Roadmap To Commercial Solar-Driven Ammonia Production

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solar Ammonia Evolution and Objectives

Ammonia synthesis has been a cornerstone of modern agriculture since the development of the Haber-Bosch process in the early 20th century. This energy-intensive process currently consumes approximately 1-2% of global energy production and generates significant carbon emissions, with an estimated 1.4% of global CO2 emissions attributable to ammonia production. The evolution of solar-driven ammonia production represents a paradigm shift toward sustainable manufacturing of this essential chemical.

The historical trajectory of ammonia synthesis began with the conventional Haber-Bosch process, which operates under harsh conditions of 400-500°C and 150-300 bar pressure. Recent decades have witnessed increasing research into alternative production methods that leverage renewable energy sources, particularly solar power. This transition has been driven by growing environmental concerns and the need to decarbonize industrial processes to meet global climate targets.

Solar-driven ammonia production has evolved through several technological approaches, including photocatalytic, photoelectrochemical, and solar thermochemical methods. Each approach offers distinct advantages and faces unique challenges in terms of efficiency, scalability, and economic viability. The integration of solar energy into ammonia synthesis processes has progressed from laboratory-scale demonstrations to pilot projects, with increasing focus on system optimization and practical implementation.

The primary objective of commercial solar-driven ammonia production is to develop economically viable processes that can compete with conventional methods while significantly reducing carbon emissions. Specific technical goals include achieving solar-to-ammonia conversion efficiencies exceeding 10%, developing stable and durable catalysts capable of operating under ambient conditions, and designing scalable reactor systems suitable for industrial deployment.

Additional objectives encompass reducing capital and operational costs to achieve price parity with conventional ammonia production, establishing reliable supply chains for critical materials, and developing integrated systems that effectively manage intermittent solar energy availability. The roadmap also aims to address regulatory and safety considerations specific to decentralized ammonia production facilities.

From a broader perspective, solar ammonia technology seeks to enable distributed production models that could revolutionize agricultural practices in remote regions by providing localized fertilizer manufacturing capabilities. This could significantly reduce transportation costs and emissions associated with ammonia distribution while improving food security in developing regions.

The evolution toward commercial solar ammonia production aligns with global sustainability initiatives and represents a critical pathway for reducing industrial carbon emissions while meeting the growing global demand for nitrogen fertilizers, which is projected to increase by approximately 1.5% annually through 2050.

The historical trajectory of ammonia synthesis began with the conventional Haber-Bosch process, which operates under harsh conditions of 400-500°C and 150-300 bar pressure. Recent decades have witnessed increasing research into alternative production methods that leverage renewable energy sources, particularly solar power. This transition has been driven by growing environmental concerns and the need to decarbonize industrial processes to meet global climate targets.

Solar-driven ammonia production has evolved through several technological approaches, including photocatalytic, photoelectrochemical, and solar thermochemical methods. Each approach offers distinct advantages and faces unique challenges in terms of efficiency, scalability, and economic viability. The integration of solar energy into ammonia synthesis processes has progressed from laboratory-scale demonstrations to pilot projects, with increasing focus on system optimization and practical implementation.

The primary objective of commercial solar-driven ammonia production is to develop economically viable processes that can compete with conventional methods while significantly reducing carbon emissions. Specific technical goals include achieving solar-to-ammonia conversion efficiencies exceeding 10%, developing stable and durable catalysts capable of operating under ambient conditions, and designing scalable reactor systems suitable for industrial deployment.

Additional objectives encompass reducing capital and operational costs to achieve price parity with conventional ammonia production, establishing reliable supply chains for critical materials, and developing integrated systems that effectively manage intermittent solar energy availability. The roadmap also aims to address regulatory and safety considerations specific to decentralized ammonia production facilities.

From a broader perspective, solar ammonia technology seeks to enable distributed production models that could revolutionize agricultural practices in remote regions by providing localized fertilizer manufacturing capabilities. This could significantly reduce transportation costs and emissions associated with ammonia distribution while improving food security in developing regions.

The evolution toward commercial solar ammonia production aligns with global sustainability initiatives and represents a critical pathway for reducing industrial carbon emissions while meeting the growing global demand for nitrogen fertilizers, which is projected to increase by approximately 1.5% annually through 2050.

