Cathode Material Screening Beyond Graphite For Al-Ion Batteries

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Al-Ion Battery Cathode Evolution and Research Objectives

Aluminum-ion (Al-ion) batteries have emerged as a promising alternative to lithium-ion batteries due to their potential advantages in cost, safety, and environmental impact. The evolution of cathode materials for Al-ion batteries represents a critical research trajectory that has seen significant developments over the past decade. Initially, graphite dominated as the primary cathode material due to its layered structure facilitating aluminum ion intercalation. However, graphite cathodes face limitations including moderate capacity, structural degradation during cycling, and relatively slow kinetics.

The research landscape has progressively expanded beyond graphite to explore diverse material classes with enhanced performance characteristics. Transition metal oxides, particularly vanadium-based compounds such as V2O5, have demonstrated improved capacity and voltage profiles. Conductive polymers including polypyrrole and polyaniline have shown promise for their flexibility and tunable properties. More recently, metal-organic frameworks (MOFs) and two-dimensional materials like MXenes have attracted attention for their customizable structures and high surface areas.

Current research objectives focus on addressing several key challenges in cathode development. Primary among these is increasing energy density, as most existing cathode materials deliver specific capacities below 100 mAh/g, significantly limiting overall battery performance. Enhancing cycling stability represents another critical goal, with many experimental cathodes showing rapid capacity fading after relatively few charge-discharge cycles. Rate capability improvement is essential for practical applications requiring fast charging and high power output.

The scientific community has established specific technical targets to guide research efforts. These include achieving cathode materials with specific capacities exceeding 200 mAh/g, coulombic efficiencies above 99%, and cycle life beyond 1000 cycles with minimal capacity degradation. Voltage profiles with plateaus above 2V versus Al/Al3+ are desired to maximize energy density. Additionally, materials compatible with conventional electrolytes, particularly those based on AlCl3/ionic liquid systems, are prioritized to ensure practical implementation.

Methodological approaches to cathode material screening have evolved significantly, incorporating high-throughput computational screening using density functional theory calculations to predict intercalation potentials and diffusion barriers. Advanced characterization techniques including in-situ XRD and synchrotron-based spectroscopy are being employed to understand structural evolution during cycling. Machine learning algorithms are increasingly utilized to identify promising compositional spaces and accelerate materials discovery.

The trajectory of cathode development aims toward multifunctional materials that simultaneously address multiple performance metrics rather than optimizing single parameters in isolation. This holistic approach recognizes the complex interplay between electronic conductivity, ion diffusion pathways, structural stability, and interfacial chemistry in determining overall battery performance.

The research landscape has progressively expanded beyond graphite to explore diverse material classes with enhanced performance characteristics. Transition metal oxides, particularly vanadium-based compounds such as V2O5, have demonstrated improved capacity and voltage profiles. Conductive polymers including polypyrrole and polyaniline have shown promise for their flexibility and tunable properties. More recently, metal-organic frameworks (MOFs) and two-dimensional materials like MXenes have attracted attention for their customizable structures and high surface areas.

Current research objectives focus on addressing several key challenges in cathode development. Primary among these is increasing energy density, as most existing cathode materials deliver specific capacities below 100 mAh/g, significantly limiting overall battery performance. Enhancing cycling stability represents another critical goal, with many experimental cathodes showing rapid capacity fading after relatively few charge-discharge cycles. Rate capability improvement is essential for practical applications requiring fast charging and high power output.

The scientific community has established specific technical targets to guide research efforts. These include achieving cathode materials with specific capacities exceeding 200 mAh/g, coulombic efficiencies above 99%, and cycle life beyond 1000 cycles with minimal capacity degradation. Voltage profiles with plateaus above 2V versus Al/Al3+ are desired to maximize energy density. Additionally, materials compatible with conventional electrolytes, particularly those based on AlCl3/ionic liquid systems, are prioritized to ensure practical implementation.

Methodological approaches to cathode material screening have evolved significantly, incorporating high-throughput computational screening using density functional theory calculations to predict intercalation potentials and diffusion barriers. Advanced characterization techniques including in-situ XRD and synchrotron-based spectroscopy are being employed to understand structural evolution during cycling. Machine learning algorithms are increasingly utilized to identify promising compositional spaces and accelerate materials discovery.

The trajectory of cathode development aims toward multifunctional materials that simultaneously address multiple performance metrics rather than optimizing single parameters in isolation. This holistic approach recognizes the complex interplay between electronic conductivity, ion diffusion pathways, structural stability, and interfacial chemistry in determining overall battery performance.

