Moisture Handling And H2S Safety Protocols For Sulfide Powders

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulfide Powder Moisture Challenges and Safety Goals

Sulfide powders represent a critical class of materials utilized across multiple industries including electronics, energy storage, and catalysis. These materials, while valuable for their unique properties, present significant challenges related to moisture sensitivity and hydrogen sulfide (H2S) gas generation. The historical development of sulfide powder technology has been marked by continuous efforts to mitigate these inherent risks while maximizing their functional benefits.

The evolution of sulfide powder handling protocols has progressed from rudimentary containment methods to sophisticated environmental control systems. Early applications often encountered degradation issues and safety incidents due to insufficient understanding of moisture-induced reactions. As industrial applications expanded in the 1980s and 1990s, more systematic approaches to moisture control emerged, leading to standardized handling procedures.

Recent technological advancements have focused on developing moisture-resistant coatings and passivation techniques that preserve the intrinsic properties of sulfide materials while enhancing their stability. The trajectory of innovation indicates a shift toward engineered sulfide composites with reduced hygroscopic properties and improved safety profiles.

The primary technical objectives in this domain center on achieving multi-faceted improvements: extending shelf-life stability, minimizing H2S gas evolution under varying humidity conditions, developing cost-effective moisture barriers, and establishing reliable detection systems for early warning of potential hazardous reactions.

Specifically, the industry aims to develop sulfide powders capable of maintaining less than 2% performance degradation after exposure to 60% relative humidity for 30 days. Additionally, there are targets to reduce H2S emissions to below 1 ppm during standard handling operations and to create packaging solutions that maintain internal relative humidity below 15% for at least 24 months under normal storage conditions.

Another critical goal involves the development of real-time monitoring systems capable of detecting moisture ingress and H2S concentrations at parts-per-billion levels, enabling preventive actions before safety thresholds are breached. These systems must be sufficiently robust for industrial environments while remaining cost-effective for widespread deployment.

The technical roadmap also emphasizes the importance of establishing standardized testing protocols that accurately predict long-term stability under various environmental conditions, allowing for meaningful comparisons between different sulfide formulations and protective strategies. This standardization would facilitate more rapid advancement in the field by enabling consistent evaluation methodologies across research institutions and industrial laboratories.

The evolution of sulfide powder handling protocols has progressed from rudimentary containment methods to sophisticated environmental control systems. Early applications often encountered degradation issues and safety incidents due to insufficient understanding of moisture-induced reactions. As industrial applications expanded in the 1980s and 1990s, more systematic approaches to moisture control emerged, leading to standardized handling procedures.

Recent technological advancements have focused on developing moisture-resistant coatings and passivation techniques that preserve the intrinsic properties of sulfide materials while enhancing their stability. The trajectory of innovation indicates a shift toward engineered sulfide composites with reduced hygroscopic properties and improved safety profiles.

The primary technical objectives in this domain center on achieving multi-faceted improvements: extending shelf-life stability, minimizing H2S gas evolution under varying humidity conditions, developing cost-effective moisture barriers, and establishing reliable detection systems for early warning of potential hazardous reactions.

Specifically, the industry aims to develop sulfide powders capable of maintaining less than 2% performance degradation after exposure to 60% relative humidity for 30 days. Additionally, there are targets to reduce H2S emissions to below 1 ppm during standard handling operations and to create packaging solutions that maintain internal relative humidity below 15% for at least 24 months under normal storage conditions.

Another critical goal involves the development of real-time monitoring systems capable of detecting moisture ingress and H2S concentrations at parts-per-billion levels, enabling preventive actions before safety thresholds are breached. These systems must be sufficiently robust for industrial environments while remaining cost-effective for widespread deployment.

The technical roadmap also emphasizes the importance of establishing standardized testing protocols that accurately predict long-term stability under various environmental conditions, allowing for meaningful comparisons between different sulfide formulations and protective strategies. This standardization would facilitate more rapid advancement in the field by enabling consistent evaluation methodologies across research institutions and industrial laboratories.

