EIS-Based Diagnostics For Sulfide Interphase Evolution

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EIS Diagnostics Background and Objectives

Electrochemical Impedance Spectroscopy (EIS) has emerged as a powerful non-destructive technique for investigating electrochemical processes in battery systems. The evolution of sulfide interphases in lithium-ion and solid-state batteries represents a critical area of research due to their significant impact on battery performance, safety, and longevity. This technical pre-research report aims to comprehensively examine the development trajectory of EIS-based diagnostic methods specifically tailored for monitoring sulfide interphase evolution.

The historical development of EIS diagnostics for battery systems dates back to the 1980s, with significant advancements occurring in the past two decades as battery technologies have become increasingly central to energy storage solutions. Initially applied primarily to liquid electrolyte systems, EIS techniques have gradually been adapted and refined to address the unique challenges presented by solid-state battery configurations, particularly those utilizing sulfide-based solid electrolytes.

Recent technological trends indicate a shift toward more sophisticated EIS methodologies that combine traditional impedance measurements with advanced data processing algorithms, machine learning approaches, and multi-scale modeling. These developments have substantially enhanced the resolution and interpretability of EIS data, enabling researchers to distinguish between different interfacial phenomena occurring simultaneously within battery cells.

The primary technical objectives of this research domain include: developing high-precision EIS protocols capable of isolating sulfide interphase formation signals from other electrochemical processes; establishing reliable equivalent circuit models that accurately represent sulfide interphase evolution; creating in-situ and operando EIS measurement capabilities for real-time monitoring; and correlating impedance signatures with specific chemical and structural changes in the sulfide interphase.

A particularly challenging aspect of this field involves distinguishing between different types of interfacial phenomena, such as differentiating between the formation of solid electrolyte interphase (SEI) layers and lithium dendrite growth, both of which can manifest similarly in impedance spectra. Addressing this challenge requires innovative approaches to data acquisition and interpretation.

The technological trajectory suggests that future EIS diagnostic systems will likely incorporate multi-modal measurement techniques, combining traditional EIS with complementary methods such as X-ray photoelectron spectroscopy (XPS), transmission electron microscopy (TEM), and nuclear magnetic resonance (NMR) spectroscopy to provide more comprehensive insights into sulfide interphase evolution processes.

This report aims to explore these developments in depth, with particular emphasis on identifying breakthrough opportunities that could significantly advance our understanding of sulfide interphase dynamics and ultimately contribute to the development of more efficient, safer, and longer-lasting battery technologies.

The historical development of EIS diagnostics for battery systems dates back to the 1980s, with significant advancements occurring in the past two decades as battery technologies have become increasingly central to energy storage solutions. Initially applied primarily to liquid electrolyte systems, EIS techniques have gradually been adapted and refined to address the unique challenges presented by solid-state battery configurations, particularly those utilizing sulfide-based solid electrolytes.

Recent technological trends indicate a shift toward more sophisticated EIS methodologies that combine traditional impedance measurements with advanced data processing algorithms, machine learning approaches, and multi-scale modeling. These developments have substantially enhanced the resolution and interpretability of EIS data, enabling researchers to distinguish between different interfacial phenomena occurring simultaneously within battery cells.

The primary technical objectives of this research domain include: developing high-precision EIS protocols capable of isolating sulfide interphase formation signals from other electrochemical processes; establishing reliable equivalent circuit models that accurately represent sulfide interphase evolution; creating in-situ and operando EIS measurement capabilities for real-time monitoring; and correlating impedance signatures with specific chemical and structural changes in the sulfide interphase.

A particularly challenging aspect of this field involves distinguishing between different types of interfacial phenomena, such as differentiating between the formation of solid electrolyte interphase (SEI) layers and lithium dendrite growth, both of which can manifest similarly in impedance spectra. Addressing this challenge requires innovative approaches to data acquisition and interpretation.

The technological trajectory suggests that future EIS diagnostic systems will likely incorporate multi-modal measurement techniques, combining traditional EIS with complementary methods such as X-ray photoelectron spectroscopy (XPS), transmission electron microscopy (TEM), and nuclear magnetic resonance (NMR) spectroscopy to provide more comprehensive insights into sulfide interphase evolution processes.

This report aims to explore these developments in depth, with particular emphasis on identifying breakthrough opportunities that could significantly advance our understanding of sulfide interphase dynamics and ultimately contribute to the development of more efficient, safer, and longer-lasting battery technologies.