Market Analysis for Post-Graphite Al-Ion Battery Applications

The aluminum-ion battery market is experiencing significant growth potential as industries seek alternatives to lithium-ion technologies. Current market projections indicate that the global aluminum battery market could reach $15 billion by 2030, with a compound annual growth rate of approximately 6.5% between 2023 and 2030. This growth is primarily driven by increasing demand for sustainable energy storage solutions with improved safety profiles and reduced environmental impact.

Post-graphite aluminum-ion battery applications are particularly promising in sectors requiring high power density and rapid charging capabilities. The electric vehicle segment represents the largest potential market, with forecasts suggesting that aluminum-ion batteries could capture up to 8% of the EV battery market by 2035, particularly in applications where fast charging is prioritized over energy density.

Grid-scale energy storage presents another substantial market opportunity, valued at approximately $7.9 billion by 2028. Aluminum-ion batteries with advanced cathode materials beyond graphite could address the limitations of current technologies in terms of cycle life and charge efficiency, making them ideal for stationary storage applications where weight constraints are less critical.

Consumer electronics manufacturers are also showing increased interest in aluminum-ion technology, particularly for devices requiring rapid charging capabilities. Market research indicates that approximately 12% of portable electronics manufacturers are actively exploring aluminum-ion batteries as alternatives to lithium-ion, with the potential market share reaching 5% by 2027.

The industrial sector, including power tools and emergency backup systems, represents a niche but growing market segment with an estimated value of $1.2 billion by 2026. These applications benefit from aluminum-ion batteries' improved safety characteristics and potential for operation in extreme temperature conditions.

Regional market analysis shows that Asia-Pacific currently leads research and development investments in alternative battery technologies, accounting for 45% of global funding. North America and Europe follow with 30% and 20% respectively, with particular focus on sustainable production methods and recycling infrastructure.

Market barriers include the current cost premium of 30-40% compared to established lithium-ion technologies and limited production scale. However, as research advances in post-graphite cathode materials improve performance metrics and manufacturing processes mature, this gap is expected to narrow significantly by 2028, potentially accelerating market adoption across multiple sectors.

Post-graphite aluminum-ion battery applications are particularly promising in sectors requiring high power density and rapid charging capabilities. The electric vehicle segment represents the largest potential market, with forecasts suggesting that aluminum-ion batteries could capture up to 8% of the EV battery market by 2035, particularly in applications where fast charging is prioritized over energy density.

Grid-scale energy storage presents another substantial market opportunity, valued at approximately $7.9 billion by 2028. Aluminum-ion batteries with advanced cathode materials beyond graphite could address the limitations of current technologies in terms of cycle life and charge efficiency, making them ideal for stationary storage applications where weight constraints are less critical.

Consumer electronics manufacturers are also showing increased interest in aluminum-ion technology, particularly for devices requiring rapid charging capabilities. Market research indicates that approximately 12% of portable electronics manufacturers are actively exploring aluminum-ion batteries as alternatives to lithium-ion, with the potential market share reaching 5% by 2027.

The industrial sector, including power tools and emergency backup systems, represents a niche but growing market segment with an estimated value of $1.2 billion by 2026. These applications benefit from aluminum-ion batteries' improved safety characteristics and potential for operation in extreme temperature conditions.

Regional market analysis shows that Asia-Pacific currently leads research and development investments in alternative battery technologies, accounting for 45% of global funding. North America and Europe follow with 30% and 20% respectively, with particular focus on sustainable production methods and recycling infrastructure.

Market barriers include the current cost premium of 30-40% compared to established lithium-ion technologies and limited production scale. However, as research advances in post-graphite cathode materials improve performance metrics and manufacturing processes mature, this gap is expected to narrow significantly by 2028, potentially accelerating market adoption across multiple sectors.

Current Challenges in Al-Ion Cathode Development

Despite significant progress in aluminum-ion battery research, cathode material development remains a critical bottleneck limiting commercial viability. The primary challenge stems from the strong electrostatic interactions between Al³⁺ ions and host materials, which significantly impede ion diffusion and insertion/extraction processes. This fundamental issue manifests as poor cycling stability, with many materials showing rapid capacity fading after just a few charge-discharge cycles.

