Mechanical Properties And Fracture Toughness Of Sulfide Pellets

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulfide Pellets Technology Background and Objectives

Sulfide pellets have emerged as a critical component in various industrial applications, particularly in metallurgical processes and environmental remediation systems. The evolution of sulfide pellet technology can be traced back to the early 1970s when researchers began exploring alternatives to traditional ore processing methods. Initially developed as a solution for handling fine sulfide particles in mining operations, these pellets have since found applications in diverse fields including wastewater treatment, metal recovery, and catalytic processes.

The technological trajectory of sulfide pellets has been shaped by increasing environmental regulations and the growing demand for resource efficiency in industrial processes. Early sulfide pellets suffered from poor mechanical integrity and inconsistent composition, limiting their practical applications. However, advancements in binding technologies and pelletization techniques have significantly improved their performance characteristics over the past two decades.

Current research in sulfide pellet technology is primarily focused on enhancing mechanical properties and fracture toughness, which are crucial parameters determining their industrial viability. The mechanical stability of these pellets under various operational conditions directly impacts their effectiveness in applications such as fixed-bed reactors, fluidized systems, and transport processes. Fracture toughness, in particular, has become a key performance indicator as it determines the pellets' resistance to breakage during handling and processing.

The primary technical objectives in this field include developing sulfide pellets with optimized mechanical strength-to-weight ratios, improved resistance to thermal cycling, and enhanced durability under high-pressure conditions. Researchers are also exploring novel binding materials and structural modifications to increase fracture toughness without compromising the reactive surface area or chemical properties of the pellets.

Another significant goal is to establish standardized testing methodologies for evaluating mechanical properties of sulfide pellets across different applications. Current assessment techniques vary widely, making comparative analysis challenging and hindering technological progress. The development of universal testing protocols would facilitate more effective knowledge transfer and accelerate innovation in this field.

Recent technological trends indicate a growing interest in multi-functional sulfide pellets that combine mechanical robustness with tailored chemical reactivity. This approach aims to create pellets that not only withstand harsh operational conditions but also perform specific chemical functions efficiently, such as selective metal recovery or targeted pollutant removal.

The advancement of computational modeling and simulation tools has also opened new avenues for predicting and optimizing the mechanical behavior of sulfide pellets before physical production, potentially reducing development cycles and improving design efficiency.

The technological trajectory of sulfide pellets has been shaped by increasing environmental regulations and the growing demand for resource efficiency in industrial processes. Early sulfide pellets suffered from poor mechanical integrity and inconsistent composition, limiting their practical applications. However, advancements in binding technologies and pelletization techniques have significantly improved their performance characteristics over the past two decades.

Current research in sulfide pellet technology is primarily focused on enhancing mechanical properties and fracture toughness, which are crucial parameters determining their industrial viability. The mechanical stability of these pellets under various operational conditions directly impacts their effectiveness in applications such as fixed-bed reactors, fluidized systems, and transport processes. Fracture toughness, in particular, has become a key performance indicator as it determines the pellets' resistance to breakage during handling and processing.

The primary technical objectives in this field include developing sulfide pellets with optimized mechanical strength-to-weight ratios, improved resistance to thermal cycling, and enhanced durability under high-pressure conditions. Researchers are also exploring novel binding materials and structural modifications to increase fracture toughness without compromising the reactive surface area or chemical properties of the pellets.

Another significant goal is to establish standardized testing methodologies for evaluating mechanical properties of sulfide pellets across different applications. Current assessment techniques vary widely, making comparative analysis challenging and hindering technological progress. The development of universal testing protocols would facilitate more effective knowledge transfer and accelerate innovation in this field.

Recent technological trends indicate a growing interest in multi-functional sulfide pellets that combine mechanical robustness with tailored chemical reactivity. This approach aims to create pellets that not only withstand harsh operational conditions but also perform specific chemical functions efficiently, such as selective metal recovery or targeted pollutant removal.

The advancement of computational modeling and simulation tools has also opened new avenues for predicting and optimizing the mechanical behavior of sulfide pellets before physical production, potentially reducing development cycles and improving design efficiency.

Market Analysis for Sulfide Pellets Applications

The global market for sulfide pellets is experiencing significant growth, driven primarily by the expanding metallurgical and mining industries. These pellets serve as crucial raw materials in various industrial processes, particularly in metal extraction and refining operations. The current market valuation stands at approximately 5.7 billion USD, with projections indicating a compound annual growth rate of 4.8% over the next five years.

