalyst loading and mass transfer. The past decade has witnessed remarkable advancements in optical path engineering, including the development of optical fibers, light-guiding elements, and reflective surfaces that have pushed photon utilization efficiencies above 40% in laboratory settings.

Current technological trends focus on maximizing the interaction between photons and catalyst surfaces while minimizing energy losses. This includes the development of multi-dimensional light distribution systems, plasmonic enhancement techniques, and quantum dot sensitization to extend the spectral response range. Computational fluid dynamics (CFD) coupled with radiation transfer equations (RTE) have become essential tools for reactor design optimization, enabling precise modeling of light distribution patterns within complex geometries.

The primary objective of photocatalytic reactor optical path optimization is to achieve uniform light distribution throughout the reactor volume while maximizing photon absorption by the catalyst. Secondary goals include minimizing energy consumption, reducing hotspots that can lead to catalyst deactivation, and enabling scalable designs suitable for industrial implementation. Quantitative targets include achieving photon utilization efficiencies exceeding 60%, reducing energy consumption by 30% compared to conventional designs, and maintaining performance stability over extended operation periods.

Future development aims to integrate advanced materials science with precision optical engineering to create next-generation reactors capable of addressing global challenges in environmental remediation and renewable energy production. This includes the development of solar-driven systems with concentrated light harvesting capabilities, microstructured reactors with optimized light paths, and hybrid systems that combine photocatalysis with other advanced oxidation processes. The ultimate goal is to create economically viable photocatalytic systems with predictable performance across varying scales and operating conditions.

Market Analysis for Advanced Photocatalytic Systems

The global market for advanced photocatalytic systems has experienced significant growth in recent years, driven by increasing environmental concerns and stringent regulations regarding water and air purification. The market value reached approximately $2.1 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 8.7% through 2028, potentially reaching $3.5 billion by the end of the forecast period.

Water treatment applications currently dominate the market, accounting for nearly 40% of total revenue. This segment is particularly strong in regions facing severe water scarcity and pollution challenges, including parts of Asia-Pacific and North America. Air purification applications follow closely at 30% market share, with growing adoption in both industrial settings and consumer products.

The Asia-Pacific region leads the global market with approximately 45% share, primarily due to extensive industrial activities in China, Japan, and South Korea, coupled with severe environmental pollution issues. North America and Europe collectively account for approximately 40% of the market, driven by stringent environmental regulations and increasing investment in sustainable technologies.

Key market drivers include growing environmental awareness, tightening regulatory frameworks for emissions and water quality, and increasing industrial applications. The COVID-19 pandemic has further accelerated market growth by highlighting the importance of air purification technologies in indoor environments.

Customer segments for advanced photocatalytic systems include municipal water treatment facilities, industrial manufacturers (particularly in chemical, pharmaceutical, and food & beverage sectors), commercial building operators, and increasingly, residential consumers. The residential segment is experiencing the fastest growth at approximately 12% annually, albeit from a smaller base.

Pricing trends indicate a gradual decrease in system costs as manufacturing scales up and technology matures. However, premium pricing remains viable for systems with advanced optical path optimization that can demonstrate superior efficiency metrics and lower operational costs over the system lifetime.

Market challenges include high initial investment costs, limited awareness about photocatalytic technology benefits among potential end-users, and competition from alternative purification technologies. Additionally, the fragmented nature of the market with numerous small and medium-sized players creates challenges for standardization and quality assurance.

Future market opportunities lie in developing integrated systems that combine photocatalytic reactors with IoT capabilities for remote monitoring and optimization, as well as in creating modular, scalable designs suitable for diverse applications ranging from point-of-use water treatment to large industrial installations.

Water treatment applications currently dominate the market, accounting for nearly 40% of total revenue. This segment is particularly strong in regions facing severe water scarcity and pollution challenges, including parts of Asia-Pacific and North America. Air purification applications follow closely at 30% market share, with growing adoption in both industrial settings and consumer products.

The Asia-Pacific region leads the global market with approximately 45% share, primarily due to extensive industrial activities in China, Japan, and South Korea, coupled with severe environmental pollution issues. North America and Europe collectively account for approximately 40% of the market, driven by stringent environmental regulations and increasing investment in sustainable technologies.

Key market drivers include growing environmental awareness, tightening regulatory frameworks for emissions and water quality, and increasing industrial applications. The COVID-19 pandemic has further accelerated market growth by highlighting the importance of air purification technologies in indoor environments.

Customer segments for advanced photocatalytic systems include municipal water treatment facilities, industrial manufacturers (particularly in chemical, pharmaceutical, and food & beverage sectors), commercial building operators, and increasingly, residential consumers. The residential segment is experiencing the fastest growth at approximately 12% annually, albeit from a smaller base.