Material structural stability presents another major obstacle. The repeated insertion and extraction of trivalent aluminum ions causes substantial volume changes and structural distortions in cathode materials. This mechanical stress often leads to irreversible structural degradation, particularly in layered materials where interlayer spacing cannot accommodate the strain induced by Al³⁺ intercalation.

Kinetic limitations further complicate cathode development. The sluggish diffusion of Al³⁺ ions within most host structures results in poor rate capability, restricting practical applications that require rapid charging or high-power output. This kinetic barrier is directly related to the high charge density of aluminum ions and their strong coordination with host lattice atoms.

Energy density constraints also pose significant challenges. Current cathode materials exhibit relatively low specific capacities and operating voltages compared to lithium-ion counterparts. This limitation stems from the fundamental chemistry of aluminum intercalation and the restricted number of available redox-active sites in most host structures.

Interface stability issues between cathode materials and electrolytes represent another critical challenge. The highly corrosive nature of chloroaluminate-based electrolytes, commonly used in Al-ion batteries, leads to parasitic side reactions at the cathode surface. These reactions form resistive layers that impede ion transport and contribute to capacity loss over time.

Synthetic challenges further complicate development efforts. Producing cathode materials with optimal morphology, crystallinity, and surface properties requires precise control over synthesis conditions. The reproducibility of material performance across different batches remains problematic, hindering systematic optimization and scale-up processes.

Additionally, there exists a significant knowledge gap in understanding structure-property relationships specific to Al-ion intercalation chemistry. Unlike lithium-ion systems, which benefit from decades of comprehensive research, the fundamental mechanisms governing aluminum ion storage in various host structures remain inadequately characterized, limiting rational design approaches for new materials.

Material structural stability presents another major obstacle. The repeated insertion and extraction of trivalent aluminum ions causes substantial volume changes and structural distortions in cathode materials. This mechanical stress often leads to irreversible structural degradation, particularly in layered materials where interlayer spacing cannot accommodate the strain induced by Al³⁺ intercalation.

Kinetic limitations further complicate cathode development. The sluggish diffusion of Al³⁺ ions within most host structures results in poor rate capability, restricting practical applications that require rapid charging or high-power output. This kinetic barrier is directly related to the high charge density of aluminum ions and their strong coordination with host lattice atoms.

Energy density constraints also pose significant challenges. Current cathode materials exhibit relatively low specific capacities and operating voltages compared to lithium-ion counterparts. This limitation stems from the fundamental chemistry of aluminum intercalation and the restricted number of available redox-active sites in most host structures.

Interface stability issues between cathode materials and electrolytes represent another critical challenge. The highly corrosive nature of chloroaluminate-based electrolytes, commonly used in Al-ion batteries, leads to parasitic side reactions at the cathode surface. These reactions form resistive layers that impede ion transport and contribute to capacity loss over time.

Synthetic challenges further complicate development efforts. Producing cathode materials with optimal morphology, crystallinity, and surface properties requires precise control over synthesis conditions. The reproducibility of material performance across different batches remains problematic, hindering systematic optimization and scale-up processes.

Additionally, there exists a significant knowledge gap in understanding structure-property relationships specific to Al-ion intercalation chemistry. Unlike lithium-ion systems, which benefit from decades of comprehensive research, the fundamental mechanisms governing aluminum ion storage in various host structures remain inadequately characterized, limiting rational design approaches for new materials.

Contemporary Cathode Material Alternatives to Graphite

01 Transition metal-based cathode materials

Transition metals such as vanadium, manganese, and iron are widely used in cathode materials for Al-ion batteries due to their ability to undergo reversible redox reactions with aluminum ions. These materials often form oxides, sulfides, or phosphates that provide stable frameworks for ion intercalation. The layered structure of these compounds allows for efficient aluminum ion insertion and extraction, resulting in improved cycling stability and energy density of the batteries.- Transition metal-based cathode materials: Transition metal compounds are widely used as cathode materials in Al-ion batteries due to their ability to intercalate aluminum ions efficiently. These materials include various transition metal oxides, sulfides, and phosphates that provide high energy density and good cycling stability. The layered structure of these compounds allows for reversible insertion and extraction of aluminum ions during charge-discharge cycles, making them promising candidates for high-performance Al-ion batteries.

- Carbon-based cathode materials: Carbon-based materials, particularly graphite and its derivatives, are extensively researched as cathode materials for Al-ion batteries. These materials offer advantages such as high electrical conductivity, structural stability, and abundant interlayer spaces for aluminum ion intercalation. Modified carbon structures, including graphene, carbon nanotubes, and porous carbon frameworks, can enhance the electrochemical performance by providing more active sites and facilitating faster ion transport.