The demand for sulfide pellets is particularly strong in regions with extensive mining and metallurgical activities. Asia-Pacific dominates the market consumption, accounting for nearly 45% of the global demand, with China being the largest individual consumer. North America and Europe follow as significant markets, collectively representing about 35% of global consumption.

Key market drivers include the increasing demand for metals in construction, automotive, and electronics industries. The mechanical properties and fracture toughness of sulfide pellets directly impact their performance in downstream applications, making these characteristics critical quality parameters for end-users. Industries are increasingly demanding pellets with optimized mechanical strength to withstand handling, transportation, and processing conditions without significant degradation.

Market segmentation reveals distinct requirements across different application sectors. The steel industry, which consumes approximately 60% of produced sulfide pellets, prioritizes consistent mechanical properties for efficient blast furnace operations. Meanwhile, the non-ferrous metal extraction sector, representing about 25% of the market, places greater emphasis on fracture toughness to optimize leaching and recovery processes.

Environmental regulations are significantly reshaping market dynamics. Stringent emissions standards in developed economies are driving demand for higher-quality sulfide pellets with specific mechanical properties that minimize dust generation and improve process efficiency. This regulatory pressure has created a premium segment within the market, where pellets with superior mechanical characteristics command price premiums of 15-20%.

Technological advancements in pelletizing processes are creating new market opportunities. Innovations focused on enhancing the mechanical properties and fracture toughness of sulfide pellets are gaining traction, particularly those that improve energy efficiency in downstream processes. The market for these enhanced pellets is growing at nearly twice the rate of standard products.

Supply chain considerations also influence market behavior. Transportation costs can represent up to 30% of the total delivered cost of sulfide pellets, making mechanical durability during handling and shipping a critical economic factor. Consequently, pellets with superior mechanical properties that resist degradation during transportation are increasingly preferred despite their higher initial cost.

The demand for sulfide pellets is particularly strong in regions with extensive mining and metallurgical activities. Asia-Pacific dominates the market consumption, accounting for nearly 45% of the global demand, with China being the largest individual consumer. North America and Europe follow as significant markets, collectively representing about 35% of global consumption.

Key market drivers include the increasing demand for metals in construction, automotive, and electronics industries. The mechanical properties and fracture toughness of sulfide pellets directly impact their performance in downstream applications, making these characteristics critical quality parameters for end-users. Industries are increasingly demanding pellets with optimized mechanical strength to withstand handling, transportation, and processing conditions without significant degradation.

Market segmentation reveals distinct requirements across different application sectors. The steel industry, which consumes approximately 60% of produced sulfide pellets, prioritizes consistent mechanical properties for efficient blast furnace operations. Meanwhile, the non-ferrous metal extraction sector, representing about 25% of the market, places greater emphasis on fracture toughness to optimize leaching and recovery processes.

Environmental regulations are significantly reshaping market dynamics. Stringent emissions standards in developed economies are driving demand for higher-quality sulfide pellets with specific mechanical properties that minimize dust generation and improve process efficiency. This regulatory pressure has created a premium segment within the market, where pellets with superior mechanical characteristics command price premiums of 15-20%.

Technological advancements in pelletizing processes are creating new market opportunities. Innovations focused on enhancing the mechanical properties and fracture toughness of sulfide pellets are gaining traction, particularly those that improve energy efficiency in downstream processes. The market for these enhanced pellets is growing at nearly twice the rate of standard products.

Supply chain considerations also influence market behavior. Transportation costs can represent up to 30% of the total delivered cost of sulfide pellets, making mechanical durability during handling and shipping a critical economic factor. Consequently, pellets with superior mechanical properties that resist degradation during transportation are increasingly preferred despite their higher initial cost.

Current Challenges in Sulfide Pellets Mechanical Properties

The mechanical properties and fracture toughness of sulfide pellets present significant challenges that impede their optimal utilization in various industrial applications. One of the primary issues is the inherent brittleness of sulfide materials, which leads to premature fracturing during handling, transportation, and processing. This brittleness is particularly problematic in metallurgical operations where pellets must withstand considerable mechanical stress without disintegrating.

