Stack Pressure Windows And Contact Resistance In Sulfide ASSLBs

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ASSLB Stack Pressure Technology Background and Objectives

All-Solid-State Lithium Batteries (ASSLBs) represent a significant evolution in energy storage technology, emerging as a promising alternative to conventional lithium-ion batteries with liquid electrolytes. The development of ASSLBs can be traced back to the 1970s, but substantial progress has been made only in the past decade due to advancements in materials science and manufacturing techniques.

The technological trajectory of ASSLBs has been driven by increasing demands for safer, higher energy density, and longer-lasting energy storage solutions. Sulfide-based solid electrolytes have gained particular attention due to their high ionic conductivity comparable to liquid electrolytes, making them ideal candidates for practical applications in ASSLBs.

Stack pressure has emerged as a critical parameter in ASSLB performance optimization. Historically, researchers focused primarily on electrolyte composition and electrode materials, with less attention paid to mechanical factors. However, recent studies have demonstrated that the interface contact between solid electrolytes and electrodes significantly impacts battery performance, and this contact is directly influenced by applied stack pressure.

The evolution of stack pressure research in ASSLBs has progressed from empirical observations to systematic investigations. Early work noted improved performance with increased pressure but lacked comprehensive understanding of the underlying mechanisms. Recent research has begun quantifying optimal pressure windows and correlating them with contact resistance reduction at critical interfaces.

Contact resistance at solid-solid interfaces represents one of the most significant barriers to ASSLB commercialization. This resistance arises from incomplete physical contact between components and chemical instabilities at interfaces, both of which can be modulated through appropriate stack pressure application.

The primary technical objective of current research is to establish well-defined stack pressure windows that optimize performance while preventing mechanical degradation of sulfide electrolytes. This includes determining pressure thresholds that minimize contact resistance without inducing electrolyte fracture or deformation that could lead to short circuits.

Additional objectives include developing pressure application methods suitable for mass production, understanding pressure distribution effects in multi-layer battery stacks, and creating predictive models that correlate stack pressure with electrochemical performance metrics across different cell designs and material combinations.

The ultimate goal is to establish standardized protocols for stack pressure application in sulfide-based ASSLBs that can be implemented in manufacturing processes, thereby accelerating the transition of this promising technology from laboratory research to commercial reality.

The technological trajectory of ASSLBs has been driven by increasing demands for safer, higher energy density, and longer-lasting energy storage solutions. Sulfide-based solid electrolytes have gained particular attention due to their high ionic conductivity comparable to liquid electrolytes, making them ideal candidates for practical applications in ASSLBs.

Stack pressure has emerged as a critical parameter in ASSLB performance optimization. Historically, researchers focused primarily on electrolyte composition and electrode materials, with less attention paid to mechanical factors. However, recent studies have demonstrated that the interface contact between solid electrolytes and electrodes significantly impacts battery performance, and this contact is directly influenced by applied stack pressure.

The evolution of stack pressure research in ASSLBs has progressed from empirical observations to systematic investigations. Early work noted improved performance with increased pressure but lacked comprehensive understanding of the underlying mechanisms. Recent research has begun quantifying optimal pressure windows and correlating them with contact resistance reduction at critical interfaces.

Contact resistance at solid-solid interfaces represents one of the most significant barriers to ASSLB commercialization. This resistance arises from incomplete physical contact between components and chemical instabilities at interfaces, both of which can be modulated through appropriate stack pressure application.

The primary technical objective of current research is to establish well-defined stack pressure windows that optimize performance while preventing mechanical degradation of sulfide electrolytes. This includes determining pressure thresholds that minimize contact resistance without inducing electrolyte fracture or deformation that could lead to short circuits.

Additional objectives include developing pressure application methods suitable for mass production, understanding pressure distribution effects in multi-layer battery stacks, and creating predictive models that correlate stack pressure with electrochemical performance metrics across different cell designs and material combinations.

