Cold-Press Densification Versus Sintering For Sulfide Solid Electrolytes

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulfide Solid Electrolytes: Background and Objectives

Sulfide solid electrolytes have emerged as promising candidates for next-generation all-solid-state batteries (ASSBs) due to their high ionic conductivity comparable to liquid electrolytes. The development of these materials can be traced back to the 1980s, when researchers first identified sulfide-based glasses with significant lithium-ion conductivity. Over the past four decades, substantial progress has been made in enhancing their properties and understanding their fundamental characteristics.

The evolution of sulfide solid electrolytes has been marked by several breakthrough discoveries, including the identification of thio-LISICON structures in the early 2000s and the development of Li10GeP2S12 (LGPS) in 2011, which demonstrated unprecedented room-temperature ionic conductivity exceeding 10 mS/cm. This milestone catalyzed intensive research efforts worldwide, establishing sulfide electrolytes as leading candidates for practical solid-state battery applications.

Despite their promising ionic conductivity, sulfide solid electrolytes face significant challenges related to their mechanical properties, air/moisture sensitivity, and interfacial stability with electrode materials. These limitations have necessitated the development of various processing techniques to optimize their performance in battery systems, with cold-press densification and sintering emerging as two primary approaches.

Cold-press densification offers advantages in maintaining the original structure and composition of sulfide electrolytes while achieving reasonable ionic contact, whereas sintering techniques can potentially enhance grain boundary conductivity but risk compositional changes and crystallization that may affect overall performance. The tension between these processing approaches represents a critical technical challenge that must be resolved to advance sulfide-based ASSBs toward commercialization.

The primary objective of this technical research is to comprehensively evaluate the relative merits and limitations of cold-press densification versus sintering techniques for sulfide solid electrolytes. This assessment aims to identify optimal processing conditions that maximize ionic conductivity while maintaining mechanical integrity and electrochemical stability within practical battery configurations.

Additionally, this research seeks to establish clear correlations between processing parameters and resulting electrolyte properties, develop predictive models for performance optimization, and propose innovative hybrid approaches that might combine the advantages of both techniques. The ultimate goal is to establish processing guidelines that enable the scalable production of high-performance sulfide solid electrolytes suitable for next-generation energy storage applications.

The evolution of sulfide solid electrolytes has been marked by several breakthrough discoveries, including the identification of thio-LISICON structures in the early 2000s and the development of Li10GeP2S12 (LGPS) in 2011, which demonstrated unprecedented room-temperature ionic conductivity exceeding 10 mS/cm. This milestone catalyzed intensive research efforts worldwide, establishing sulfide electrolytes as leading candidates for practical solid-state battery applications.

Despite their promising ionic conductivity, sulfide solid electrolytes face significant challenges related to their mechanical properties, air/moisture sensitivity, and interfacial stability with electrode materials. These limitations have necessitated the development of various processing techniques to optimize their performance in battery systems, with cold-press densification and sintering emerging as two primary approaches.

Cold-press densification offers advantages in maintaining the original structure and composition of sulfide electrolytes while achieving reasonable ionic contact, whereas sintering techniques can potentially enhance grain boundary conductivity but risk compositional changes and crystallization that may affect overall performance. The tension between these processing approaches represents a critical technical challenge that must be resolved to advance sulfide-based ASSBs toward commercialization.

The primary objective of this technical research is to comprehensively evaluate the relative merits and limitations of cold-press densification versus sintering techniques for sulfide solid electrolytes. This assessment aims to identify optimal processing conditions that maximize ionic conductivity while maintaining mechanical integrity and electrochemical stability within practical battery configurations.

Additionally, this research seeks to establish clear correlations between processing parameters and resulting electrolyte properties, develop predictive models for performance optimization, and propose innovative hybrid approaches that might combine the advantages of both techniques. The ultimate goal is to establish processing guidelines that enable the scalable production of high-performance sulfide solid electrolytes suitable for next-generation energy storage applications.

Market Analysis for Solid-State Battery Technologies

The global solid-state battery market is experiencing significant growth, driven by increasing demand for safer, higher energy density power solutions across multiple sectors. Current market valuations place the solid-state battery sector at approximately $500 million in 2023, with projections indicating potential growth to reach $8-10 billion by 2030, representing a compound annual growth rate (CAGR) of over 34% during this forecast period.