Pricing trends indicate a gradual decrease in system costs as manufacturing scales up and technology matures. However, premium pricing remains viable for systems with advanced optical path optimization that can demonstrate superior efficiency metrics and lower operational costs over the system lifetime.

Market challenges include high initial investment costs, limited awareness about photocatalytic technology benefits among potential end-users, and competition from alternative purification technologies. Additionally, the fragmented nature of the market with numerous small and medium-sized players creates challenges for standardization and quality assurance.

Future market opportunities lie in developing integrated systems that combine photocatalytic reactors with IoT capabilities for remote monitoring and optimization, as well as in creating modular, scalable designs suitable for diverse applications ranging from point-of-use water treatment to large industrial installations.

Current Optical Path Technologies and Limitations

Current photocatalytic reactor designs employ several optical path technologies, each with specific advantages and inherent limitations. The most widely implemented approach involves external illumination systems, where light sources such as mercury lamps, xenon lamps, or LED arrays are positioned outside the reactor vessel. This configuration offers simplicity in design and maintenance but suffers from significant light attenuation as photons travel through the reaction medium, particularly in scaled-up reactors with higher catalyst loadings.

Internal illumination configurations represent an advancement by positioning light sources within the reaction medium, typically using submersible UV lamps or fiber optic light guides. While this approach improves light distribution and reduces path length issues, it introduces challenges related to heat management, lamp fouling, and creates "dead zones" where catalyst particles receive insufficient illumination due to shadowing effects.

Distributed light delivery systems have emerged as a promising alternative, utilizing optical fibers or light guides with engineered emission characteristics to deliver photons throughout the reactor volume. These systems can achieve more uniform illumination but face challenges in maintaining mechanical integrity during operation and often require complex manufacturing processes that limit industrial scalability.

Reflective and refractive elements incorporated into reactor designs represent another approach to optical path optimization. Internal reflective surfaces, light-guiding structures, and specialized reactor geometries can redirect photons for multiple passes through the reaction medium, effectively increasing photon utilization efficiency. However, these designs frequently suffer from performance degradation over time due to surface fouling and material degradation in aggressive reaction environments.

Recent innovations in plasmonic photocatalysis have introduced nanoscale optical path considerations, where metal nanoparticles generate localized surface plasmon resonance effects that concentrate electromagnetic fields at the catalyst surface. While promising at laboratory scale, these approaches face significant challenges in maintaining consistent performance during continuous operation and scale-up.

A fundamental limitation across all current technologies is the inherent trade-off between light penetration depth and catalyst concentration. Higher catalyst loadings improve reaction rates but reduce light penetration, creating a design paradox that has yet to be fully resolved. Additionally, most current optical path designs fail to account for the dynamic nature of photocatalytic reactions, where bubble formation, particle agglomeration, and flow patterns continuously alter the optical properties of the reaction medium.

Internal illumination configurations represent an advancement by positioning light sources within the reaction medium, typically using submersible UV lamps or fiber optic light guides. While this approach improves light distribution and reduces path length issues, it introduces challenges related to heat management, lamp fouling, and creates "dead zones" where catalyst particles receive insufficient illumination due to shadowing effects.

Distributed light delivery systems have emerged as a promising alternative, utilizing optical fibers or light guides with engineered emission characteristics to deliver photons throughout the reactor volume. These systems can achieve more uniform illumination but face challenges in maintaining mechanical integrity during operation and often require complex manufacturing processes that limit industrial scalability.

Reflective and refractive elements incorporated into reactor designs represent another approach to optical path optimization. Internal reflective surfaces, light-guiding structures, and specialized reactor geometries can redirect photons for multiple passes through the reaction medium, effectively increasing photon utilization efficiency. However, these designs frequently suffer from performance degradation over time due to surface fouling and material degradation in aggressive reaction environments.

Recent innovations in plasmonic photocatalysis have introduced nanoscale optical path considerations, where metal nanoparticles generate localized surface plasmon resonance effects that concentrate electromagnetic fields at the catalyst surface. While promising at laboratory scale, these approaches face significant challenges in maintaining consistent performance during continuous operation and scale-up.

A fundamental limitation across all current technologies is the inherent trade-off between light penetration depth and catalyst concentration. Higher catalyst loadings improve reaction rates but reduce light penetration, creating a design paradox that has yet to be fully resolved. Additionally, most current optical path designs fail to account for the dynamic nature of photocatalytic reactions, where bubble formation, particle agglomeration, and flow patterns continuously alter the optical properties of the reaction medium.