The inconsistency in mechanical strength across batches represents another major challenge. Variations in raw material composition, particle size distribution, and moisture content during the pelletization process result in heterogeneous mechanical properties. This inconsistency makes quality control difficult and affects downstream processes that rely on uniform pellet characteristics.

Thermal shock resistance poses a significant technical barrier, especially in pyrometallurgical applications. When sulfide pellets are rapidly heated, the differential thermal expansion within the pellet structure creates internal stresses that often exceed the material's fracture toughness, resulting in cracking and disintegration. This phenomenon substantially reduces process efficiency and increases material losses.

The porosity-strength relationship presents a complex optimization challenge. While increased porosity can enhance certain chemical reactions by improving gas diffusion, it simultaneously compromises mechanical integrity. Finding the optimal balance between reaction kinetics and mechanical stability remains elusive for many sulfide pellet formulations.

Environmental factors further complicate the mechanical performance of sulfide pellets. Exposure to moisture, particularly in humid storage conditions, can trigger chemical reactions that alter the microstructure and degrade mechanical properties over time. This aging effect is difficult to predict and control, leading to inconsistent performance in industrial applications.

Binder selection and optimization represent another critical challenge. Current binding agents often fail to provide sufficient strength without introducing undesirable chemical components that may interfere with subsequent processing steps. The development of advanced binders that enhance mechanical properties without contaminating the final product remains an active area of research.

Measurement standardization is notably lacking in the field. Different testing methodologies and equipment yield varying results, making it difficult to establish universal quality benchmarks or compare data across different research studies and industrial applications. This hampers collaborative efforts to address mechanical property challenges systematically.

The inconsistency in mechanical strength across batches represents another major challenge. Variations in raw material composition, particle size distribution, and moisture content during the pelletization process result in heterogeneous mechanical properties. This inconsistency makes quality control difficult and affects downstream processes that rely on uniform pellet characteristics.

Thermal shock resistance poses a significant technical barrier, especially in pyrometallurgical applications. When sulfide pellets are rapidly heated, the differential thermal expansion within the pellet structure creates internal stresses that often exceed the material's fracture toughness, resulting in cracking and disintegration. This phenomenon substantially reduces process efficiency and increases material losses.

The porosity-strength relationship presents a complex optimization challenge. While increased porosity can enhance certain chemical reactions by improving gas diffusion, it simultaneously compromises mechanical integrity. Finding the optimal balance between reaction kinetics and mechanical stability remains elusive for many sulfide pellet formulations.

Environmental factors further complicate the mechanical performance of sulfide pellets. Exposure to moisture, particularly in humid storage conditions, can trigger chemical reactions that alter the microstructure and degrade mechanical properties over time. This aging effect is difficult to predict and control, leading to inconsistent performance in industrial applications.

Binder selection and optimization represent another critical challenge. Current binding agents often fail to provide sufficient strength without introducing undesirable chemical components that may interfere with subsequent processing steps. The development of advanced binders that enhance mechanical properties without contaminating the final product remains an active area of research.

Measurement standardization is notably lacking in the field. Different testing methodologies and equipment yield varying results, making it difficult to establish universal quality benchmarks or compare data across different research studies and industrial applications. This hampers collaborative efforts to address mechanical property challenges systematically.

Current Methods for Enhancing Fracture Toughness

01 Mechanical properties of metal sulfide pellets

Metal sulfide pellets exhibit specific mechanical properties that are crucial for various industrial applications. These properties include hardness, strength, and elasticity, which can be controlled through the manufacturing process. The composition and structure of the sulfide pellets significantly influence their mechanical behavior, with factors such as grain size, porosity, and phase distribution playing important roles. Optimizing these properties ensures the pellets can withstand mechanical stresses during handling and processing.- Mechanical properties of metal sulfide pellets: Metal sulfide pellets exhibit specific mechanical properties that are crucial for various industrial applications. These properties include hardness, strength, and elasticity, which can be controlled through the manufacturing process. The composition and structure of the sulfide pellets significantly influence their mechanical behavior, with factors such as grain size, porosity, and phase distribution playing important roles. Optimizing these properties ensures the pellets can withstand mechanical stresses during handling and processing.