Within this expanding market, sulfide-based solid electrolytes have emerged as a particularly promising segment due to their superior ionic conductivity compared to oxide and polymer alternatives. The manufacturing methods for these electrolytes—specifically cold-press densification versus sintering—represent a critical decision point for manufacturers that directly impacts production costs, scalability, and final product performance.

Market analysis reveals that automotive applications currently dominate demand for solid-state batteries incorporating sulfide electrolytes, accounting for approximately 45% of market interest. Major automotive manufacturers including Toyota, BMW, and Volkswagen have announced significant investments in sulfide-based solid-state battery technology, with commercialization targets set between 2025-2028.

Consumer electronics represents the second largest application segment at 30% market share, with manufacturers seeking higher energy density and improved safety profiles. The remaining market distribution spans aerospace, medical devices, and grid storage applications, each with specific performance requirements that influence manufacturing method selection.

Regional analysis shows Asia-Pacific leading market development with 55% share, primarily driven by Japan and South Korea's advanced research infrastructure and manufacturing capabilities in sulfide electrolyte processing. North America follows at 25%, with significant research initiatives focused on cold-press techniques that promise lower energy consumption during manufacturing.

The economic comparison between cold-press densification and sintering technologies reveals distinct market implications. Cold-press methods require approximately 40% lower capital investment for production equipment but may result in electrolytes with 15-20% lower performance metrics. Conversely, sintering approaches demand higher initial investment but deliver superior electrolyte performance that commands premium pricing in high-end applications.

Market forecasts indicate that cold-press densification technologies will likely dominate the mass-market segment due to cost advantages and easier scalability, potentially capturing 65% of production volume by 2027. However, sintering methods are expected to maintain significant value share (approximately 55%) due to their application in premium performance products with higher margins.

Within this expanding market, sulfide-based solid electrolytes have emerged as a particularly promising segment due to their superior ionic conductivity compared to oxide and polymer alternatives. The manufacturing methods for these electrolytes—specifically cold-press densification versus sintering—represent a critical decision point for manufacturers that directly impacts production costs, scalability, and final product performance.

Market analysis reveals that automotive applications currently dominate demand for solid-state batteries incorporating sulfide electrolytes, accounting for approximately 45% of market interest. Major automotive manufacturers including Toyota, BMW, and Volkswagen have announced significant investments in sulfide-based solid-state battery technology, with commercialization targets set between 2025-2028.

Consumer electronics represents the second largest application segment at 30% market share, with manufacturers seeking higher energy density and improved safety profiles. The remaining market distribution spans aerospace, medical devices, and grid storage applications, each with specific performance requirements that influence manufacturing method selection.

Regional analysis shows Asia-Pacific leading market development with 55% share, primarily driven by Japan and South Korea's advanced research infrastructure and manufacturing capabilities in sulfide electrolyte processing. North America follows at 25%, with significant research initiatives focused on cold-press techniques that promise lower energy consumption during manufacturing.

The economic comparison between cold-press densification and sintering technologies reveals distinct market implications. Cold-press methods require approximately 40% lower capital investment for production equipment but may result in electrolytes with 15-20% lower performance metrics. Conversely, sintering approaches demand higher initial investment but deliver superior electrolyte performance that commands premium pricing in high-end applications.

Market forecasts indicate that cold-press densification technologies will likely dominate the mass-market segment due to cost advantages and easier scalability, potentially capturing 65% of production volume by 2027. However, sintering methods are expected to maintain significant value share (approximately 55%) due to their application in premium performance products with higher margins.

Current Challenges in Sulfide Electrolyte Processing

The processing of sulfide solid electrolytes presents significant challenges that impact their performance in solid-state batteries. Currently, two primary methods dominate the densification process: cold-pressing and sintering. Each approach carries distinct advantages and limitations that researchers must navigate to optimize electrolyte performance.

