Scaling Cathode Areal Capacity Above 6 mAh cm-2 With Sulfide SSEs

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Capacity Cathode Development Background and Objectives

The evolution of lithium-ion battery technology has been marked by continuous efforts to enhance energy density, power capability, and safety. In recent years, the development of solid-state batteries has emerged as a promising direction to overcome the limitations of conventional liquid electrolyte systems. Within this context, achieving high cathode areal capacity exceeding 6 mAh cm-2 with sulfide solid-state electrolytes (SSEs) represents a critical technological frontier that could revolutionize energy storage systems.

Historically, commercial lithium-ion batteries have operated with cathode areal capacities of 2-4 mAh cm-2, which has been sufficient for consumer electronics but inadequate for demanding applications such as electric vehicles and grid storage. The technological trajectory has been moving toward higher energy densities through materials innovation and electrode engineering, with solid-state technology representing the next significant leap forward.

Sulfide-based solid-state electrolytes have garnered substantial attention due to their high ionic conductivity comparable to liquid electrolytes (>10-3 S cm-1 at room temperature) and favorable mechanical properties that allow good contact with electrode materials. However, integrating these materials with high-capacity cathodes presents unique challenges that must be addressed to realize their full potential.

The primary objective of developing high-capacity cathodes with sulfide SSEs is to achieve energy densities exceeding 500 Wh/kg at the cell level, which would represent a significant improvement over current lithium-ion technology (250-300 Wh/kg). This advancement would enable electric vehicles with driving ranges comparable to conventional combustion engine vehicles while maintaining competitive costs and safety profiles.

Technical goals include developing cathode architectures that can accommodate volumetric changes during cycling, establishing effective interfaces between cathode materials and sulfide electrolytes, and ensuring uniform lithium-ion transport throughout thick electrode structures. Additionally, the technology aims to maintain high capacity retention over thousands of cycles while operating at practical current densities.

The evolution trend points toward multi-component cathode systems that combine high-capacity active materials (such as nickel-rich NCM or sulfur) with engineered conductive networks and specialized interface modifiers. Computational modeling and advanced characterization techniques are increasingly being employed to understand fundamental mechanisms and accelerate materials discovery.

Achieving these ambitious goals would position solid-state battery technology as a viable successor to conventional lithium-ion batteries, potentially triggering a paradigm shift in energy storage applications ranging from portable electronics to transportation and stationary storage systems. The technological roadmap envisions commercial implementation within the next 5-10 years, contingent upon overcoming the remaining scientific and engineering challenges.

Historically, commercial lithium-ion batteries have operated with cathode areal capacities of 2-4 mAh cm-2, which has been sufficient for consumer electronics but inadequate for demanding applications such as electric vehicles and grid storage. The technological trajectory has been moving toward higher energy densities through materials innovation and electrode engineering, with solid-state technology representing the next significant leap forward.

Sulfide-based solid-state electrolytes have garnered substantial attention due to their high ionic conductivity comparable to liquid electrolytes (>10-3 S cm-1 at room temperature) and favorable mechanical properties that allow good contact with electrode materials. However, integrating these materials with high-capacity cathodes presents unique challenges that must be addressed to realize their full potential.

The primary objective of developing high-capacity cathodes with sulfide SSEs is to achieve energy densities exceeding 500 Wh/kg at the cell level, which would represent a significant improvement over current lithium-ion technology (250-300 Wh/kg). This advancement would enable electric vehicles with driving ranges comparable to conventional combustion engine vehicles while maintaining competitive costs and safety profiles.

Technical goals include developing cathode architectures that can accommodate volumetric changes during cycling, establishing effective interfaces between cathode materials and sulfide electrolytes, and ensuring uniform lithium-ion transport throughout thick electrode structures. Additionally, the technology aims to maintain high capacity retention over thousands of cycles while operating at practical current densities.

The evolution trend points toward multi-component cathode systems that combine high-capacity active materials (such as nickel-rich NCM or sulfur) with engineered conductive networks and specialized interface modifiers. Computational modeling and advanced characterization techniques are increasingly being employed to understand fundamental mechanisms and accelerate materials discovery.