Market Applications for Sulfide Interphase Analysis

The electrochemical impedance spectroscopy (EIS) based diagnostics for sulfide interphase evolution represents a significant advancement in battery technology monitoring, with diverse market applications spanning multiple industries. The automotive sector stands as the primary beneficiary, where lithium-ion batteries with sulfide solid electrolytes are increasingly adopted in electric vehicles. EIS diagnostics enable real-time monitoring of the critical solid-electrolyte interphase, allowing manufacturers to optimize battery performance, extend lifespan, and enhance safety protocols.

Energy storage systems for grid applications constitute another substantial market, where large-scale battery installations require sophisticated monitoring solutions to maintain operational efficiency. The ability to detect early signs of sulfide interphase degradation through EIS diagnostics provides utility companies with crucial data for predictive maintenance, potentially saving millions in replacement costs and preventing system failures.

Consumer electronics manufacturers are integrating advanced battery technologies with improved safety profiles, creating demand for sophisticated diagnostic tools that can be miniaturized and embedded within devices. The non-destructive nature of EIS makes it particularly valuable for continuous monitoring in sealed consumer products, where traditional testing methods would be impractical.

The industrial equipment sector represents a growing application area, particularly in environments where battery reliability is mission-critical. Mining operations, maritime applications, and aerospace systems all benefit from enhanced battery diagnostics that can function reliably under extreme conditions where sulfide-based batteries may offer performance advantages.

Research institutions and battery manufacturers form a specialized market segment, requiring high-precision analytical tools for material development and quality control. EIS-based systems provide these organizations with detailed insights into interphase formation mechanisms, accelerating the development cycle for next-generation energy storage solutions.

Medical device manufacturers are exploring sulfide-based battery technologies for implantable devices, where safety and longevity are paramount concerns. EIS diagnostics offer the potential for remote monitoring of battery health in critical applications such as pacemakers and neurostimulators, creating a niche but high-value market opportunity.

The emerging market for second-life battery applications creates demand for sophisticated diagnostic tools that can accurately assess the condition of used batteries. EIS-based systems can determine the extent of sulfide interphase degradation, enabling more precise valuation and appropriate repurposing of battery components that would otherwise be discarded.

Energy storage systems for grid applications constitute another substantial market, where large-scale battery installations require sophisticated monitoring solutions to maintain operational efficiency. The ability to detect early signs of sulfide interphase degradation through EIS diagnostics provides utility companies with crucial data for predictive maintenance, potentially saving millions in replacement costs and preventing system failures.

Consumer electronics manufacturers are integrating advanced battery technologies with improved safety profiles, creating demand for sophisticated diagnostic tools that can be miniaturized and embedded within devices. The non-destructive nature of EIS makes it particularly valuable for continuous monitoring in sealed consumer products, where traditional testing methods would be impractical.

The industrial equipment sector represents a growing application area, particularly in environments where battery reliability is mission-critical. Mining operations, maritime applications, and aerospace systems all benefit from enhanced battery diagnostics that can function reliably under extreme conditions where sulfide-based batteries may offer performance advantages.

Research institutions and battery manufacturers form a specialized market segment, requiring high-precision analytical tools for material development and quality control. EIS-based systems provide these organizations with detailed insights into interphase formation mechanisms, accelerating the development cycle for next-generation energy storage solutions.

Medical device manufacturers are exploring sulfide-based battery technologies for implantable devices, where safety and longevity are paramount concerns. EIS diagnostics offer the potential for remote monitoring of battery health in critical applications such as pacemakers and neurostimulators, creating a niche but high-value market opportunity.

The emerging market for second-life battery applications creates demand for sophisticated diagnostic tools that can accurately assess the condition of used batteries. EIS-based systems can determine the extent of sulfide interphase degradation, enabling more precise valuation and appropriate repurposing of battery components that would otherwise be discarded.

Technical Challenges in EIS-Based Sulfide Detection

Electrochemical Impedance Spectroscopy (EIS) faces significant technical challenges when applied to sulfide interphase evolution detection in battery systems. The complex nature of sulfide formation at electrode-electrolyte interfaces creates substantial impedance signal interpretation difficulties. Researchers struggle with distinguishing between various electrochemical processes occurring simultaneously, as sulfide layers generate overlapping time constants that complicate data analysis.