Current Optical Path Optimization Methodologies

01 Optical path optimization in photocatalytic reactors

Optimizing the optical path in photocatalytic reactors involves designing light distribution systems that maximize photon utilization. This includes strategic placement of light sources, reflective surfaces, and light guides to ensure uniform illumination throughout the reactor volume. Proper optical path design reduces shadowing effects and increases the efficiency of photocatalytic reactions by ensuring that catalyst surfaces receive optimal light exposure.- Optical path optimization in photocatalytic reactors: Optimizing the optical path in photocatalytic reactors is crucial for maximizing light utilization efficiency. This involves designing the reactor geometry to ensure proper light distribution throughout the catalyst surface. Various approaches include using reflective surfaces, light guides, and specific reactor configurations that minimize light loss and maximize contact between photons and the catalyst material. These optimizations can significantly improve the overall efficiency of photocatalytic processes.

- Light source integration and waveguide systems: Integration of appropriate light sources with waveguide systems is essential for effective photocatalytic reactions. These systems direct light through specific paths to the catalyst surface, ensuring uniform illumination. Waveguides can be designed with various geometries and materials to control light distribution, minimize scattering, and enhance photon utilization. Advanced designs incorporate fiber optics or planar waveguides that deliver light precisely where needed in the reactor, improving energy efficiency and reaction rates.

- Optical components for light manipulation in reactors: Specialized optical components are employed in photocatalytic reactors to manipulate light paths effectively. These include lenses, mirrors, diffusers, and filters that can focus, redirect, or distribute light according to specific requirements. Such components help in controlling light intensity, wavelength selection, and beam shaping to match the absorption characteristics of photocatalysts. Strategic placement of these optical elements within the reactor design enhances light utilization and reaction efficiency while reducing energy consumption.

- Reactor design for enhanced light penetration: Innovative reactor designs focus on enhancing light penetration through reaction media to reach catalyst surfaces effectively. These designs consider factors such as reactor geometry, material transparency, and fluid dynamics to optimize light distribution. Thin-film reactors, annular reactors, and microreactors are examples that maximize the surface area exposed to light while minimizing light attenuation through the reaction medium. Such designs are particularly important for reactions involving turbid solutions or high catalyst loadings where light penetration is challenging.

- Advanced optical monitoring and control systems: Advanced optical monitoring and control systems are integrated into photocatalytic reactors to optimize performance in real-time. These systems use sensors to measure light intensity, distribution, and utilization efficiency throughout the reactor. Feedback mechanisms adjust light sources or reactor parameters to maintain optimal conditions as reaction conditions change. Some systems incorporate spectroscopic techniques to monitor reaction progress and catalyst activity, enabling precise control of the photocatalytic process and improved efficiency through adaptive operation.

02 Light transmission and waveguide systems

Specialized waveguide systems can be incorporated into photocatalytic reactors to direct light efficiently to catalyst surfaces. These systems may include fiber optic elements, light pipes, or specialized optical materials that can transmit light with minimal losses. By controlling the light path through waveguides, reactors can achieve better penetration into opaque media and more uniform distribution of photons, enhancing the overall photocatalytic efficiency.Expand Specific Solutions03 Reactor geometry and catalyst arrangement

The geometric design of photocatalytic reactors significantly impacts the optical path and reaction efficiency. Various configurations such as annular reactors, flat plate reactors, and honeycomb structures can be employed to optimize light distribution. The arrangement of catalyst materials within these geometries is crucial for maximizing surface area exposure to light while maintaining efficient mass transfer of reactants and products.Expand Specific Solutions04 Advanced optical components for light management

Integration of specialized optical components such as lenses, mirrors, diffusers, and reflectors can significantly enhance light utilization in photocatalytic reactors. These components help to focus, redirect, or distribute light more effectively throughout the reactor volume. Advanced designs may incorporate adjustable optical elements that can be tuned to optimize performance under varying reaction conditions or catalyst loadings.Expand Specific Solutions05 Monitoring and control systems for optical paths

Real-time monitoring and control systems can be implemented to optimize the optical path in photocatalytic reactors. These systems may include sensors that measure light intensity, distribution, and spectral characteristics at various points within the reactor. Feedback mechanisms can then adjust light sources or optical elements to maintain optimal conditions as reaction parameters change, ensuring consistent photocatalytic performance over time.Expand Specific Solutions

Leading Companies and Research Institutions in Photocatalysis

Photocatalytic reactor optical path optimization is currently in a growth phase, with the market expanding due to increasing environmental applications and clean energy demands. The global market size is projected to reach significant scale as industries adopt more sustainable chemical processes. Technologically, the field shows varying maturity levels across applications, with companies demonstrating different specialization areas. Syzygy Plasmonics leads with innovative light-powered reactors operating at lower temperatures than conventional systems, while AquiSense Technologies focuses on UV-LED disinfection applications. Research institutions like Beijing Institute of Technology and Ghent University contribute fundamental advancements, while established corporations such as BASF, Fujitsu, and Applied Materials leverage their manufacturing expertise to scale technologies. Collaboration between academic institutions and industry players is accelerating commercialization efforts in this promising field.