Market Analysis for Green Ammonia Production

The global green ammonia market is experiencing unprecedented growth, driven by increasing environmental concerns and the push for decarbonization across industries. Current market valuations place green ammonia at approximately $72 million in 2022, with projections indicating a compound annual growth rate (CAGR) of 72.9% through 2030, potentially reaching a market size of $7.6 billion. This explosive growth trajectory reflects the critical role green ammonia is expected to play in the global energy transition.

Demand for green ammonia spans multiple sectors, with fertilizer production currently representing the largest application segment. Agriculture accounts for roughly 80% of conventional ammonia consumption worldwide, presenting an enormous opportunity for green alternatives. Beyond fertilizers, emerging applications in energy storage, maritime fuel, and power generation are creating new market opportunities that could potentially eclipse traditional uses within the next decade.

Regionally, Europe leads in green ammonia development, with countries like Germany, the Netherlands, and Denmark making significant investments in production facilities. The Asia-Pacific region, particularly Japan, South Korea, and Australia, is rapidly accelerating development efforts, leveraging abundant renewable energy resources. North America is also gaining momentum, with several large-scale projects announced in the United States and Canada.

The economic landscape for green ammonia is evolving rapidly. Current production costs range between $900-1,600 per ton, significantly higher than conventional ammonia's $200-450 per ton. However, this gap is expected to narrow substantially by 2030 as renewable electricity costs decline and electrolyzer technologies mature. Bloomberg New Energy Finance forecasts green ammonia achieving cost parity with conventional production in optimal locations by 2030, and widespread competitiveness by 2035.

Policy support is increasingly favorable, with carbon pricing mechanisms, renewable energy subsidies, and green hydrogen strategies creating economic incentives for green ammonia production. The European Union's Hydrogen Strategy and various national hydrogen roadmaps explicitly include ammonia as a key hydrogen carrier, while countries like Japan have established concrete targets for ammonia in their energy mix.

Market barriers remain significant, including high capital expenditure requirements, infrastructure limitations, and regulatory uncertainties. The initial investment for commercial-scale solar-driven ammonia production facilities ranges from $50-200 million, creating substantial entry barriers. Additionally, the lack of standardized certification schemes for "green" ammonia presents challenges for market differentiation and premium pricing.

Demand for green ammonia spans multiple sectors, with fertilizer production currently representing the largest application segment. Agriculture accounts for roughly 80% of conventional ammonia consumption worldwide, presenting an enormous opportunity for green alternatives. Beyond fertilizers, emerging applications in energy storage, maritime fuel, and power generation are creating new market opportunities that could potentially eclipse traditional uses within the next decade.

Regionally, Europe leads in green ammonia development, with countries like Germany, the Netherlands, and Denmark making significant investments in production facilities. The Asia-Pacific region, particularly Japan, South Korea, and Australia, is rapidly accelerating development efforts, leveraging abundant renewable energy resources. North America is also gaining momentum, with several large-scale projects announced in the United States and Canada.

The economic landscape for green ammonia is evolving rapidly. Current production costs range between $900-1,600 per ton, significantly higher than conventional ammonia's $200-450 per ton. However, this gap is expected to narrow substantially by 2030 as renewable electricity costs decline and electrolyzer technologies mature. Bloomberg New Energy Finance forecasts green ammonia achieving cost parity with conventional production in optimal locations by 2030, and widespread competitiveness by 2035.

Policy support is increasingly favorable, with carbon pricing mechanisms, renewable energy subsidies, and green hydrogen strategies creating economic incentives for green ammonia production. The European Union's Hydrogen Strategy and various national hydrogen roadmaps explicitly include ammonia as a key hydrogen carrier, while countries like Japan have established concrete targets for ammonia in their energy mix.

Market barriers remain significant, including high capital expenditure requirements, infrastructure limitations, and regulatory uncertainties. The initial investment for commercial-scale solar-driven ammonia production facilities ranges from $50-200 million, creating substantial entry barriers. Additionally, the lack of standardized certification schemes for "green" ammonia presents challenges for market differentiation and premium pricing.

