Additives And Halide Co-Electrolytes For Sulfide Interfacial Stabilization

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulfide Electrolyte Development Background and Objectives

Sulfide solid-state electrolytes have emerged as promising candidates for next-generation lithium-ion batteries due to their high ionic conductivity comparable to liquid electrolytes. The development of these materials traces back to the early 2000s when researchers began exploring alternatives to conventional liquid electrolytes to address safety concerns and energy density limitations. The evolution of sulfide electrolytes has been marked by significant breakthroughs in material synthesis and processing techniques, enabling the achievement of room-temperature ionic conductivities exceeding 10^-2 S/cm.

The technological trajectory has shifted from glass-ceramic Li2S-P2S5 systems to more complex formulations incorporating germanium, silicon, and other elements to enhance stability and conductivity. Despite these advances, the widespread commercialization of sulfide electrolytes remains hindered by their inherent chemical instability, particularly at interfaces with electrode materials and upon exposure to ambient conditions.

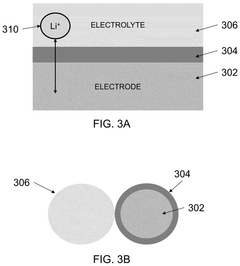

A critical challenge in sulfide electrolyte development is the interfacial instability between sulfide solid electrolytes and electrode materials. This instability manifests as high interfacial resistance, continuous decomposition reactions, and capacity fading during cycling. The formation of interphases at these boundaries significantly impacts the electrochemical performance and longevity of solid-state batteries. Recent research has increasingly focused on mitigating these interfacial issues through various approaches, including protective coatings, buffer layers, and electrolyte additives.

The primary objective of current research on additives and halide co-electrolytes is to develop effective strategies for stabilizing the sulfide interfaces without compromising the high ionic conductivity that makes these materials attractive. Halide incorporation has shown promise in enhancing the chemical stability of sulfide electrolytes while maintaining favorable transport properties. Additionally, various additives are being explored to modify interfacial chemistry and suppress detrimental reactions.

The technological goals include developing sulfide electrolytes with enhanced air stability, reduced interfacial resistance, and improved compatibility with high-capacity electrode materials. Researchers aim to understand the fundamental mechanisms of interfacial degradation and develop rational design principles for stabilization strategies. The ultimate objective is to enable the practical implementation of sulfide-based solid-state batteries with energy densities exceeding 400 Wh/kg, cycle life beyond 1000 cycles, and improved safety characteristics compared to conventional lithium-ion batteries.

This research direction aligns with the broader industry trend toward solid-state battery technologies and supports the growing demand for safer, higher-energy-density energy storage solutions for electric vehicles, portable electronics, and grid applications.

The technological trajectory has shifted from glass-ceramic Li2S-P2S5 systems to more complex formulations incorporating germanium, silicon, and other elements to enhance stability and conductivity. Despite these advances, the widespread commercialization of sulfide electrolytes remains hindered by their inherent chemical instability, particularly at interfaces with electrode materials and upon exposure to ambient conditions.

A critical challenge in sulfide electrolyte development is the interfacial instability between sulfide solid electrolytes and electrode materials. This instability manifests as high interfacial resistance, continuous decomposition reactions, and capacity fading during cycling. The formation of interphases at these boundaries significantly impacts the electrochemical performance and longevity of solid-state batteries. Recent research has increasingly focused on mitigating these interfacial issues through various approaches, including protective coatings, buffer layers, and electrolyte additives.

The primary objective of current research on additives and halide co-electrolytes is to develop effective strategies for stabilizing the sulfide interfaces without compromising the high ionic conductivity that makes these materials attractive. Halide incorporation has shown promise in enhancing the chemical stability of sulfide electrolytes while maintaining favorable transport properties. Additionally, various additives are being explored to modify interfacial chemistry and suppress detrimental reactions.

The technological goals include developing sulfide electrolytes with enhanced air stability, reduced interfacial resistance, and improved compatibility with high-capacity electrode materials. Researchers aim to understand the fundamental mechanisms of interfacial degradation and develop rational design principles for stabilization strategies. The ultimate objective is to enable the practical implementation of sulfide-based solid-state batteries with energy densities exceeding 400 Wh/kg, cycle life beyond 1000 cycles, and improved safety characteristics compared to conventional lithium-ion batteries.