The ultimate goal is to establish standardized protocols for stack pressure application in sulfide-based ASSLBs that can be implemented in manufacturing processes, thereby accelerating the transition of this promising technology from laboratory research to commercial reality.

Market Analysis for Sulfide-Based Solid-State Batteries

The global market for sulfide-based solid-state batteries is experiencing significant growth, driven by increasing demand for safer and higher energy density battery solutions. Current market projections indicate that the solid-state battery market will reach approximately $8 billion by 2030, with sulfide-based technologies representing a substantial segment due to their superior ionic conductivity compared to oxide-based alternatives.

Automotive applications represent the primary market driver, with major manufacturers including Toyota, BMW, and Volkswagen investing heavily in sulfide-based ASSLBs. These investments are motivated by the potential for extended electric vehicle range, faster charging capabilities, and enhanced safety profiles compared to conventional lithium-ion batteries with liquid electrolytes.

Consumer electronics constitutes the second largest market segment, where the compact form factor and safety advantages of sulfide-based batteries are particularly valuable. Companies like Samsung and LG are actively developing sulfide-based solutions for next-generation smartphones, tablets, and wearable devices.

Market penetration faces significant challenges related to manufacturing scalability and cost. Current production costs for sulfide-based solid electrolytes remain 5-10 times higher than liquid electrolyte systems, primarily due to complex processing requirements and the need for specialized handling environments to prevent moisture contamination.

Regional market analysis reveals Asia-Pacific as the dominant market, with Japan and South Korea leading research and commercialization efforts. North America and Europe are rapidly expanding their market presence through strategic partnerships and substantial government funding initiatives focused on battery technology innovation.

The competitive landscape features both established battery manufacturers and specialized startups. Companies like Solid Power, QuantumScape, and ProLogium have secured significant venture capital funding specifically for sulfide-based ASSLB development, while traditional battery giants are acquiring or partnering with these technology innovators.

Market adoption timelines suggest initial commercial applications in premium consumer electronics by 2023-2024, followed by limited automotive deployment in 2025-2026. Mass market penetration is expected post-2028, contingent upon resolving current technical challenges including stack pressure optimization and contact resistance issues.

Customer demand analysis indicates strong interest from both OEMs and end consumers, with surveys showing over 70% of potential electric vehicle buyers consider improved battery safety and performance as critical purchasing factors. This consumer sentiment is driving manufacturer investment despite current technical and cost barriers.

Automotive applications represent the primary market driver, with major manufacturers including Toyota, BMW, and Volkswagen investing heavily in sulfide-based ASSLBs. These investments are motivated by the potential for extended electric vehicle range, faster charging capabilities, and enhanced safety profiles compared to conventional lithium-ion batteries with liquid electrolytes.

Consumer electronics constitutes the second largest market segment, where the compact form factor and safety advantages of sulfide-based batteries are particularly valuable. Companies like Samsung and LG are actively developing sulfide-based solutions for next-generation smartphones, tablets, and wearable devices.

Market penetration faces significant challenges related to manufacturing scalability and cost. Current production costs for sulfide-based solid electrolytes remain 5-10 times higher than liquid electrolyte systems, primarily due to complex processing requirements and the need for specialized handling environments to prevent moisture contamination.

Regional market analysis reveals Asia-Pacific as the dominant market, with Japan and South Korea leading research and commercialization efforts. North America and Europe are rapidly expanding their market presence through strategic partnerships and substantial government funding initiatives focused on battery technology innovation.

The competitive landscape features both established battery manufacturers and specialized startups. Companies like Solid Power, QuantumScape, and ProLogium have secured significant venture capital funding specifically for sulfide-based ASSLB development, while traditional battery giants are acquiring or partnering with these technology innovators.

Market adoption timelines suggest initial commercial applications in premium consumer electronics by 2023-2024, followed by limited automotive deployment in 2025-2026. Mass market penetration is expected post-2028, contingent upon resolving current technical challenges including stack pressure optimization and contact resistance issues.