Solar-Driven Ammonia Synthesis: Status and Barriers

Solar-driven ammonia synthesis represents a promising pathway for sustainable fertilizer production and energy storage, yet faces significant technical and economic barriers that impede commercial implementation. Current industrial ammonia production via the Haber-Bosch process consumes approximately 1-2% of global energy and generates substantial CO2 emissions. Solar-driven alternatives offer potential carbon-neutral pathways but remain in early development stages.

The primary technical barriers include low conversion efficiency in photocatalytic and photoelectrochemical systems, with nitrogen reduction reaction (NRR) rates typically below 10^-10 mol cm^-2 s^-1, far from commercial viability. Competing hydrogen evolution reactions frequently dominate, resulting in ammonia selectivity below 10% in many experimental systems. Catalyst stability presents another significant challenge, with performance degradation observed over relatively short operational periods.

Material limitations constitute another major barrier, as current photocatalysts and electrocatalysts demonstrate insufficient solar absorption, charge separation, and active site availability. Most systems operate only under UV light, capturing merely a small fraction of the solar spectrum. Additionally, nitrogen activation remains fundamentally challenging due to the strong N≡N triple bond (941 kJ/mol), requiring significant energy input and specialized catalytic environments.

Scale-up challenges further complicate commercialization efforts. Laboratory demonstrations typically operate at microliter or milliliter scales, while commercial implementation would require several orders of magnitude increase in production capacity. Reactor design for efficient light harvesting, mass transport, and product separation at scale remains largely unexplored.

Economic barriers are equally formidable. Current solar ammonia production costs are estimated at $1,200-2,500 per ton, compared to $200-500 per ton for conventional Haber-Bosch ammonia. Capital expenditure requirements for solar-driven systems remain high due to specialized materials and complex integration needs. The intermittent nature of solar energy necessitates either energy storage systems or hybrid approaches, further increasing system complexity and cost.

Regulatory and infrastructure limitations also impede progress. Existing ammonia distribution networks are optimized for centralized production facilities, whereas solar-driven approaches may benefit from distributed production models. Additionally, safety standards and certification processes for novel ammonia production technologies remain underdeveloped, creating uncertainty for potential investors and technology developers.

Addressing these interconnected barriers requires coordinated research efforts across multiple disciplines, including materials science, catalysis, process engineering, and techno-economic analysis. Recent advances in two-dimensional materials, plasmonic catalysts, and hybrid electrochemical-photochemical systems offer promising directions, but substantial breakthroughs are still needed to establish a viable commercial pathway.

The primary technical barriers include low conversion efficiency in photocatalytic and photoelectrochemical systems, with nitrogen reduction reaction (NRR) rates typically below 10^-10 mol cm^-2 s^-1, far from commercial viability. Competing hydrogen evolution reactions frequently dominate, resulting in ammonia selectivity below 10% in many experimental systems. Catalyst stability presents another significant challenge, with performance degradation observed over relatively short operational periods.

Material limitations constitute another major barrier, as current photocatalysts and electrocatalysts demonstrate insufficient solar absorption, charge separation, and active site availability. Most systems operate only under UV light, capturing merely a small fraction of the solar spectrum. Additionally, nitrogen activation remains fundamentally challenging due to the strong N≡N triple bond (941 kJ/mol), requiring significant energy input and specialized catalytic environments.

Scale-up challenges further complicate commercialization efforts. Laboratory demonstrations typically operate at microliter or milliliter scales, while commercial implementation would require several orders of magnitude increase in production capacity. Reactor design for efficient light harvesting, mass transport, and product separation at scale remains largely unexplored.

Economic barriers are equally formidable. Current solar ammonia production costs are estimated at $1,200-2,500 per ton, compared to $200-500 per ton for conventional Haber-Bosch ammonia. Capital expenditure requirements for solar-driven systems remain high due to specialized materials and complex integration needs. The intermittent nature of solar energy necessitates either energy storage systems or hybrid approaches, further increasing system complexity and cost.

Regulatory and infrastructure limitations also impede progress. Existing ammonia distribution networks are optimized for centralized production facilities, whereas solar-driven approaches may benefit from distributed production models. Additionally, safety standards and certification processes for novel ammonia production technologies remain underdeveloped, creating uncertainty for potential investors and technology developers.

Addressing these interconnected barriers requires coordinated research efforts across multiple disciplines, including materials science, catalysis, process engineering, and techno-economic analysis. Recent advances in two-dimensional materials, plasmonic catalysts, and hybrid electrochemical-photochemical systems offer promising directions, but substantial breakthroughs are still needed to establish a viable commercial pathway.