This research direction aligns with the broader industry trend toward solid-state battery technologies and supports the growing demand for safer, higher-energy-density energy storage solutions for electric vehicles, portable electronics, and grid applications.

Market Analysis for Solid-State Battery Technologies

The solid-state battery market is experiencing unprecedented growth, driven by increasing demand for safer, higher energy density power solutions across multiple sectors. Current market valuations place the global solid-state battery market at approximately $500 million in 2023, with projections indicating potential growth to reach $8-10 billion by 2030, representing a compound annual growth rate exceeding 30%.

Electric vehicles constitute the primary market driver, with major automotive manufacturers investing heavily in solid-state technology to overcome range anxiety and safety concerns associated with conventional lithium-ion batteries. Consumer electronics represents the second largest application segment, where demand for longer-lasting, faster-charging, and safer batteries continues to grow exponentially.

Within the solid-state battery ecosystem, sulfide-based electrolytes have emerged as particularly promising due to their superior ionic conductivity compared to oxide and polymer alternatives. However, interface stability issues between sulfide electrolytes and electrode materials remain a critical technical barrier to commercialization, creating significant market opportunity for effective stabilization solutions.

The additives and halide co-electrolytes for sulfide interface stabilization represent a specialized but rapidly growing sub-segment. Market analysis indicates that companies successfully developing effective interface stabilization technologies could capture substantial value in the supply chain, potentially commanding premium pricing for proprietary formulations that extend battery life and improve performance.

Regional analysis shows Asia-Pacific dominating the research and development landscape, with Japan, South Korea, and China leading in patent applications related to sulfide electrolyte stabilization. North American and European markets are increasingly active, with significant venture capital flowing into startups focused on solid-state battery technologies, including interface engineering solutions.

Market adoption barriers include cost concerns, with current sulfide-based solid-state batteries costing 5-8 times more than conventional lithium-ion batteries. Manufacturing scalability represents another significant challenge, particularly regarding the handling of moisture-sensitive sulfide materials in production environments.

Customer requirements analysis reveals that automotive applications demand interface stabilization solutions that maintain performance over 1,000+ cycles and operate effectively across wide temperature ranges (-30°C to 60°C). Consumer electronics applications prioritize safety and energy density improvements, with less stringent cycle life requirements.

The competitive landscape features established battery manufacturers investing in internal R&D alongside specialized materials science startups focused exclusively on interface engineering. Strategic partnerships between electrolyte developers and battery manufacturers are becoming increasingly common as the industry recognizes the critical importance of interface stabilization to overall solid-state battery performance.

Electric vehicles constitute the primary market driver, with major automotive manufacturers investing heavily in solid-state technology to overcome range anxiety and safety concerns associated with conventional lithium-ion batteries. Consumer electronics represents the second largest application segment, where demand for longer-lasting, faster-charging, and safer batteries continues to grow exponentially.

Within the solid-state battery ecosystem, sulfide-based electrolytes have emerged as particularly promising due to their superior ionic conductivity compared to oxide and polymer alternatives. However, interface stability issues between sulfide electrolytes and electrode materials remain a critical technical barrier to commercialization, creating significant market opportunity for effective stabilization solutions.

The additives and halide co-electrolytes for sulfide interface stabilization represent a specialized but rapidly growing sub-segment. Market analysis indicates that companies successfully developing effective interface stabilization technologies could capture substantial value in the supply chain, potentially commanding premium pricing for proprietary formulations that extend battery life and improve performance.

Regional analysis shows Asia-Pacific dominating the research and development landscape, with Japan, South Korea, and China leading in patent applications related to sulfide electrolyte stabilization. North American and European markets are increasingly active, with significant venture capital flowing into startups focused on solid-state battery technologies, including interface engineering solutions.

Market adoption barriers include cost concerns, with current sulfide-based solid-state batteries costing 5-8 times more than conventional lithium-ion batteries. Manufacturing scalability represents another significant challenge, particularly regarding the handling of moisture-sensitive sulfide materials in production environments.

