Cathode Composite Design With Sulfide SSEs For High Areal Loading

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulfide SSE Cathode Composite Background and Objectives

Solid-state batteries represent a revolutionary advancement in energy storage technology, with sulfide solid-state electrolytes (SSEs) emerging as particularly promising candidates due to their high ionic conductivity comparable to liquid electrolytes. The development of sulfide SSE cathode composites has evolved significantly over the past decade, transitioning from fundamental material exploration to sophisticated composite design strategies aimed at maximizing electrochemical performance.

The historical trajectory of sulfide SSE cathode composites began with simple physical mixtures of active materials and electrolytes, which suffered from poor interfacial contact and limited electrochemical performance. As understanding deepened, researchers recognized the critical importance of interfaces and developed various strategies to enhance ionic and electronic transport pathways within the composite structure.

Current technological trends indicate a shift toward multi-component composite systems that integrate active materials, sulfide electrolytes, and functional additives in precisely engineered architectures. This evolution is driven by the fundamental challenge of achieving high areal loading (>4 mAh/cm²) while maintaining excellent rate capability and cycle life—a prerequisite for commercial viability of all-solid-state batteries.

The primary objective of advanced cathode composite design with sulfide SSEs is to overcome the inherent limitations of solid-state systems, particularly the high interfacial resistance between cathode active materials and sulfide electrolytes. This resistance stems from chemical incompatibility, mechanical stress during cycling, and limited contact area, all of which become more pronounced at high areal loadings.

Specifically, research aims to develop composite structures that simultaneously address multiple technical challenges: (1) maximizing ionic conductivity throughout the composite, (2) ensuring sufficient electronic conductivity, (3) accommodating volume changes during cycling, (4) minimizing interfacial resistance, and (5) maintaining structural integrity at high areal loadings.

The ultimate goal is to enable all-solid-state batteries with energy densities exceeding 400 Wh/kg at the cell level, while providing superior safety, fast charging capability, and extended cycle life compared to conventional lithium-ion batteries. This represents a critical stepping stone toward next-generation energy storage systems for electric vehicles, grid storage, and portable electronics.

Recent breakthroughs in nanoscale engineering and interface modification have demonstrated promising results, suggesting that properly designed sulfide SSE cathode composites can indeed support high areal loadings while maintaining excellent electrochemical performance. These advances set the stage for transformative improvements in battery technology that could accelerate the global transition to sustainable energy systems.

The historical trajectory of sulfide SSE cathode composites began with simple physical mixtures of active materials and electrolytes, which suffered from poor interfacial contact and limited electrochemical performance. As understanding deepened, researchers recognized the critical importance of interfaces and developed various strategies to enhance ionic and electronic transport pathways within the composite structure.

Current technological trends indicate a shift toward multi-component composite systems that integrate active materials, sulfide electrolytes, and functional additives in precisely engineered architectures. This evolution is driven by the fundamental challenge of achieving high areal loading (>4 mAh/cm²) while maintaining excellent rate capability and cycle life—a prerequisite for commercial viability of all-solid-state batteries.

The primary objective of advanced cathode composite design with sulfide SSEs is to overcome the inherent limitations of solid-state systems, particularly the high interfacial resistance between cathode active materials and sulfide electrolytes. This resistance stems from chemical incompatibility, mechanical stress during cycling, and limited contact area, all of which become more pronounced at high areal loadings.

Specifically, research aims to develop composite structures that simultaneously address multiple technical challenges: (1) maximizing ionic conductivity throughout the composite, (2) ensuring sufficient electronic conductivity, (3) accommodating volume changes during cycling, (4) minimizing interfacial resistance, and (5) maintaining structural integrity at high areal loadings.

The ultimate goal is to enable all-solid-state batteries with energy densities exceeding 400 Wh/kg at the cell level, while providing superior safety, fast charging capability, and extended cycle life compared to conventional lithium-ion batteries. This represents a critical stepping stone toward next-generation energy storage systems for electric vehicles, grid storage, and portable electronics.