Customer demand analysis indicates strong interest from both OEMs and end consumers, with surveys showing over 70% of potential electric vehicle buyers consider improved battery safety and performance as critical purchasing factors. This consumer sentiment is driving manufacturer investment despite current technical and cost barriers.

Contact Resistance Challenges in ASSLBs

Contact resistance represents one of the most significant challenges in the development of sulfide all-solid-state lithium batteries (ASSLBs). This interfacial resistance occurs primarily at the electrode-electrolyte boundaries and substantially impacts overall battery performance. Unlike liquid electrolyte systems where intimate contact is naturally achieved, solid-state interfaces create inherent barriers to ion transport, resulting in increased internal resistance and reduced power capability.

The fundamental issue stems from the physical nature of solid-solid interfaces. When two solid materials meet, contact is limited to discrete points rather than continuous surfaces, creating void spaces that impede lithium ion migration. This problem is particularly pronounced in sulfide-based systems due to their brittle mechanical properties and sensitivity to environmental conditions.

Several factors contribute to contact resistance challenges in sulfide ASSLBs. First, surface roughness at the microscale creates non-uniform contact areas, with estimates suggesting that actual contact may be limited to less than 60% of the theoretical interface area in unoptimized systems. Second, chemical incompatibility between sulfide solid electrolytes and electrode materials often leads to the formation of resistive interphases during battery operation.

Stack pressure has emerged as a critical parameter for managing contact resistance. Research indicates that applying external pressure during both battery assembly and operation can significantly reduce interfacial resistance by forcing better physical contact between components. However, the pressure window is remarkably narrow - insufficient pressure fails to establish adequate contact, while excessive pressure can fracture the brittle sulfide electrolyte or cause lithium dendrite formation.

Recent studies have demonstrated that optimal stack pressure typically falls within 5-20 MPa for sulfide systems, though this varies based on specific material compositions. This pressure dependency creates substantial engineering challenges for practical device implementation, particularly for large-format batteries where uniform pressure distribution becomes increasingly difficult to maintain.

Temperature fluctuations further complicate contact resistance management due to the different thermal expansion coefficients of battery components. During thermal cycling, these mismatches can create mechanical stress that degrades interfacial contact over time, leading to capacity fade and performance deterioration.

Advanced characterization techniques including impedance spectroscopy and in-situ pressure-controlled measurements have been instrumental in quantifying these effects, revealing that contact resistance can contribute up to 70% of the total internal resistance in poorly optimized sulfide ASSLBs, highlighting the critical importance of addressing this challenge.

The fundamental issue stems from the physical nature of solid-solid interfaces. When two solid materials meet, contact is limited to discrete points rather than continuous surfaces, creating void spaces that impede lithium ion migration. This problem is particularly pronounced in sulfide-based systems due to their brittle mechanical properties and sensitivity to environmental conditions.

Several factors contribute to contact resistance challenges in sulfide ASSLBs. First, surface roughness at the microscale creates non-uniform contact areas, with estimates suggesting that actual contact may be limited to less than 60% of the theoretical interface area in unoptimized systems. Second, chemical incompatibility between sulfide solid electrolytes and electrode materials often leads to the formation of resistive interphases during battery operation.

Stack pressure has emerged as a critical parameter for managing contact resistance. Research indicates that applying external pressure during both battery assembly and operation can significantly reduce interfacial resistance by forcing better physical contact between components. However, the pressure window is remarkably narrow - insufficient pressure fails to establish adequate contact, while excessive pressure can fracture the brittle sulfide electrolyte or cause lithium dendrite formation.

Recent studies have demonstrated that optimal stack pressure typically falls within 5-20 MPa for sulfide systems, though this varies based on specific material compositions. This pressure dependency creates substantial engineering challenges for practical device implementation, particularly for large-format batteries where uniform pressure distribution becomes increasingly difficult to maintain.