Customer requirements analysis reveals that automotive applications demand interface stabilization solutions that maintain performance over 1,000+ cycles and operate effectively across wide temperature ranges (-30°C to 60°C). Consumer electronics applications prioritize safety and energy density improvements, with less stringent cycle life requirements.

The competitive landscape features established battery manufacturers investing in internal R&D alongside specialized materials science startups focused exclusively on interface engineering. Strategic partnerships between electrolyte developers and battery manufacturers are becoming increasingly common as the industry recognizes the critical importance of interface stabilization to overall solid-state battery performance.

Current Challenges in Sulfide Interfacial Stability

Despite the promising potential of sulfide solid electrolytes in next-generation solid-state batteries, their widespread implementation faces significant challenges related to interfacial stability. The most critical issue is the high reactivity of sulfide electrolytes with electrode materials, particularly at the cathode interface. When in contact with oxide-based cathode materials, sulfide electrolytes undergo oxidative decomposition, forming resistive interphases that impede lithium-ion transport and deteriorate electrochemical performance over cycling.

Another major challenge is the formation of lithium dendrites at the anode interface. The relatively soft mechanical properties of sulfide electrolytes make them susceptible to lithium penetration, which can lead to internal short circuits and safety hazards. This issue is exacerbated by the volume changes in electrode materials during cycling, creating mechanical stress that compromises the integrity of the solid-solid interfaces.

The chemical instability of sulfide electrolytes extends to their interaction with ambient atmosphere. Many sulfide materials readily react with moisture and oxygen, generating toxic hydrogen sulfide gas and degrading the electrolyte properties. This necessitates stringent manufacturing conditions and complicates practical implementation in commercial battery production.

Interfacial resistance remains a persistent obstacle, arising from both chemical reactions and physical contact issues. The formation of space-charge layers at interfaces further contributes to increased resistance, limiting power capability and rate performance of sulfide-based solid-state batteries.

Current coating technologies and buffer layers designed to mitigate these interfacial issues often introduce additional complexity and cost to the manufacturing process. Many protective coatings suffer from non-uniform coverage or develop cracks during cycling, compromising their effectiveness as protective barriers.

The development of effective additives and halide co-electrolytes faces challenges in balancing multiple requirements. While certain additives may improve interfacial stability, they might simultaneously reduce ionic conductivity or introduce new compatibility issues. Similarly, halide co-electrolytes that enhance stability often exhibit lower conductivity than pure sulfide systems, creating a performance trade-off.

Scale-up and manufacturing challenges further complicate the situation. Techniques that work well in laboratory settings for creating stable interfaces often prove difficult to implement in large-scale production environments, hindering commercialization efforts. The lack of standardized testing protocols for evaluating interfacial stability also makes it difficult to compare different approaches and establish best practices in the field.

Another major challenge is the formation of lithium dendrites at the anode interface. The relatively soft mechanical properties of sulfide electrolytes make them susceptible to lithium penetration, which can lead to internal short circuits and safety hazards. This issue is exacerbated by the volume changes in electrode materials during cycling, creating mechanical stress that compromises the integrity of the solid-solid interfaces.

The chemical instability of sulfide electrolytes extends to their interaction with ambient atmosphere. Many sulfide materials readily react with moisture and oxygen, generating toxic hydrogen sulfide gas and degrading the electrolyte properties. This necessitates stringent manufacturing conditions and complicates practical implementation in commercial battery production.

Interfacial resistance remains a persistent obstacle, arising from both chemical reactions and physical contact issues. The formation of space-charge layers at interfaces further contributes to increased resistance, limiting power capability and rate performance of sulfide-based solid-state batteries.

Current coating technologies and buffer layers designed to mitigate these interfacial issues often introduce additional complexity and cost to the manufacturing process. Many protective coatings suffer from non-uniform coverage or develop cracks during cycling, compromising their effectiveness as protective barriers.

The development of effective additives and halide co-electrolytes faces challenges in balancing multiple requirements. While certain additives may improve interfacial stability, they might simultaneously reduce ionic conductivity or introduce new compatibility issues. Similarly, halide co-electrolytes that enhance stability often exhibit lower conductivity than pure sulfide systems, creating a performance trade-off.