Current Solar Ammonia Production Methodologies

01 Solar-powered ammonia synthesis technologies

Various technologies have been developed for solar-powered ammonia synthesis, including photocatalytic processes, solar thermal systems, and integrated solar-electrochemical approaches. These technologies utilize solar energy to drive the ammonia synthesis reaction, reducing dependence on fossil fuels and decreasing carbon emissions. The systems typically incorporate specialized catalysts, reactor designs, and energy conversion mechanisms to efficiently harness solar energy for nitrogen fixation and hydrogen production.- Solar-powered ammonia synthesis technologies: Various technologies have been developed for solar-powered ammonia synthesis, including photocatalytic processes, solar thermal systems, and integrated solar-electrochemical approaches. These technologies harness solar energy to drive the ammonia synthesis reaction under milder conditions than conventional Haber-Bosch processes. The integration of solar energy can significantly reduce the carbon footprint of ammonia production while potentially enabling distributed manufacturing models.

- Economic feasibility and cost reduction strategies: The commercial viability of solar-driven ammonia production depends on several economic factors including capital costs, operational expenses, and production efficiency. Cost reduction strategies focus on improving catalyst performance, optimizing system integration, and scaling up production. Innovations in reactor design and process intensification are key to achieving cost parity with conventional ammonia production methods. Market incentives for green ammonia and carbon pricing mechanisms can further enhance economic feasibility.

- Novel catalyst systems for solar ammonia synthesis: Advanced catalyst systems are being developed to enhance the efficiency of solar-driven ammonia production. These include nanostructured materials, non-noble metal catalysts, and hybrid photocatalysts that can operate at lower temperatures and pressures. Some catalysts are designed to work specifically with solar energy inputs, enabling direct conversion of nitrogen and water to ammonia using sunlight. Improvements in catalyst stability, selectivity, and activity are critical for commercial implementation.

- Integrated energy systems and storage solutions: Solar-driven ammonia production can be integrated with other renewable energy systems to ensure continuous operation despite the intermittent nature of solar energy. These integrated systems may include energy storage solutions, hybrid power sources, and smart grid connections. Ammonia itself serves as an energy carrier and storage medium, enabling the storage of excess renewable energy in chemical form. This dual-purpose aspect of ammonia as both a chemical feedstock and energy storage medium enhances the overall commercial viability of solar-driven production systems.

- Scalability and industrial implementation challenges: Scaling up solar-driven ammonia production from laboratory to industrial scale presents significant engineering challenges. These include maintaining efficiency at larger scales, ensuring process stability under variable solar conditions, and developing appropriate infrastructure for production and distribution. Pilot projects and demonstration plants are being established to validate technologies and address implementation barriers. Regulatory frameworks, standardization, and supply chain development are additional factors affecting the timeline for commercial deployment of solar ammonia technologies.

02 Economic feasibility and cost reduction strategies

The commercial viability of solar-driven ammonia production depends on economic factors such as capital costs, operational expenses, and market competitiveness. Cost reduction strategies include developing more efficient catalysts, optimizing system integration, scaling up production, and utilizing low-cost materials. Economic analyses suggest that solar ammonia production could become competitive with conventional methods as technology advances and renewable energy costs continue to decrease, particularly in regions with abundant solar resources.Expand Specific Solutions03 System integration and energy storage solutions

Effective integration of solar energy systems with ammonia production processes is crucial for commercial viability. This includes solutions for intermittency issues through energy storage, hybrid systems combining multiple renewable sources, and smart control systems for optimizing production based on solar availability. Ammonia itself serves as an energy carrier and storage medium, allowing solar energy to be stored chemically and transported efficiently, which enhances the overall commercial potential of these systems.Expand Specific Solutions04 Environmental benefits and sustainability aspects

Solar-driven ammonia production offers significant environmental advantages over conventional fossil fuel-based methods, including reduced greenhouse gas emissions, lower water consumption, and decreased air pollution. Life cycle assessments demonstrate the sustainability benefits of solar ammonia systems, particularly when considering long-term environmental impacts. These environmental advantages can translate to commercial benefits through carbon credits, compliance with increasingly stringent regulations, and meeting growing market demand for sustainable fertilizers and clean energy carriers.Expand Specific Solutions05 Scalability and industrial implementation challenges