Recent breakthroughs in nanoscale engineering and interface modification have demonstrated promising results, suggesting that properly designed sulfide SSE cathode composites can indeed support high areal loadings while maintaining excellent electrochemical performance. These advances set the stage for transformative improvements in battery technology that could accelerate the global transition to sustainable energy systems.

Market Analysis for High-Loading Solid-State Batteries

The solid-state battery market is experiencing unprecedented growth, driven by the increasing demand for high-energy-density storage solutions across multiple sectors. Current market projections indicate that the global solid-state battery market will reach approximately $8 billion by 2030, with a compound annual growth rate exceeding 30% between 2023 and 2030. This remarkable expansion is primarily fueled by automotive applications, which are expected to account for over 60% of the total market share.

High-loading cathode composites with sulfide solid-state electrolytes (SSEs) represent a critical technological advancement within this market. The demand for these advanced battery components stems from their potential to significantly increase energy density while maintaining safety standards that conventional lithium-ion batteries cannot achieve.

Consumer electronics manufacturers are increasingly seeking batteries with higher capacity in smaller form factors, creating a substantial market pull for high-loading cathode technologies. This segment is projected to grow at 25% annually through 2028, representing the second-largest application area after automotive.

Geographically, Asia-Pacific dominates the market landscape, with Japan, South Korea, and China collectively accounting for approximately 70% of global research and production capacity. North America and Europe are rapidly expanding their market presence, with substantial investments in research and manufacturing infrastructure.

Market analysis reveals that the high-loading cathode composite segment specifically is expected to grow faster than the overall solid-state battery market, with a projected CAGR of 35% through 2030. This accelerated growth is attributed to the critical role these components play in achieving the energy density targets required for mass-market electric vehicle adoption.

Industry surveys indicate that battery manufacturers are willing to pay premium prices for cathode materials that can deliver areal capacities exceeding 6 mAh/cm², representing a 50-100% increase over current commercial offerings. This price premium creates significant market opportunities for innovative cathode composite designs.

The market for sulfide-based SSEs specifically is projected to grow at 40% annually through 2028, outpacing oxide-based alternatives due to their superior ionic conductivity and better interfacial contact with cathode materials. This growth is creating a specialized sub-market for cathode composites specifically designed to work optimally with sulfide electrolytes.

High-loading cathode composites with sulfide solid-state electrolytes (SSEs) represent a critical technological advancement within this market. The demand for these advanced battery components stems from their potential to significantly increase energy density while maintaining safety standards that conventional lithium-ion batteries cannot achieve.

Consumer electronics manufacturers are increasingly seeking batteries with higher capacity in smaller form factors, creating a substantial market pull for high-loading cathode technologies. This segment is projected to grow at 25% annually through 2028, representing the second-largest application area after automotive.

Geographically, Asia-Pacific dominates the market landscape, with Japan, South Korea, and China collectively accounting for approximately 70% of global research and production capacity. North America and Europe are rapidly expanding their market presence, with substantial investments in research and manufacturing infrastructure.

Market analysis reveals that the high-loading cathode composite segment specifically is expected to grow faster than the overall solid-state battery market, with a projected CAGR of 35% through 2030. This accelerated growth is attributed to the critical role these components play in achieving the energy density targets required for mass-market electric vehicle adoption.

Industry surveys indicate that battery manufacturers are willing to pay premium prices for cathode materials that can deliver areal capacities exceeding 6 mAh/cm², representing a 50-100% increase over current commercial offerings. This price premium creates significant market opportunities for innovative cathode composite designs.

The market for sulfide-based SSEs specifically is projected to grow at 40% annually through 2028, outpacing oxide-based alternatives due to their superior ionic conductivity and better interfacial contact with cathode materials. This growth is creating a specialized sub-market for cathode composites specifically designed to work optimally with sulfide electrolytes.