Temperature fluctuations further complicate contact resistance management due to the different thermal expansion coefficients of battery components. During thermal cycling, these mismatches can create mechanical stress that degrades interfacial contact over time, leading to capacity fade and performance deterioration.

Advanced characterization techniques including impedance spectroscopy and in-situ pressure-controlled measurements have been instrumental in quantifying these effects, revealing that contact resistance can contribute up to 70% of the total internal resistance in poorly optimized sulfide ASSLBs, highlighting the critical importance of addressing this challenge.

Current Stack Pressure and Interface Engineering Solutions

01 Stack pressure optimization for sulfide ASSLBs

Optimizing stack pressure in sulfide all-solid-state lithium batteries is crucial for improving battery performance. Proper stack pressure ensures good contact between components, reducing interfacial resistance and enhancing ionic conductivity. The pressure must be carefully controlled to prevent excessive compression that could damage the sulfide solid electrolyte while maintaining sufficient contact for efficient charge transfer. Various pressure application methods and optimal pressure ranges have been developed to balance these requirements.- Stack pressure optimization for sulfide ASSLBs: Optimizing stack pressure in sulfide all-solid-state lithium batteries is crucial for improving battery performance. Appropriate stack pressure ensures good contact between components, reducing interfacial resistance and enhancing ionic conductivity. However, excessive pressure can damage the sulfide solid electrolyte due to its brittle nature. Finding the optimal pressure range that balances contact improvement without causing mechanical degradation is essential for maximizing battery efficiency and cycle life.

- Interface engineering to reduce contact resistance: Interface engineering techniques are employed to reduce contact resistance between the sulfide solid electrolyte and electrodes. These include surface modifications, buffer layers, and interlayers that improve adhesion and compatibility. By addressing the poor contact at interfaces, these approaches enhance ion transport across boundaries and minimize resistance losses. Various coating materials and interface treatments can be applied to create more stable and conductive interfaces in sulfide-based ASSLBs.

- Composite electrode design for improved contact: Composite electrode designs incorporate conductive additives and binders with active materials to improve contact with sulfide solid electrolytes. These formulations help maintain intimate contact during battery operation and volume changes. By optimizing the ratio and distribution of components, composite electrodes can significantly reduce contact resistance and enhance electrochemical performance. The design considers both electronic and ionic conductivity pathways to ensure efficient charge transfer throughout the battery stack.

- Mechanical properties of sulfide electrolytes under pressure: The mechanical properties of sulfide solid electrolytes under applied pressure significantly impact battery performance. Sulfide electrolytes exhibit plastic deformation characteristics that can be beneficial for conforming to electrode surfaces but may lead to structural degradation under excessive pressure. Understanding the relationship between pressure, deformation, and conductivity is essential for designing robust battery systems. Research focuses on improving the mechanical stability while maintaining the high ionic conductivity that makes sulfide electrolytes attractive for ASSLBs.

- Manufacturing processes affecting stack pressure and contact resistance: Manufacturing processes significantly influence stack pressure distribution and contact resistance in sulfide ASSLBs. Techniques such as cold pressing, hot pressing, and roll-to-roll processing affect the microstructure and interfaces within the battery. Process parameters including temperature, pressure application method, and duration must be carefully controlled to achieve uniform contact without damaging components. Advanced manufacturing approaches aim to create scalable production methods that consistently deliver low contact resistance and optimal stack pressure across the entire battery area.

02 Contact resistance reduction techniques

Reducing contact resistance between components in sulfide ASSLBs is essential for improving overall battery performance. Techniques include surface modification of electrode materials, addition of conductive additives, and interface engineering. These approaches help to enhance the contact area between the solid electrolyte and electrodes, facilitating ion transfer across interfaces. Minimizing contact resistance leads to lower internal resistance, higher power density, and improved cycling stability.Expand Specific Solutions03 Composite interfaces for improved conductivity