Syzygy Plasmonics, Inc.

Technical Solution: Syzygy Plasmonics has developed an innovative photocatalytic reactor system that leverages plasmonic nanoparticles to enhance light absorption and catalytic efficiency. Their proprietary technology employs a structured reactor design with optimized optical paths that maximize photon utilization through strategic light distribution. The company's reactors feature advanced light-directing components that focus illumination onto catalyst-coated surfaces, significantly increasing quantum efficiency. Their approach includes multi-layered catalyst supports with tailored optical properties that create controlled light scattering and absorption zones within the reactor. Syzygy has implemented computational fluid dynamics coupled with optical modeling to predict and optimize photon transport through their reactors, allowing for precise engineering of light paths to match catalyst activation requirements. Their systems incorporate adjustable light intensity zones to accommodate different reaction stages, with specialized reflective surfaces that minimize photon loss.

Strengths: Superior light utilization efficiency through plasmonic enhancement; modular design allowing for scalability; reduced energy requirements compared to thermal catalysis processes. Weaknesses: Higher initial capital costs; potential fouling of optical surfaces over extended operation; requires specialized maintenance expertise for optimal performance.

BASF Corp.

Technical Solution: BASF has pioneered advanced photocatalytic reactor designs with sophisticated optical path optimization techniques focused on industrial-scale applications. Their technology incorporates specially engineered light distribution systems that ensure uniform illumination across large catalyst surfaces, addressing one of the key challenges in scaling photocatalytic processes. BASF's reactors feature proprietary light-guiding elements that direct photons efficiently through reaction media with minimal losses. The company has developed multi-phase reactor configurations with optimized interfaces to enhance light penetration while maintaining efficient mass transfer. Their systems employ computational ray-tracing algorithms to model and refine light paths through complex reactor geometries, enabling precise prediction of illumination patterns and catalyst activation zones. BASF has also implemented adaptive optical systems that can adjust light distribution based on reaction conditions and conversion rates, maximizing energy efficiency throughout the reaction cycle.

Strengths: Extensive experience in industrial-scale chemical processes; robust engineering capabilities for commercial implementation; comprehensive material science expertise for catalyst-optical system integration. Weaknesses: Solutions may prioritize reliability over cutting-edge innovation; systems often require significant space and infrastructure; higher energy consumption compared to some newer technologies.