Signal-to-noise ratio presents another major obstacle, particularly when monitoring early-stage sulfide formation where impedance changes may be subtle. Environmental factors such as temperature fluctuations and mechanical vibrations can introduce artifacts that mask the actual sulfide-related impedance responses, necessitating advanced filtering techniques and controlled testing environments.

The dynamic nature of sulfide interphase evolution creates temporal resolution challenges. Traditional EIS measurements require relatively long acquisition times, during which the sulfide interface may continue evolving, resulting in time-averaged data rather than instantaneous snapshots. This limitation becomes particularly problematic when studying rapid sulfide formation processes or transient phenomena at electrode surfaces.

Electrode surface heterogeneity compounds these difficulties, as sulfide formation rarely occurs uniformly across electrode surfaces. This spatial variability creates distributed impedance responses that conventional EIS models struggle to accurately represent. Current equivalent circuit models often oversimplify the complex physicochemical processes involved in sulfide interphase formation and evolution.

Reference electrode configuration and placement issues further complicate accurate measurements. Improper reference electrode positioning can introduce phase shifts and distortions in impedance spectra, leading to misinterpretation of sulfide layer properties. This becomes especially problematic in miniaturized cell configurations or when studying specific localized sulfide formation.

Data interpretation frameworks remain underdeveloped for sulfide systems specifically. While general EIS analysis techniques exist, they often lack the specificity needed to isolate sulfide-related phenomena from other interfacial processes. Researchers frequently encounter difficulties correlating impedance features with specific physical or chemical aspects of the sulfide interphase.

Reproducibility challenges persist due to the sensitivity of sulfide formation to minute variations in experimental conditions. Small differences in electrolyte composition, electrode surface preparation, or environmental factors can significantly alter sulfide evolution pathways, making standardized testing protocols difficult to establish and maintain across different research groups.

Signal-to-noise ratio presents another major obstacle, particularly when monitoring early-stage sulfide formation where impedance changes may be subtle. Environmental factors such as temperature fluctuations and mechanical vibrations can introduce artifacts that mask the actual sulfide-related impedance responses, necessitating advanced filtering techniques and controlled testing environments.

The dynamic nature of sulfide interphase evolution creates temporal resolution challenges. Traditional EIS measurements require relatively long acquisition times, during which the sulfide interface may continue evolving, resulting in time-averaged data rather than instantaneous snapshots. This limitation becomes particularly problematic when studying rapid sulfide formation processes or transient phenomena at electrode surfaces.

Electrode surface heterogeneity compounds these difficulties, as sulfide formation rarely occurs uniformly across electrode surfaces. This spatial variability creates distributed impedance responses that conventional EIS models struggle to accurately represent. Current equivalent circuit models often oversimplify the complex physicochemical processes involved in sulfide interphase formation and evolution.

Reference electrode configuration and placement issues further complicate accurate measurements. Improper reference electrode positioning can introduce phase shifts and distortions in impedance spectra, leading to misinterpretation of sulfide layer properties. This becomes especially problematic in miniaturized cell configurations or when studying specific localized sulfide formation.

Data interpretation frameworks remain underdeveloped for sulfide systems specifically. While general EIS analysis techniques exist, they often lack the specificity needed to isolate sulfide-related phenomena from other interfacial processes. Researchers frequently encounter difficulties correlating impedance features with specific physical or chemical aspects of the sulfide interphase.

Reproducibility challenges persist due to the sensitivity of sulfide formation to minute variations in experimental conditions. Small differences in electrolyte composition, electrode surface preparation, or environmental factors can significantly alter sulfide evolution pathways, making standardized testing protocols difficult to establish and maintain across different research groups.

Current EIS Diagnostic Methodologies

01 EIS techniques for monitoring sulfide interphase formation in batteries

Electrochemical Impedance Spectroscopy (EIS) can be used to monitor the formation and evolution of sulfide-based solid electrolyte interphases in battery systems. This technique provides real-time data on the electrochemical properties of the interphase layer, allowing researchers to understand how the sulfide interphase forms and changes during battery operation. The impedance measurements can reveal critical information about the resistance, capacitance, and overall stability of the interphase, which directly impacts battery performance and longevity.- EIS techniques for monitoring sulfide interphase formation in batteries: Electrochemical Impedance Spectroscopy (EIS) can be used to monitor the formation and evolution of sulfide-based solid electrolyte interphases in battery systems. This technique provides real-time data on the electrochemical properties of the interphase layer, allowing researchers to understand how the sulfide interphase forms and changes during battery operation. The impedance measurements can reveal critical information about the resistance, capacitance, and other properties of the interphase, which directly affect battery performance and longevity.

