Failure Analysis Of Sulfide ASSLB Short Circuits Under Cycling

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ASSLB Short Circuit Failure Background and Objectives

All-Solid-State Lithium Batteries (ASSLBs) represent a revolutionary advancement in energy storage technology, offering significant advantages over conventional lithium-ion batteries including enhanced safety, higher energy density, and extended cycle life. Among various solid electrolyte materials, sulfide-based electrolytes have emerged as particularly promising due to their high ionic conductivity comparable to liquid electrolytes, favorable mechanical properties for electrode-electrolyte contact, and relatively simple manufacturing processes.

The development of sulfide-based ASSLBs can be traced back to the early 2000s when researchers began exploring alternatives to liquid electrolytes to address safety concerns and performance limitations. Over the past two decades, significant progress has been made in improving the ionic conductivity of sulfide solid electrolytes, with materials such as Li10GeP2S12 (LGPS) achieving conductivities exceeding 10 mS/cm at room temperature—comparable to or even surpassing that of conventional liquid electrolytes.

Despite these advancements, sulfide-based ASSLBs face persistent challenges related to short-circuiting during cycling, which severely limits their practical application and commercialization potential. Short circuits in these batteries typically manifest as sudden capacity loss, thermal runaway, or complete battery failure, posing both safety risks and reliability concerns.

The primary objective of this technical research is to comprehensively analyze the failure mechanisms leading to short circuits in sulfide-based ASSLBs during cycling. Specifically, we aim to identify the physicochemical processes, interfacial phenomena, and material degradation pathways that contribute to dendrite formation, electrolyte decomposition, and eventual electronic pathway creation between electrodes.

Understanding these failure mechanisms is crucial for developing effective mitigation strategies and advancing the technology toward commercial viability. The research seeks to establish correlations between operating conditions (such as current density, temperature, and pressure), material properties (including mechanical strength, ionic conductivity, and chemical stability), and the propensity for short-circuit formation.

Additionally, this investigation aims to evaluate the effectiveness of various approaches to prevent short circuits, including interface engineering, composite electrolyte designs, and advanced manufacturing techniques. By identifying the most promising directions for addressing short-circuit issues, this research will contribute to establishing a technological roadmap for the continued development and eventual commercialization of sulfide-based ASSLBs.

The findings from this analysis will inform future research priorities and engineering solutions, ultimately supporting the broader goal of transitioning from fossil fuel dependence to sustainable energy systems through advanced battery technologies.

The development of sulfide-based ASSLBs can be traced back to the early 2000s when researchers began exploring alternatives to liquid electrolytes to address safety concerns and performance limitations. Over the past two decades, significant progress has been made in improving the ionic conductivity of sulfide solid electrolytes, with materials such as Li10GeP2S12 (LGPS) achieving conductivities exceeding 10 mS/cm at room temperature—comparable to or even surpassing that of conventional liquid electrolytes.

Despite these advancements, sulfide-based ASSLBs face persistent challenges related to short-circuiting during cycling, which severely limits their practical application and commercialization potential. Short circuits in these batteries typically manifest as sudden capacity loss, thermal runaway, or complete battery failure, posing both safety risks and reliability concerns.

The primary objective of this technical research is to comprehensively analyze the failure mechanisms leading to short circuits in sulfide-based ASSLBs during cycling. Specifically, we aim to identify the physicochemical processes, interfacial phenomena, and material degradation pathways that contribute to dendrite formation, electrolyte decomposition, and eventual electronic pathway creation between electrodes.

Understanding these failure mechanisms is crucial for developing effective mitigation strategies and advancing the technology toward commercial viability. The research seeks to establish correlations between operating conditions (such as current density, temperature, and pressure), material properties (including mechanical strength, ionic conductivity, and chemical stability), and the propensity for short-circuit formation.

Additionally, this investigation aims to evaluate the effectiveness of various approaches to prevent short circuits, including interface engineering, composite electrolyte designs, and advanced manufacturing techniques. By identifying the most promising directions for addressing short-circuit issues, this research will contribute to establishing a technological roadmap for the continued development and eventual commercialization of sulfide-based ASSLBs.