Market Analysis for Sulfide Powder Handling Solutions

The global market for sulfide powder handling solutions has experienced significant growth in recent years, driven primarily by expanding applications in mining, electronics, pharmaceuticals, and chemical manufacturing sectors. The market size for specialized moisture handling and H2S safety equipment reached approximately $3.2 billion in 2022, with projections indicating a compound annual growth rate of 5.7% through 2028.

North America currently dominates the market with a 34% share, followed by Europe (28%) and Asia-Pacific (26%). The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth due to rapid industrialization and increasing adoption of stringent safety protocols in manufacturing facilities handling hazardous materials.

The demand for advanced moisture control systems for sulfide powders has seen a notable uptick, particularly in regions with high humidity levels where material degradation and safety risks are heightened. Market research indicates that approximately 72% of industrial facilities handling sulfide powders report moisture-related challenges as their primary operational concern.

H2S safety equipment segment holds the largest market share at 41%, followed by moisture control systems (32%) and integrated handling solutions (27%). This distribution reflects the critical nature of hydrogen sulfide hazards in industrial settings and the prioritization of worker safety compliance.

Key market drivers include increasingly stringent occupational safety regulations, growing awareness of the dangers associated with improper sulfide powder handling, and technological advancements in sensor technologies and automated handling systems. The implementation of IoT and real-time monitoring capabilities has created a premium segment growing at 8.3% annually.

Customer surveys reveal that purchasing decisions are primarily influenced by safety certification compliance (38%), operational efficiency improvements (27%), integration capabilities with existing systems (21%), and total cost of ownership (14%). This indicates a market that values regulatory compliance and operational benefits over initial acquisition costs.

Market challenges include high initial investment requirements for comprehensive safety systems, technical complexity requiring specialized training, and varying regulatory standards across different regions creating compliance difficulties for global manufacturers. These barriers have created a significant opportunity for turnkey solution providers who can offer integrated systems with simplified implementation processes.

The competitive landscape features both specialized safety equipment manufacturers and diversified industrial suppliers expanding their offerings through strategic acquisitions. Recent market consolidation has resulted in the top five players controlling approximately 47% of the global market share, indicating moderate market concentration with room for innovative new entrants.

North America currently dominates the market with a 34% share, followed by Europe (28%) and Asia-Pacific (26%). The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth due to rapid industrialization and increasing adoption of stringent safety protocols in manufacturing facilities handling hazardous materials.

The demand for advanced moisture control systems for sulfide powders has seen a notable uptick, particularly in regions with high humidity levels where material degradation and safety risks are heightened. Market research indicates that approximately 72% of industrial facilities handling sulfide powders report moisture-related challenges as their primary operational concern.

H2S safety equipment segment holds the largest market share at 41%, followed by moisture control systems (32%) and integrated handling solutions (27%). This distribution reflects the critical nature of hydrogen sulfide hazards in industrial settings and the prioritization of worker safety compliance.

Key market drivers include increasingly stringent occupational safety regulations, growing awareness of the dangers associated with improper sulfide powder handling, and technological advancements in sensor technologies and automated handling systems. The implementation of IoT and real-time monitoring capabilities has created a premium segment growing at 8.3% annually.

Customer surveys reveal that purchasing decisions are primarily influenced by safety certification compliance (38%), operational efficiency improvements (27%), integration capabilities with existing systems (21%), and total cost of ownership (14%). This indicates a market that values regulatory compliance and operational benefits over initial acquisition costs.

Market challenges include high initial investment requirements for comprehensive safety systems, technical complexity requiring specialized training, and varying regulatory standards across different regions creating compliance difficulties for global manufacturers. These barriers have created a significant opportunity for turnkey solution providers who can offer integrated systems with simplified implementation processes.

The competitive landscape features both specialized safety equipment manufacturers and diversified industrial suppliers expanding their offerings through strategic acquisitions. Recent market consolidation has resulted in the top five players controlling approximately 47% of the global market share, indicating moderate market concentration with room for innovative new entrants.