Scale-up and manufacturing challenges further complicate the situation. Techniques that work well in laboratory settings for creating stable interfaces often prove difficult to implement in large-scale production environments, hindering commercialization efforts. The lack of standardized testing protocols for evaluating interfacial stability also makes it difficult to compare different approaches and establish best practices in the field.

Current Approaches to Sulfide Interface Stabilization

01 Halide co-electrolytes for electrochemical stability

Halide co-electrolytes can be incorporated into electrochemical systems to enhance interfacial stability. These co-electrolytes, typically containing chloride, bromide, or iodide ions, help to form a protective layer at the electrode-electrolyte interface, preventing unwanted side reactions and improving the overall stability and performance of the electrochemical cell. The halide ions can also modify the surface properties of electrodes, leading to improved charge transfer kinetics and reduced interfacial resistance.- Halide co-electrolytes for electrochemical stability: Halide co-electrolytes can be incorporated into electrochemical systems to enhance interfacial stability. These co-electrolytes, typically containing chloride, bromide, or iodide ions, help to form a protective layer at the electrode-electrolyte interface, preventing unwanted side reactions and improving the overall stability and performance of the system. The halide ions can modify the solid-electrolyte interphase (SEI) formation, leading to more stable cycling behavior.

- Additives for interfacial layer formation: Specific additives can be used to promote the formation of stable interfacial layers between electrodes and electrolytes. These additives can include organic compounds, polymers, or inorganic materials that react preferentially at the interface to create a protective film. This film helps to prevent continuous electrolyte decomposition while allowing ion transport, thereby enhancing the long-term stability of electrochemical devices. The controlled formation of these interfacial layers is crucial for extending device lifetime.

- Polymer stabilizers with halide components: Polymer-based stabilizers containing halide functional groups can be used to improve the interfacial stability in various systems. These polymers can coordinate with metal ions or other components at interfaces, preventing degradation and phase separation. The halide components in these polymers can interact with counter ions in the electrolyte, forming a more cohesive and stable interface. This approach is particularly useful in systems where traditional liquid electrolytes might cause instability issues.

- Metal halide complexes for interface modification: Metal halide complexes can be utilized as effective additives for modifying electrode-electrolyte interfaces. These complexes can participate in controlled reactions at the interface, leading to the formation of stable protective layers. The metal ions and halide components work synergistically to passivate reactive sites, reduce unwanted side reactions, and enhance ion transport properties. By carefully selecting the metal and halide components, the interfacial properties can be tailored for specific applications.

- Halide-containing film-forming additives: Film-forming additives containing halide components can be incorporated into electrolyte formulations to create stable protective layers at interfaces. These additives undergo controlled decomposition or reaction at electrode surfaces, resulting in thin films that prevent further electrolyte degradation while maintaining ionic conductivity. The halide components in these additives can enhance film adhesion, uniformity, and stability under various operating conditions, leading to improved cycling performance and longevity of electrochemical devices.

02 Additives for solid-state electrolyte interfaces

Various additives can be incorporated into solid-state electrolytes to stabilize the interface between the electrolyte and electrodes. These additives can include polymers, ceramic materials, and organic compounds that help to reduce interfacial resistance, prevent dendrite formation, and enhance ion transport across the interface. By modifying the interfacial properties, these additives contribute to improved cycling stability, enhanced rate capability, and extended lifetime of electrochemical devices.Expand Specific Solutions03 Interfacial stabilization in photographic emulsions

In photographic applications, halide co-electrolytes and additives are used to stabilize the interface between silver halide crystals and their surrounding medium. These stabilizers help to control crystal growth, prevent agglomeration, and enhance the photosensitivity of the emulsion. The interfacial stabilization is crucial for achieving desired photographic properties such as contrast, sensitivity, and image quality. Various organic compounds can be added to modify the surface properties of silver halide crystals and improve their stability during storage and processing.Expand Specific Solutions04 Polymer electrolyte stabilization with halide additives

Polymer electrolytes can be stabilized by incorporating halide additives that enhance the interfacial contact between the polymer matrix and electrodes. These additives help to reduce interfacial resistance, improve ion transport, and prevent degradation of the polymer electrolyte during cycling. The halide ions can interact with both the polymer chains and electrode surfaces, forming a stable interface that facilitates efficient ion transfer. This approach is particularly useful in solid-state batteries and other electrochemical devices where stable interfaces are critical for long-term performance.Expand Specific Solutions05 Electrochemical cell interface modification