Cold-pressing techniques offer simplicity and cost-effectiveness but struggle to achieve optimal ionic conductivity due to insufficient particle-to-particle contact. The pressure applied during cold-pressing (typically 100-700 MPa) often results in non-uniform density distribution throughout the electrolyte pellet, creating pathways for lithium dendrite growth during battery operation. Additionally, the mechanical integrity of cold-pressed sulfide electrolytes remains problematic, with many exhibiting brittleness and poor adhesion to electrode materials.

Sintering processes, while potentially offering higher densification, introduce thermal stability concerns for sulfide materials. Most sulfide solid electrolytes exhibit narrow thermal stability windows, with decomposition or phase transitions occurring at relatively low temperatures (150-400°C depending on composition). This thermal sensitivity severely restricts sintering parameters and often necessitates precisely controlled environments to prevent sulfur volatilization and oxidation.

The air-sensitivity of sulfide electrolytes compounds processing difficulties for both methods. Exposure to ambient moisture rapidly degrades these materials through hydrolysis reactions that generate toxic H2S gas and compromise ionic conductivity. Consequently, all processing steps require sophisticated glove box environments with stringent oxygen and moisture controls (<0.1 ppm), significantly increasing manufacturing complexity and cost.

Interface management represents another critical challenge. The high interfacial resistance between sulfide electrolytes and electrode materials limits overall battery performance. Current processing techniques struggle to create intimate contact at these interfaces without introducing additional stability issues or forming resistive interphases during densification procedures.

Scalability concerns persist for both densification approaches. Cold-pressing techniques face limitations in producing large-format, uniform electrolyte layers at industrial scales. Meanwhile, sintering processes require specialized equipment and precise thermal management systems that are difficult to scale economically while maintaining quality control.

The mechanical properties resulting from either densification method often fail to meet the requirements for practical battery applications. Cold-pressed sulfides typically lack sufficient mechanical strength to withstand volume changes during cycling, while sintered materials may become excessively brittle, leading to microcrack formation and eventual battery failure.

Cold-pressing techniques offer simplicity and cost-effectiveness but struggle to achieve optimal ionic conductivity due to insufficient particle-to-particle contact. The pressure applied during cold-pressing (typically 100-700 MPa) often results in non-uniform density distribution throughout the electrolyte pellet, creating pathways for lithium dendrite growth during battery operation. Additionally, the mechanical integrity of cold-pressed sulfide electrolytes remains problematic, with many exhibiting brittleness and poor adhesion to electrode materials.

Sintering processes, while potentially offering higher densification, introduce thermal stability concerns for sulfide materials. Most sulfide solid electrolytes exhibit narrow thermal stability windows, with decomposition or phase transitions occurring at relatively low temperatures (150-400°C depending on composition). This thermal sensitivity severely restricts sintering parameters and often necessitates precisely controlled environments to prevent sulfur volatilization and oxidation.

The air-sensitivity of sulfide electrolytes compounds processing difficulties for both methods. Exposure to ambient moisture rapidly degrades these materials through hydrolysis reactions that generate toxic H2S gas and compromise ionic conductivity. Consequently, all processing steps require sophisticated glove box environments with stringent oxygen and moisture controls (<0.1 ppm), significantly increasing manufacturing complexity and cost.

Interface management represents another critical challenge. The high interfacial resistance between sulfide electrolytes and electrode materials limits overall battery performance. Current processing techniques struggle to create intimate contact at these interfaces without introducing additional stability issues or forming resistive interphases during densification procedures.

Scalability concerns persist for both densification approaches. Cold-pressing techniques face limitations in producing large-format, uniform electrolyte layers at industrial scales. Meanwhile, sintering processes require specialized equipment and precise thermal management systems that are difficult to scale economically while maintaining quality control.

The mechanical properties resulting from either densification method often fail to meet the requirements for practical battery applications. Cold-pressed sulfides typically lack sufficient mechanical strength to withstand volume changes during cycling, while sintered materials may become excessively brittle, leading to microcrack formation and eventual battery failure.