Achieving these ambitious goals would position solid-state battery technology as a viable successor to conventional lithium-ion batteries, potentially triggering a paradigm shift in energy storage applications ranging from portable electronics to transportation and stationary storage systems. The technological roadmap envisions commercial implementation within the next 5-10 years, contingent upon overcoming the remaining scientific and engineering challenges.

Market Analysis for High Energy Density Solid-State Batteries

The global solid-state battery market is experiencing significant growth, driven by increasing demand for high energy density power solutions across multiple sectors. Current market valuations place the solid-state battery market at approximately $500 million in 2023, with projections indicating a compound annual growth rate (CAGR) of 34-36% through 2030, potentially reaching $8-10 billion by the end of the decade.

High energy density solid-state batteries featuring sulfide solid-state electrolytes (SSEs) with cathode areal capacities above 6 mAh cm-2 represent a particularly promising segment within this market. This advanced technology addresses critical pain points in current lithium-ion battery limitations, especially for electric vehicles (EVs) and consumer electronics applications.

The EV market serves as the primary driver for high-capacity solid-state battery demand, accounting for roughly 60% of potential applications. With global EV sales exceeding 10 million units in 2022 and growing at 35% annually, automakers are actively seeking battery technologies that can deliver greater range, faster charging, and enhanced safety profiles. Major automotive manufacturers including Toyota, Volkswagen, and BMW have announced significant investments totaling over $13 billion in solid-state battery development programs specifically targeting high energy density solutions.

Consumer electronics represents the second largest market segment at approximately 25% of potential applications. Smartphone manufacturers face increasing pressure to extend battery life while maintaining or reducing device thickness, creating strong demand for batteries with higher energy density. Apple, Samsung, and other major electronics companies have established dedicated research divisions focused on solid-state battery integration.

Grid storage applications constitute an emerging market segment (10-12% of potential applications) where high-capacity solid-state batteries could provide advantages in safety and longevity compared to current lithium-ion solutions. This sector is projected to grow at 25% annually through 2028.

Regional analysis indicates Asia-Pacific dominates the current market landscape with approximately 45% share, led by Japan and South Korea where companies like Toyota, Samsung, and LG are heavily invested in sulfide SSE technology. North America follows at 30%, with significant research activities concentrated in California and Massachusetts. Europe accounts for 20% of the market, with particularly strong growth in Germany and France.

Key market barriers include high production costs (currently 4-5 times higher than conventional lithium-ion batteries), manufacturing scalability challenges, and competition from other advanced battery technologies. However, industry analysts project that achieving cathode areal capacities above 6 mAh cm-2 with sulfide SSEs could reduce production costs by 30-40% through material efficiency improvements, potentially accelerating market adoption significantly.

High energy density solid-state batteries featuring sulfide solid-state electrolytes (SSEs) with cathode areal capacities above 6 mAh cm-2 represent a particularly promising segment within this market. This advanced technology addresses critical pain points in current lithium-ion battery limitations, especially for electric vehicles (EVs) and consumer electronics applications.

The EV market serves as the primary driver for high-capacity solid-state battery demand, accounting for roughly 60% of potential applications. With global EV sales exceeding 10 million units in 2022 and growing at 35% annually, automakers are actively seeking battery technologies that can deliver greater range, faster charging, and enhanced safety profiles. Major automotive manufacturers including Toyota, Volkswagen, and BMW have announced significant investments totaling over $13 billion in solid-state battery development programs specifically targeting high energy density solutions.

Consumer electronics represents the second largest market segment at approximately 25% of potential applications. Smartphone manufacturers face increasing pressure to extend battery life while maintaining or reducing device thickness, creating strong demand for batteries with higher energy density. Apple, Samsung, and other major electronics companies have established dedicated research divisions focused on solid-state battery integration.

Grid storage applications constitute an emerging market segment (10-12% of potential applications) where high-capacity solid-state batteries could provide advantages in safety and longevity compared to current lithium-ion solutions. This sector is projected to grow at 25% annually through 2028.