Current H2S Safety Protocols and Technical Limitations

Current hydrogen sulfide (H2S) safety protocols for handling sulfide powders have evolved significantly over the past decades, yet still face considerable technical limitations. The Occupational Safety and Health Administration (OSHA) and the National Institute for Occupational Safety and Health (NIOSH) have established comprehensive guidelines that mandate exposure limits of 10 ppm for 8-hour time-weighted averages and 15 ppm for short-term exposure limits. These standards form the foundation of most industrial safety practices but are increasingly viewed as conservative in specialized applications.

Standard protocols typically include multi-tiered detection systems utilizing electrochemical sensors, metal oxide semiconductors, and optical sensors. While electrochemical sensors offer high sensitivity (detecting H2S at concentrations as low as 0.1 ppm), they suffer from cross-sensitivity issues with other sulfur compounds and require frequent calibration in high-humidity environments—a significant limitation when handling moisture-sensitive sulfide powders.

Personal protective equipment requirements currently specify supplied-air respirators for concentrations exceeding 100 ppm, but the integration of these systems with moisture-control environments presents substantial engineering challenges. The sealed environments necessary for moisture control often conflict with ventilation requirements for H2S mitigation, creating competing technical demands that current solutions address inadequately.

Emergency response protocols rely heavily on evacuation procedures triggered by detection thresholds, but these systems face reliability issues in environments where moisture levels fluctuate. False alarms due to humidity-induced sensor drift remain a persistent problem, with error rates as high as 15-20% reported in industrial settings with relative humidity exceeding 85%.

Material handling guidelines recommend specialized containers with moisture barriers and oxygen scavengers, yet these solutions often compromise real-time monitoring capabilities. Current moisture-resistant packaging materials that maintain hermeticity typically impede continuous gas monitoring, creating blind spots in safety surveillance systems.

The technical limitations extend to decontamination procedures as well. Current neutralization methods using alkaline solutions effectively address H2S hazards but introduce additional moisture that can trigger accelerated decomposition of certain sulfide compounds, potentially creating secondary reaction hazards that existing protocols fail to address comprehensively.

Integration of safety systems with process control automation represents another significant gap. While Industry 4.0 approaches have advanced in many sectors, the specialized requirements for simultaneous moisture and H2S management have resulted in fragmented solutions rather than holistic control architectures, limiting the effectiveness of predictive safety measures and real-time risk assessment capabilities.

Standard protocols typically include multi-tiered detection systems utilizing electrochemical sensors, metal oxide semiconductors, and optical sensors. While electrochemical sensors offer high sensitivity (detecting H2S at concentrations as low as 0.1 ppm), they suffer from cross-sensitivity issues with other sulfur compounds and require frequent calibration in high-humidity environments—a significant limitation when handling moisture-sensitive sulfide powders.

Personal protective equipment requirements currently specify supplied-air respirators for concentrations exceeding 100 ppm, but the integration of these systems with moisture-control environments presents substantial engineering challenges. The sealed environments necessary for moisture control often conflict with ventilation requirements for H2S mitigation, creating competing technical demands that current solutions address inadequately.

Emergency response protocols rely heavily on evacuation procedures triggered by detection thresholds, but these systems face reliability issues in environments where moisture levels fluctuate. False alarms due to humidity-induced sensor drift remain a persistent problem, with error rates as high as 15-20% reported in industrial settings with relative humidity exceeding 85%.

Material handling guidelines recommend specialized containers with moisture barriers and oxygen scavengers, yet these solutions often compromise real-time monitoring capabilities. Current moisture-resistant packaging materials that maintain hermeticity typically impede continuous gas monitoring, creating blind spots in safety surveillance systems.

The technical limitations extend to decontamination procedures as well. Current neutralization methods using alkaline solutions effectively address H2S hazards but introduce additional moisture that can trigger accelerated decomposition of certain sulfide compounds, potentially creating secondary reaction hazards that existing protocols fail to address comprehensively.