The findings from this analysis will inform future research priorities and engineering solutions, ultimately supporting the broader goal of transitioning from fossil fuel dependence to sustainable energy systems through advanced battery technologies.

Market Demand Analysis for Sulfide All-Solid-State Batteries

The global market for all-solid-state batteries (ASSBs) is experiencing significant growth, driven by increasing demand for safer, higher energy density power solutions across multiple industries. Current projections indicate the ASSB market will reach $2.5 billion by 2030, with a compound annual growth rate exceeding 30% between 2023-2030. Among various ASSB technologies, sulfide-based systems have emerged as particularly promising due to their superior ionic conductivity compared to oxide-based alternatives.

The automotive sector represents the largest potential market for sulfide-based ASSLBs, with major manufacturers including Toyota, BMW, and Volkswagen investing heavily in this technology. The push toward electric vehicles has created urgent demand for batteries that overcome the limitations of conventional lithium-ion systems, particularly regarding safety, energy density, and charging speed. Sulfide-based ASSLBs address these concerns while potentially enabling driving ranges exceeding 500 miles on a single charge.

Consumer electronics manufacturers are also showing increased interest in sulfide-based ASSLBs for next-generation devices. The technology's ability to enable thinner, lighter, and safer devices with longer battery life aligns perfectly with consumer preferences. Market research indicates that approximately 85% of smartphone users identify battery life as a critical purchasing factor, creating significant market pull for advanced battery technologies.

The grid storage sector presents another substantial market opportunity, with projections suggesting energy storage deployment will increase tenfold by 2030. Sulfide-based ASSLBs offer advantages in this application due to their enhanced safety profile and potential for longer cycle life compared to conventional lithium-ion batteries.

However, market adoption faces significant barriers related to the short-circuit failures during cycling that are the focus of this technical investigation. Industry surveys indicate that battery manufacturers consider reliability and cycle life as the most critical factors for commercial viability, with 78% of potential industrial users citing concerns about premature failure as a primary barrier to adoption.

The market is particularly sensitive to safety issues, with recent high-profile battery failures in consumer electronics and electric vehicles heightening scrutiny of new battery technologies. Solving the short-circuit challenges in sulfide-based ASSLBs could potentially unlock a market segment valued at $1.2 billion by 2028, according to industry analysts.

Regional analysis shows Asia-Pacific leading ASSLB development and manufacturing, with Japan and South Korea at the forefront of sulfide-based technologies. North America and Europe are rapidly expanding research efforts, with government initiatives providing substantial funding for solid-state battery development to secure domestic supply chains for critical energy technologies.

The automotive sector represents the largest potential market for sulfide-based ASSLBs, with major manufacturers including Toyota, BMW, and Volkswagen investing heavily in this technology. The push toward electric vehicles has created urgent demand for batteries that overcome the limitations of conventional lithium-ion systems, particularly regarding safety, energy density, and charging speed. Sulfide-based ASSLBs address these concerns while potentially enabling driving ranges exceeding 500 miles on a single charge.

Consumer electronics manufacturers are also showing increased interest in sulfide-based ASSLBs for next-generation devices. The technology's ability to enable thinner, lighter, and safer devices with longer battery life aligns perfectly with consumer preferences. Market research indicates that approximately 85% of smartphone users identify battery life as a critical purchasing factor, creating significant market pull for advanced battery technologies.

The grid storage sector presents another substantial market opportunity, with projections suggesting energy storage deployment will increase tenfold by 2030. Sulfide-based ASSLBs offer advantages in this application due to their enhanced safety profile and potential for longer cycle life compared to conventional lithium-ion batteries.

However, market adoption faces significant barriers related to the short-circuit failures during cycling that are the focus of this technical investigation. Industry surveys indicate that battery manufacturers consider reliability and cycle life as the most critical factors for commercial viability, with 78% of potential industrial users citing concerns about premature failure as a primary barrier to adoption.