Regional analysis indicates Asia-Pacific dominates the current market landscape with approximately 45% share, led by Japan and South Korea where companies like Toyota, Samsung, and LG are heavily invested in sulfide SSE technology. North America follows at 30%, with significant research activities concentrated in California and Massachusetts. Europe accounts for 20% of the market, with particularly strong growth in Germany and France.

Key market barriers include high production costs (currently 4-5 times higher than conventional lithium-ion batteries), manufacturing scalability challenges, and competition from other advanced battery technologies. However, industry analysts project that achieving cathode areal capacities above 6 mAh cm-2 with sulfide SSEs could reduce production costs by 30-40% through material efficiency improvements, potentially accelerating market adoption significantly.

Technical Challenges in Scaling Cathode Areal Capacity

Scaling cathode areal capacity beyond conventional limits represents one of the most significant challenges in solid-state battery development. Current commercial lithium-ion batteries typically operate with cathode loadings of 2-4 mAh cm-2, which limits energy density at the cell level. Achieving areal capacities above 6 mAh cm-2 with sulfide solid-state electrolytes (SSEs) requires overcoming multiple interdependent technical barriers.

The primary challenge stems from the inherent trade-off between electrode thickness and ionic conductivity. As cathode thickness increases to accommodate higher active material loading, the ionic transport pathway lengthens substantially, creating significant resistance to lithium-ion movement. This resistance manifests as concentration polarization during cycling, particularly at high current densities, leading to capacity fade and reduced rate capability.

Interface stability presents another critical obstacle. The cathode-electrolyte interface experiences high mechanical stress during cycling due to volume changes in the active material. With thicker electrodes, these stresses are magnified, potentially causing delamination, contact loss, and formation of resistive interfacial layers. Sulfide SSEs are particularly susceptible to these issues due to their relatively low mechanical strength compared to oxide-based alternatives.

Electronic conductivity limitations further complicate high-loading designs. Traditional cathode compositions rely on carbon additives for electronic conduction, but excessive carbon can disrupt the ionic pathways in solid-state systems. Finding the optimal balance between electronic conductivity and maintaining solid-state ionic transport becomes increasingly difficult as electrode thickness grows.

Manufacturing challenges also emerge when scaling cathode loading. Conventional slurry-based coating processes struggle to produce uniform, crack-free thick electrodes. The drying process introduces significant stresses that can lead to mechanical failure before the battery even enters service. Alternative processing techniques like dry powder coating show promise but remain in early development stages.

Thermal management concerns intensify with higher areal capacities. Thicker electrodes generate and retain more heat during operation, potentially triggering thermal runaway or accelerating degradation mechanisms in sulfide SSEs, which typically have lower thermal stability thresholds than liquid electrolytes.

Addressing these challenges requires a multidisciplinary approach combining materials science innovations, engineering solutions, and advanced manufacturing techniques. Recent research has explored hierarchical electrode architectures, novel composite formulations, and gradient structures to mitigate these limitations, but commercial implementation remains elusive.

The primary challenge stems from the inherent trade-off between electrode thickness and ionic conductivity. As cathode thickness increases to accommodate higher active material loading, the ionic transport pathway lengthens substantially, creating significant resistance to lithium-ion movement. This resistance manifests as concentration polarization during cycling, particularly at high current densities, leading to capacity fade and reduced rate capability.

Interface stability presents another critical obstacle. The cathode-electrolyte interface experiences high mechanical stress during cycling due to volume changes in the active material. With thicker electrodes, these stresses are magnified, potentially causing delamination, contact loss, and formation of resistive interfacial layers. Sulfide SSEs are particularly susceptible to these issues due to their relatively low mechanical strength compared to oxide-based alternatives.

Electronic conductivity limitations further complicate high-loading designs. Traditional cathode compositions rely on carbon additives for electronic conduction, but excessive carbon can disrupt the ionic pathways in solid-state systems. Finding the optimal balance between electronic conductivity and maintaining solid-state ionic transport becomes increasingly difficult as electrode thickness grows.