- Characterization of sulfide interphase components using EIS: EIS-based diagnostic methods can characterize the chemical composition and structure of sulfide interphases. By analyzing the impedance response at different frequencies, researchers can identify specific components within the interphase layer, such as lithium sulfide, metal sulfides, and other reaction products. This characterization helps in understanding how different electrolyte additives and electrode materials influence the composition of the interphase, which is crucial for designing more stable and efficient battery systems.

- Correlation between EIS parameters and sulfide interphase stability: Research has established correlations between specific EIS parameters and the stability of sulfide interphases. Changes in impedance spectra, particularly in the mid-to-low frequency range, can indicate degradation or stabilization of the interphase layer. By monitoring these parameters over time, researchers can predict the long-term stability of the sulfide interphase and develop strategies to enhance its protective properties. This approach enables the design of battery systems with improved cycle life and safety characteristics.

- Advanced EIS modeling for sulfide interphase evolution: Advanced mathematical models have been developed to interpret EIS data specifically for sulfide interphase evolution. These models incorporate equivalent circuit elements that represent different physical and chemical processes occurring at the electrode-electrolyte interface. By fitting experimental EIS data to these models, researchers can quantify parameters such as charge transfer resistance, diffusion coefficients, and double-layer capacitance, providing insights into how the sulfide interphase evolves under different operating conditions and how it affects overall battery performance.

- In-situ EIS monitoring systems for sulfide interphase diagnostics: In-situ EIS monitoring systems have been developed specifically for real-time diagnostics of sulfide interphase evolution. These systems integrate EIS measurement capabilities directly into battery cells or testing platforms, allowing for continuous monitoring of interphase properties during cycling. The in-situ approach eliminates artifacts that may arise from disassembling cells for ex-situ analysis and provides more accurate information about dynamic processes occurring at the electrode-electrolyte interface. This technology is particularly valuable for understanding transient phenomena and early-stage interphase formation.

02 Characterization of sulfide interphase components using advanced EIS analysis

Advanced EIS analysis methods can be employed to characterize the specific components and properties of sulfide interphases. These methods include equivalent circuit modeling, distribution of relaxation times analysis, and frequency response analysis. By applying these techniques, researchers can identify the chemical composition, morphology, and electrochemical properties of the sulfide interphase layers. This detailed characterization helps in understanding how different components of the interphase contribute to its overall behavior and how they evolve during cycling.Expand Specific Solutions03 In-situ EIS monitoring of sulfide interphase degradation mechanisms

In-situ EIS measurements enable real-time monitoring of sulfide interphase degradation mechanisms during battery operation. This approach allows researchers to observe changes in the interphase as they occur, providing insights into degradation pathways such as cracking, dissolution, or chemical transformation of the sulfide components. By correlating impedance changes with cycling conditions, researchers can identify critical factors that accelerate interphase degradation and develop strategies to mitigate these effects, ultimately improving battery stability and cycle life.Expand Specific Solutions04 EIS-based diagnostic algorithms for sulfide interphase quality assessment

Specialized diagnostic algorithms based on EIS data can be developed to assess the quality and functionality of sulfide interphases. These algorithms analyze impedance patterns to identify signatures associated with favorable or unfavorable interphase properties. Machine learning approaches can be incorporated to process complex EIS data and extract meaningful indicators of interphase health. These diagnostic tools enable rapid evaluation of interphase quality during battery manufacturing and operation, allowing for early detection of potential issues and optimization of formation protocols.Expand Specific Solutions05 Temperature-dependent EIS analysis of sulfide interphase kinetics

Temperature-dependent EIS analysis provides valuable insights into the kinetics of processes occurring at sulfide interphases. By conducting impedance measurements across a range of temperatures, researchers can determine activation energies for ion transport through the interphase and identify rate-limiting steps in the electrochemical reactions. This approach helps in understanding how temperature affects the formation, growth, and properties of sulfide interphases, which is crucial for optimizing battery performance under various operating conditions and developing more robust sulfide-based solid electrolyte systems.Expand Specific Solutions