The transition from laboratory-scale demonstrations to commercially viable solar ammonia production faces several challenges related to scalability and industrial implementation. These include developing robust systems capable of continuous operation under variable conditions, establishing supply chains for specialized components, and creating appropriate infrastructure for distribution and use. Pilot projects and demonstration plants are addressing these challenges by testing various configurations, validating performance metrics, and identifying pathways for successful commercial deployment across different geographical and market contexts.Expand Specific Solutions

Industry Leaders in Solar-Driven Ammonia Technology

The solar-driven ammonia production market is in an early growth phase, characterized by significant research activity and emerging commercial applications. The global market potential is substantial, driven by decarbonization initiatives in transportation and agriculture sectors. Technologically, the field shows varying maturity levels across players: AMOGY has demonstrated ammonia-based power solutions in vehicles and vessels; Toyota brings manufacturing expertise; academic institutions like Xi'an Jiaotong University and King Abdullah University contribute fundamental research; while industrial players such as Stamicarbon, Wacker Chemie, and Saudi Aramco provide infrastructure and scaling capabilities. The competitive landscape features a mix of startups (AMOGY, Pani Clean), established industrial giants (Linde, Siemens), and research institutions collaborating to overcome efficiency and cost barriers to commercial viability.

AMOGY, Inc.

Technical Solution: AMOGY has developed an innovative ammonia-to-power system that efficiently converts ammonia to hydrogen for fuel cell applications. Their technology focuses on the downstream utilization of ammonia rather than production, but they're actively working on integrating with renewable energy sources for green ammonia production. Their system uses a catalytic cracking technology that efficiently breaks down ammonia into hydrogen at lower temperatures than conventional methods, making it more compatible with solar thermal inputs. AMOGY's approach includes specialized catalysts that enable ammonia decomposition at temperatures achievable through concentrated solar thermal systems, potentially creating a closed-loop system where solar energy drives both ammonia production and its subsequent conversion to power.

Strengths: Highly efficient ammonia cracking technology that could be integrated with solar production systems; established partnerships with shipping and transportation sectors for ammonia utilization. Weaknesses: Primary focus is on ammonia utilization rather than production; still requires integration with third-party green ammonia production technologies.

Stamicarbon BV

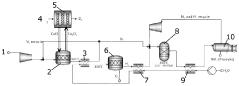

Technical Solution: Stamicarbon has developed an innovative solar-powered ammonia production technology as part of their green ammonia initiative. Their system integrates photovoltaic electricity generation with their proprietary electrolysis technology and optimized Haber-Bosch process. Stamicarbon's approach focuses on process intensification, reducing energy requirements through advanced heat integration and catalyst improvements. Their system utilizes a novel ruthenium-based catalyst that operates efficiently at lower temperatures (380-420°C) and pressures (80-100 bar) than conventional iron catalysts, making it more compatible with renewable energy inputs. Stamicarbon has implemented sophisticated process control systems that can manage the variable nature of solar energy input, maintaining stable operation despite fluctuations. Their modular design approach allows for scalable implementation, from small distributed production facilities to large centralized plants, with production capacities ranging from 10 to 1000 tons per day depending on configuration.

Strengths: Extensive experience in ammonia synthesis technology; established market presence in fertilizer production sector; advanced catalyst technology specifically designed for renewable energy integration. Weaknesses: Higher capital costs compared to conventional production; requires integration of multiple complex subsystems; technology still transitioning from demonstration to full commercial scale.

Key Patents and Breakthroughs in Solar Ammonia Synthesis

Solar energy driven ammonia synthesis in wet nitrogen environment using modified perovskite nanostructure-based photo-catalytic water splitting

PatentInactiveIN201731026537A

Innovation

- A solar energy-driven ammonia synthesis system using a modified perovskite nanostructure-based photo-catalytic water splitting mechanism, employing niobium-doped strontium titanate as a photocatalyst and noble metal nano-particles for efficient ammonia production in a wet nitrogen environment at normal temperature and pressure, without emitting greenhouse gases.

solar ammonia production

PatentActiveDE102014213987A1

Innovation

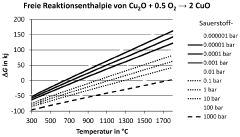

- A method combining a thermochemical cycle with the Haber-Bosch process to produce nitrogen and hydrogen, utilizing redox materials to extract nitrogen from air and generate hydrogen through solar energy, reducing the need for fossil fuels and cryogenic air separation.