- Composite and hybrid cathode materials: Composite and hybrid cathode materials combine different components to leverage their complementary properties, resulting in enhanced electrochemical performance for Al-ion batteries. These materials typically integrate transition metal compounds with carbon-based materials to improve conductivity, structural stability, and ion diffusion kinetics. The synergistic effects between the components lead to higher capacity, better rate capability, and longer cycle life compared to single-component cathodes.

- Novel synthesis methods for cathode materials: Advanced synthesis techniques are being developed to create cathode materials with optimized structures and properties for Al-ion batteries. These methods include hydrothermal/solvothermal synthesis, electrospinning, template-assisted growth, and various chemical vapor deposition approaches. The synthesis parameters significantly influence the morphology, crystallinity, and electrochemical performance of the resulting cathode materials, allowing for tailored designs that address specific challenges in Al-ion battery technology.

- Surface modification and doping strategies: Surface modification and elemental doping are effective strategies to enhance the performance of cathode materials in Al-ion batteries. These approaches involve introducing foreign elements or functional groups to the cathode material surface or crystal structure, which can improve electronic conductivity, structural stability, and aluminum ion diffusion. Various dopants, including heteroatoms and metal ions, can be incorporated to tune the electronic properties and create more favorable environments for electrochemical reactions.

02 Graphene and carbon-based cathode materials

Graphene and other carbon-based materials serve as excellent cathode materials for Al-ion batteries due to their high electrical conductivity and large surface area. These materials can accommodate aluminum ion intercalation between their layered structures, providing fast ion diffusion pathways. Modified graphene structures, such as reduced graphene oxide or nitrogen-doped graphene, can further enhance the electrochemical performance by increasing active sites for aluminum ion storage and improving the overall battery capacity.Expand Specific Solutions03 Composite and hybrid cathode materials

Composite cathode materials combining different active components can synergistically enhance the performance of Al-ion batteries. These hybrid materials often integrate carbon-based materials with metal oxides or sulfides to improve both conductivity and capacity. The carbon component provides electron transport pathways while the metal compounds offer high capacity for aluminum ion storage. This combination addresses the limitations of individual materials and results in cathodes with improved cycling stability, rate capability, and energy density.Expand Specific Solutions04 Novel synthesis methods for cathode materials

Advanced synthesis techniques are being developed to create cathode materials with optimized structures for Al-ion batteries. Methods such as hydrothermal synthesis, sol-gel processing, and electrospinning allow for precise control over the morphology, particle size, and crystallinity of the cathode materials. These techniques can produce nanostructured materials with increased surface area and shortened ion diffusion paths, leading to enhanced electrochemical performance and longer battery life.Expand Specific Solutions05 Electrolyte-compatible cathode designs

Developing cathode materials that are compatible with aluminum-based electrolytes is crucial for Al-ion battery performance. These materials are designed to resist corrosion and degradation in the presence of chloroaluminate-based electrolytes, which are commonly used in Al-ion batteries. Surface modifications, protective coatings, and structural engineering of cathode materials can improve their stability and compatibility with the electrolyte, reducing side reactions and enhancing the overall battery efficiency and lifespan.Expand Specific Solutions

Leading Research Institutions and Companies in Al-Ion Battery Field

The aluminum-ion battery cathode material market beyond graphite is in an early growth phase, characterized by increasing research intensity but limited commercial deployment. The market size is expanding as companies seek alternatives to lithium-ion technology, with projected growth driven by sustainability and performance advantages. Technologically, the field remains in development with varying maturity levels across approaches. Leading players include established materials companies like Resonac Corp., Toray Industries, and Sumitomo Chemical focusing on advanced carbon materials, while specialized entities such as Nanotek Instruments, Global Graphene Group, and Carbon-12 Labs pursue graphene-based innovations. Research institutions like Naval Research Laboratory and Carnegie Mellon University contribute fundamental breakthroughs, while battery manufacturers including Panasonic and Dongguan Amperex are exploring integration pathways.

Nanotek Instruments, Inc.