Creating composite interfaces between the sulfide solid electrolyte and electrodes can significantly improve ionic and electronic conductivity. These interfaces often incorporate materials that are compatible with both the electrolyte and electrode, serving as a buffer layer that facilitates ion transfer while minimizing chemical reactions. Composite interfaces can be formed using polymer-sulfide mixtures, gradient compositions, or specialized coating techniques that reduce interfacial resistance while maintaining mechanical integrity under stack pressure.Expand Specific Solutions04 Mechanical properties and deformation behavior

Understanding the mechanical properties and deformation behavior of sulfide solid electrolytes under stack pressure is critical for ASSLB design. Sulfide electrolytes typically exhibit viscoelastic or plastic deformation under pressure, which affects the contact resistance and overall battery performance. Research focuses on characterizing the mechanical response of these materials, developing models to predict deformation, and designing battery structures that accommodate the unique mechanical properties of sulfide electrolytes while maintaining optimal stack pressure.Expand Specific Solutions05 Pressure distribution and cell design considerations

Even pressure distribution across the battery stack is essential for uniform performance in sulfide ASSLBs. Cell design considerations include the use of pressure distribution layers, specialized housing structures, and mechanical constraints that ensure homogeneous pressure application. Innovative designs incorporate flexible components that can accommodate volume changes during cycling while maintaining consistent contact pressure. These approaches help minimize local stress concentrations that could lead to electrolyte fracture or delamination, thereby extending battery life and improving performance consistency.Expand Specific Solutions

Leading Companies and Research Institutions in ASSLB Development

The all-solid-state lithium battery (ASSLB) market is currently in an early commercialization phase, with stack pressure and contact resistance optimization representing critical technical challenges. The global market is projected to grow significantly, reaching approximately $2-3 billion by 2030, driven by demand for safer, higher-energy-density batteries. Leading players like LG Energy Solution, Samsung SDI, and LG Chem are investing heavily in sulfide-based ASSLB technology, while emerging companies such as Factorial and Gelion Technologies are developing innovative approaches to address interface challenges. Research institutions including KIST, University of Maryland, and Chinese Academy of Sciences are advancing fundamental understanding of pressure-dependent ionic conductivity. The technology remains in pre-commercial maturity, with most major automotive manufacturers (Nissan, Ford, Renault) forming strategic partnerships to accelerate development toward mass production.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a proprietary stack pressure optimization system for sulfide-based ASSLBs that addresses the critical interface challenges. Their technology employs a gradient pressure distribution mechanism that maintains optimal contact at the electrode-electrolyte interfaces while preventing excessive compression of the sulfide solid electrolyte. The company utilizes specialized pressure-sensitive interlayers between the cathode and sulfide electrolyte that can deform elastically under applied pressure, creating more uniform contact points and reducing interfacial resistance by up to 60% compared to conventional designs. Their approach incorporates real-time pressure monitoring sensors embedded within the cell stack to dynamically adjust pressure during cycling, accounting for volume changes that occur during lithiation/delithiation processes. This adaptive pressure control system has demonstrated significant improvements in cycle life, with cells maintaining over 80% capacity after 1000 cycles at room temperature.

Strengths: Advanced pressure distribution technology that significantly reduces contact resistance while preventing electrolyte fracture; integrated pressure monitoring system allows for dynamic adjustment during cycling. Weaknesses: The complex pressure control system adds manufacturing complexity and cost; the technology requires precise calibration for different cell formats and chemistries.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has pioneered a multi-layer interface engineering approach to address stack pressure and contact resistance challenges in sulfide ASSLBs. Their solution incorporates a composite interlayer system between the cathode and sulfide electrolyte consisting of a gradient-structured buffer layer that effectively distributes mechanical stress while maintaining excellent ionic conductivity. This proprietary buffer layer contains nano-engineered particles with core-shell structures that deform plastically under pressure to create optimal contact points without fracturing the brittle sulfide electrolyte. Samsung's technology also features specialized surface treatment of active materials to enhance wettability with the sulfide electrolyte, reducing interfacial resistance by creating chemical bonds that facilitate ion transfer across interfaces. Their pressure optimization protocol involves a precisely controlled thermal-pressure co-treatment process during cell assembly that establishes optimal interfacial contact while minimizing microcracks in the electrolyte layer. Testing has shown this approach reduces interfacial resistance by approximately 70% compared to conventional pressing methods.