The market is particularly sensitive to safety issues, with recent high-profile battery failures in consumer electronics and electric vehicles heightening scrutiny of new battery technologies. Solving the short-circuit challenges in sulfide-based ASSLBs could potentially unlock a market segment valued at $1.2 billion by 2028, according to industry analysts.

Regional analysis shows Asia-Pacific leading ASSLB development and manufacturing, with Japan and South Korea at the forefront of sulfide-based technologies. North America and Europe are rapidly expanding research efforts, with government initiatives providing substantial funding for solid-state battery development to secure domestic supply chains for critical energy technologies.

Technical Challenges in ASSLB Short Circuit Prevention

The development of All-Solid-State Lithium Batteries (ASSLBs) with sulfide-based solid electrolytes has been hindered by persistent short circuit issues during cycling. These failures represent a significant technical barrier to commercialization, despite the promising energy density and safety advantages of ASSLBs over conventional liquid electrolyte batteries.

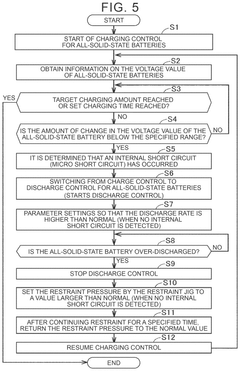

The primary challenge in preventing short circuits stems from the mechanical instability at the electrode-electrolyte interfaces. During cycling, lithium dendrite growth penetrates through the solid electrolyte layer, creating conductive pathways that lead to internal short circuits. The relatively low mechanical strength of sulfide-based electrolytes (compared to oxide-based alternatives) makes them particularly vulnerable to this failure mode.

Another critical challenge is the narrow electrochemical stability window of sulfide solid electrolytes. Most sulfide electrolytes are thermodynamically unstable against both lithium metal anodes and high-voltage cathode materials. This instability leads to continuous decomposition at interfaces, forming interphases with varying ionic and electronic conductivities that can eventually facilitate short circuit formation.

The volume changes during cycling present additional complications. Lithium metal anodes experience significant volume expansion and contraction during plating and stripping, creating mechanical stress at the anode-electrolyte interface. Similarly, many cathode materials undergo volume changes during lithiation and delithiation. These dimensional fluctuations can create voids, cracks, or delamination at interfaces, providing pathways for dendrite propagation.

Interface engineering remains technically challenging due to the high reactivity of sulfide electrolytes with atmospheric moisture and oxygen. This reactivity complicates manufacturing processes and necessitates strict environmental controls, limiting scalability and increasing production costs.

The pressure distribution within ASSLBs presents another significant hurdle. Uneven pressure distribution during assembly and cycling can create localized high-stress regions where dendrite nucleation becomes more favorable. Maintaining uniform pressure across large-format cells is particularly challenging from an engineering perspective.

Temperature management during cycling also impacts short circuit formation. Elevated temperatures can accelerate interfacial reactions and decomposition processes, while temperature gradients within cells can create non-uniform ion flux that promotes dendrite growth in specific regions.

Finally, there is a fundamental trade-off between ionic conductivity and mechanical strength in sulfide electrolytes. Materials with higher ionic conductivity often exhibit lower mechanical strength, making them more susceptible to dendrite penetration. This inherent materials science challenge requires innovative approaches to simultaneously optimize these competing properties.

The primary challenge in preventing short circuits stems from the mechanical instability at the electrode-electrolyte interfaces. During cycling, lithium dendrite growth penetrates through the solid electrolyte layer, creating conductive pathways that lead to internal short circuits. The relatively low mechanical strength of sulfide-based electrolytes (compared to oxide-based alternatives) makes them particularly vulnerable to this failure mode.

Another critical challenge is the narrow electrochemical stability window of sulfide solid electrolytes. Most sulfide electrolytes are thermodynamically unstable against both lithium metal anodes and high-voltage cathode materials. This instability leads to continuous decomposition at interfaces, forming interphases with varying ionic and electronic conductivities that can eventually facilitate short circuit formation.