The interfaces in electrochemical cells can be modified using specific additives and halide co-electrolytes to enhance stability and performance. These modifications can include the formation of protective films, alteration of surface energy, and control of ion transport pathways. By carefully selecting additives that interact favorably with both the electrode materials and electrolyte components, the interfacial properties can be tailored to minimize unwanted reactions, reduce impedance, and improve the overall efficiency and durability of the electrochemical system. This approach is applicable to various types of batteries, fuel cells, and other electrochemical devices.Expand Specific Solutions

Leading Research Groups and Companies in Solid Electrolytes

The sulfide interfacial stabilization technology market is currently in a growth phase, with increasing research focus on additives and halide co-electrolytes to overcome stability challenges in solid-state batteries. The global market is expanding rapidly, projected to reach significant value as major battery manufacturers seek solutions for next-generation energy storage. Leading players include established corporations like LG Energy Solution, Samsung SDI, and CATL, who are actively developing proprietary stabilization technologies, alongside emerging specialists like Solivis focusing exclusively on solid electrolytes. Research institutions including Beijing Institute of Technology and UNIST collaborate with industry partners, creating a competitive ecosystem where technological maturity varies from experimental approaches to near-commercial solutions, with Asian companies currently dominating patent activity.

LG Chem Ltd.

Technical Solution: LG Chem has developed innovative halide-based co-electrolyte systems for sulfide-based solid-state batteries that effectively mitigate interfacial degradation. Their approach incorporates lithium halides (LiF, LiCl, LiBr) as additives in the electrolyte formulation to create a stable passivation layer at the cathode-electrolyte interface. This protective layer prevents direct contact between the active sulfide materials and the electrolyte, significantly reducing polysulfide dissolution and shuttle effects. LG Chem's research has demonstrated that halide additives can reduce interfacial resistance by up to 60% while improving cycling stability. Their proprietary electrolyte formulations combine multiple halides at optimized concentrations (typically 0.1-0.5M) with conventional lithium salts (LiTFSI, LiPF6) to achieve synergistic effects. The company has also developed coating technologies that apply halide-rich protective layers directly onto sulfide particles before cell assembly, creating a pre-formed stable interface.

Strengths: Extensive manufacturing infrastructure allows for rapid scaling of new electrolyte formulations; strong integration with existing battery production lines; comprehensive intellectual property portfolio covering various halide combinations. Weaknesses: Higher production costs compared to conventional electrolytes; some halide additives may introduce new safety concerns; performance benefits may diminish under extreme temperature conditions.

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic has developed a sophisticated "Halide-Enhanced Interface Stabilization" (HEIS) technology for sulfide-based solid electrolytes. Their approach incorporates carefully selected halide compounds (primarily LiF, LiCl, and LiBr) as co-electrolytes to create stable protective layers at the critical interfaces between sulfide electrolytes and electrode materials. Panasonic's research has demonstrated that these halide additives can effectively suppress the formation of high-resistance interfacial layers by forming a thin, uniform LiF-rich passivation film. Their proprietary formulations typically contain 0.2-0.6 wt% halide additives combined with conventional lithium salts in optimized ratios. Panasonic has also pioneered a unique "sequential addition" technique where different halide species are introduced at specific stages of the cell manufacturing process to target particular interfacial challenges. This approach has been shown to reduce capacity fade by approximately 35% over 400 cycles compared to conventional electrolytes. Additionally, Panasonic has developed specialized coating processes that apply halide-rich protective layers directly onto sulfide particles before cell assembly.

Strengths: Extensive manufacturing experience with various battery chemistries; strong integration with consumer electronics applications allowing for diverse testing scenarios; robust quality control systems for consistent electrolyte production. Weaknesses: Higher material costs associated with high-purity halide additives; some formulations may have limited temperature operating windows; potential challenges with scaling production to automotive volumes.