Integration of safety systems with process control automation represents another significant gap. While Industry 4.0 approaches have advanced in many sectors, the specialized requirements for simultaneous moisture and H2S management have resulted in fragmented solutions rather than holistic control architectures, limiting the effectiveness of predictive safety measures and real-time risk assessment capabilities.

Existing Moisture Management and H2S Mitigation Solutions

01 Moisture control techniques for sulfide powders

Controlling moisture in sulfide powders is critical to prevent hydrogen sulfide (H2S) generation. Various techniques include specialized packaging with desiccants, humidity-controlled storage environments, and moisture barrier materials. Some methods involve treating the powder surface with hydrophobic agents to repel moisture. Proper moisture control not only prevents dangerous H2S formation but also maintains the quality and stability of the sulfide powders during storage and handling.- Moisture control in sulfide powder handling: Controlling moisture during sulfide powder handling is critical to prevent hydrogen sulfide (H2S) gas formation. Techniques include using desiccants, sealed containers, and controlled humidity environments. Proper moisture management prevents chemical reactions that could lead to the release of toxic H2S gas and reduces the risk of powder clumping or degradation. Implementing moisture barriers and regular monitoring of environmental conditions are essential practices for safe handling.

- H2S detection and monitoring systems: Advanced detection and monitoring systems are crucial for H2S safety in environments where sulfide powders are handled. These systems include gas sensors, alarm mechanisms, and continuous monitoring equipment that can detect even low concentrations of H2S. Early detection allows for prompt evacuation and emergency response, significantly reducing the risk of exposure to this potentially lethal gas. Modern systems may incorporate wireless technology and remote monitoring capabilities for comprehensive safety coverage.

- Personal protective equipment for H2S exposure: Specialized personal protective equipment (PPE) is essential when handling sulfide powders that may release H2S. This includes respiratory protection with appropriate filters or self-contained breathing apparatus, chemical-resistant gloves, face shields, and protective clothing. Training on proper PPE use and maintenance is critical, as is establishing protocols for equipment inspection before entering hazardous areas. Emergency escape respirators should be readily accessible in areas where sudden H2S release is possible.

- Ventilation and containment systems: Effective ventilation and containment systems are fundamental for managing H2S risks in facilities handling sulfide powders. These systems include local exhaust ventilation, fume hoods, negative pressure environments, and sealed processing equipment. Properly designed air handling systems can capture and treat H2S emissions before they reach personnel. Containment strategies may include enclosed processing areas, airlocks, and specialized transfer systems that minimize powder exposure to air and moisture.

- Emergency response protocols for H2S release: Comprehensive emergency response protocols are necessary when working with sulfide powders that may generate H2S. These include evacuation plans, rescue procedures, medical response guidelines, and communication systems. Personnel must be trained to recognize H2S exposure symptoms and provide first aid. Emergency protocols should address various scenarios including small leaks, major releases, and equipment failures. Regular drills and coordination with local emergency services enhance preparedness for potential H2S incidents.

02 H2S detection and monitoring systems

Advanced detection and monitoring systems are essential for H2S safety when handling sulfide powders. These systems include continuous gas monitors, portable detectors, and integrated alarm systems that provide early warning of dangerous H2S concentrations. Some technologies incorporate wireless connectivity for remote monitoring and automated emergency response protocols. Modern detection systems can detect H2S at parts-per-million levels, allowing for immediate evacuation or ventilation before concentrations reach hazardous levels.Expand Specific Solutions03 Ventilation and containment strategies

Effective ventilation and containment systems are crucial for managing H2S risks when handling sulfide powders. These include specialized fume hoods, local exhaust ventilation, and negative pressure environments that prevent gas dispersion. Some systems incorporate scrubbers or chemical neutralization units to treat extracted air. Proper containment strategies also involve sealed processing equipment, transfer systems designed to minimize powder exposure to air, and dedicated handling areas with controlled access to limit potential exposure to personnel.Expand Specific Solutions04 Chemical stabilization of sulfide powders