The volume changes during cycling present additional complications. Lithium metal anodes experience significant volume expansion and contraction during plating and stripping, creating mechanical stress at the anode-electrolyte interface. Similarly, many cathode materials undergo volume changes during lithiation and delithiation. These dimensional fluctuations can create voids, cracks, or delamination at interfaces, providing pathways for dendrite propagation.

Interface engineering remains technically challenging due to the high reactivity of sulfide electrolytes with atmospheric moisture and oxygen. This reactivity complicates manufacturing processes and necessitates strict environmental controls, limiting scalability and increasing production costs.

The pressure distribution within ASSLBs presents another significant hurdle. Uneven pressure distribution during assembly and cycling can create localized high-stress regions where dendrite nucleation becomes more favorable. Maintaining uniform pressure across large-format cells is particularly challenging from an engineering perspective.

Temperature management during cycling also impacts short circuit formation. Elevated temperatures can accelerate interfacial reactions and decomposition processes, while temperature gradients within cells can create non-uniform ion flux that promotes dendrite growth in specific regions.

Finally, there is a fundamental trade-off between ionic conductivity and mechanical strength in sulfide electrolytes. Materials with higher ionic conductivity often exhibit lower mechanical strength, making them more susceptible to dendrite penetration. This inherent materials science challenge requires innovative approaches to simultaneously optimize these competing properties.

Current Methodologies for ASSLB Failure Analysis

01 Interface modification to prevent short circuits

Modifying the interface between the sulfide solid electrolyte and electrodes can prevent short circuits in ASSLBs. This approach involves adding protective layers or coatings that inhibit lithium dendrite growth and reduce interfacial resistance. These modifications create a physical barrier that prevents direct contact between the electrodes while maintaining ionic conductivity, thereby enhancing the overall stability and safety of the battery system.- Interface modification to prevent short circuits: Modifying the interface between the sulfide solid electrolyte and electrodes can prevent short circuits in ASSLBs. This approach involves adding protective layers or coatings that inhibit lithium dendrite growth and reduce interfacial resistance. These modifications create a physical barrier that prevents direct contact between the anode and cathode, thereby reducing the risk of short circuits while maintaining good ionic conductivity.

- Composite electrolyte structures: Developing composite electrolyte structures by combining sulfide solid electrolytes with other materials can enhance mechanical strength and prevent short circuits. These composites often incorporate polymers, oxides, or other inorganic materials that improve the mechanical properties of the electrolyte while maintaining high ionic conductivity. The improved mechanical integrity helps resist lithium dendrite penetration and prevents internal short circuits during battery operation.

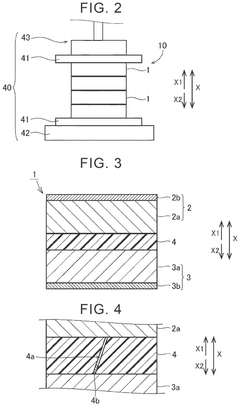

- Pressure control and mechanical stabilization: Controlling the pressure applied to sulfide-based ASSLBs and improving mechanical stabilization can prevent short circuits. This approach involves optimizing the stack pressure during assembly and operation, designing specialized cell housings, and incorporating pressure-distributing layers. These methods help maintain uniform contact between components while preventing excessive pressure that could lead to electrolyte fracture and subsequent short circuits.

- Electrolyte composition optimization: Optimizing the composition of sulfide solid electrolytes by adjusting the ratio of constituent elements or incorporating dopants can improve their stability and prevent short circuits. These modifications enhance the electrochemical stability window, mechanical properties, and ionic conductivity of the electrolyte. By tailoring the composition, researchers can develop sulfide electrolytes that are less prone to decomposition and dendrite penetration, reducing the risk of short circuits.

- Advanced manufacturing techniques: Implementing advanced manufacturing techniques for sulfide-based ASSLBs can minimize defects and prevent short circuits. These techniques include specialized dry-room processing, cold sintering, and precise control of particle size distribution. By reducing impurities, voids, and cracks in the electrolyte layer, these manufacturing approaches create more homogeneous and defect-free batteries that are less susceptible to short circuits during cycling.