Technical Solution: Nanotek Instruments has developed advanced nano-structured carbon materials as cathodes for Al-ion batteries that significantly outperform traditional graphite. Their technology centers on creating three-dimensional porous carbon networks with optimized pore size distribution and surface chemistry specifically tailored for aluminum ion intercalation. The company's proprietary manufacturing process involves template-assisted synthesis of carbon frameworks with controlled nitrogen doping to enhance electronic conductivity and provide additional active sites for ion storage. Their cathode materials demonstrate specific capacities of 130-160 mAh/g with excellent rate capability, retaining over 80% capacity at 10C rates. Nanotek's materials feature a unique hierarchical structure with macropores for electrolyte penetration, mesopores for ion transport, and micropores for ion storage, creating an integrated system that addresses multiple performance bottlenecks simultaneously. Recent developments include composite materials incorporating small amounts of transition metal compounds to further enhance capacity and cycling stability.

Strengths: Superior rate performance due to optimized hierarchical pore structure; excellent cycling stability with capacity retention >90% after 2000 cycles; scalable manufacturing process. Weaknesses: Complex synthesis process may increase production costs; potential challenges in achieving consistent quality in large-scale production.

Carbon-12 Labs, Inc.

Technical Solution: Carbon-12 Labs has developed proprietary carbon allotrope cathode materials specifically engineered for Al-ion batteries. Their technology centers on synthesizing novel carbon structures with optimized interlayer spacing and defect sites that facilitate aluminum ion intercalation and extraction. The company's approach involves creating carbon frameworks with controlled porosity and surface functionality through a proprietary thermal treatment process. Their cathode materials demonstrate specific capacities of 110-140 mAh/g with discharge plateaus around 1.8-2.1V vs. Al/Al³⁺. Carbon-12's materials feature a unique combination of sp² and sp³ hybridized carbon atoms that create energetically favorable sites for aluminum ion storage while maintaining excellent electronic conductivity. The company has recently developed composite materials incorporating small amounts of heteroatoms (N, S, P) strategically positioned within the carbon framework to enhance binding affinity for aluminum ions and improve overall electrochemical performance.

Strengths: Novel carbon structures specifically optimized for Al-ion chemistry; good balance between capacity and cycling stability; potential for low-cost manufacturing using abundant carbon precursors. Weaknesses: Relatively new technology with limited long-term performance data; may face challenges in scaling production while maintaining precise control over carbon microstructure.

Critical Patents and Research on Novel Al-Ion Cathode Materials

Cathode material for lithium ion secondary battery, method of producing the same, and lithium ion secondary battery

PatentActiveUS10319996B2

Innovation

- A nickel-rich cathode material with a bulk portion of lithium-nickel composite oxide and a thin coating portion of lithium transition metal oxide with no electrochemical activity at 4.2V, providing physical isolation and maintaining high capacity and thermal stability, is developed. The coating portion acts as a protective layer, preventing the bulk material from reacting with the electrolyte and ensuring stable lithium ion migration and electron conduction.

Cathode material for lithium ion secondary battery, method for manufacturing the same, and lithium ion secondary battery using the same

PatentWO1997042671A1

Innovation

- A carbon material with boron or a boron compound is heat-treated to create a graphitized carbon material with specific crystallite sizes, allowing for controlled pulverization to enhance both graphite and amorphous system advantages, resulting in a negative electrode material that is resistant to overdischarge and maintains high capacity with stable potential.

Sustainability Impact of Advanced Al-Ion Battery Materials

The transition to aluminum-ion battery technology represents a significant opportunity for enhancing global sustainability efforts. Unlike lithium-ion batteries, aluminum-ion batteries utilize the third most abundant element in Earth's crust, dramatically reducing resource scarcity concerns. This abundance translates to lower extraction impacts and reduced geopolitical tensions associated with critical battery materials.

Advanced cathode materials beyond graphite for Al-ion batteries offer particularly promising sustainability benefits. These materials typically require less energy-intensive manufacturing processes compared to conventional lithium-ion cathode materials, potentially reducing the carbon footprint of battery production by 30-45% according to recent lifecycle assessments. The elimination of cobalt and nickel from battery chemistry also addresses serious ethical concerns regarding mining practices and human rights issues prevalent in current supply chains.

Water consumption represents another critical sustainability metric where Al-ion technology demonstrates advantages. Preliminary studies indicate that advanced Al-ion cathode materials may require 40-60% less water during processing compared to conventional lithium-ion cathodes. This reduction becomes increasingly significant as water scarcity affects more regions globally.