Comparative Analysis of Cold-Press vs Sintering Techniques

01 Cold sintering processes for sulfide solid electrolytes

Cold sintering techniques can be employed to densify sulfide solid electrolytes at lower temperatures than conventional methods, which helps preserve the electrolyte's ionic conductivity and prevents decomposition. This process typically involves applying pressure and moderate heat to the sulfide materials in the presence of a small amount of liquid phase that facilitates mass transport. The resulting densified electrolytes show improved mechanical properties while maintaining high ionic conductivity essential for solid-state battery applications.- Cold sintering processes for sulfide solid electrolytes: Cold sintering processes can be used to densify sulfide solid electrolytes at lower temperatures than conventional methods. This approach helps preserve the electrochemical properties of the sulfide materials while achieving high density. The process typically involves applying pressure and moderate heat to the sulfide materials in the presence of a small amount of liquid phase that facilitates mass transport and densification without degrading the electrolyte properties.

- Hot pressing techniques for sulfide electrolyte densification: Hot pressing techniques involve the application of heat and pressure simultaneously to densify sulfide solid electrolytes. These methods can achieve high density while controlling grain growth and microstructure development. The process parameters such as temperature, pressure, and duration are optimized to enhance the ionic conductivity of the electrolytes while minimizing unwanted phase transformations or decomposition reactions that could degrade performance.

- Additives and dopants for enhanced densification: Various additives and dopants can be incorporated into sulfide solid electrolytes to enhance densification behavior. These additives can lower sintering temperatures, promote grain boundary diffusion, or create liquid phases that facilitate mass transport during sintering. Common additives include halides, oxides, and other sulfide compounds that are compatible with the base electrolyte material while improving mechanical properties and ionic conductivity after densification.

- Spark plasma sintering for rapid densification: Spark plasma sintering (SPS) enables rapid densification of sulfide solid electrolytes through the application of pulsed direct current along with pressure. This technique allows for faster processing times and lower temperatures compared to conventional sintering methods, which helps preserve the electrochemical properties of sulfide electrolytes. The rapid heating rates and shorter dwell times minimize unwanted reactions and phase transformations during the densification process.

- Interface engineering for improved densification: Interface engineering approaches focus on modifying the surfaces and grain boundaries of sulfide solid electrolyte particles to enhance densification. These methods include surface coatings, chemical treatments, or the introduction of secondary phases at interfaces to control grain growth and improve sinterability. By engineering the interfaces, the mechanical properties and ionic conductivity of the densified electrolytes can be significantly improved while maintaining electrochemical stability.

02 Hot pressing and spark plasma sintering methods

Hot pressing and spark plasma sintering (SPS) are effective densification methods for sulfide solid electrolytes that apply both heat and pressure simultaneously. These techniques enable rapid densification at relatively lower temperatures compared to conventional sintering, which is crucial for sulfide materials that are thermally sensitive. The rapid heating rates in SPS help minimize grain growth and secondary phase formation, resulting in densified electrolytes with enhanced mechanical strength and maintained ionic conductivity properties.Expand Specific Solutions03 Composite approaches with polymer binders

Incorporating polymer binders into sulfide solid electrolytes creates composite structures that can be densified at lower temperatures while improving mechanical flexibility. These composite approaches typically involve mixing sulfide particles with polymers that enhance interfacial contact and reduce porosity during the densification process. The resulting composite electrolytes exhibit improved processability, reduced interfacial resistance, and better compatibility with electrode materials, while maintaining sufficient ionic conductivity for battery applications.Expand Specific Solutions04 Pressure-assisted densification techniques

Pressure-assisted densification techniques apply external pressure during the consolidation of sulfide solid electrolytes to achieve higher density at lower processing temperatures. These methods include uniaxial pressing, isostatic pressing, and roll-pressing approaches that help overcome the poor sinterability of sulfide materials. By applying controlled pressure, these techniques reduce porosity and improve particle-to-particle contact, resulting in enhanced mechanical integrity and ionic transport properties in the densified electrolytes.Expand Specific Solutions05 Chemical additives and dopants for enhanced densification

Chemical additives and dopants can be incorporated into sulfide solid electrolytes to enhance their densification behavior. These additives often function by creating liquid phases during sintering, modifying grain boundary properties, or promoting mass transport mechanisms. Common additives include halides, oxides, and other sulfide compounds that can lower the sintering temperature, improve densification kinetics, and enhance the mechanical properties of the final electrolyte while maintaining or even improving ionic conductivity.Expand Specific Solutions