Chemical stabilization methods can reduce the reactivity of sulfide powders with moisture and subsequent H2S generation. These include surface treatments with passivating agents, incorporation of pH buffers to control reaction rates, and addition of scavenging compounds that preferentially react with any H2S formed. Some formulations include oxidation inhibitors or chemical modifiers that form protective layers on powder particles. These approaches help maintain powder stability during storage, transportation, and processing while reducing safety hazards.Expand Specific Solutions05 Emergency response and safety protocols

Comprehensive emergency response and safety protocols are essential when handling sulfide powders that may generate H2S. These include detailed evacuation procedures, respiratory protection requirements, and emergency neutralization methods for spills. Training programs focus on recognizing H2S exposure symptoms, proper use of personal protective equipment, and emergency first aid techniques. Some protocols incorporate automated shutdown systems, emergency ventilation activation, and communication procedures to coordinate response efforts during H2S release incidents.Expand Specific Solutions

Leading Companies in Sulfide Handling Equipment

The moisture handling and H2S safety protocols for sulfide powders market is in a growth phase, driven by increasing safety concerns in petroleum, chemical, and water treatment industries. The market is estimated to reach significant value due to stringent safety regulations and growing industrial applications. Technologically, the field is moderately mature with established protocols, but continuous innovation is evident. Leading players include China Petroleum & Chemical Corp. (Sinopec) and its Safety Engineering Research Institute, which focus on comprehensive safety systems; Schlumberger and Halliburton, which specialize in oilfield-specific solutions; and BASF and Lonza, which contribute advanced chemical handling technologies. Academic institutions like China University of Petroleum and King Fahd University of Petroleum & Minerals provide research support, accelerating technological advancement in this critical safety domain.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed comprehensive moisture handling protocols for sulfide powders that integrate multi-stage drying processes with controlled atmosphere storage systems. Their approach includes specialized nitrogen-purged containers that maintain relative humidity below 30% during transportation and storage, effectively preventing moisture-induced hydrogen sulfide generation. For H2S safety, Sinopec implements a three-tier detection system with portable personal monitors (10 ppm alarm threshold), fixed area monitors (5 ppm warning level), and advanced wireless sensor networks providing real-time concentration mapping across facilities. Their emergency response protocol incorporates positive-pressure breathing apparatus for personnel and automated ventilation systems that activate at 15 ppm H2S levels. Sinopec's handling procedures require double containment for all sulfide materials with moisture-reactive properties and specialized training programs focusing on early detection of compromised containers[1][3].

Strengths: Comprehensive integration of monitoring technologies with automated safety systems; advanced containment strategies specifically designed for moisture-sensitive sulfides. Weaknesses: System complexity requires significant infrastructure investment and extensive personnel training; potential over-reliance on technological solutions may create vulnerabilities if systems fail.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed the SulfSafe™ system for handling moisture-sensitive sulfide powders in oilfield and laboratory environments. Their approach integrates specialized packaging with multi-layer moisture barriers incorporating humidity indicators that change color at critical moisture thresholds (30%, 40%, and 50% RH). For material handling, they employ negative pressure glove boxes with continuous nitrogen purging and real-time humidity monitoring. Their H2S safety protocol features a three-tier detection system with personal monitors worn at breathing zone level, fixed area monitors positioned strategically based on computational fluid dynamics modeling of potential release scenarios, and advanced electrochemical sensors with digital logging capabilities for trend analysis. Schlumberger's emergency response procedures include mandatory evacuation at 10 ppm H2S detection, designated safe assembly points with supplied air systems, and specialized decontamination procedures for personnel and equipment exposed to H2S. Their training program incorporates virtual reality simulations of emergency scenarios and hands-on exercises with actual detection equipment. The company has also developed specialized transport containers with impact-resistant outer shells and moisture-proof inner liners designed specifically for field transportation in harsh environments[9][10].