Technical Challenges in Sulfide SSE Implementation

Despite the promising potential of sulfide solid-state electrolytes (SSEs) in next-generation batteries, their implementation faces significant technical challenges, particularly in cathode composite design for high areal loading applications. The high reactivity of sulfide SSEs with conventional cathode materials creates interfacial instability issues, leading to increased impedance and capacity degradation during cycling. This chemical incompatibility manifests as the formation of space-charge layers and decomposition products at the cathode-electrolyte interface, compromising the electrochemical performance.

Mechanical issues present another major challenge. The volume changes during lithiation/delithiation cycles create mechanical stress at interfaces, leading to contact loss between active materials and the electrolyte. This problem is exacerbated at high areal loadings, where thicker electrodes experience more severe mechanical degradation. The inherent brittleness of sulfide SSEs further complicates this issue, as they cannot accommodate the strain induced during cycling.

Processing difficulties also hinder sulfide SSE implementation. Their moisture sensitivity necessitates strict handling conditions, typically requiring dry room or glove box environments with less than 0.1 ppm water content. This significantly increases manufacturing complexity and cost. Additionally, achieving homogeneous mixing of cathode active materials, sulfide SSEs, and conductive additives remains challenging, particularly for high loading electrodes where uniform distribution becomes increasingly difficult.

The electronic/ionic conductivity balance presents a fundamental challenge. While sulfide SSEs offer superior ionic conductivity compared to oxide counterparts, the electronic conductivity within high-loading cathode composites remains insufficient. This creates a trade-off: increasing the proportion of conductive additives improves electronic conductivity but reduces energy density and compromises mechanical integrity.

Temperature sensitivity further complicates implementation. Many sulfide SSEs exhibit phase transitions or accelerated degradation at elevated temperatures (typically above 60°C), limiting their operational temperature range. This becomes particularly problematic in high-loading cathodes where heat generation during cycling is more pronounced due to increased current densities and internal resistance.

Scalability remains perhaps the most significant barrier to commercialization. Current laboratory-scale synthesis methods for sulfide SSEs are difficult to scale up while maintaining consistent quality and performance. The specialized equipment required for processing moisture-sensitive materials at industrial scales represents a substantial investment barrier, particularly for cathode composites with high areal loading where material quantities are greater.

Mechanical issues present another major challenge. The volume changes during lithiation/delithiation cycles create mechanical stress at interfaces, leading to contact loss between active materials and the electrolyte. This problem is exacerbated at high areal loadings, where thicker electrodes experience more severe mechanical degradation. The inherent brittleness of sulfide SSEs further complicates this issue, as they cannot accommodate the strain induced during cycling.

Processing difficulties also hinder sulfide SSE implementation. Their moisture sensitivity necessitates strict handling conditions, typically requiring dry room or glove box environments with less than 0.1 ppm water content. This significantly increases manufacturing complexity and cost. Additionally, achieving homogeneous mixing of cathode active materials, sulfide SSEs, and conductive additives remains challenging, particularly for high loading electrodes where uniform distribution becomes increasingly difficult.

The electronic/ionic conductivity balance presents a fundamental challenge. While sulfide SSEs offer superior ionic conductivity compared to oxide counterparts, the electronic conductivity within high-loading cathode composites remains insufficient. This creates a trade-off: increasing the proportion of conductive additives improves electronic conductivity but reduces energy density and compromises mechanical integrity.

Temperature sensitivity further complicates implementation. Many sulfide SSEs exhibit phase transitions or accelerated degradation at elevated temperatures (typically above 60°C), limiting their operational temperature range. This becomes particularly problematic in high-loading cathodes where heat generation during cycling is more pronounced due to increased current densities and internal resistance.