Leading Companies and Research Institutions

The solid-state battery market, particularly for sulfide solid electrolytes, is currently in a transitional phase from research to early commercialization, with a projected market size reaching $6-8 billion by 2030. Cold-press densification is emerging as a cost-effective alternative to traditional sintering processes, attracting significant industry attention. Major automotive players like Toyota, Hyundai, and Kia are actively investing in this technology, while specialized materials companies including LG Energy Solution, Samsung SDI, and Idemitsu Kosan are advancing electrolyte formulations. Research institutions such as Shanghai Institute of Ceramics and Huazhong University are contributing fundamental breakthroughs, while battery manufacturers like CATL (Ningde Amperex) and Svolt are scaling production capabilities to meet anticipated demand from the electric vehicle sector.

Toyota Motor Corp.

Technical Solution: Toyota Motor Corporation has developed advanced sulfide solid electrolytes using both cold-press densification and sintering methods. Their approach focuses on Li2S-P2S5 glass-ceramic electrolytes, achieving ionic conductivities exceeding 10^-3 S/cm. Toyota's cold-press densification technique involves applying pressure (typically 300-500 MPa) at room temperature to compact sulfide powders without heating, creating dense pellets with good grain-to-grain contact. This method preserves the original material properties while minimizing interfacial resistance. For sintering applications, Toyota has developed specialized low-temperature sintering protocols (150-250°C) that promote densification while preventing decomposition of sulfide materials. Their research demonstrates that controlled sintering can enhance grain boundary conductivity while maintaining bulk properties. Toyota has also pioneered composite approaches combining cold-pressing with partial sintering to optimize the mechanical properties and ionic conductivity simultaneously.

Strengths: Toyota's dual-approach methodology allows flexibility in electrolyte preparation based on specific battery design requirements. Their cold-press techniques achieve high density without thermal degradation, while their controlled sintering protocols enhance grain boundary conductivity. Weaknesses: Cold-pressed materials may still have higher interfacial resistance than sintered alternatives, and both approaches require precise process control that may be challenging to scale for mass production.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed proprietary sulfide solid electrolyte processing techniques focusing on optimized cold-press densification. Their approach utilizes argyrodite-type Li6PS5Cl electrolytes with ionic conductivities reaching 5×10^-3 S/cm at room temperature. LG's cold-press densification process employs precisely controlled pressure application (typically 350-400 MPa) combined with specialized particle size distribution engineering to maximize packing density without thermal treatment. This method preserves the original crystalline structure while achieving relative densities of 85-90%. The company has also developed proprietary surface treatment technologies that enhance the interfacial contact between electrolyte particles during cold-pressing, reducing grain boundary resistance without requiring sintering. For applications requiring enhanced mechanical properties, LG has pioneered hybrid approaches involving minimal heat treatment (below 150°C) following cold-pressing, which maintains the advantages of cold-pressing while slightly improving mechanical integrity.

Strengths: LG's cold-press techniques achieve excellent ionic conductivity while avoiding thermal decomposition issues associated with sintering. Their process is more energy-efficient and potentially more scalable for mass production. Weaknesses: The mechanical properties of cold-pressed electrolytes may be inferior to sintered alternatives, potentially leading to challenges in maintaining solid-solid interfaces during battery cycling, especially under mechanical stress conditions.

Key Patents and Scientific Breakthroughs

Method for densification of sulfide solid electrolytes

PatentPendingUS20250125410A1

Innovation

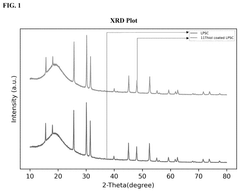

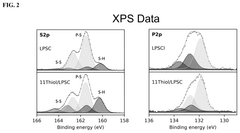

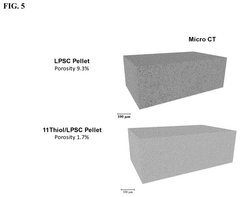

- A sulfide-containing solid state electrolyte material is modified with an organic coating, such as a long chain thiol, to enhance densification, ionic conductivity, and mechanical properties, thereby improving the safety and performance of solid state batteries.