Economic Feasibility and Cost Reduction Strategies

The economic feasibility of solar-driven ammonia production remains a significant challenge for commercial implementation. Current cost estimates for solar ammonia range from $600 to $1,200 per ton, substantially higher than conventional Haber-Bosch production costs of $200-400 per ton. This cost differential represents the primary barrier to market entry and widespread adoption of this sustainable technology.

Capital expenditure (CAPEX) for solar ammonia facilities constitutes approximately 60-70% of total production costs, with electrolyzer systems representing the largest component. Recent technological advancements suggest electrolyzer costs could decrease by 40-60% by 2030 through economies of scale, manufacturing innovations, and material optimizations. Photovoltaic system costs continue their downward trajectory, with utility-scale installations projected to reach $0.30-0.40/W by 2030, further enhancing economic viability.

Operational expenditure (OPEX) optimization presents additional cost reduction opportunities. Improving system integration efficiency between solar collection, hydrogen production, and ammonia synthesis could reduce energy losses by 15-25%. Implementing advanced control systems and predictive maintenance protocols may extend equipment lifespans and reduce downtime, potentially decreasing maintenance costs by 10-15% over facility lifetime.

Location selection emerges as a critical economic factor. Regions with high solar irradiance (>2000 kWh/m²/year) can achieve capacity factors exceeding 25%, significantly improving return on investment. Strategic facility placement near agricultural centers or industrial ammonia consumers reduces transportation costs, which currently add $50-100 per ton to delivered ammonia prices.

Policy interventions and financial mechanisms will likely play decisive roles in bridging the cost gap. Carbon pricing mechanisms valuing emissions at $50-100 per ton of CO₂ would significantly improve solar ammonia's competitiveness. Green financing instruments, including sustainability-linked bonds and green loans with preferential interest rates, could reduce capital costs by 1-2 percentage points, translating to $30-50 per ton in production cost savings.

Hybrid business models incorporating grid electricity during low solar periods can improve capacity utilization by 30-40%, enhancing overall economic performance. Additionally, monetizing oxygen as a by-product of water electrolysis could offset production costs by $20-40 per ton of ammonia, depending on local market conditions and industrial oxygen demand.

Capital expenditure (CAPEX) for solar ammonia facilities constitutes approximately 60-70% of total production costs, with electrolyzer systems representing the largest component. Recent technological advancements suggest electrolyzer costs could decrease by 40-60% by 2030 through economies of scale, manufacturing innovations, and material optimizations. Photovoltaic system costs continue their downward trajectory, with utility-scale installations projected to reach $0.30-0.40/W by 2030, further enhancing economic viability.

Operational expenditure (OPEX) optimization presents additional cost reduction opportunities. Improving system integration efficiency between solar collection, hydrogen production, and ammonia synthesis could reduce energy losses by 15-25%. Implementing advanced control systems and predictive maintenance protocols may extend equipment lifespans and reduce downtime, potentially decreasing maintenance costs by 10-15% over facility lifetime.

Location selection emerges as a critical economic factor. Regions with high solar irradiance (>2000 kWh/m²/year) can achieve capacity factors exceeding 25%, significantly improving return on investment. Strategic facility placement near agricultural centers or industrial ammonia consumers reduces transportation costs, which currently add $50-100 per ton to delivered ammonia prices.

Policy interventions and financial mechanisms will likely play decisive roles in bridging the cost gap. Carbon pricing mechanisms valuing emissions at $50-100 per ton of CO₂ would significantly improve solar ammonia's competitiveness. Green financing instruments, including sustainability-linked bonds and green loans with preferential interest rates, could reduce capital costs by 1-2 percentage points, translating to $30-50 per ton in production cost savings.

Hybrid business models incorporating grid electricity during low solar periods can improve capacity utilization by 30-40%, enhancing overall economic performance. Additionally, monetizing oxygen as a by-product of water electrolysis could offset production costs by $20-40 per ton of ammonia, depending on local market conditions and industrial oxygen demand.