Scalability remains perhaps the most significant barrier to commercialization. Current laboratory-scale synthesis methods for sulfide SSEs are difficult to scale up while maintaining consistent quality and performance. The specialized equipment required for processing moisture-sensitive materials at industrial scales represents a substantial investment barrier, particularly for cathode composites with high areal loading where material quantities are greater.

Current Cathode Composite Design Approaches

01 Cathode composite formulations with sulfide SSEs

Cathode composite formulations incorporating sulfide solid-state electrolytes (SSEs) can be designed to achieve higher areal loading. These formulations typically combine active cathode materials with sulfide-based electrolytes and conductive additives to create a composite structure that maintains both ionic and electronic conductivity. The specific ratio of components and mixing methods significantly impact the electrochemical performance and loading capacity of the cathode.- Cathode composite formulations with sulfide SSEs: Specific formulations of cathode composites incorporating sulfide solid-state electrolytes (SSEs) to achieve higher areal loading. These formulations typically include active cathode materials, sulfide-based electrolytes, and conductive additives in optimized ratios. The composition is designed to enhance ionic conductivity while maintaining structural integrity at higher loadings, which is crucial for increasing energy density in solid-state batteries.

- Interface engineering for high-loading cathode composites: Engineering techniques focused on the interfaces between cathode active materials and sulfide SSEs to enable higher areal loading. This includes surface coatings, buffer layers, and interface modifiers that reduce interfacial resistance and prevent unwanted side reactions. These approaches stabilize the cathode-electrolyte interface, allowing for increased active material loading without compromising electrochemical performance.

- Processing methods for high-loading cathode composites: Specialized processing and manufacturing methods to achieve high areal loading in cathode composites with sulfide SSEs. These include advanced mixing techniques, cold sintering processes, and pressure-assisted assembly methods that enable uniform distribution of components and optimal packing density. The processing conditions are critical for maintaining the integrity of sulfide electrolytes while achieving the desired microstructure for high loading.

- Binder systems for high-loading sulfide-based cathodes: Development of specialized binder systems compatible with sulfide SSEs that enable higher cathode loadings. These binders provide mechanical stability to high-loading electrodes while maintaining ionic pathways. The binder systems are designed to be electrochemically stable with sulfide electrolytes and help maintain electrode integrity during cycling, even at increased thickness and mass loading levels.

- Architectures for high areal capacity sulfide-based cathodes: Novel structural designs and architectures for cathode composites that enable increased areal loading with sulfide SSEs. These include gradient structures, 3D architectures, and hierarchical porous frameworks that facilitate ion transport through thick electrodes. The engineered architectures address limitations in ion diffusion and electronic conductivity that typically constrain the practical loading of conventional cathode designs.

02 Interface engineering for high-loading cathodes

Interface engineering between cathode active materials and sulfide solid-state electrolytes is crucial for achieving high areal loading. Various coating technologies and buffer layers can be applied to reduce interfacial resistance and prevent unwanted side reactions. These engineering approaches help maintain stable interfaces during cycling, especially at higher loadings where volume changes and stress can be more pronounced.Expand Specific Solutions03 Binder systems for improved mechanical stability

Specialized binder systems are developed to enhance the mechanical stability of high-loading cathode composites with sulfide SSEs. These binders help maintain contact between particles during cycling and prevent crack formation that can occur with higher mass loadings. Polymer-based and inorganic binders with specific elasticity and adhesion properties can significantly improve the cycle life of high-loading cathodes.Expand Specific Solutions04 Porosity control and calendering techniques

Controlling the porosity and employing specific calendering techniques are essential for optimizing the areal loading of cathode composites with sulfide SSEs. The pore structure affects both the ionic transport pathways and the mechanical integrity of the composite. Advanced manufacturing processes can create tailored pore networks that accommodate higher active material loadings while maintaining sufficient ionic conductivity throughout the electrode.Expand Specific Solutions05 Pressure-assisted sintering for dense cathode structures