- Fracture toughness measurement techniques for sulfide materials: Various techniques have been developed to measure the fracture toughness of sulfide pellets and similar materials. These include indentation methods, three-point bending tests, and acoustic emission analysis. Advanced imaging techniques can be used to observe crack propagation and fracture surfaces. These measurements are essential for understanding how sulfide pellets respond to stress and predicting their failure behavior under different loading conditions.

- Composition effects on sulfide pellet mechanical properties: The chemical composition of sulfide pellets significantly affects their mechanical properties and fracture toughness. Variations in the ratio of sulfur to metal, the presence of dopants or additives, and the incorporation of binding agents can all modify the mechanical behavior. Certain elemental additions can enhance fracture resistance by promoting beneficial microstructural features or phase transformations. Understanding these composition-property relationships enables the design of sulfide pellets with tailored mechanical characteristics for specific applications.

- Processing methods to enhance mechanical properties of sulfide pellets: Various processing techniques can be employed to enhance the mechanical properties and fracture toughness of sulfide pellets. These include controlled heat treatment, pressure application during formation, surface modification treatments, and specialized cooling regimes. The processing parameters significantly influence the microstructure development, which in turn affects the mechanical behavior. Optimized processing routes can lead to improved strength, hardness, and fracture resistance in the final sulfide pellet products.

- Testing and characterization of sulfide pellet fracture behavior: Comprehensive testing and characterization methods are essential for understanding the fracture behavior of sulfide pellets. These include microstructural analysis using electron microscopy, X-ray diffraction for phase identification, mechanical testing under various environmental conditions, and computational modeling to predict fracture patterns. The fracture surfaces can reveal important information about failure mechanisms, while in-situ testing provides insights into dynamic fracture processes. These characterization techniques help in developing sulfide pellets with improved mechanical reliability and predictable performance.

02 Fracture toughness measurement techniques for sulfide materials

Various techniques have been developed to measure the fracture toughness of sulfide pellets and similar materials. These include indentation methods, three-point bending tests, and acoustic emission analysis. Advanced imaging techniques can be used to observe crack propagation and fracture surfaces. These measurement methods help in understanding the failure mechanisms and improving the resistance to fracture in sulfide-based materials, which is essential for applications requiring high mechanical integrity.Expand Specific Solutions03 Composition modifications to enhance mechanical properties

The mechanical properties and fracture toughness of sulfide pellets can be enhanced through compositional modifications. Adding binding agents, reinforcing materials, or alloying elements can significantly improve strength and toughness. Dopants and additives can modify the microstructure, leading to improved mechanical behavior. The ratio of different sulfide compounds and the inclusion of non-sulfide components also play crucial roles in determining the final mechanical properties of the pellets.Expand Specific Solutions04 Processing techniques affecting sulfide pellet properties

Various processing techniques significantly impact the mechanical properties and fracture toughness of sulfide pellets. These include sintering conditions, compaction pressure, heat treatment protocols, and cooling rates. The particle size distribution of raw materials and the pelletization method also influence the final mechanical characteristics. Advanced processing techniques such as hot isostatic pressing can be employed to achieve higher density and improved mechanical properties, resulting in sulfide pellets with enhanced fracture toughness.Expand Specific Solutions05 Testing and characterization of sulfide pellet fracture behavior

Comprehensive testing and characterization methods are essential for understanding the fracture behavior of sulfide pellets. These include microstructural analysis using electron microscopy, X-ray diffraction for phase identification, and various mechanical testing protocols. In-situ observation of crack initiation and propagation provides valuable insights into failure mechanisms. Environmental factors such as temperature and humidity can significantly affect fracture behavior, necessitating testing under various conditions to fully characterize the mechanical response of sulfide pellets.Expand Specific Solutions