Strengths: Sophisticated packaging with visual moisture indicators; integration of computational modeling for optimal sensor placement; comprehensive training using advanced simulation technologies. Weaknesses: System complexity requires specialized technical knowledge; higher implementation costs compared to basic safety systems; potential challenges in remote field locations with limited infrastructure.

Key Innovations in Sulfide Powder Safety Technologies

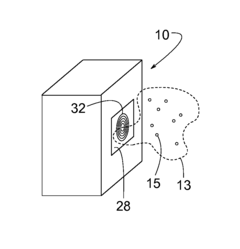

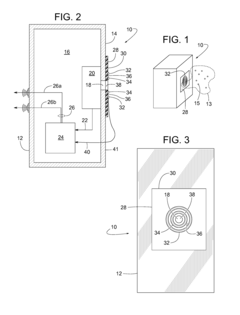

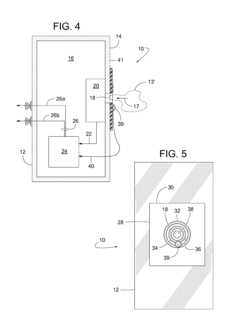

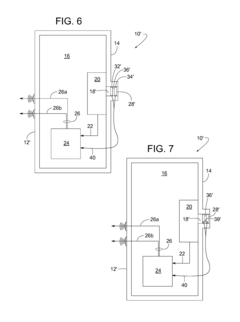

Hydrogen sulfide sensor with water detection

PatentActiveUS8836520B1

Innovation

- Incorporating a moisture sensor with radially separated uninsulated conductors on a printed circuit board, which generates a moisture signal when liquid water bridges the gap, allowing the controller to differentiate between H2S and moisture contamination, and trigger appropriate alarms to prevent false hydrogen sulfide alarms.

Hydrogen sulfide adsorption process and apparatus

PatentPendingUS20230113433A1

Innovation

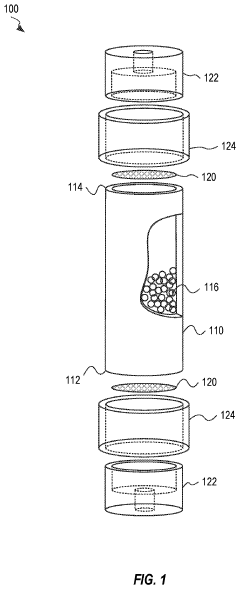

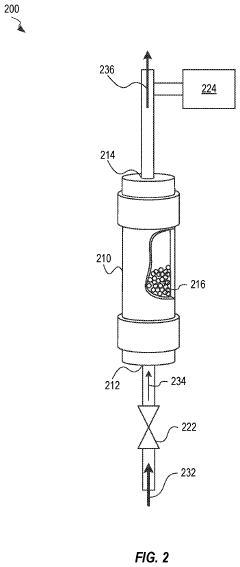

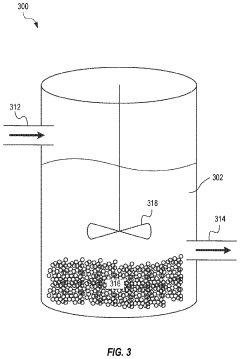

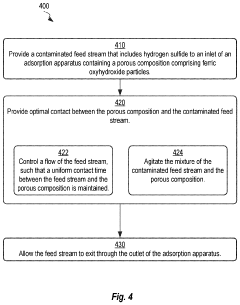

- An adsorbent composition comprising ferric oxyhydroxide particles combined with additional components like copper chloride, zinc chloride, or activated carbon is used to capture hydrogen sulfide from gaseous streams, liquids, and sludge, allowing for chemical adsorption without the need for further disposal treatments, and is designed for use in replaceable cartridges for ease of replacement.

Regulatory Compliance for Hazardous Sulfide Materials

Regulatory compliance for hazardous sulfide materials represents a critical framework governing the handling, storage, and transportation of sulfide powders that pose significant health and environmental risks. The regulatory landscape is complex and multifaceted, with requirements varying across jurisdictions while maintaining core safety principles.