Pressure-assisted sintering methods can create dense cathode structures with sulfide SSEs that support higher areal loadings. These techniques apply controlled pressure and temperature to improve particle-to-particle contact and reduce void spaces within the composite. The resulting densified structure exhibits enhanced mechanical properties and electrochemical performance, allowing for increased active material loading without sacrificing power capability.Expand Specific Solutions

Leading Companies in Sulfide-Based Solid-State Battery Development

The cathode composite design with sulfide solid-state electrolytes (SSEs) for high areal loading is currently in an emerging growth phase, with the market expected to expand significantly as solid-state battery technology matures. Major players like LG Energy Solution, CATL, and Sion Power are driving innovation in this space, with research institutions such as Shanghai Institute of Ceramics and Beijing Institute of Technology providing fundamental scientific breakthroughs. The technology is approaching commercial viability but still faces challenges in scaling manufacturing processes. Companies like Factorial and Hydro-Québec are developing proprietary cathode-SSE interface engineering solutions, while automotive manufacturers including Nissan, Renault, and Ford are investing heavily to secure competitive advantages in this critical EV battery technology.

Sion Power Corp.

Technical Solution: Sion Power has developed a novel cathode composite design for sulfide solid-state electrolytes specifically engineered for ultra-high areal loading applications. Their approach centers on a hierarchical composite structure where high-capacity cathode materials (primarily sulfur-based and conversion-type materials) are encapsulated within a protective matrix of sulfide SSE and specialized carbon additives. This design creates a three-dimensional network that maintains both ionic and electronic pathways throughout the electrode, even at extreme loadings. Sion's technology employs Li2S-P2S5 glass-ceramic electrolytes with tailored compositions that enhance compatibility with their proprietary cathode materials while providing ionic conductivities exceeding 3 mS/cm at room temperature. The company has pioneered a unique processing technique that combines dry and wet mixing steps to achieve optimal component distribution without compromising the stability of moisture-sensitive sulfide electrolytes. Their cathode composites incorporate specialized carbon nanostructures that form a percolating network throughout the electrode, enabling electronic transport while accommodating the substantial volume changes associated with high-capacity materials. Sion Power has demonstrated cathodes with areal loadings exceeding 10 mg/cm² while maintaining areal capacities of 5-7 mAh/cm². Their cells show stable cycling at moderate current densities with capacity retention above 75% after 100 cycles.

Strengths: Industry-leading areal loading capabilities (>10 mg/cm²); excellent accommodation of volume changes during cycling; high energy density potential through use of high-capacity cathode materials; innovative processing techniques that preserve sulfide SSE properties. Weaknesses: Limited cycle life compared to some competitors; challenges with rate capability at the highest loadings; complex manufacturing process that may impact scalability; potential safety concerns related to the reactivity of sulfide electrolytes if cell integrity is compromised.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an innovative cathode composite design for sulfide solid-state electrolytes (SSEs) that addresses the critical challenges of high areal loading. Their approach involves a multi-layered cathode structure where active material particles are coated with a thin layer of sulfide SSE, followed by carbon additives to enhance electronic conductivity. This design creates a three-dimensional ionic and electronic conductive network that maintains intimate contact between components even during volume changes during cycling. LG's technology incorporates nano-sized sulfide SSE particles (typically Li6PS5Cl or Li3PS4) that are uniformly distributed throughout the cathode matrix using a solution-based wet mixing process, achieving loading capacities exceeding 6 mAh/cm². The company has also developed a gradient cathode design where the SSE concentration varies across the thickness, optimizing both ionic conductivity and energy density. Their composite cathodes demonstrate stable cycling at high loading (>5 mg/cm²) with capacity retention above 80% after 500 cycles.

Strengths: Superior ionic conductivity pathways through optimized SSE distribution; excellent mechanical stability during cycling; high areal capacity achievement (>6 mAh/cm²); scalable manufacturing process compatible with existing production lines. Weaknesses: Higher production costs compared to conventional lithium-ion batteries; potential challenges with sulfide SSE sensitivity to moisture during manufacturing; requires precise control of interface properties to maintain performance at high loading conditions.