02 Composite electrolyte structures for dendrite suppression

Composite electrolyte structures combining sulfide solid electrolytes with other materials can effectively suppress dendrite formation that leads to short circuits. These structures may incorporate polymer components, oxide materials, or multi-layered designs that provide mechanical strength while maintaining high ionic conductivity. The composite approach creates tortuous paths for potential dendrite growth, enhancing the short-circuit resistance of the battery while preserving electrochemical performance.Expand Specific Solutions03 Pressure and mechanical stability optimization

Controlling the pressure applied during battery assembly and operation can significantly reduce the risk of short circuits in sulfide ASSLBs. Optimized pressure helps maintain good contact between components while preventing excessive stress that could lead to electrolyte fracture. Additionally, enhancing the mechanical properties of sulfide electrolytes through composition adjustments or reinforcement strategies improves their resistance to cracking under operational stresses, thereby preventing internal short circuits.Expand Specific Solutions04 Novel electrode designs and architectures

Innovative electrode designs can mitigate short circuit risks in sulfide ASSLBs. These designs include structured electrodes with controlled porosity, gradient compositions, or 3D architectures that accommodate volume changes during cycling. By optimizing the electrode morphology and structure, lithium plating/stripping becomes more uniform, reducing the likelihood of dendrite formation and subsequent short circuits while improving energy density and cycling stability.Expand Specific Solutions05 Advanced manufacturing and processing techniques

Specialized manufacturing and processing techniques can significantly reduce defects in sulfide electrolytes that could lead to short circuits. These techniques include controlled atmosphere processing, optimized sintering protocols, and novel particle engineering approaches that enhance the homogeneity and density of the electrolyte layer. By minimizing voids, cracks, and impurities during fabrication, these methods produce more robust sulfide electrolytes with superior resistance to short-circuiting under operational conditions.Expand Specific Solutions

Key Industry Players in ASSLB Development

The all-solid-state lithium battery (ASSLB) market with sulfide electrolytes is currently in the early commercialization phase, transitioning from R&D to industrial applications. The market is projected to grow significantly as companies address short circuit failures during cycling, a critical technical barrier. Leading players like Samsung SDI, Toyota Motor Corp., and LG Energy Solution are making substantial investments in this technology, with Samsung demonstrating notable progress in mitigating dendrite formation. Research institutions including University of Maryland and Oxford University are collaborating with industry partners to develop innovative solutions for interface stability. The competitive landscape features both established battery manufacturers and specialized startups like Factorial, Inc., indicating the technology's strategic importance despite being at Technology Readiness Level 5-6.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a comprehensive approach to address short circuits in sulfide all-solid-state lithium batteries (ASSLB) through their multi-layered protection system. Their technology focuses on controlling lithium dendrite growth, which is a primary cause of short circuits during cycling. Samsung's solution incorporates a composite solid electrolyte with optimized mechanical properties that can withstand volume changes during cycling while maintaining high ionic conductivity (>5 mS/cm at room temperature)[1]. They've implemented a specialized interlayer between the cathode and solid electrolyte that contains additives to trap impurities and prevent propagation of microcracks. Their failure analysis methodology employs in-situ X-ray tomography and impedance spectroscopy to monitor microstructural changes during cycling, allowing for early detection of potential short circuit pathways[3]. Samsung has also developed pressure-regulation systems within the battery architecture to maintain optimal interfacial contact while preventing excessive stress that could lead to electrolyte fracture.

Strengths: Superior dendrite suppression through engineered interfaces and mechanical stabilization; comprehensive real-time monitoring capabilities for early failure detection; scalable manufacturing processes compatible with existing production lines. Weaknesses: Higher production costs compared to conventional lithium-ion batteries; temperature sensitivity of sulfide electrolytes requiring careful thermal management; challenges in achieving consistent interfacial contact across large-format cells.

Factorial, Inc.