Environmental Impact and Sustainability Assessment

The transition to solar-driven ammonia production represents a significant opportunity to reduce the environmental footprint of one of the world's most energy-intensive chemical processes. Traditional ammonia synthesis via the Haber-Bosch process currently accounts for approximately 1-2% of global carbon emissions and consumes about 3-5% of the world's natural gas production. Solar-driven alternatives offer a pathway to dramatically reduce these impacts.

Life cycle assessment (LCA) studies indicate that solar-powered ammonia production could potentially reduce greenhouse gas emissions by 60-90% compared to conventional methods, depending on the specific technology pathway and geographic location. The elimination of fossil fuels as both energy source and hydrogen feedstock represents the most substantial environmental benefit, directly addressing the 1.8 tons of CO2 typically generated per ton of ammonia produced conventionally.

Water consumption presents another critical environmental consideration. While electrolysis-based hydrogen production requires significant water inputs, innovative approaches such as atmospheric moisture harvesting and wastewater integration are emerging as solutions for water-scarce regions. These technologies could reduce freshwater withdrawal by up to 40% compared to conventional systems when implemented alongside solar ammonia production.

Land use impacts vary considerably between different solar technologies. Concentrated solar thermal systems typically require 2-3 hectares per MW of capacity, while photovoltaic installations may require 1-2 hectares per MW. This land requirement must be balanced against the environmental benefits, particularly in regions where land competition with agriculture or natural ecosystems is a concern.

From a sustainability perspective, solar ammonia production aligns with multiple UN Sustainable Development Goals, including affordable and clean energy (SDG 7), responsible consumption and production (SDG 12), and climate action (SDG 13). The technology also supports circular economy principles through potential integration with agricultural systems, where ammonia serves as both fertilizer and energy carrier.

Material sustainability represents another dimension requiring assessment. Current solar technologies rely on various critical materials including silver, indium, and rare earth elements. Developing recycling pathways and alternative material formulations will be essential for long-term sustainability, particularly as deployment scales to industrial levels. Recent research suggests that over 90% of photovoltaic materials could be recovered and reused, significantly improving the technology's overall environmental profile.

Noise pollution and visual impacts, while less significant than chemical emissions, must also be considered in comprehensive environmental assessments, particularly for installations near populated areas. These factors, though often overlooked, can influence community acceptance and the social license to operate.

Life cycle assessment (LCA) studies indicate that solar-powered ammonia production could potentially reduce greenhouse gas emissions by 60-90% compared to conventional methods, depending on the specific technology pathway and geographic location. The elimination of fossil fuels as both energy source and hydrogen feedstock represents the most substantial environmental benefit, directly addressing the 1.8 tons of CO2 typically generated per ton of ammonia produced conventionally.

Water consumption presents another critical environmental consideration. While electrolysis-based hydrogen production requires significant water inputs, innovative approaches such as atmospheric moisture harvesting and wastewater integration are emerging as solutions for water-scarce regions. These technologies could reduce freshwater withdrawal by up to 40% compared to conventional systems when implemented alongside solar ammonia production.

Land use impacts vary considerably between different solar technologies. Concentrated solar thermal systems typically require 2-3 hectares per MW of capacity, while photovoltaic installations may require 1-2 hectares per MW. This land requirement must be balanced against the environmental benefits, particularly in regions where land competition with agriculture or natural ecosystems is a concern.

From a sustainability perspective, solar ammonia production aligns with multiple UN Sustainable Development Goals, including affordable and clean energy (SDG 7), responsible consumption and production (SDG 12), and climate action (SDG 13). The technology also supports circular economy principles through potential integration with agricultural systems, where ammonia serves as both fertilizer and energy carrier.

Material sustainability represents another dimension requiring assessment. Current solar technologies rely on various critical materials including silver, indium, and rare earth elements. Developing recycling pathways and alternative material formulations will be essential for long-term sustainability, particularly as deployment scales to industrial levels. Recent research suggests that over 90% of photovoltaic materials could be recovered and reused, significantly improving the technology's overall environmental profile.

Noise pollution and visual impacts, while less significant than chemical emissions, must also be considered in comprehensive environmental assessments, particularly for installations near populated areas. These factors, though often overlooked, can influence community acceptance and the social license to operate.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!