Leading Research Groups and Industry Players

EIS-Based Diagnostics for Sulfide Interphase Evolution is currently in an early development stage, with a growing market driven by the increasing demand for advanced battery technologies. The market is characterized by academic-industrial collaborations, with universities like Cornell, Leeds, and Osaka leading fundamental research while companies such as Ballard Power Systems and Analog Devices focus on commercial applications. Technical maturity varies significantly across players, with established research institutions (National Research Council of Canada, University of Leeds) demonstrating more advanced capabilities in electrochemical impedance spectroscopy techniques. Companies like Cellsine are developing specialized EIS devices for real-time monitoring, while larger corporations like Siemens Healthcare Diagnostics are integrating these diagnostic tools into broader analytical platforms, indicating a technology transitioning from research to practical implementation.

Ballard Power Systems, Inc.

Technical Solution: Ballard Power Systems has developed advanced EIS-based diagnostic techniques specifically for sulfide interphase evolution monitoring in fuel cell systems. Their approach integrates multi-frequency impedance measurements with machine learning algorithms to detect and characterize the formation of sulfide layers at critical interfaces. The technology employs a proprietary electrode configuration that enables in-situ monitoring during actual operation conditions, allowing for real-time detection of performance degradation caused by sulfur poisoning. Their diagnostic system can distinguish between different sulfide formation mechanisms and quantify the thickness and composition of interfacial layers with nanometer precision. This technology has been implemented in their latest generation of fuel cell stacks, where it continuously monitors interface evolution to predict maintenance needs and extend operational lifetime.

Strengths: Industry-leading real-time monitoring capability with high sensitivity to early-stage sulfide formation; integrated with commercial fuel cell systems for practical implementation. Weaknesses: Requires specialized hardware components that increase system complexity and cost; calibration process is time-consuming and needs to be repeated for different operating conditions.

Hefei University of Technology

Technical Solution: Hefei University of Technology has developed an innovative EIS-based diagnostic platform specifically for tracking sulfide interphase evolution in next-generation battery systems. Their approach combines traditional electrochemical impedance spectroscopy with advanced signal processing techniques to isolate the impedance response associated with sulfide layer formation and growth. The university's research team has created a unique measurement protocol that employs multiple excitation signals across different frequency domains, enabling the separation of overlapping electrochemical processes. Their diagnostic system incorporates machine learning algorithms trained on extensive experimental datasets to identify specific sulfide species based on their characteristic impedance signatures. The technology has been validated through extensive testing on various battery chemistries, demonstrating the ability to detect sulfide interphase changes that correlate with capacity fade and resistance increase. Recent publications highlight their success in using this technique to optimize electrolyte additives that suppress detrimental sulfide formation.

Strengths: Highly specialized for battery applications with demonstrated correlation to performance metrics; adaptable to different cell chemistries and formats. Weaknesses: Currently limited to laboratory settings with controlled environments; requires significant computing resources for real-time analysis of complex impedance data.

Key Patents and Literature on Sulfide Interphase Characterization

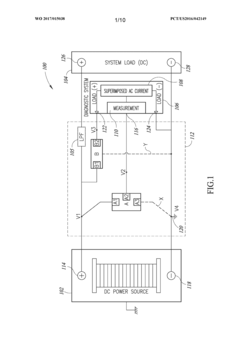

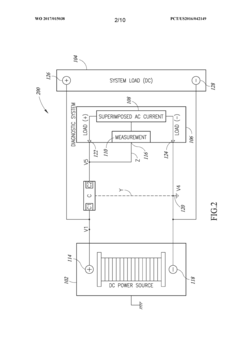

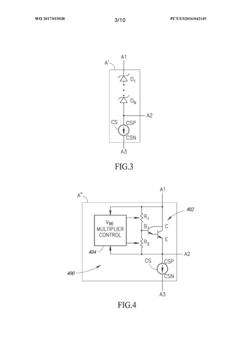

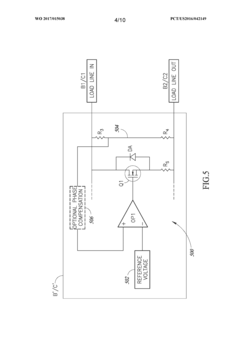

Reduced stack voltage circuitry for energy storage system diagnostics

PatentWO2017015038A1

Innovation

- A reduced voltage circuitry is introduced to interface a DC power source with an AC signal diagnostic system, using a voltage-reduction circuit that reduces the DC component of the input voltage without affecting the AC component, allowing for efficient diagnostic measurements and improving high voltage to low voltage isolation, enabling the use of lower-cost signal processing electronics.