In the United States, the Occupational Safety and Health Administration (OSHA) establishes comprehensive standards under 29 CFR 1910.1000 for workplace exposure limits to hydrogen sulfide (H2S), mandating that employers implement engineering controls and work practices to maintain exposure below 20 ppm ceiling. The Environmental Protection Agency (EPA) further regulates sulfide materials under the Resource Conservation and Recovery Act (RCRA) and the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), with reporting requirements for releases exceeding reportable quantities.

The European Union's regulatory framework centers on the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) and Classification, Labeling and Packaging (CLP) regulations. These frameworks require comprehensive safety data sheets, appropriate hazard labeling, and strict exposure controls for sulfide materials. The Seveso III Directive additionally imposes requirements for facilities handling large quantities of hazardous substances.

International transportation of sulfide powders falls under the United Nations' Recommendations on the Transport of Dangerous Goods, with sulfide materials typically classified under Class 4.2 (substances liable to spontaneous combustion) or Class 6.1 (toxic substances). These classifications dictate specific packaging requirements, documentation needs, and handling protocols during transit.

Industry-specific standards complement these regulatory frameworks. The American Conference of Governmental Industrial Hygienists (ACGIH) recommends threshold limit values for H2S exposure, while the National Fire Protection Association (NFPA) provides guidelines for emergency response to sulfide-related incidents. The International Maritime Dangerous Goods (IMDG) Code governs sea transport of hazardous sulfides.

Recent regulatory trends indicate increasing stringency in compliance requirements, with greater emphasis on worker training, emergency response planning, and community right-to-know provisions. Regulatory bodies are also focusing more attention on the cumulative effects of low-level chronic exposure to H2S and other sulfide compounds, potentially leading to more restrictive exposure limits in the future.

Companies handling sulfide powders must implement comprehensive compliance programs that address these multifaceted requirements, including regular monitoring, documentation, training, and emergency response planning to mitigate both regulatory and operational risks.

In the United States, the Occupational Safety and Health Administration (OSHA) establishes comprehensive standards under 29 CFR 1910.1000 for workplace exposure limits to hydrogen sulfide (H2S), mandating that employers implement engineering controls and work practices to maintain exposure below 20 ppm ceiling. The Environmental Protection Agency (EPA) further regulates sulfide materials under the Resource Conservation and Recovery Act (RCRA) and the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), with reporting requirements for releases exceeding reportable quantities.

The European Union's regulatory framework centers on the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) and Classification, Labeling and Packaging (CLP) regulations. These frameworks require comprehensive safety data sheets, appropriate hazard labeling, and strict exposure controls for sulfide materials. The Seveso III Directive additionally imposes requirements for facilities handling large quantities of hazardous substances.

International transportation of sulfide powders falls under the United Nations' Recommendations on the Transport of Dangerous Goods, with sulfide materials typically classified under Class 4.2 (substances liable to spontaneous combustion) or Class 6.1 (toxic substances). These classifications dictate specific packaging requirements, documentation needs, and handling protocols during transit.

Industry-specific standards complement these regulatory frameworks. The American Conference of Governmental Industrial Hygienists (ACGIH) recommends threshold limit values for H2S exposure, while the National Fire Protection Association (NFPA) provides guidelines for emergency response to sulfide-related incidents. The International Maritime Dangerous Goods (IMDG) Code governs sea transport of hazardous sulfides.

Recent regulatory trends indicate increasing stringency in compliance requirements, with greater emphasis on worker training, emergency response planning, and community right-to-know provisions. Regulatory bodies are also focusing more attention on the cumulative effects of low-level chronic exposure to H2S and other sulfide compounds, potentially leading to more restrictive exposure limits in the future.

Companies handling sulfide powders must implement comprehensive compliance programs that address these multifaceted requirements, including regular monitoring, documentation, training, and emergency response planning to mitigate both regulatory and operational risks.