Manufacturing challenges also emerge when scaling cathode loading. Conventional slurry-based coating processes struggle to produce uniform, crack-free thick electrodes. The drying process introduces significant stresses that can lead to mechanical failure before the battery even enters service. Alternative processing techniques like dry powder coating show promise but remain in early development stages.

Thermal management concerns intensify with higher areal capacities. Thicker electrodes generate and retain more heat during operation, potentially triggering thermal runaway or accelerating degradation mechanisms in sulfide SSEs, which typically have lower thermal stability thresholds than liquid electrolytes.

Addressing these challenges requires a multidisciplinary approach combining materials science innovations, engineering solutions, and advanced manufacturing techniques. Recent research has explored hierarchical electrode architectures, novel composite formulations, and gradient structures to mitigate these limitations, but commercial implementation remains elusive.

Current Approaches to High-Loading Cathode Design

01 High-capacity cathode materials for sulfide SSEs

Various high-capacity cathode materials can be paired with sulfide solid-state electrolytes to achieve improved areal capacity. These materials include lithium-rich layered oxides, nickel-rich NMC (nickel manganese cobalt) cathodes, and sulfur-based cathodes. The selection of compatible cathode materials is critical as they must maintain good interfacial contact with the sulfide electrolyte while delivering high capacity per unit area.- High-loading cathodes for increased areal capacity: Developing high-loading cathodes is crucial for achieving increased areal capacity in sulfide solid-state batteries. These cathodes incorporate higher amounts of active material while maintaining good contact with the sulfide solid-state electrolyte. Techniques include optimizing particle size distribution, using hierarchical structures, and controlling porosity to accommodate volume changes during cycling while maximizing active material loading. These approaches can significantly enhance the energy density of solid-state batteries.

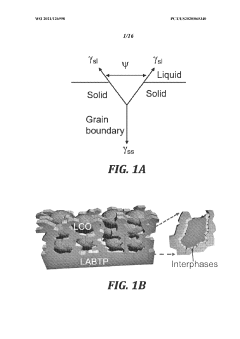

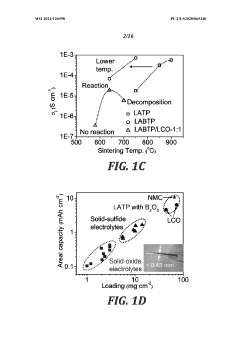

- Interface engineering between cathode and sulfide electrolyte: Interface engineering between the cathode and sulfide solid-state electrolyte is essential for improving areal capacity. This involves creating stable interfaces that minimize chemical and electrochemical reactions while enhancing ion transport. Techniques include applying protective coatings on cathode particles, introducing buffer layers, and developing gradient interfaces. These approaches reduce interfacial resistance, prevent side reactions, and maintain good mechanical contact during cycling, resulting in improved capacity retention and higher areal capacities.

- Composite cathodes with optimized electrolyte distribution: Composite cathodes with optimized sulfide electrolyte distribution enhance ionic conductivity throughout the electrode, leading to improved areal capacity. These composites typically contain active material, sulfide solid-state electrolyte, and sometimes conductive additives in carefully controlled ratios. The uniform distribution of the electrolyte ensures efficient lithium-ion transport pathways, reduces concentration polarization, and enables higher utilization of active materials, especially at high loading conditions.

- Novel cathode materials compatible with sulfide electrolytes: Development of novel cathode materials specifically designed to be compatible with sulfide solid-state electrolytes can significantly improve areal capacity. These materials often feature modified surface chemistry, doped structures, or core-shell architectures that minimize detrimental reactions with sulfide electrolytes. By reducing chemical incompatibilities and enhancing electrochemical stability, these materials enable higher loading densities and improved utilization of active materials, resulting in enhanced areal capacities.