Strengths: Sophisticated interface engineering with gradient structures provides excellent ionic conductivity while managing mechanical stress; proprietary surface treatments create chemical bonding at interfaces for reduced resistance. Weaknesses: The complex multi-layer approach increases manufacturing steps and material costs; the technology may be sensitive to temperature fluctuations that affect the mechanical properties of the buffer layers.

Key Patents and Research on ASSLB Contact Resistance Reduction

High-energy all-solid-state lithium batteries

PatentWO2024009303A3

Innovation

- Development of cost-effective sulfide-based cathode materials as an alternative to expensive cobalt and co-based cathode materials for ASSLBs.

- Implementation of high-pressure synthesis technique for creating protective layers that enhance the structural stability of cathode materials.

- Application of atomic layer deposition (ALD) technique to create high-quality interphase coatings that improve interface stability and fast interfacial transport dynamics.

Cathode for all-solid-state battery

PatentActiveUS11855286B2

Innovation

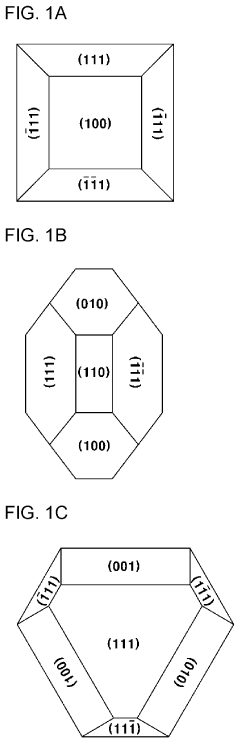

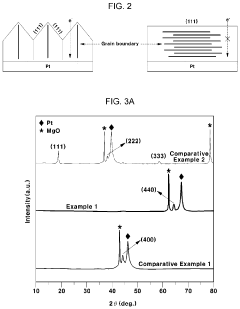

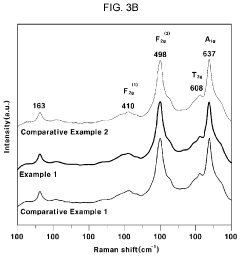

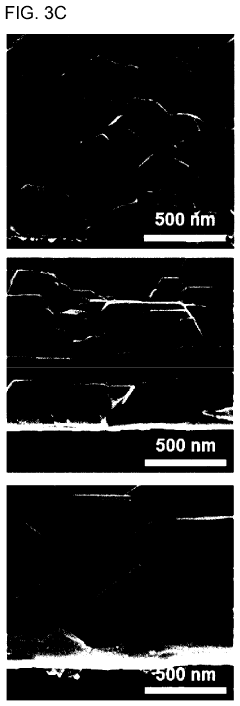

- A cathode for all-solid-state batteries featuring a grain with a grain boundary parallel to the electron movement direction and predominantly having a plane with low surface energy, specifically a compound represented by LiaNibMcNdLeOx with a spinel structure, which suppresses the dissolution and diffusion of transition metals, thereby improving interfacial characteristics without introducing additional materials or processes.

Safety and Stability Considerations for Sulfide-Based ASSLBs

Safety considerations for sulfide-based ASSLBs are paramount due to the reactive nature of sulfide solid electrolytes. These materials are highly sensitive to moisture and air, readily decomposing to produce toxic hydrogen sulfide gas when exposed to ambient conditions. This necessitates stringent handling protocols in both manufacturing and laboratory environments, typically requiring controlled atmosphere gloveboxes with moisture and oxygen levels below 0.1 ppm.