Solid electrolyte and preparation method thereof, and electrochemical device and electronic device comprising solid electrolyte

PatentActiveUS20200235421A1

Innovation

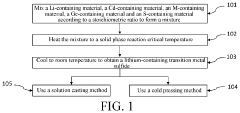

- A lithium-containing transition metal sulfide with a thio-LISICON structure, represented by Li2−2a+bCd1+aMcGe1−dS4, is developed, incorporating a binder and lithium salt, and prepared through a high-temperature solid phase method, offering enhanced chemical stability and ionic conductivity.

Material Cost and Scalability Assessment

The economic viability of sulfide solid electrolytes depends significantly on material costs and manufacturing scalability. Raw material costs for sulfide-based solid electrolytes vary considerably depending on composition. Li2S, a common precursor, costs approximately $300-500/kg at research grade, while industrial-scale pricing could potentially decrease to $100-150/kg with volume production. Other components like P2S5 and additives such as GeS2 or Li3PS4 contribute additional costs, with rare elements substantially increasing overall material expenses.

Cold-press densification offers notable cost advantages compared to sintering processes. The elimination of high-temperature treatment reduces energy consumption by approximately 60-70%, translating to significant operational cost savings. Additionally, cold-pressing equipment requires lower capital investment, with industrial presses costing 30-50% less than comparable sintering furnaces with their associated temperature control systems and inert gas handling equipment.

From a scalability perspective, cold-press densification demonstrates superior throughput potential. The process cycle time for cold-pressing typically ranges from 1-5 minutes per component, compared to sintering processes that may require 5-12 hours for thermal treatment cycles. This dramatic difference in processing time enables substantially higher production volumes with equivalent equipment investment.

Manufacturing complexity also favors cold-pressing approaches. Sintering processes require precise temperature control, specialized atmospheres, and careful heating/cooling profiles to prevent material degradation or undesired phase transitions. Cold-pressing operations can be more readily automated and integrated into continuous production lines, reducing labor requirements and improving consistency.

However, yield considerations present a more complex picture. While cold-pressed sulfide electrolytes may achieve 85-90% theoretical density, sintered materials typically reach 95-98% density. This density differential impacts electrochemical performance, potentially requiring thicker electrolyte layers in cold-pressed implementations to achieve equivalent ionic conductivity, partially offsetting material savings.

Supply chain resilience must also be considered. Cold-pressing processes generally require fewer specialized materials and equipment, reducing dependency on potentially constrained supply chains. This advantage becomes particularly significant when scaling to gigafactory-level production volumes where consistent material availability becomes critical.

For large-scale commercialization, the simplified process flow of cold-pressing represents a compelling advantage, potentially reducing time-to-market and enabling more agile production scaling. This factor, combined with the substantial cost advantages, positions cold-press densification as the more economically viable approach for mass production of sulfide solid electrolytes in next-generation battery systems.

Cold-press densification offers notable cost advantages compared to sintering processes. The elimination of high-temperature treatment reduces energy consumption by approximately 60-70%, translating to significant operational cost savings. Additionally, cold-pressing equipment requires lower capital investment, with industrial presses costing 30-50% less than comparable sintering furnaces with their associated temperature control systems and inert gas handling equipment.

From a scalability perspective, cold-press densification demonstrates superior throughput potential. The process cycle time for cold-pressing typically ranges from 1-5 minutes per component, compared to sintering processes that may require 5-12 hours for thermal treatment cycles. This dramatic difference in processing time enables substantially higher production volumes with equivalent equipment investment.

Manufacturing complexity also favors cold-pressing approaches. Sintering processes require precise temperature control, specialized atmospheres, and careful heating/cooling profiles to prevent material degradation or undesired phase transitions. Cold-pressing operations can be more readily automated and integrated into continuous production lines, reducing labor requirements and improving consistency.

However, yield considerations present a more complex picture. While cold-pressed sulfide electrolytes may achieve 85-90% theoretical density, sintered materials typically reach 95-98% density. This density differential impacts electrochemical performance, potentially requiring thicker electrolyte layers in cold-pressed implementations to achieve equivalent ionic conductivity, partially offsetting material savings.

Supply chain resilience must also be considered. Cold-pressing processes generally require fewer specialized materials and equipment, reducing dependency on potentially constrained supply chains. This advantage becomes particularly significant when scaling to gigafactory-level production volumes where consistent material availability becomes critical.