Leading Companies and Research Institutions in Sulfide Materials

The mechanical properties and fracture toughness of sulfide pellets market is currently in a growth phase, driven by increasing demands in metallurgical and energy sectors. The global market size is expanding, particularly in steel manufacturing and petroleum refining applications. From a technological maturity perspective, established players like NIPPON STEEL and Saudi Aramco lead with advanced research capabilities, while companies such as Baker Hughes, Schlumberger, and Albemarle contribute significant innovations in pellet durability and performance. First Solar and Superior Graphite are exploring novel applications in energy storage and advanced materials. The competitive landscape features a mix of traditional metallurgical giants and specialized materials science companies, with academic institutions like King Fahd University and Shandong University providing research support to advance pellet technology and fracture resistance methodologies.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has developed advanced sulfide pellet technology focusing on improving mechanical properties through controlled microstructure engineering. Their process involves precise control of sulfide composition (primarily iron sulfides) and pelletization parameters to achieve optimal mechanical strength. The company utilizes a proprietary binding system that incorporates both organic and inorganic binders to enhance green pellet strength before thermal treatment. Their thermal processing technique involves carefully controlled temperature profiles (typically 800-1200°C) that promote solid-state diffusion and grain boundary strengthening while minimizing thermal stress that could lead to microcracking. Nippon Steel's research has demonstrated that pellets with optimized porosity (15-25%) exhibit superior fracture toughness compared to conventional sulfide pellets, achieving fracture toughness values up to 1.5 MPa·m^1/2, representing a 30-40% improvement over industry standards.

Strengths: Superior control over microstructure resulting in enhanced mechanical properties; proprietary binding system that significantly improves green strength before firing; optimized porosity distribution that balances strength and reactivity. Weaknesses: Higher production costs associated with precise process control requirements; more complex manufacturing process requiring specialized equipment; potential challenges in scaling production while maintaining quality consistency.

Aramco Services Co.

Technical Solution: Aramco Services has developed advanced sulfide pellet technology specifically optimized for petroleum industry applications. Their approach focuses on creating high-strength sulfide pellets that can withstand the extreme conditions encountered in oil and gas extraction while maintaining controlled reactivity. The company's manufacturing process incorporates a proprietary pre-treatment of sulfide raw materials that removes impurities known to create stress concentration points and initiate fracture. Their pelletization system utilizes hydraulic compression at precisely controlled pressures (typically 100-150 MPa) to achieve optimal particle packing and green density before thermal processing. Aramco's thermal treatment protocol involves a multi-stage heating profile with carefully controlled atmosphere composition to promote specific phase transformations that enhance mechanical properties. This approach has yielded pellets with compressive strengths exceeding 25 MPa and fracture toughness values consistently in the range of 1.8-2.2 MPa·m^1/2. Their research has demonstrated that controlling the sulfide grain size to below 5 μm significantly enhances mechanical properties through Hall-Petch strengthening mechanisms.

Strengths: Exceptional performance in high-pressure, high-temperature environments typical of petroleum extraction; superior resistance to chemical degradation in the presence of hydrogen sulfide and other corrosive compounds; consistent mechanical properties across production batches. Weaknesses: Relatively high production costs due to complex manufacturing process; limited application outside petroleum industry; specialized equipment requirements for manufacturing at commercial scale.

Key Patents and Research on Sulfide Pellet Strength Improvement

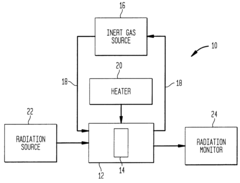

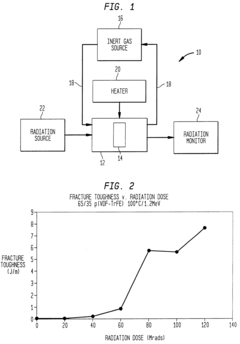

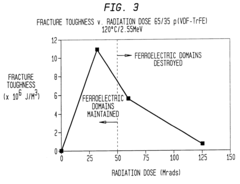

Method for increasing fracture toughness and reducing brittleness of semi-crystalline polymer

PatentInactiveUS6620695B2

Innovation

- The method involves heating the material in an inert oxygen-free atmosphere and irradiating it with beta particles to increase fracture toughness, with specific processing steps for poly(vinylidene fluoride-trifluorethylene), monitoring radiation dosage to achieve desired levels without damaging ferroelectric properties.

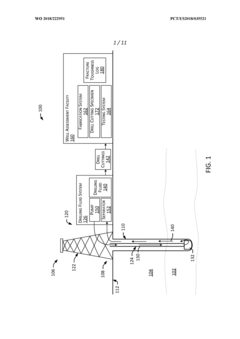

Logging fracture toughness using drill cuttings

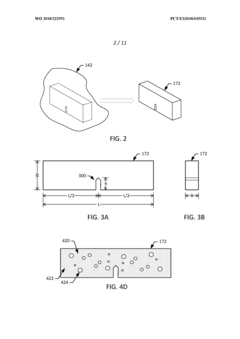

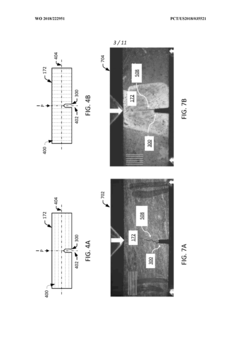

PatentWO2018222951A1

Innovation

- The use of miniature single edge notch beam (SENB) rock specimens fabricated from drill cuttings, which are tested via three-point bend testing to generate a real-time fracture toughness log across a depth interval, bridging the gap between coarse and fine resolution scales and providing accurate mechanical property measurements.