Key Patents in High Areal Loading Sulfide SSE Technology

Solid-state cathode composition

PatentWO2025111401A1

Innovation

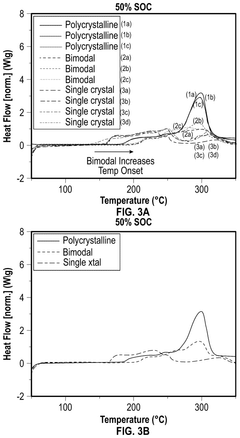

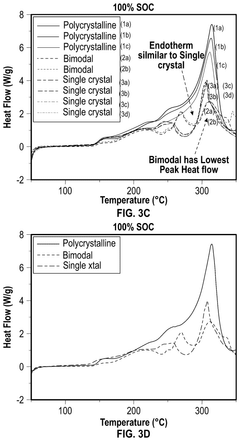

- A cathode composite composition comprising a blend of single-crystal and polycrystalline cathode active materials combined with solid sulfide electrolytes, such as Li7-yPS6-yXy, where 0≤y≤2 and X is a halogen, to reduce exothermic reactions and enhance safety.

Solid-state cathode composition

PatentPendingUS20250167203A1

Innovation

- A cathode composite composition comprising a blend of single-crystal and polycrystalline cathode active materials combined with a solid sulfide electrolyte, such as Li7−yPS6−yXy, where 0≤y≤2 and X is a halogen, which reduces the exothermic reaction and enhances safety.

Materials Supply Chain Considerations for Sulfide SSEs

The development of high-performance sulfide solid-state electrolytes (SSEs) for all-solid-state batteries faces significant supply chain challenges that must be addressed for commercial viability. Currently, the raw materials required for sulfide SSEs, particularly lithium and sulfur compounds, face supply constraints and price volatility. Lithium resources are concentrated in specific geographical regions, with over 70% of global lithium production occurring in Australia, Chile, and China, creating potential geopolitical dependencies and supply risks.

Sulfide SSE production requires high-purity precursors and specialized processing environments due to their air and moisture sensitivity. The manufacturing infrastructure for these materials remains limited, with only a few companies globally possessing the technical capabilities for large-scale production. This bottleneck significantly impacts material availability and cost structures throughout the value chain.

The processing of sulfide SSEs demands specialized equipment for handling air-sensitive materials, including glove boxes and controlled atmosphere processing lines. These requirements substantially increase production costs and complexity compared to conventional battery materials. Additionally, the energy-intensive nature of sulfide SSE synthesis contributes to higher embodied carbon footprints, potentially offsetting some environmental benefits of all-solid-state batteries.

Recycling infrastructure for sulfide-based batteries remains underdeveloped, presenting both environmental challenges and opportunities for material recovery. The reactive nature of sulfide materials complicates end-of-life handling, requiring new recycling protocols and technologies to safely recover valuable components and minimize waste.

Several companies are working to address these supply chain challenges. NEI Corporation and Solid Power have developed scalable manufacturing processes for sulfide SSEs, while materials suppliers like Toray and Solvay are expanding their offerings of specialized components for solid-state battery production. Vertical integration strategies are being pursued by major battery manufacturers to secure material supplies and reduce dependencies.

Future supply chain resilience will likely depend on diversification of material sources, development of alternative sulfide compositions with less constrained raw materials, and establishment of regional manufacturing capabilities. Advances in air-stable coating technologies and dry processing methods could significantly reduce production costs and expand manufacturing capacity, enabling the high areal loading cathode designs necessary for commercial viability of sulfide-based all-solid-state batteries.

Sulfide SSE production requires high-purity precursors and specialized processing environments due to their air and moisture sensitivity. The manufacturing infrastructure for these materials remains limited, with only a few companies globally possessing the technical capabilities for large-scale production. This bottleneck significantly impacts material availability and cost structures throughout the value chain.