Environmental Impact Assessment of Sulfide Processing

The processing of sulfide powders presents significant environmental challenges that require comprehensive assessment and mitigation strategies. Sulfide minerals, when exposed to air and moisture, can generate acidic drainage containing heavy metals and sulfuric acid, leading to potential contamination of soil, groundwater, and surface water systems. This acid mine drainage (AMD) represents one of the most serious environmental threats associated with sulfide processing operations.

Air quality impacts from sulfide processing include the release of sulfur dioxide (SO2), hydrogen sulfide (H2S), and particulate matter. H2S emissions are particularly concerning due to their toxicity at relatively low concentrations and distinctive odor. Proper ventilation systems and gas detection equipment are essential for monitoring and controlling these emissions. Additionally, dust suppression techniques must be implemented to prevent the dispersion of sulfide particles, which can lead to respiratory issues in nearby communities and workers.

Water resource management presents another critical environmental consideration. Processing facilities typically require substantial water inputs, potentially competing with local communities and ecosystems for this resource. Closed-loop water systems and water recycling technologies can significantly reduce freshwater consumption and minimize wastewater discharge. Treatment of process water before release is mandatory to remove heavy metals, adjust pH levels, and eliminate sulfide compounds.

Waste management strategies for sulfide processing must address the long-term stability of tailings and waste rock. These materials often contain residual sulfides that can continue to generate acid drainage for decades if improperly managed. Modern approaches include paste backfill techniques, dry stacking of filtered tailings, and the use of geomembrane liners to prevent leachate migration. Co-disposal with neutralizing materials such as limestone can help maintain non-acid generating conditions.

Regulatory compliance frameworks vary globally but typically include requirements for environmental impact assessments, monitoring programs, and closure planning. Many jurisdictions now mandate financial assurance mechanisms to ensure funds are available for site remediation. Companies processing sulfide materials must navigate these complex regulatory landscapes while implementing best practices that often exceed minimum compliance standards.

Climate change considerations are increasingly relevant to environmental assessments of sulfide processing operations. Extreme weather events can compromise containment structures, while changing precipitation patterns may alter acid generation rates and water management requirements. Forward-looking environmental impact assessments now incorporate climate resilience planning to address these emerging challenges.

Air quality impacts from sulfide processing include the release of sulfur dioxide (SO2), hydrogen sulfide (H2S), and particulate matter. H2S emissions are particularly concerning due to their toxicity at relatively low concentrations and distinctive odor. Proper ventilation systems and gas detection equipment are essential for monitoring and controlling these emissions. Additionally, dust suppression techniques must be implemented to prevent the dispersion of sulfide particles, which can lead to respiratory issues in nearby communities and workers.

Water resource management presents another critical environmental consideration. Processing facilities typically require substantial water inputs, potentially competing with local communities and ecosystems for this resource. Closed-loop water systems and water recycling technologies can significantly reduce freshwater consumption and minimize wastewater discharge. Treatment of process water before release is mandatory to remove heavy metals, adjust pH levels, and eliminate sulfide compounds.

Waste management strategies for sulfide processing must address the long-term stability of tailings and waste rock. These materials often contain residual sulfides that can continue to generate acid drainage for decades if improperly managed. Modern approaches include paste backfill techniques, dry stacking of filtered tailings, and the use of geomembrane liners to prevent leachate migration. Co-disposal with neutralizing materials such as limestone can help maintain non-acid generating conditions.

Regulatory compliance frameworks vary globally but typically include requirements for environmental impact assessments, monitoring programs, and closure planning. Many jurisdictions now mandate financial assurance mechanisms to ensure funds are available for site remediation. Companies processing sulfide materials must navigate these complex regulatory landscapes while implementing best practices that often exceed minimum compliance standards.

Climate change considerations are increasingly relevant to environmental assessments of sulfide processing operations. Extreme weather events can compromise containment structures, while changing precipitation patterns may alter acid generation rates and water management requirements. Forward-looking environmental impact assessments now incorporate climate resilience planning to address these emerging challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!