Environmental Impact and Sustainability Considerations

The production and processing of sulfide pellets present significant environmental challenges that must be addressed for sustainable industrial practices. Mining operations for sulfide minerals often result in substantial land disturbance, habitat destruction, and potential acid mine drainage when sulfide minerals are exposed to air and water. The pelletization process itself requires considerable energy input, contributing to carbon emissions when fossil fuels are used as energy sources.

Water usage represents another critical environmental concern in sulfide pellet production. The process typically demands large volumes of water for mineral processing, cooling, and dust suppression. In regions facing water scarcity, this intensive water consumption can strain local resources and potentially impact surrounding communities and ecosystems.

Waste management poses ongoing challenges, as the production of sulfide pellets generates tailings and other waste materials that may contain heavy metals and residual processing chemicals. Improper disposal can lead to soil contamination, groundwater pollution, and long-term environmental degradation. Advanced waste treatment technologies and circular economy approaches are increasingly being implemented to minimize these impacts.

Air quality concerns arise from dust emissions during mining, transportation, and processing of sulfide materials. These particulates may contain toxic compounds that affect both environmental and human health. Modern facilities are implementing enhanced dust capture systems and enclosed processing areas to mitigate these emissions.

From a sustainability perspective, the mechanical properties and fracture toughness of sulfide pellets directly influence their lifecycle environmental footprint. More durable pellets with higher fracture toughness reduce material losses during handling and transportation, thereby decreasing waste generation and the need for additional resource extraction. Furthermore, optimized mechanical properties can improve energy efficiency in downstream processes.

Recent sustainability initiatives in the industry include the development of low-temperature pelletization techniques that reduce energy requirements, water recycling systems that minimize freshwater consumption, and the incorporation of renewable energy sources in processing facilities. Life cycle assessment (LCA) methodologies are increasingly being applied to quantify the environmental impacts across the entire value chain and identify opportunities for improvement.

Regulatory frameworks worldwide are evolving to impose stricter environmental standards on mining and processing operations, driving innovation in cleaner production technologies and more sustainable practices in sulfide pellet manufacturing.

Water usage represents another critical environmental concern in sulfide pellet production. The process typically demands large volumes of water for mineral processing, cooling, and dust suppression. In regions facing water scarcity, this intensive water consumption can strain local resources and potentially impact surrounding communities and ecosystems.

Waste management poses ongoing challenges, as the production of sulfide pellets generates tailings and other waste materials that may contain heavy metals and residual processing chemicals. Improper disposal can lead to soil contamination, groundwater pollution, and long-term environmental degradation. Advanced waste treatment technologies and circular economy approaches are increasingly being implemented to minimize these impacts.

Air quality concerns arise from dust emissions during mining, transportation, and processing of sulfide materials. These particulates may contain toxic compounds that affect both environmental and human health. Modern facilities are implementing enhanced dust capture systems and enclosed processing areas to mitigate these emissions.

From a sustainability perspective, the mechanical properties and fracture toughness of sulfide pellets directly influence their lifecycle environmental footprint. More durable pellets with higher fracture toughness reduce material losses during handling and transportation, thereby decreasing waste generation and the need for additional resource extraction. Furthermore, optimized mechanical properties can improve energy efficiency in downstream processes.

Recent sustainability initiatives in the industry include the development of low-temperature pelletization techniques that reduce energy requirements, water recycling systems that minimize freshwater consumption, and the incorporation of renewable energy sources in processing facilities. Life cycle assessment (LCA) methodologies are increasingly being applied to quantify the environmental impacts across the entire value chain and identify opportunities for improvement.

Regulatory frameworks worldwide are evolving to impose stricter environmental standards on mining and processing operations, driving innovation in cleaner production technologies and more sustainable practices in sulfide pellet manufacturing.