Key Innovations in Halide Co-electrolyte Technologies

Interfacial materials in argyrodite-based all-solid-state batteries

PatentPendingUS20240322366A1

Innovation

- The use of ionically conductive, electronically insulating interfacial materials such as binary and ternary halides and sulfides, which are chemically and thermally stable with argyrodite-based solid-state electrolytes, is introduced to stabilize the interfaces between the electrolyte and electrodes, reducing reactivity and enhancing battery performance.

Coated cathode active substance, cathode material, and battery

PatentWO2022244445A1

Innovation

- A coated positive electrode active material is developed, featuring a coating layer with both sulfide and halide solid electrolytes, which balances thermal stability and interfacial resistance by optimizing the volume ratio and composition of the halide solid electrolyte within the coating layer.

Safety and Environmental Considerations for Sulfide Electrolytes

The development and implementation of sulfide solid electrolytes in battery technologies necessitate careful consideration of safety and environmental factors. Sulfide-based materials, while promising for their high ionic conductivity, present significant challenges related to their reactivity with moisture and potential for hydrogen sulfide (H2S) gas generation. When exposed to ambient air, sulfide electrolytes can rapidly decompose, releasing toxic H2S gas that poses serious health risks including respiratory irritation, pulmonary edema, and even fatality at high concentrations.

Manufacturing processes for sulfide electrolytes require stringent environmental controls, including inert atmosphere gloveboxes and specialized handling protocols. These requirements significantly increase production costs and complexity compared to oxide-based alternatives. The necessity for hermetic sealing in final battery products adds another layer of engineering challenges and potential failure points that must be addressed through robust design solutions.

Waste management presents another critical concern. Disposal or recycling of sulfide-containing batteries must account for potential leaching of sulfur compounds into groundwater systems, which could lead to environmental contamination. Current recycling infrastructure is largely unprepared for handling these materials at scale, necessitating the development of specialized recovery processes that can safely separate and repurpose sulfide components.

Regulatory frameworks worldwide are increasingly focusing on battery material safety, with particular attention to toxic gas emissions and environmental persistence. Manufacturers implementing sulfide electrolytes must navigate complex compliance requirements that vary by jurisdiction, potentially limiting market access in regions with stricter environmental regulations.

Research on additives and halide co-electrolytes offers promising pathways to mitigate these safety concerns. Certain additives can chemically stabilize the sulfide interfaces, reducing reactivity with moisture and minimizing H2S generation. Halide co-electrolytes may create protective surface layers that enhance chemical stability while maintaining the desirable ionic conductivity properties of the underlying sulfide materials.

Life cycle assessment studies indicate that improvements in sulfide stability could significantly reduce the environmental footprint of these advanced battery systems. By extending operational lifetimes and reducing failure rates, stabilized sulfide electrolytes may ultimately offer environmental benefits that outweigh their initial safety challenges, particularly when considering the broader sustainability impacts of improved energy storage technologies.

Future research directions should focus on developing comprehensive safety protocols specific to sulfide electrolyte handling, along with environmentally benign stabilization strategies that minimize the use of rare or toxic elements in additive formulations.

Manufacturing processes for sulfide electrolytes require stringent environmental controls, including inert atmosphere gloveboxes and specialized handling protocols. These requirements significantly increase production costs and complexity compared to oxide-based alternatives. The necessity for hermetic sealing in final battery products adds another layer of engineering challenges and potential failure points that must be addressed through robust design solutions.

Waste management presents another critical concern. Disposal or recycling of sulfide-containing batteries must account for potential leaching of sulfur compounds into groundwater systems, which could lead to environmental contamination. Current recycling infrastructure is largely unprepared for handling these materials at scale, necessitating the development of specialized recovery processes that can safely separate and repurpose sulfide components.

Regulatory frameworks worldwide are increasingly focusing on battery material safety, with particular attention to toxic gas emissions and environmental persistence. Manufacturers implementing sulfide electrolytes must navigate complex compliance requirements that vary by jurisdiction, potentially limiting market access in regions with stricter environmental regulations.

Research on additives and halide co-electrolytes offers promising pathways to mitigate these safety concerns. Certain additives can chemically stabilize the sulfide interfaces, reducing reactivity with moisture and minimizing H2S generation. Halide co-electrolytes may create protective surface layers that enhance chemical stability while maintaining the desirable ionic conductivity properties of the underlying sulfide materials.