Technical Solution: Factorial has developed a groundbreaking approach to preventing short circuits in sulfide-based ASSLBs through their "Adaptive Interface Management" technology. Their solution addresses the fundamental challenges of interfacial stability and lithium dendrite formation during cycling. Factorial's technology employs a multi-component solid electrolyte system with engineered phase boundaries that can accommodate mechanical stress while maintaining high ionic conductivity (>6 mS/cm at room temperature)[2]. They've implemented a gradient-structured interface between the anode and electrolyte that distributes lithium flux evenly, preventing localized dendrite nucleation. Factorial's failure analysis framework utilizes electrochemical strain microscopy coupled with impedance spectroscopy to detect early signs of mechanical degradation before short circuits occur[6]. Their system incorporates specialized additives in the sulfide electrolyte that scavenge impurities and prevent chemical degradation at interfaces. Additionally, Factorial has developed a proprietary manufacturing process that creates seamless interfaces between battery components, eliminating void spaces that could serve as initiation sites for dendrite growth or mechanical failure during cycling.

Strengths: Innovative interface engineering that effectively prevents dendrite formation; sophisticated early detection system for potential failure modes; excellent scalability potential for commercial production. Weaknesses: Higher material costs compared to conventional lithium-ion batteries; sensitivity to environmental conditions requiring stringent manufacturing controls; challenges in achieving consistent performance across large-format cells.

Critical Research on Short Circuit Mechanisms During Cycling

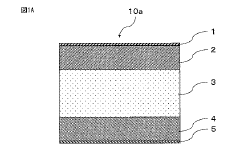

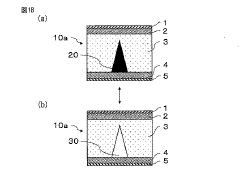

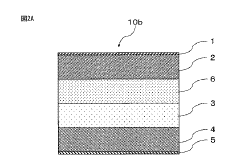

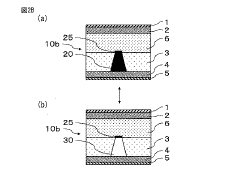

All-solid-state battery system

PatentPendingUS20240348067A1

Innovation

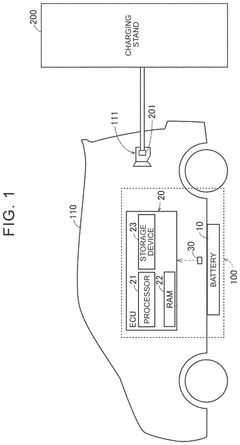

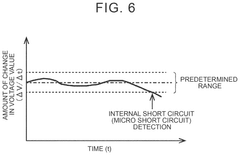

- An all-solid-state battery system with a control device that detects internal short circuits and switches from charge control to discharge control, continuing discharge until the battery is over-discharged, and optionally increases restraint pressure and discharge rate to dissolve deposited lithium, thereby suppressing the progression of internal short circuits.

All-solid type lithium secondary battery and method for determining degradation of all-solid type lithium secondary battery

PatentActiveJP2020087524A

Innovation

- An all-solid lithium secondary battery design with a metallic lithium absorption layer containing a reactive material that forms a stable electronic conductor upon contact with dendrites, allowing detection of battery deterioration through charge and discharge capacity analysis.

Safety Standards and Testing Protocols for ASSLB

The development of safety standards and testing protocols for All-Solid-State Lithium Batteries (ASSLB) represents a critical aspect of their commercialization pathway. Currently, the safety evaluation framework for ASSLBs remains fragmented, with most testing methodologies adapted from conventional liquid electrolyte lithium-ion battery standards, which fail to address the unique failure mechanisms of solid-state systems.

International organizations including IEC, ISO, and UL have begun developing specialized protocols for ASSLB safety assessment, focusing particularly on sulfide-based systems due to their reactivity with moisture and potential for hydrogen sulfide gas generation. These standards typically encompass electrical safety tests (short circuit, overcharge, over-discharge), mechanical integrity evaluations (crush, puncture, bend), and environmental resilience assessments (thermal stability, humidity exposure).