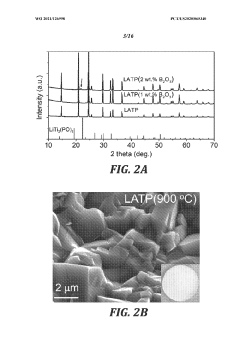

- Advanced manufacturing techniques for high-density cathodes: Advanced manufacturing techniques enable the production of high-density cathodes with improved areal capacity when used with sulfide solid-state electrolytes. These techniques include controlled pressure sintering, solution-based processing methods, and novel deposition approaches that create optimized microstructures. By precisely controlling porosity, particle arrangement, and interfacial contacts, these manufacturing methods enhance ionic and electronic transport while accommodating volume changes during cycling, leading to higher areal capacities.

02 Interface engineering between cathode and sulfide electrolyte

Engineering the interface between cathode materials and sulfide solid-state electrolytes is crucial for achieving high areal capacity. Techniques include applying protective coatings on cathode particles, using buffer layers to prevent chemical reactions, and developing gradient interfaces. These approaches minimize interfacial resistance and prevent degradation reactions that can limit the practical areal capacity of the battery system.Expand Specific Solutions03 Composite cathode structures with sulfide electrolytes

Composite cathode structures incorporating sulfide solid-state electrolytes can enhance ionic conductivity throughout the cathode, leading to improved areal capacity. These composites typically combine active cathode materials, sulfide electrolytes, and conductive additives in optimized ratios. The three-dimensional network formed allows for better lithium-ion transport and utilization of the active material, resulting in higher practical capacities.Expand Specific Solutions04 Cathode thickness optimization for sulfide-based solid-state batteries

Optimizing cathode thickness is essential for maximizing areal capacity in sulfide-based solid-state batteries. Thicker cathodes can accommodate more active material but face challenges related to ion transport limitations. Advanced manufacturing techniques and cathode formulations allow for increased thickness while maintaining efficient ion transport pathways, thereby achieving higher areal capacities without sacrificing rate performance.Expand Specific Solutions05 Pressure-assisted techniques for improving cathode-electrolyte contact

Pressure-assisted techniques can significantly improve the contact between cathode materials and sulfide solid-state electrolytes, leading to enhanced areal capacity. These methods include hot pressing, cold sintering, and stack pressure optimization during battery assembly. Better physical contact reduces interfacial resistance and improves the utilization of active materials, resulting in batteries with higher areal capacity and improved cycling stability.Expand Specific Solutions

Leading Companies in Solid-State Battery Technology

The scaling of cathode areal capacity above 6 mAh cm-2 with sulfide solid-state electrolytes (SSEs) represents an emerging frontier in battery technology, currently in early commercialization stages. The market is expanding rapidly, driven by electric vehicle demand, with projections exceeding $10 billion by 2030. Technologically, the field shows varied maturity levels across competitors. Academic institutions (MIT, Cornell, University of Washington) are advancing fundamental research, while established manufacturers (LG Energy Solution, Samsung SDI, Tesla) are scaling commercial applications. Specialized companies like Honeycomb Battery, PolyPlus, and Sila Nanotechnologies are developing innovative materials solutions. Chinese entities (Zhejiang Fengli, Suzhou Qingtao) are rapidly gaining ground through aggressive R&D investments, creating a globally competitive landscape with significant regional innovation clusters.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an innovative approach to scaling cathode areal capacity above 6 mAh cm-2 with sulfide solid-state electrolytes (SSEs). Their technology employs a multi-layer cathode architecture with gradient porosity design that facilitates optimal ion transport while maintaining mechanical integrity. The company utilizes high-nickel NCM cathodes (typically NCM9055) combined with proprietary sulfide electrolytes featuring enhanced ionic conductivity (>10 mS/cm at room temperature). A key innovation is their "pressure-less" sintering technique that creates robust cathode-electrolyte interfaces without compromising the sulfide SSE stability. LG's solution incorporates a specialized carbon-based conductive network that maintains electronic pathways throughout the thick cathode (>100 μm), enabling high loading without sacrificing rate capability. Their manufacturing process includes a solvent-free dry mixing approach that prevents degradation of sulfide electrolytes while ensuring homogeneous distribution throughout the cathode matrix.