Key Patents and Innovations in Light Distribution Systems

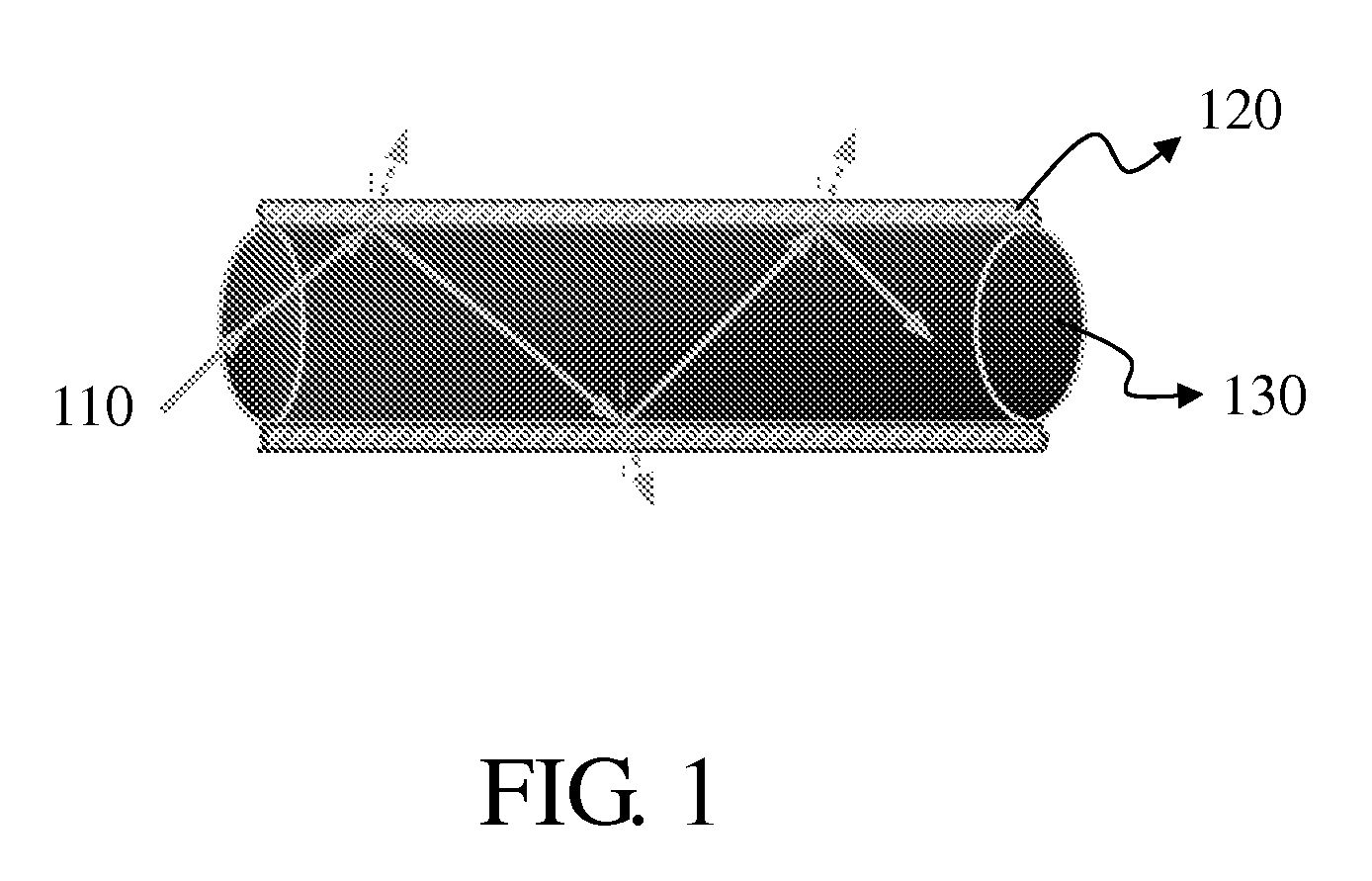

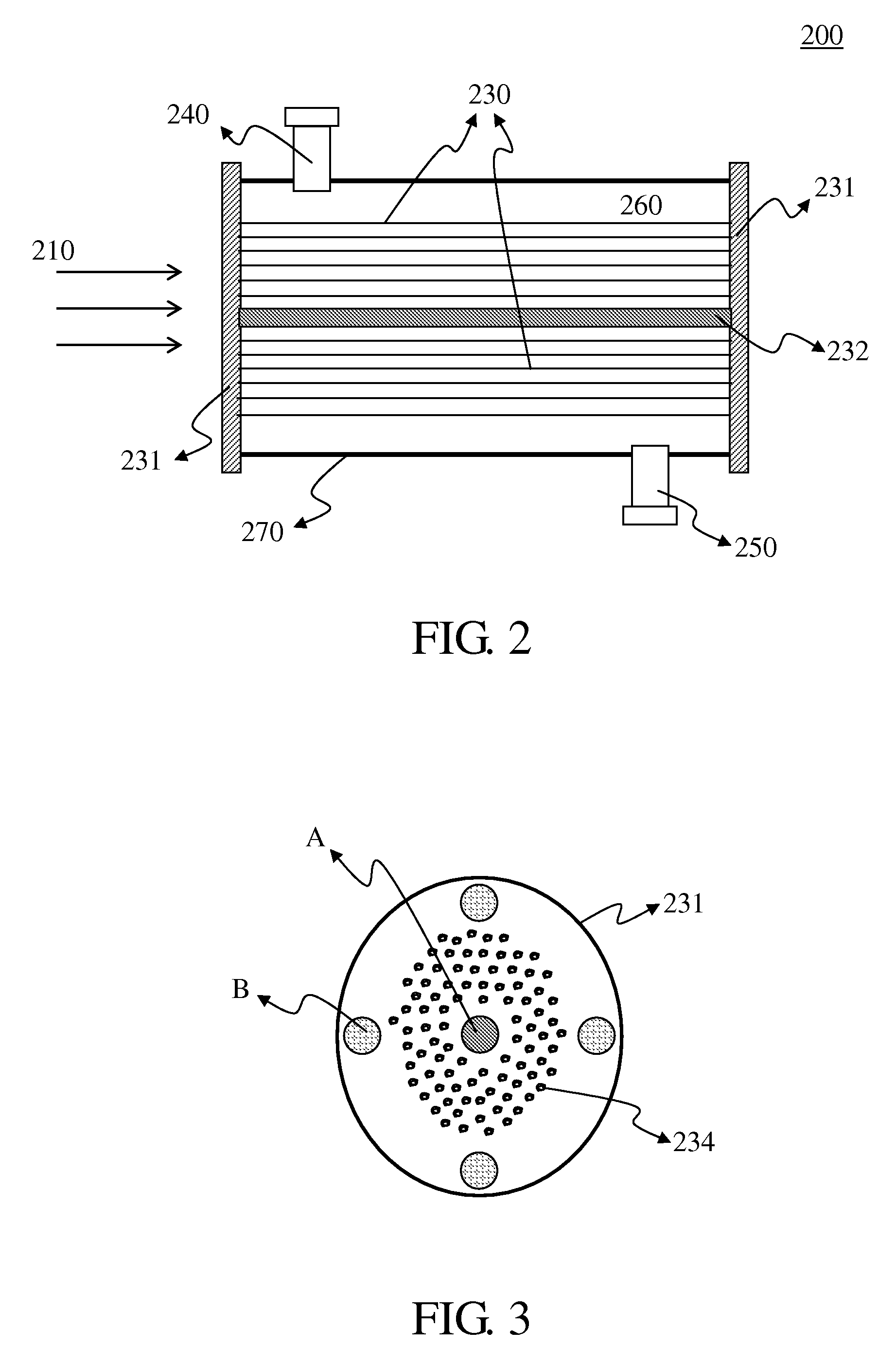