The unique properties of sulfide electrolytes necessitate modified testing approaches. For instance, standard nail penetration tests must be conducted in controlled atmospheres to prevent moisture-induced degradation that could mask intrinsic safety behaviors. Similarly, thermal runaway evaluations require specialized instrumentation to detect hydrogen sulfide emissions that may occur before visible thermal events.

Recent collaborative efforts between industry and research institutions have established preliminary testing frameworks specifically addressing lithium dendrite formation in sulfide ASSLBs under cycling conditions. These protocols typically involve accelerated cycling under elevated current densities combined with periodic impedance spectroscopy to detect early signs of internal short circuits before catastrophic failure occurs.

Regulatory bodies in major markets have begun establishing certification requirements for ASSLB technologies. Japan's NEDO has pioneered specific safety guidelines for solid-state batteries, while the European Commission's Battery Directive revision includes provisions for solid-state systems. In the United States, the Department of Energy has funded initiatives to develop standardized testing methodologies through the Battery500 Consortium.

The harmonization of these emerging standards remains a significant challenge. Current efforts focus on establishing minimum safety requirements that address the unique failure modes of sulfide-based ASSLBs while enabling innovation. Industry consortia including the International Solid-State Battery Consortium (ISSBAT) are working to develop consensus-based testing protocols that can be universally adopted.

For manufacturers developing sulfide-based ASSLBs, compliance with evolving safety standards requires implementing comprehensive testing regimes that evaluate performance under normal operation, abuse conditions, and long-term cycling. This includes specialized facilities capable of handling moisture-sensitive materials and detecting sulfur-containing gaseous emissions during failure events.

International organizations including IEC, ISO, and UL have begun developing specialized protocols for ASSLB safety assessment, focusing particularly on sulfide-based systems due to their reactivity with moisture and potential for hydrogen sulfide gas generation. These standards typically encompass electrical safety tests (short circuit, overcharge, over-discharge), mechanical integrity evaluations (crush, puncture, bend), and environmental resilience assessments (thermal stability, humidity exposure).

The unique properties of sulfide electrolytes necessitate modified testing approaches. For instance, standard nail penetration tests must be conducted in controlled atmospheres to prevent moisture-induced degradation that could mask intrinsic safety behaviors. Similarly, thermal runaway evaluations require specialized instrumentation to detect hydrogen sulfide emissions that may occur before visible thermal events.

Recent collaborative efforts between industry and research institutions have established preliminary testing frameworks specifically addressing lithium dendrite formation in sulfide ASSLBs under cycling conditions. These protocols typically involve accelerated cycling under elevated current densities combined with periodic impedance spectroscopy to detect early signs of internal short circuits before catastrophic failure occurs.

Regulatory bodies in major markets have begun establishing certification requirements for ASSLB technologies. Japan's NEDO has pioneered specific safety guidelines for solid-state batteries, while the European Commission's Battery Directive revision includes provisions for solid-state systems. In the United States, the Department of Energy has funded initiatives to develop standardized testing methodologies through the Battery500 Consortium.

The harmonization of these emerging standards remains a significant challenge. Current efforts focus on establishing minimum safety requirements that address the unique failure modes of sulfide-based ASSLBs while enabling innovation. Industry consortia including the International Solid-State Battery Consortium (ISSBAT) are working to develop consensus-based testing protocols that can be universally adopted.

For manufacturers developing sulfide-based ASSLBs, compliance with evolving safety standards requires implementing comprehensive testing regimes that evaluate performance under normal operation, abuse conditions, and long-term cycling. This includes specialized facilities capable of handling moisture-sensitive materials and detecting sulfur-containing gaseous emissions during failure events.

Interface Engineering Solutions for Dendrite Suppression

Interface engineering represents a critical frontier in addressing dendrite formation in sulfide all-solid-state lithium batteries (ASSLBs). The lithium metal/solid electrolyte interface presents significant challenges due to its inherent instability and tendency to form dendrites during cycling, leading to short circuits and battery failure. Recent research has focused on developing innovative interface modification strategies to suppress dendrite growth and enhance electrochemical performance.