Strengths: Superior energy density (>900 Wh/L) due to high areal capacity achievement; excellent cycle stability with >80% capacity retention after 500 cycles; scalable manufacturing process compatible with existing production lines. Weaknesses: Higher production costs compared to conventional lithium-ion batteries; temperature sensitivity of sulfide electrolytes requiring controlled operating environments; potential safety concerns with some sulfide compositions that may generate H2S upon exposure to moisture.

24M Technologies, Inc.

Technical Solution: 24M Technologies has developed a revolutionary approach to high-loading sulfide-based solid-state batteries through their proprietary semi-solid electrode technology. Their solution for achieving cathode areal capacities above 6 mAh cm-2 leverages a unique "clay-like" cathode formulation that combines active materials, sulfide SSEs, and minimal liquid phase to create a flowable yet stable electrode structure. 24M employs specialized Li-rich cathode materials with engineered particle morphologies that maximize active material packing while maintaining sufficient ion transport pathways. Their technology incorporates a gradient-functional design where cathode composition varies through the electrode thickness, optimizing both electronic and ionic conductivity. A key innovation is their low-pressure cell assembly process that creates intimate contact between cathode components and sulfide electrolytes without mechanical degradation. 24M has also developed proprietary interface engineering techniques that minimize cathode-electrolyte interfacial resistance while preventing unwanted side reactions. Their manufacturing approach eliminates conventional electrode fabrication steps like coating, drying, and calendering, instead using a direct deposition process that enables precise control of thick electrode structures.

Strengths: Simplified manufacturing process reducing production costs by up to 40%; excellent mechanical stability during cycling with minimal capacity fade; ability to create ultra-thick electrodes (>200 μm) with maintained rate capability. Weaknesses: Requires specialized manufacturing equipment not compatible with existing battery production lines; challenges with precise control of electrode homogeneity at scale; potential limitations in power density compared to conventional designs.

Critical Patents in High-Capacity Sulfide-Based Systems

Solid-state battery cathodes and methods thereof

PatentWO2021126998A1

Innovation

- The use of low-melting-point additives, such as B2O3, for liquid-phase sintering to create mixed conductive interphases at lower temperatures, reducing sintering temperatures and minimizing side reactions, while achieving high electronic and ionic conductivity, mechanical deformability, and high oxidation potential, thereby enhancing cathode performance.

Solid-state cathode composition

PatentPendingUS20250167203A1

Innovation

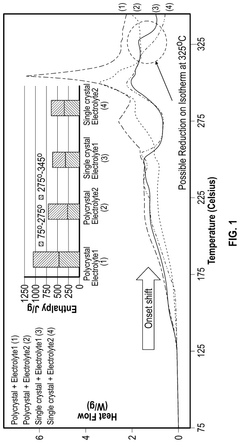

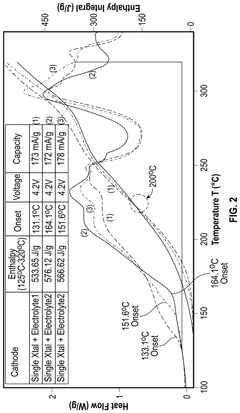

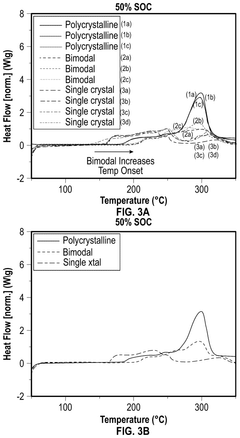

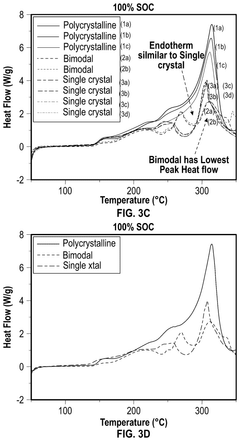

- A cathode composite composition comprising a blend of single-crystal and polycrystalline cathode active materials combined with a solid sulfide electrolyte, such as Li7−yPS6−yXy, where 0≤y≤2 and X is a halogen, which reduces the exothermic reaction and enhances safety.