Stack pressure, while essential for reducing interfacial resistance, introduces additional safety concerns. Excessive pressure can lead to mechanical failure of cell components, potentially causing internal short circuits. This risk is particularly pronounced in sulfide systems due to their relatively low mechanical strength compared to oxide-based solid electrolytes.

Thermal stability represents another critical safety consideration. Sulfide electrolytes generally exhibit lower thermal decomposition temperatures than their oxide counterparts. For instance, Li₇P₃S₁₁ begins to decompose at approximately 200°C, while Li₁₀GeP₂S₁₂ shows instability above 300°C. This limited thermal stability narrows the operating temperature window and requires robust thermal management systems to prevent thermal runaway events.

Chemical compatibility between sulfide electrolytes and electrode materials presents ongoing challenges. The narrow electrochemical stability window of most sulfide electrolytes (typically 1.7-2.5V) leads to interfacial decomposition reactions during cycling. These reactions not only degrade battery performance but can also generate potentially hazardous byproducts, particularly at the lithium metal anode interface where dendrite formation remains a persistent safety concern.

Long-term stability under various stack pressure conditions requires careful consideration. While higher pressures improve initial contact resistance, they may accelerate interfacial degradation mechanisms over extended cycling. Research indicates that optimal pressure windows exist (typically 5-20 MPa) where contact resistance is minimized without compromising long-term stability or safety.

Environmental considerations extend beyond operational safety to end-of-life management. The water-reactive nature of sulfide materials presents unique recycling challenges, requiring specialized processes to prevent hazardous gas generation during battery disposal or recycling operations. This aspect has received limited attention in current research but will become increasingly important as commercial deployment expands.

Standardized safety protocols specific to sulfide-based ASSLBs remain underdeveloped compared to liquid electrolyte systems. The industry requires comprehensive safety standards addressing the unique characteristics of these materials, particularly regarding stack pressure management, thermal runaway prevention, and safe handling procedures throughout the battery lifecycle.

Stack pressure, while essential for reducing interfacial resistance, introduces additional safety concerns. Excessive pressure can lead to mechanical failure of cell components, potentially causing internal short circuits. This risk is particularly pronounced in sulfide systems due to their relatively low mechanical strength compared to oxide-based solid electrolytes.

Thermal stability represents another critical safety consideration. Sulfide electrolytes generally exhibit lower thermal decomposition temperatures than their oxide counterparts. For instance, Li₇P₃S₁₁ begins to decompose at approximately 200°C, while Li₁₀GeP₂S₁₂ shows instability above 300°C. This limited thermal stability narrows the operating temperature window and requires robust thermal management systems to prevent thermal runaway events.

Chemical compatibility between sulfide electrolytes and electrode materials presents ongoing challenges. The narrow electrochemical stability window of most sulfide electrolytes (typically 1.7-2.5V) leads to interfacial decomposition reactions during cycling. These reactions not only degrade battery performance but can also generate potentially hazardous byproducts, particularly at the lithium metal anode interface where dendrite formation remains a persistent safety concern.

Long-term stability under various stack pressure conditions requires careful consideration. While higher pressures improve initial contact resistance, they may accelerate interfacial degradation mechanisms over extended cycling. Research indicates that optimal pressure windows exist (typically 5-20 MPa) where contact resistance is minimized without compromising long-term stability or safety.

Environmental considerations extend beyond operational safety to end-of-life management. The water-reactive nature of sulfide materials presents unique recycling challenges, requiring specialized processes to prevent hazardous gas generation during battery disposal or recycling operations. This aspect has received limited attention in current research but will become increasingly important as commercial deployment expands.

Standardized safety protocols specific to sulfide-based ASSLBs remain underdeveloped compared to liquid electrolyte systems. The industry requires comprehensive safety standards addressing the unique characteristics of these materials, particularly regarding stack pressure management, thermal runaway prevention, and safe handling procedures throughout the battery lifecycle.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of sulfide-based ASSLBs faces significant challenges related to stack pressure requirements and contact resistance management. Current production methods for sulfide solid electrolytes typically involve energy-intensive ball milling processes followed by cold pressing, which are difficult to scale efficiently for mass production. The precise pressure control needed to optimize interfacial contact while avoiding electrolyte fracture represents a major hurdle for industrial implementation.