Artificial interlayers have emerged as promising solutions, with materials such as LiF, Li3N, and Al2O3 demonstrating effectiveness in stabilizing the interface. These interlayers function by creating a physical barrier that regulates lithium ion transport while inhibiting dendrite penetration. For instance, ultrathin LiF layers have shown remarkable ability to promote uniform lithium deposition patterns, significantly reducing dendrite formation probability during cycling.

Gradient interface designs represent another advanced approach, where the mechanical and electrochemical properties transition gradually between the lithium metal anode and sulfide electrolyte. This strategy minimizes stress concentration at the interface and distributes lithium ion flux more uniformly, effectively suppressing localized dendrite nucleation sites.

Surface functionalization of sulfide solid electrolytes has demonstrated considerable success in improving interfacial compatibility. Chemical modifications using organic compounds containing functional groups like -OH, -NH2, or -COOH can passivate reactive sites on the electrolyte surface, reducing interfacial resistance and enhancing lithium ion transport kinetics, thereby mitigating dendrite formation conditions.

Pressure-engineered interfaces have also shown promise, where controlled external pressure application during battery assembly and operation helps maintain intimate contact between the lithium metal and solid electrolyte. This approach reduces void formation and ensures uniform current distribution, significantly decreasing dendrite nucleation probability.

Composite interfacial layers combining polymers with inorganic components offer synergistic benefits by simultaneously addressing multiple dendrite formation mechanisms. These hybrid interfaces can provide mechanical reinforcement while maintaining high ionic conductivity, effectively suppressing dendrite growth even under demanding cycling conditions.

Recent advancements in atomic layer deposition (ALD) and molecular layer deposition (MLD) techniques have enabled precise engineering of nanoscale protective layers at the lithium/sulfide electrolyte interface. These ultrathin conformal coatings can be tailored to provide optimal mechanical properties and ionic transport characteristics, representing a promising direction for next-generation interface engineering solutions in ASSLBs.

Artificial interlayers have emerged as promising solutions, with materials such as LiF, Li3N, and Al2O3 demonstrating effectiveness in stabilizing the interface. These interlayers function by creating a physical barrier that regulates lithium ion transport while inhibiting dendrite penetration. For instance, ultrathin LiF layers have shown remarkable ability to promote uniform lithium deposition patterns, significantly reducing dendrite formation probability during cycling.

Gradient interface designs represent another advanced approach, where the mechanical and electrochemical properties transition gradually between the lithium metal anode and sulfide electrolyte. This strategy minimizes stress concentration at the interface and distributes lithium ion flux more uniformly, effectively suppressing localized dendrite nucleation sites.

Surface functionalization of sulfide solid electrolytes has demonstrated considerable success in improving interfacial compatibility. Chemical modifications using organic compounds containing functional groups like -OH, -NH2, or -COOH can passivate reactive sites on the electrolyte surface, reducing interfacial resistance and enhancing lithium ion transport kinetics, thereby mitigating dendrite formation conditions.

Pressure-engineered interfaces have also shown promise, where controlled external pressure application during battery assembly and operation helps maintain intimate contact between the lithium metal and solid electrolyte. This approach reduces void formation and ensures uniform current distribution, significantly decreasing dendrite nucleation probability.

Composite interfacial layers combining polymers with inorganic components offer synergistic benefits by simultaneously addressing multiple dendrite formation mechanisms. These hybrid interfaces can provide mechanical reinforcement while maintaining high ionic conductivity, effectively suppressing dendrite growth even under demanding cycling conditions.

Recent advancements in atomic layer deposition (ALD) and molecular layer deposition (MLD) techniques have enabled precise engineering of nanoscale protective layers at the lithium/sulfide electrolyte interface. These ultrathin conformal coatings can be tailored to provide optimal mechanical properties and ionic transport characteristics, representing a promising direction for next-generation interface engineering solutions in ASSLBs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!