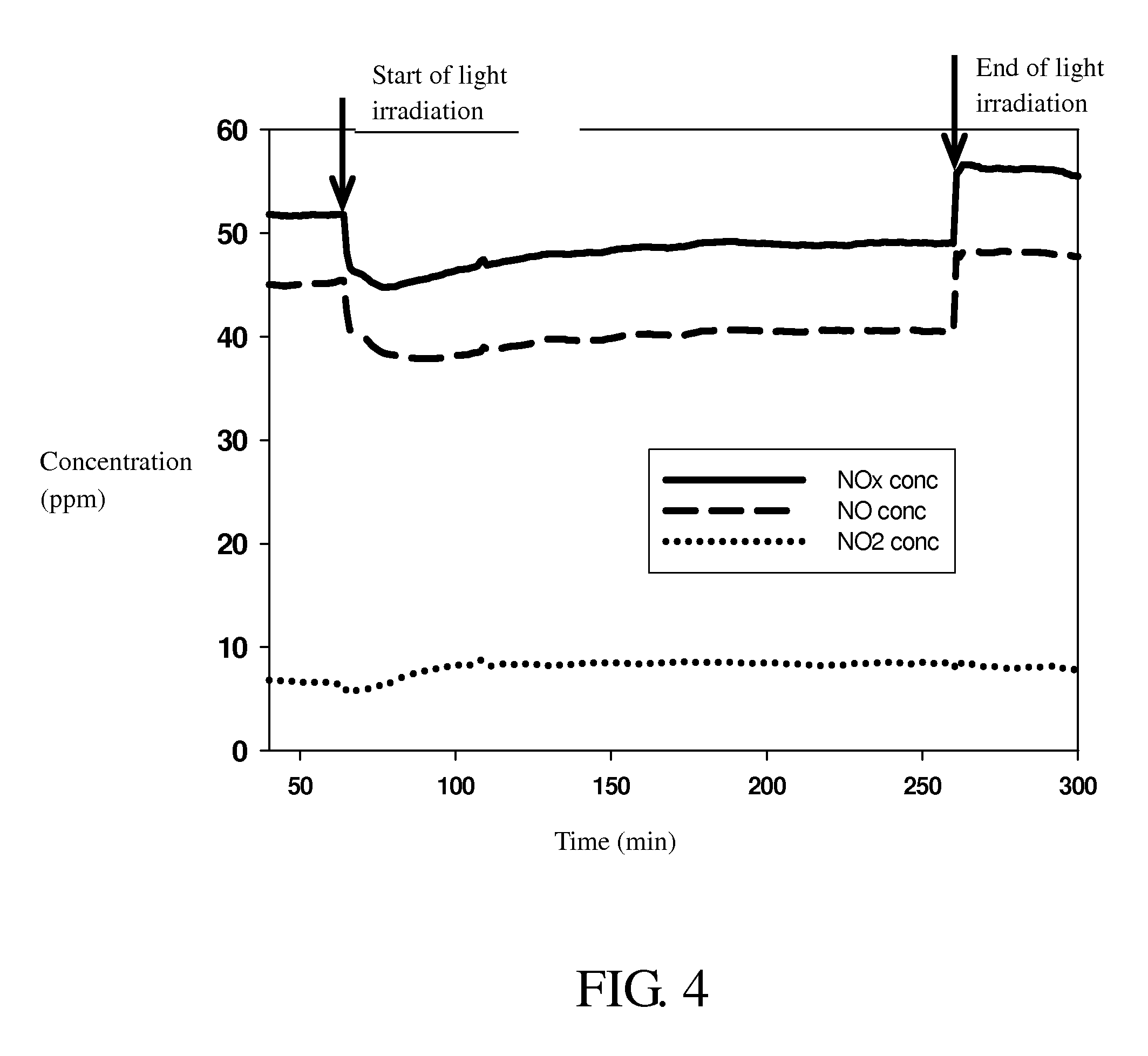

Optical Fiber Photocatalytic Reactor And Process For The Decomposition Of Nitrogen Oxide Using Said Reactor