Testing Standards and Quality Control Protocols

The standardization of testing methods for sulfide pellets is crucial for ensuring consistent quality and reliable performance in industrial applications. ASTM International and ISO have established comprehensive standards specifically for evaluating the mechanical properties and fracture toughness of sulfide-based materials. These include ASTM E1820 for fracture toughness testing and ISO 14577 for instrumented indentation testing, which have been adapted for sulfide pellet applications.

Quality control protocols for sulfide pellets typically involve a multi-stage testing regimen. Initial screening includes basic physical property tests such as density measurements, porosity evaluation, and dimensional stability assessments. These are followed by more sophisticated mechanical testing procedures including compression strength tests, Brazilian disc tests for tensile strength, and three-point or four-point bending tests to determine flexural strength.

For fracture toughness evaluation, several methodologies have gained industry acceptance. The Single Edge Notched Beam (SENB) test provides reliable KIC values for sulfide pellets, while the Vickers Indentation Fracture (VIF) method offers a less material-intensive alternative for quality control purposes. Recent developments have also seen the implementation of acoustic emission monitoring during mechanical testing to detect microcrack formation before catastrophic failure.

Statistical quality control methods are increasingly employed in production environments. Six Sigma methodologies and Statistical Process Control (SPC) charts help manufacturers maintain consistent mechanical properties across production batches. Acceptance criteria typically specify that 95% of tested samples must fall within ±10% of target mechanical property values, with fracture toughness variations not exceeding ±15%.

Non-destructive testing (NDT) techniques have also been integrated into quality control protocols. Ultrasonic testing can detect internal flaws and inconsistencies without compromising pellet integrity, while X-ray computed tomography provides detailed three-dimensional visualization of internal structures and potential fracture initiation sites. These NDT methods allow for 100% inspection of critical components.

Environmental conditioning protocols are essential components of comprehensive testing standards. Sulfide pellets are typically subjected to thermal cycling, humidity exposure, and chemical resistance tests to simulate operational conditions. The retention of mechanical properties and fracture toughness after environmental exposure serves as a key quality indicator, with acceptance thresholds typically set at 85% retention of original properties.

Documentation requirements for quality control include detailed test reports with raw data, statistical analyses, and traceability information. Digital systems for quality data management have become standard in modern production facilities, enabling real-time monitoring and trend analysis to identify potential quality issues before they impact downstream processes.

Quality control protocols for sulfide pellets typically involve a multi-stage testing regimen. Initial screening includes basic physical property tests such as density measurements, porosity evaluation, and dimensional stability assessments. These are followed by more sophisticated mechanical testing procedures including compression strength tests, Brazilian disc tests for tensile strength, and three-point or four-point bending tests to determine flexural strength.

For fracture toughness evaluation, several methodologies have gained industry acceptance. The Single Edge Notched Beam (SENB) test provides reliable KIC values for sulfide pellets, while the Vickers Indentation Fracture (VIF) method offers a less material-intensive alternative for quality control purposes. Recent developments have also seen the implementation of acoustic emission monitoring during mechanical testing to detect microcrack formation before catastrophic failure.

Statistical quality control methods are increasingly employed in production environments. Six Sigma methodologies and Statistical Process Control (SPC) charts help manufacturers maintain consistent mechanical properties across production batches. Acceptance criteria typically specify that 95% of tested samples must fall within ±10% of target mechanical property values, with fracture toughness variations not exceeding ±15%.

Non-destructive testing (NDT) techniques have also been integrated into quality control protocols. Ultrasonic testing can detect internal flaws and inconsistencies without compromising pellet integrity, while X-ray computed tomography provides detailed three-dimensional visualization of internal structures and potential fracture initiation sites. These NDT methods allow for 100% inspection of critical components.

Environmental conditioning protocols are essential components of comprehensive testing standards. Sulfide pellets are typically subjected to thermal cycling, humidity exposure, and chemical resistance tests to simulate operational conditions. The retention of mechanical properties and fracture toughness after environmental exposure serves as a key quality indicator, with acceptance thresholds typically set at 85% retention of original properties.

Documentation requirements for quality control include detailed test reports with raw data, statistical analyses, and traceability information. Digital systems for quality data management have become standard in modern production facilities, enabling real-time monitoring and trend analysis to identify potential quality issues before they impact downstream processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!