Analysis of manufacturing costs reveals that maintaining uniform stack pressure across large-format cells significantly increases production complexity and equipment costs. Conventional battery assembly lines require substantial modification to incorporate precise pressure application systems, with estimated capital expenditure increases of 30-45% compared to liquid electrolyte battery production lines. The specialized equipment needed for handling pressure-sensitive sulfide materials under inert conditions further elevates manufacturing costs.

Material handling considerations also impact scalability, as sulfide solid electrolytes are moisture-sensitive and require strictly controlled environments during all manufacturing stages. This necessitates investment in advanced dry room facilities or inert gas handling systems, adding approximately $15-20 million in infrastructure costs for a gigawatt-hour scale production facility.

Energy consumption during manufacturing presents another cost factor. The pressure application systems require continuous power to maintain optimal stack pressure, estimated at 2-5 kWh per kWh of battery capacity produced. This represents a 15-25% increase in energy costs compared to conventional lithium-ion battery manufacturing.

Recent innovations in manufacturing approaches show promise for improving scalability. These include the development of pressure-tolerant sulfide electrolyte formulations that maintain conductivity at lower stack pressures, potentially reducing equipment complexity. Additionally, advanced coating technologies that enhance interfacial contact without requiring high external pressures could significantly reduce manufacturing constraints.

Economic modeling indicates that at current technology readiness levels, the manufacturing cost premium for sulfide ASSLBs is approximately 30-40% higher than conventional lithium-ion batteries. However, sensitivity analysis suggests that advances in pressure-independent interface engineering could reduce this premium to 15-20% within five years, potentially enabling cost-competitive production at scale.

For successful commercialization, development of specialized manufacturing equipment specifically designed for pressure-controlled assembly of sulfide-based cells will be essential. This represents both a challenge and an opportunity for equipment manufacturers to develop novel solutions for this emerging battery technology.

Analysis of manufacturing costs reveals that maintaining uniform stack pressure across large-format cells significantly increases production complexity and equipment costs. Conventional battery assembly lines require substantial modification to incorporate precise pressure application systems, with estimated capital expenditure increases of 30-45% compared to liquid electrolyte battery production lines. The specialized equipment needed for handling pressure-sensitive sulfide materials under inert conditions further elevates manufacturing costs.

Material handling considerations also impact scalability, as sulfide solid electrolytes are moisture-sensitive and require strictly controlled environments during all manufacturing stages. This necessitates investment in advanced dry room facilities or inert gas handling systems, adding approximately $15-20 million in infrastructure costs for a gigawatt-hour scale production facility.

Energy consumption during manufacturing presents another cost factor. The pressure application systems require continuous power to maintain optimal stack pressure, estimated at 2-5 kWh per kWh of battery capacity produced. This represents a 15-25% increase in energy costs compared to conventional lithium-ion battery manufacturing.

Recent innovations in manufacturing approaches show promise for improving scalability. These include the development of pressure-tolerant sulfide electrolyte formulations that maintain conductivity at lower stack pressures, potentially reducing equipment complexity. Additionally, advanced coating technologies that enhance interfacial contact without requiring high external pressures could significantly reduce manufacturing constraints.

Economic modeling indicates that at current technology readiness levels, the manufacturing cost premium for sulfide ASSLBs is approximately 30-40% higher than conventional lithium-ion batteries. However, sensitivity analysis suggests that advances in pressure-independent interface engineering could reduce this premium to 15-20% within five years, potentially enabling cost-competitive production at scale.

For successful commercialization, development of specialized manufacturing equipment specifically designed for pressure-controlled assembly of sulfide-based cells will be essential. This represents both a challenge and an opportunity for equipment manufacturers to develop novel solutions for this emerging battery technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!