Life cycle assessment studies indicate that improvements in sulfide stability could significantly reduce the environmental footprint of these advanced battery systems. By extending operational lifetimes and reducing failure rates, stabilized sulfide electrolytes may ultimately offer environmental benefits that outweigh their initial safety challenges, particularly when considering the broader sustainability impacts of improved energy storage technologies.

Future research directions should focus on developing comprehensive safety protocols specific to sulfide electrolyte handling, along with environmentally benign stabilization strategies that minimize the use of rare or toxic elements in additive formulations.

Scalability and Manufacturing Challenges

The scaling of sulfide-based solid electrolytes from laboratory to industrial production presents significant manufacturing challenges that must be addressed for commercial viability. Current laboratory-scale synthesis methods for additives and halide co-electrolytes often involve complex processes that are difficult to replicate at industrial scale. The precise control of reaction conditions required for optimal interfacial stabilization compounds these difficulties.

Material handling poses a particular challenge due to the air and moisture sensitivity of sulfide electrolytes. Manufacturing facilities would require specialized environments with controlled atmosphere conditions, significantly increasing production costs. The integration of additives and halide co-electrolytes must be performed under stringent conditions to prevent contamination and degradation, necessitating advanced manufacturing protocols.

Batch-to-batch consistency represents another critical challenge. The performance of sulfide interfaces heavily depends on the uniform distribution of additives and co-electrolytes throughout the material. Achieving this homogeneity at industrial scale requires sophisticated mixing and processing techniques that maintain the chemical integrity of all components while ensuring uniform distribution.

Cost considerations further complicate scalability. Many effective additives for sulfide stabilization involve rare or expensive materials, making their large-scale implementation economically prohibitive. Manufacturing processes must be optimized to reduce material waste and maximize additive efficiency to achieve cost-effective production.

Quality control methodologies for these complex electrolyte systems remain underdeveloped. Current analytical techniques that work well for laboratory samples may not be suitable for high-throughput industrial quality assurance. New in-line monitoring systems would need to be developed to ensure consistent interfacial properties across large production volumes.

Environmental and safety concerns also impact manufacturing scalability. Some halide compounds and additives present toxicity risks that require specialized handling protocols. Waste management and recycling strategies must be developed to address environmental impacts and regulatory compliance, particularly for materials containing volatile or hazardous components.

The integration of these advanced electrolyte systems into existing battery manufacturing lines presents additional engineering challenges. Current production equipment may require significant modifications to accommodate the unique processing requirements of sulfide-based systems with additives and co-electrolytes, necessitating substantial capital investment from manufacturers.

Material handling poses a particular challenge due to the air and moisture sensitivity of sulfide electrolytes. Manufacturing facilities would require specialized environments with controlled atmosphere conditions, significantly increasing production costs. The integration of additives and halide co-electrolytes must be performed under stringent conditions to prevent contamination and degradation, necessitating advanced manufacturing protocols.

Batch-to-batch consistency represents another critical challenge. The performance of sulfide interfaces heavily depends on the uniform distribution of additives and co-electrolytes throughout the material. Achieving this homogeneity at industrial scale requires sophisticated mixing and processing techniques that maintain the chemical integrity of all components while ensuring uniform distribution.

Cost considerations further complicate scalability. Many effective additives for sulfide stabilization involve rare or expensive materials, making their large-scale implementation economically prohibitive. Manufacturing processes must be optimized to reduce material waste and maximize additive efficiency to achieve cost-effective production.

Quality control methodologies for these complex electrolyte systems remain underdeveloped. Current analytical techniques that work well for laboratory samples may not be suitable for high-throughput industrial quality assurance. New in-line monitoring systems would need to be developed to ensure consistent interfacial properties across large production volumes.

Environmental and safety concerns also impact manufacturing scalability. Some halide compounds and additives present toxicity risks that require specialized handling protocols. Waste management and recycling strategies must be developed to address environmental impacts and regulatory compliance, particularly for materials containing volatile or hazardous components.

The integration of these advanced electrolyte systems into existing battery manufacturing lines presents additional engineering challenges. Current production equipment may require significant modifications to accommodate the unique processing requirements of sulfide-based systems with additives and co-electrolytes, necessitating substantial capital investment from manufacturers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!