Standardization Efforts in Electrochemical Diagnostics

The field of electrochemical impedance spectroscopy (EIS) for sulfide interphase evolution diagnostics has seen significant efforts toward standardization in recent years. These initiatives aim to establish consistent protocols, methodologies, and reporting frameworks that enable reliable comparison of results across different research groups and industrial applications.

International organizations such as the International Electrotechnical Commission (IEC) and the International Union of Pure and Applied Chemistry (IUPAC) have been instrumental in developing standardized terminology and measurement protocols specifically for EIS applications in battery systems. Technical Committee 21 of the IEC has published several standards addressing electrochemical measurements in energy storage systems, with recent additions focusing on sulfide-based solid electrolyte interfaces.

ASTM International has also contributed through its Committee E08 on Fatigue and Fracture, which has developed testing standards that incorporate EIS methodologies for detecting and characterizing interfacial degradation mechanisms. These standards provide detailed guidelines on sample preparation, measurement conditions, and data interpretation specifically for sulfide interphase evolution.

The Battery Data Genome Project represents a collaborative effort to standardize electrochemical data collection and reporting, including EIS data for sulfide interphase characterization. This initiative has established open-source data formats and metadata requirements that facilitate data sharing and cross-validation between laboratories worldwide.

Equipment manufacturers have responded to standardization needs by developing calibration protocols and reference materials specifically designed for sulfide interphase measurements. Companies like Bio-Logic, Gamry Instruments, and Solartron have incorporated these standards into their software platforms, enabling automated compliance with established protocols.

Academic consortia, particularly those focused on solid-state battery technologies, have established round-robin testing programs to validate measurement reproducibility across different laboratories. These efforts have resulted in published best practices for EIS measurements of sulfide-based solid electrolyte interfaces, addressing issues such as contact resistance compensation and environmental control during measurements.

The emergence of machine learning approaches for EIS data interpretation has further accelerated standardization efforts, with initiatives to establish benchmark datasets and validation methodologies. The Battery Interface Genome - Materials Acceleration Platform (BIG-MAP) has been particularly active in developing standardized data structures and analysis workflows for high-throughput EIS characterization of evolving interfaces.

Despite these advances, challenges remain in achieving full standardization, particularly regarding in-situ and operando measurements where experimental conditions are difficult to control precisely. Ongoing work focuses on developing reference electrodes and cell designs specifically optimized for reproducible sulfide interphase measurements under realistic operating conditions.

International organizations such as the International Electrotechnical Commission (IEC) and the International Union of Pure and Applied Chemistry (IUPAC) have been instrumental in developing standardized terminology and measurement protocols specifically for EIS applications in battery systems. Technical Committee 21 of the IEC has published several standards addressing electrochemical measurements in energy storage systems, with recent additions focusing on sulfide-based solid electrolyte interfaces.

ASTM International has also contributed through its Committee E08 on Fatigue and Fracture, which has developed testing standards that incorporate EIS methodologies for detecting and characterizing interfacial degradation mechanisms. These standards provide detailed guidelines on sample preparation, measurement conditions, and data interpretation specifically for sulfide interphase evolution.

The Battery Data Genome Project represents a collaborative effort to standardize electrochemical data collection and reporting, including EIS data for sulfide interphase characterization. This initiative has established open-source data formats and metadata requirements that facilitate data sharing and cross-validation between laboratories worldwide.

Equipment manufacturers have responded to standardization needs by developing calibration protocols and reference materials specifically designed for sulfide interphase measurements. Companies like Bio-Logic, Gamry Instruments, and Solartron have incorporated these standards into their software platforms, enabling automated compliance with established protocols.

Academic consortia, particularly those focused on solid-state battery technologies, have established round-robin testing programs to validate measurement reproducibility across different laboratories. These efforts have resulted in published best practices for EIS measurements of sulfide-based solid electrolyte interfaces, addressing issues such as contact resistance compensation and environmental control during measurements.