PatentInactiveUS20080308405A1

Innovation

- An optical fiber photocatalytic reactor with a photocatalyst coating applied via a thermal hydrolysis method, using nano-sized anatase TiO2 or other photocatalysts like ZnO, coated onto optical fibers, which allows for efficient decomposition of nitrogen oxides at room temperature by optimizing photocatalyst adhesion and reaction efficiency.

Method for optimizing path of optical network, and optical transmission node for realizing path optimization

PatentInactiveUS7454138B2

Innovation

- The method involves each optical transmission node and add-drop node retaining and cumulatively transmitting span information to autonomously determine optimal pathways with the minimum number of regenerators and wavelength conversions, allowing for dynamic adjustment and optimization of regenerator placement and dispersion compensation on a per-path basis.

Sustainability Impact and Environmental Benefits

Photocatalytic reactor optimization represents a significant advancement in sustainable environmental technologies, offering substantial ecological benefits that extend beyond mere efficiency improvements. The implementation of optimized optical path designs in these reactors directly contributes to reduced energy consumption, as enhanced photon utilization decreases the power requirements for artificial light sources in applications where natural sunlight is insufficient.

The environmental impact of these optimizations manifests primarily through improved degradation rates of persistent organic pollutants in wastewater treatment systems. Field studies demonstrate that reactors with optimized optical paths can achieve up to 40% higher degradation efficiency for pharmaceutical compounds, pesticides, and industrial dyes compared to conventional designs, significantly reducing the ecological footprint of these contaminants in aquatic ecosystems.

Carbon footprint reduction constitutes another critical sustainability benefit. Quantitative lifecycle assessments reveal that advanced optical path designs can decrease the overall carbon emissions associated with water treatment processes by 15-25%, primarily through reduced energy requirements and extended catalyst lifespan. This reduction becomes particularly significant when considering large-scale industrial applications where treatment volumes reach thousands of cubic meters daily.

Resource conservation represents an additional environmental advantage. Optimized photocatalytic reactors demonstrate improved catalyst utilization efficiency, reducing the consumption of precious metals and rare earth elements commonly used in photocatalyst formulations. This conservation effect is particularly valuable given the environmental impact and geopolitical concerns associated with mining these materials.

The scalability of these technologies further amplifies their sustainability impact. Recent pilot projects have successfully demonstrated that optical path optimization techniques remain effective across various scales, from decentralized point-of-use systems to municipal-scale treatment facilities, making them adaptable to diverse environmental challenges globally.

Long-term environmental benefits extend to reduced chemical usage in water treatment. The enhanced efficiency of photocatalytic processes minimizes or eliminates the need for additional chemical oxidants or treatment agents, preventing the introduction of secondary pollutants and reducing the chemical burden on receiving water bodies.

Finally, these technologies contribute to circular economy principles by enabling the treatment and safe reuse of wastewater streams that would otherwise require disposal, conserving freshwater resources and closing industrial water loops. This aspect becomes increasingly critical in water-stressed regions where resource recovery and reuse represent essential sustainability strategies.

The environmental impact of these optimizations manifests primarily through improved degradation rates of persistent organic pollutants in wastewater treatment systems. Field studies demonstrate that reactors with optimized optical paths can achieve up to 40% higher degradation efficiency for pharmaceutical compounds, pesticides, and industrial dyes compared to conventional designs, significantly reducing the ecological footprint of these contaminants in aquatic ecosystems.

Carbon footprint reduction constitutes another critical sustainability benefit. Quantitative lifecycle assessments reveal that advanced optical path designs can decrease the overall carbon emissions associated with water treatment processes by 15-25%, primarily through reduced energy requirements and extended catalyst lifespan. This reduction becomes particularly significant when considering large-scale industrial applications where treatment volumes reach thousands of cubic meters daily.

Resource conservation represents an additional environmental advantage. Optimized photocatalytic reactors demonstrate improved catalyst utilization efficiency, reducing the consumption of precious metals and rare earth elements commonly used in photocatalyst formulations. This conservation effect is particularly valuable given the environmental impact and geopolitical concerns associated with mining these materials.