The processing of sulfide SSEs demands specialized equipment for handling air-sensitive materials, including glove boxes and controlled atmosphere processing lines. These requirements substantially increase production costs and complexity compared to conventional battery materials. Additionally, the energy-intensive nature of sulfide SSE synthesis contributes to higher embodied carbon footprints, potentially offsetting some environmental benefits of all-solid-state batteries.

Recycling infrastructure for sulfide-based batteries remains underdeveloped, presenting both environmental challenges and opportunities for material recovery. The reactive nature of sulfide materials complicates end-of-life handling, requiring new recycling protocols and technologies to safely recover valuable components and minimize waste.

Several companies are working to address these supply chain challenges. NEI Corporation and Solid Power have developed scalable manufacturing processes for sulfide SSEs, while materials suppliers like Toray and Solvay are expanding their offerings of specialized components for solid-state battery production. Vertical integration strategies are being pursued by major battery manufacturers to secure material supplies and reduce dependencies.

Future supply chain resilience will likely depend on diversification of material sources, development of alternative sulfide compositions with less constrained raw materials, and establishment of regional manufacturing capabilities. Advances in air-stable coating technologies and dry processing methods could significantly reduce production costs and expand manufacturing capacity, enabling the high areal loading cathode designs necessary for commercial viability of sulfide-based all-solid-state batteries.

Safety and Stability Assessment of High-Loading Cathode Designs

The safety and stability assessment of high-loading cathode designs with sulfide solid-state electrolytes (SSEs) represents a critical aspect of all-solid-state battery development. These high-loading cathodes, while promising enhanced energy density, introduce significant safety and stability challenges that must be thoroughly evaluated before commercial implementation.

Mechanical stability remains one of the primary concerns in high-loading cathode composites. The substantial volume changes during cycling—often exceeding 10% for high-capacity materials like sulfur and some transition metal oxides—create mechanical stresses at the cathode-electrolyte interface. These stresses can lead to contact loss, increased interfacial resistance, and ultimately capacity fading. Recent studies have demonstrated that incorporating elastic binders and creating gradient structures within the cathode composite can mitigate these mechanical degradation mechanisms.

Chemical compatibility between high-loading cathodes and sulfide SSEs presents another significant challenge. The increased active material content enhances the possibility of side reactions, particularly at elevated temperatures or during extended cycling. Thermodynamic instability at the cathode-electrolyte interface can lead to the formation of interphases that, while sometimes beneficial as passivation layers, often contribute to increasing cell impedance over time. Advanced characterization techniques including in-situ XPS and TEM-EELS have revealed that these interfacial reactions are more pronounced in high-loading configurations.