Manufacturing Scalability Assessment

The scalability of manufacturing processes for high areal capacity cathodes (>6 mAh cm-2) with sulfide solid-state electrolytes (SSEs) presents significant challenges that must be addressed for commercial viability. Current laboratory-scale production methods typically involve manual batch processes that are difficult to translate to industrial scales without substantial modifications.

The primary manufacturing challenge lies in maintaining uniform electrolyte distribution throughout thicker cathode structures. As cathode thickness increases to accommodate higher areal capacities, conventional slurry-based coating methods encounter limitations in achieving homogeneous sulfide SSE distribution. This non-uniformity creates resistance pathways that compromise electrochemical performance and cycle life.

Equipment compatibility represents another critical consideration. Sulfide SSEs are highly sensitive to moisture and oxygen, necessitating specialized handling environments throughout the manufacturing process. Current industrial battery production lines would require significant retrofitting with advanced dry room facilities or inert atmosphere processing chambers, substantially increasing capital expenditure requirements.

Material wastage during manufacturing poses economic challenges. Sulfide SSEs are typically more expensive than liquid electrolytes, and current processing methods can result in material losses of 15-30%. Developing more efficient deposition techniques and material recovery systems is essential for cost-effective scaling.

Energy consumption during processing also impacts manufacturing scalability. The cold pressing and subsequent heat treatment steps commonly used for sulfide SSE integration require precise temperature control and significant energy input. Optimizing these energy-intensive processes is necessary for sustainable large-scale production.

Quality control methodologies need substantial advancement for high-volume manufacturing. Current analytical techniques for evaluating sulfide SSE distribution within thick cathodes are predominantly destructive and time-consuming. Development of in-line, non-destructive testing methods would significantly enhance manufacturing efficiency and product consistency.

The supply chain for high-purity sulfide SSE materials remains underdeveloped compared to conventional battery materials. Scaling production would require establishing robust supplier networks capable of delivering consistent, high-quality materials at volumes orders of magnitude greater than current capabilities.

Based on technology readiness assessments, the manufacturing scalability of high areal capacity cathodes with sulfide SSEs currently sits at TRL 4-5, indicating validation in laboratory environments but significant challenges remaining before industrial implementation. A coordinated approach addressing material handling, process optimization, and equipment development is essential to advance manufacturing readiness.

The primary manufacturing challenge lies in maintaining uniform electrolyte distribution throughout thicker cathode structures. As cathode thickness increases to accommodate higher areal capacities, conventional slurry-based coating methods encounter limitations in achieving homogeneous sulfide SSE distribution. This non-uniformity creates resistance pathways that compromise electrochemical performance and cycle life.

Equipment compatibility represents another critical consideration. Sulfide SSEs are highly sensitive to moisture and oxygen, necessitating specialized handling environments throughout the manufacturing process. Current industrial battery production lines would require significant retrofitting with advanced dry room facilities or inert atmosphere processing chambers, substantially increasing capital expenditure requirements.

Material wastage during manufacturing poses economic challenges. Sulfide SSEs are typically more expensive than liquid electrolytes, and current processing methods can result in material losses of 15-30%. Developing more efficient deposition techniques and material recovery systems is essential for cost-effective scaling.

Energy consumption during processing also impacts manufacturing scalability. The cold pressing and subsequent heat treatment steps commonly used for sulfide SSE integration require precise temperature control and significant energy input. Optimizing these energy-intensive processes is necessary for sustainable large-scale production.

Quality control methodologies need substantial advancement for high-volume manufacturing. Current analytical techniques for evaluating sulfide SSE distribution within thick cathodes are predominantly destructive and time-consuming. Development of in-line, non-destructive testing methods would significantly enhance manufacturing efficiency and product consistency.

The supply chain for high-purity sulfide SSE materials remains underdeveloped compared to conventional battery materials. Scaling production would require establishing robust supplier networks capable of delivering consistent, high-quality materials at volumes orders of magnitude greater than current capabilities.