For large-scale commercialization, the simplified process flow of cold-pressing represents a compelling advantage, potentially reducing time-to-market and enabling more agile production scaling. This factor, combined with the substantial cost advantages, positions cold-press densification as the more economically viable approach for mass production of sulfide solid electrolytes in next-generation battery systems.

Safety and Environmental Considerations

Safety considerations are paramount when working with sulfide solid electrolytes, as these materials present unique hazards compared to traditional battery components. Sulfide-based solid electrolytes, such as Li2S-P2S5 glass-ceramic systems, are highly reactive with moisture in ambient air, producing toxic hydrogen sulfide (H2S) gas upon contact with humidity. This reactivity necessitates specialized handling protocols in both cold-press densification and sintering processes, typically requiring controlled atmosphere environments such as argon-filled glove boxes with moisture levels maintained below 0.1 ppm.

The processing methods themselves present different safety profiles. Cold-press densification generally involves lower operational risks as it avoids high-temperature processing. Conversely, sintering requires elevated temperatures (typically 200-600°C for sulfide electrolytes), introducing additional thermal hazards and potentially increasing the rate of harmful gas evolution if containment is compromised. Facilities must implement robust ventilation systems with H2S detection capabilities and emergency protocols for potential exposure incidents.

From an environmental perspective, the lifecycle assessment of sulfide solid electrolytes reveals several considerations. The raw materials for these electrolytes, particularly lithium and phosphorus compounds, involve energy-intensive mining and refining processes with significant environmental footprints. Sintering processes consume substantially more energy than cold-pressing techniques, resulting in higher carbon emissions when powered by non-renewable energy sources. A comparative analysis indicates that sintering may increase the carbon footprint of electrolyte production by 30-45% compared to cold-pressing methods.

Waste management presents another critical environmental challenge. Sulfide materials cannot be disposed of through conventional waste streams due to their reactivity with moisture. Both processing methods generate waste materials that require specialized neutralization procedures before disposal. However, cold-pressed materials may present slightly higher end-of-life challenges due to their potentially higher reactivity resulting from incomplete particle bonding and higher surface area.

Recycling potential differs between the two processing methods as well. Sintered sulfide electrolytes typically form more stable phases that may be more amenable to recycling processes, potentially offering better material recovery rates. Research indicates that up to 85% of lithium content might be recoverable from sintered electrolytes, compared to 70-75% from cold-pressed variants, though these figures vary significantly based on specific material compositions and recycling technologies employed.

The processing methods themselves present different safety profiles. Cold-press densification generally involves lower operational risks as it avoids high-temperature processing. Conversely, sintering requires elevated temperatures (typically 200-600°C for sulfide electrolytes), introducing additional thermal hazards and potentially increasing the rate of harmful gas evolution if containment is compromised. Facilities must implement robust ventilation systems with H2S detection capabilities and emergency protocols for potential exposure incidents.

From an environmental perspective, the lifecycle assessment of sulfide solid electrolytes reveals several considerations. The raw materials for these electrolytes, particularly lithium and phosphorus compounds, involve energy-intensive mining and refining processes with significant environmental footprints. Sintering processes consume substantially more energy than cold-pressing techniques, resulting in higher carbon emissions when powered by non-renewable energy sources. A comparative analysis indicates that sintering may increase the carbon footprint of electrolyte production by 30-45% compared to cold-pressing methods.

Waste management presents another critical environmental challenge. Sulfide materials cannot be disposed of through conventional waste streams due to their reactivity with moisture. Both processing methods generate waste materials that require specialized neutralization procedures before disposal. However, cold-pressed materials may present slightly higher end-of-life challenges due to their potentially higher reactivity resulting from incomplete particle bonding and higher surface area.

Recycling potential differs between the two processing methods as well. Sintered sulfide electrolytes typically form more stable phases that may be more amenable to recycling processes, potentially offering better material recovery rates. Research indicates that up to 85% of lithium content might be recoverable from sintered electrolytes, compared to 70-75% from cold-pressed variants, though these figures vary significantly based on specific material compositions and recycling technologies employed.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!