The emergence of machine learning approaches for EIS data interpretation has further accelerated standardization efforts, with initiatives to establish benchmark datasets and validation methodologies. The Battery Interface Genome - Materials Acceleration Platform (BIG-MAP) has been particularly active in developing standardized data structures and analysis workflows for high-throughput EIS characterization of evolving interfaces.

Despite these advances, challenges remain in achieving full standardization, particularly regarding in-situ and operando measurements where experimental conditions are difficult to control precisely. Ongoing work focuses on developing reference electrodes and cell designs specifically optimized for reproducible sulfide interphase measurements under realistic operating conditions.

Safety and Environmental Implications of Sulfide Materials

The safety and environmental implications of sulfide materials in battery systems present significant challenges that must be addressed for widespread adoption of solid-state sulfide electrolytes. Sulfide-based solid electrolytes, while promising for next-generation batteries, pose unique hazards due to their chemical reactivity. When exposed to moisture or ambient air, these materials readily decompose to produce hydrogen sulfide (H₂S), a highly toxic gas that can cause respiratory distress, eye irritation, and even death at high concentrations. This reactivity necessitates stringent handling protocols in both research and manufacturing environments.

Manufacturing processes for sulfide materials require specialized equipment and controlled atmospheres, typically utilizing inert gas gloveboxes to prevent moisture contact. These requirements substantially increase production costs and complexity compared to oxide-based alternatives. The implementation of robust safety systems, including H₂S detection sensors and emergency ventilation protocols, is essential for facilities working with these materials at scale.

Environmental considerations extend beyond immediate safety concerns to the full lifecycle of sulfide-based batteries. The potential for sulfide leaching into soil and water systems during improper disposal presents ecological risks that must be mitigated through comprehensive recycling programs. Current recycling technologies for conventional lithium-ion batteries may require significant adaptation to safely process sulfide components without generating hazardous byproducts.

Regulatory frameworks governing the transportation, storage, and disposal of sulfide materials vary globally, creating compliance challenges for international supply chains. The classification of certain sulfide electrolytes as hazardous materials imposes additional documentation requirements and shipping restrictions that impact commercialization timelines and costs.

Recent research has focused on developing more environmentally stable sulfide materials through surface modification techniques and compositional engineering. These approaches aim to reduce reactivity with atmospheric moisture while maintaining favorable ionic conductivity properties. Electrochemical impedance spectroscopy (EIS) serves as a critical diagnostic tool for monitoring the degradation of these materials under various environmental conditions, enabling researchers to quantify stability improvements and optimize protective measures.

The development of encapsulation technologies and protective coatings represents another promising direction for mitigating safety concerns while preserving the performance advantages of sulfide electrolytes. These engineering solutions must balance protection against environmental factors with minimal impact on electrochemical performance and manufacturing scalability.

Manufacturing processes for sulfide materials require specialized equipment and controlled atmospheres, typically utilizing inert gas gloveboxes to prevent moisture contact. These requirements substantially increase production costs and complexity compared to oxide-based alternatives. The implementation of robust safety systems, including H₂S detection sensors and emergency ventilation protocols, is essential for facilities working with these materials at scale.

Environmental considerations extend beyond immediate safety concerns to the full lifecycle of sulfide-based batteries. The potential for sulfide leaching into soil and water systems during improper disposal presents ecological risks that must be mitigated through comprehensive recycling programs. Current recycling technologies for conventional lithium-ion batteries may require significant adaptation to safely process sulfide components without generating hazardous byproducts.

Regulatory frameworks governing the transportation, storage, and disposal of sulfide materials vary globally, creating compliance challenges for international supply chains. The classification of certain sulfide electrolytes as hazardous materials imposes additional documentation requirements and shipping restrictions that impact commercialization timelines and costs.

Recent research has focused on developing more environmentally stable sulfide materials through surface modification techniques and compositional engineering. These approaches aim to reduce reactivity with atmospheric moisture while maintaining favorable ionic conductivity properties. Electrochemical impedance spectroscopy (EIS) serves as a critical diagnostic tool for monitoring the degradation of these materials under various environmental conditions, enabling researchers to quantify stability improvements and optimize protective measures.

The development of encapsulation technologies and protective coatings represents another promising direction for mitigating safety concerns while preserving the performance advantages of sulfide electrolytes. These engineering solutions must balance protection against environmental factors with minimal impact on electrochemical performance and manufacturing scalability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!