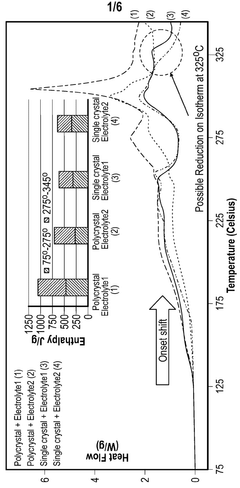

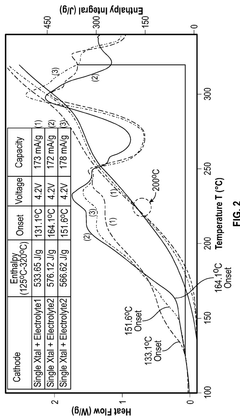

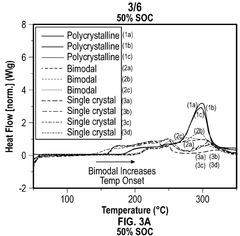

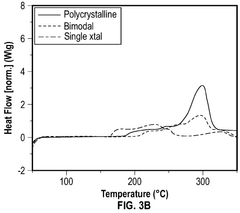

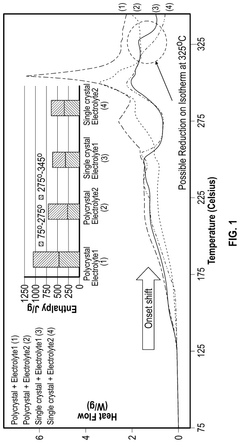

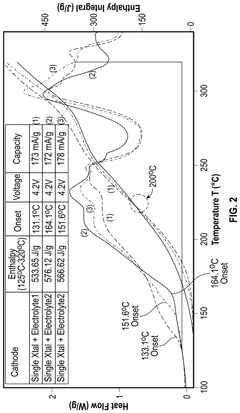

Thermal stability assessment is particularly crucial for sulfide-based systems due to their relatively narrow electrochemical stability windows. High-loading cathodes generate more heat during fast charging and discharging processes, potentially triggering thermal runaway events. Differential scanning calorimetry studies have shown that the onset temperature for exothermic reactions between cathode materials and sulfide SSEs can decrease by 20-30°C in high-loading configurations compared to conventional designs.

Long-term cycling stability represents perhaps the most practical assessment metric for high-loading cathode designs. Accelerated aging tests under various temperature and current density conditions have demonstrated that capacity retention in high-loading cathodes is highly dependent on the mechanical framework supporting the active materials. Hierarchical porous structures that accommodate volume changes while maintaining ionic and electronic pathways have shown the most promising results, with some systems maintaining over 80% capacity after 500 cycles.

Environmental stability, particularly moisture sensitivity, remains a significant concern for sulfide-based systems. High-loading cathodes typically require more complex processing methods, potentially increasing exposure to ambient conditions during manufacturing. Protective coatings and dry-room processing protocols have been developed specifically for high-loading cathode composites to address these challenges.

Mechanical stability remains one of the primary concerns in high-loading cathode composites. The substantial volume changes during cycling—often exceeding 10% for high-capacity materials like sulfur and some transition metal oxides—create mechanical stresses at the cathode-electrolyte interface. These stresses can lead to contact loss, increased interfacial resistance, and ultimately capacity fading. Recent studies have demonstrated that incorporating elastic binders and creating gradient structures within the cathode composite can mitigate these mechanical degradation mechanisms.

Chemical compatibility between high-loading cathodes and sulfide SSEs presents another significant challenge. The increased active material content enhances the possibility of side reactions, particularly at elevated temperatures or during extended cycling. Thermodynamic instability at the cathode-electrolyte interface can lead to the formation of interphases that, while sometimes beneficial as passivation layers, often contribute to increasing cell impedance over time. Advanced characterization techniques including in-situ XPS and TEM-EELS have revealed that these interfacial reactions are more pronounced in high-loading configurations.

Thermal stability assessment is particularly crucial for sulfide-based systems due to their relatively narrow electrochemical stability windows. High-loading cathodes generate more heat during fast charging and discharging processes, potentially triggering thermal runaway events. Differential scanning calorimetry studies have shown that the onset temperature for exothermic reactions between cathode materials and sulfide SSEs can decrease by 20-30°C in high-loading configurations compared to conventional designs.

Long-term cycling stability represents perhaps the most practical assessment metric for high-loading cathode designs. Accelerated aging tests under various temperature and current density conditions have demonstrated that capacity retention in high-loading cathodes is highly dependent on the mechanical framework supporting the active materials. Hierarchical porous structures that accommodate volume changes while maintaining ionic and electronic pathways have shown the most promising results, with some systems maintaining over 80% capacity after 500 cycles.

Environmental stability, particularly moisture sensitivity, remains a significant concern for sulfide-based systems. High-loading cathodes typically require more complex processing methods, potentially increasing exposure to ambient conditions during manufacturing. Protective coatings and dry-room processing protocols have been developed specifically for high-loading cathode composites to address these challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!