Based on technology readiness assessments, the manufacturing scalability of high areal capacity cathodes with sulfide SSEs currently sits at TRL 4-5, indicating validation in laboratory environments but significant challenges remaining before industrial implementation. A coordinated approach addressing material handling, process optimization, and equipment development is essential to advance manufacturing readiness.

Safety and Performance Benchmarking

Safety and performance benchmarking for high areal capacity cathodes with sulfide solid-state electrolytes (SSEs) requires rigorous evaluation protocols to ensure both operational safety and competitive performance metrics. Current industry standards typically assess cathodes with areal capacities below 4 mAh cm-2, making benchmarking for capacities above 6 mAh cm-2 particularly challenging.

From a safety perspective, sulfide SSEs present unique considerations compared to conventional liquid electrolyte systems. These materials demonstrate improved thermal stability with reduced risk of thermal runaway, but may generate toxic H2S gas when exposed to moisture. Benchmark testing must therefore include hermetic sealing evaluation and gas evolution monitoring under various operating conditions and failure modes.

Mechanical stability represents another critical benchmarking parameter. High-loading cathodes (>6 mAh cm-2) experience significant volume changes during cycling, creating substantial interfacial stress. Standard protocols now incorporate pressure-controlled cycling tests and acoustic emission analysis to quantify mechanical degradation thresholds specific to sulfide SSE systems.

Performance benchmarking for these advanced cathodes focuses on several key metrics. Energy density measurements must account for both gravimetric (Wh/kg) and volumetric (Wh/L) parameters, with current high-loading sulfide SSE cells achieving 350-400 Wh/kg at the cell level. Rate capability testing reveals that most sulfide SSE systems with high-loading cathodes maintain only 60-70% capacity retention at 1C rates compared to C/10 rates.

Cycle life benchmarking shows current state-of-the-art systems achieving 80% capacity retention after 500-700 cycles at moderate temperatures (25°C), but performance degrades significantly at elevated temperatures (>45°C) or during fast charging protocols. Industry leaders have established a benchmark target of 1,000 cycles with less than 20% capacity fade for commercial viability.

Cost-performance metrics indicate that while high-loading cathodes reduce inactive material costs, the increased complexity of manufacturing thick electrodes with sulfide SSEs currently adds 15-25% to production costs compared to conventional lithium-ion batteries. Benchmark analyses suggest these costs will decrease as manufacturing processes mature, potentially reaching cost parity by 2025-2027.

From a safety perspective, sulfide SSEs present unique considerations compared to conventional liquid electrolyte systems. These materials demonstrate improved thermal stability with reduced risk of thermal runaway, but may generate toxic H2S gas when exposed to moisture. Benchmark testing must therefore include hermetic sealing evaluation and gas evolution monitoring under various operating conditions and failure modes.

Mechanical stability represents another critical benchmarking parameter. High-loading cathodes (>6 mAh cm-2) experience significant volume changes during cycling, creating substantial interfacial stress. Standard protocols now incorporate pressure-controlled cycling tests and acoustic emission analysis to quantify mechanical degradation thresholds specific to sulfide SSE systems.

Performance benchmarking for these advanced cathodes focuses on several key metrics. Energy density measurements must account for both gravimetric (Wh/kg) and volumetric (Wh/L) parameters, with current high-loading sulfide SSE cells achieving 350-400 Wh/kg at the cell level. Rate capability testing reveals that most sulfide SSE systems with high-loading cathodes maintain only 60-70% capacity retention at 1C rates compared to C/10 rates.

Cycle life benchmarking shows current state-of-the-art systems achieving 80% capacity retention after 500-700 cycles at moderate temperatures (25°C), but performance degrades significantly at elevated temperatures (>45°C) or during fast charging protocols. Industry leaders have established a benchmark target of 1,000 cycles with less than 20% capacity fade for commercial viability.

Cost-performance metrics indicate that while high-loading cathodes reduce inactive material costs, the increased complexity of manufacturing thick electrodes with sulfide SSEs currently adds 15-25% to production costs compared to conventional lithium-ion batteries. Benchmark analyses suggest these costs will decrease as manufacturing processes mature, potentially reaching cost parity by 2025-2027.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!