The scalability of these technologies further amplifies their sustainability impact. Recent pilot projects have successfully demonstrated that optical path optimization techniques remain effective across various scales, from decentralized point-of-use systems to municipal-scale treatment facilities, making them adaptable to diverse environmental challenges globally.

Long-term environmental benefits extend to reduced chemical usage in water treatment. The enhanced efficiency of photocatalytic processes minimizes or eliminates the need for additional chemical oxidants or treatment agents, preventing the introduction of secondary pollutants and reducing the chemical burden on receiving water bodies.

Finally, these technologies contribute to circular economy principles by enabling the treatment and safe reuse of wastewater streams that would otherwise require disposal, conserving freshwater resources and closing industrial water loops. This aspect becomes increasingly critical in water-stressed regions where resource recovery and reuse represent essential sustainability strategies.

Scalability and Industrial Implementation Challenges

The scaling of photocatalytic reactor systems from laboratory to industrial scale presents significant challenges that must be addressed for successful commercial implementation. Current laboratory-scale reactors typically operate with volumes of 0.1-5 liters, while industrial applications require capacities of hundreds to thousands of liters. This substantial increase in scale introduces complex optical path issues that are not present in smaller systems, particularly regarding light penetration depth and uniformity across larger reaction volumes.

A primary challenge is maintaining optimal light distribution throughout scaled-up reactors. As reactor dimensions increase, light intensity decreases exponentially with distance from the source according to the Beer-Lambert law. In industrial-scale reactors, this creates "dark zones" where photocatalytic activity is minimal or non-existent, significantly reducing overall efficiency. Engineering solutions such as multiple light sources, light-guiding elements, or reactor geometry modifications become increasingly complex and costly at larger scales.

Energy consumption represents another critical barrier to industrial implementation. High-powered UV or specialized LED arrays required for large-scale operations can consume substantial electricity, potentially offsetting the environmental benefits of photocatalytic processes. Current industrial photocatalytic systems typically operate with energy efficiencies of only 5-15%, making economic viability challenging without significant improvements in optical path design.

Material constraints further complicate scaling efforts. Transparent materials suitable for laboratory reactors may not possess the mechanical strength, chemical resistance, or durability required for industrial operations. Additionally, fouling of optical surfaces in continuous industrial processes can progressively degrade light transmission, necessitating regular maintenance or innovative self-cleaning mechanisms.

The capital expenditure for scaled photocatalytic systems remains prohibitively high for many potential applications. Current estimates suggest installation costs of $500-2,000 per cubic meter of treatment capacity, significantly higher than conventional treatment technologies. This economic barrier is directly related to the complexity of optical systems required to maintain effective light distribution at scale.

Standardization presents an additional challenge, as optical path optimization methods developed for specific laboratory conditions often cannot be directly transferred to different reactor geometries or operating conditions. The lack of standardized design principles for optical path optimization hampers widespread industrial adoption and increases engineering costs for custom implementations.

A primary challenge is maintaining optimal light distribution throughout scaled-up reactors. As reactor dimensions increase, light intensity decreases exponentially with distance from the source according to the Beer-Lambert law. In industrial-scale reactors, this creates "dark zones" where photocatalytic activity is minimal or non-existent, significantly reducing overall efficiency. Engineering solutions such as multiple light sources, light-guiding elements, or reactor geometry modifications become increasingly complex and costly at larger scales.

Energy consumption represents another critical barrier to industrial implementation. High-powered UV or specialized LED arrays required for large-scale operations can consume substantial electricity, potentially offsetting the environmental benefits of photocatalytic processes. Current industrial photocatalytic systems typically operate with energy efficiencies of only 5-15%, making economic viability challenging without significant improvements in optical path design.

Material constraints further complicate scaling efforts. Transparent materials suitable for laboratory reactors may not possess the mechanical strength, chemical resistance, or durability required for industrial operations. Additionally, fouling of optical surfaces in continuous industrial processes can progressively degrade light transmission, necessitating regular maintenance or innovative self-cleaning mechanisms.

The capital expenditure for scaled photocatalytic systems remains prohibitively high for many potential applications. Current estimates suggest installation costs of $500-2,000 per cubic meter of treatment capacity, significantly higher than conventional treatment technologies. This economic barrier is directly related to the complexity of optical systems required to maintain effective light distribution at scale.

Standardization presents an additional challenge, as optical path optimization methods developed for specific laboratory conditions often cannot be directly transferred to different reactor geometries or operating conditions. The lack of standardized design principles for optical path optimization hampers widespread industrial adoption and increases engineering costs for custom implementations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!