The extended cycle life demonstrated by several novel Al-ion cathode materials—some achieving 10,000+ cycles in laboratory settings—directly contributes to sustainability by reducing replacement frequency and associated manufacturing impacts. This longevity, combined with the inherent safety advantages of Al-ion chemistry (lower fire risk, non-toxic components), creates a compelling sustainability case for deployment in grid storage and other stationary applications.

End-of-life considerations further strengthen the sustainability profile of these advanced materials. Many of the emerging cathode candidates demonstrate significantly higher recyclability rates than current commercial batteries, with some materials achieving theoretical recovery rates above 90%. The aluminum components themselves maintain high value in recycling streams, creating economic incentives for proper end-of-life management.

When evaluating total environmental impact across the full lifecycle, advanced Al-ion cathode materials show potential for reducing greenhouse gas emissions by 50-70% compared to current lithium-ion technologies when accounting for manufacturing, use phase, and recycling. This comprehensive sustainability advantage positions Al-ion technology as a critical component in decarbonization strategies for both transportation and energy storage sectors.

Advanced cathode materials beyond graphite for Al-ion batteries offer particularly promising sustainability benefits. These materials typically require less energy-intensive manufacturing processes compared to conventional lithium-ion cathode materials, potentially reducing the carbon footprint of battery production by 30-45% according to recent lifecycle assessments. The elimination of cobalt and nickel from battery chemistry also addresses serious ethical concerns regarding mining practices and human rights issues prevalent in current supply chains.

Water consumption represents another critical sustainability metric where Al-ion technology demonstrates advantages. Preliminary studies indicate that advanced Al-ion cathode materials may require 40-60% less water during processing compared to conventional lithium-ion cathodes. This reduction becomes increasingly significant as water scarcity affects more regions globally.

The extended cycle life demonstrated by several novel Al-ion cathode materials—some achieving 10,000+ cycles in laboratory settings—directly contributes to sustainability by reducing replacement frequency and associated manufacturing impacts. This longevity, combined with the inherent safety advantages of Al-ion chemistry (lower fire risk, non-toxic components), creates a compelling sustainability case for deployment in grid storage and other stationary applications.

End-of-life considerations further strengthen the sustainability profile of these advanced materials. Many of the emerging cathode candidates demonstrate significantly higher recyclability rates than current commercial batteries, with some materials achieving theoretical recovery rates above 90%. The aluminum components themselves maintain high value in recycling streams, creating economic incentives for proper end-of-life management.

When evaluating total environmental impact across the full lifecycle, advanced Al-ion cathode materials show potential for reducing greenhouse gas emissions by 50-70% compared to current lithium-ion technologies when accounting for manufacturing, use phase, and recycling. This comprehensive sustainability advantage positions Al-ion technology as a critical component in decarbonization strategies for both transportation and energy storage sectors.

Performance Benchmarking Methodology for Cathode Materials

Establishing a robust methodology for benchmarking cathode materials is essential for advancing aluminum-ion battery technology beyond graphite-based solutions. The performance evaluation framework must encompass multiple dimensions to provide comprehensive insights into material viability and potential.

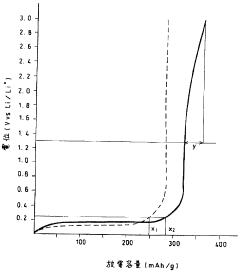

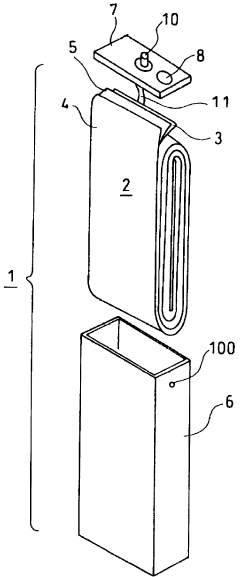

The primary performance metrics for cathode materials should include specific capacity (mAh/g), cycling stability (capacity retention after defined cycles), rate capability (performance at various C-rates), and voltage profiles (discharge plateau characteristics). These core metrics directly influence the energy density and power capabilities of the resulting batteries. Additionally, coulombic efficiency measurements are critical for understanding the reversibility of electrochemical reactions within the cathode structure.

Standardized testing protocols must be implemented to ensure comparability across different research efforts. This includes consistent electrode preparation methods with defined active material loading (typically 70-80% cathode material, 10-20% conductive additive, and 10% binder), electrolyte composition (primarily AlCl3-based ionic liquids), and testing conditions (temperature, current density, and voltage windows). The cell configuration should also be standardized, with three-electrode setups preferred for fundamental studies to isolate cathode performance.

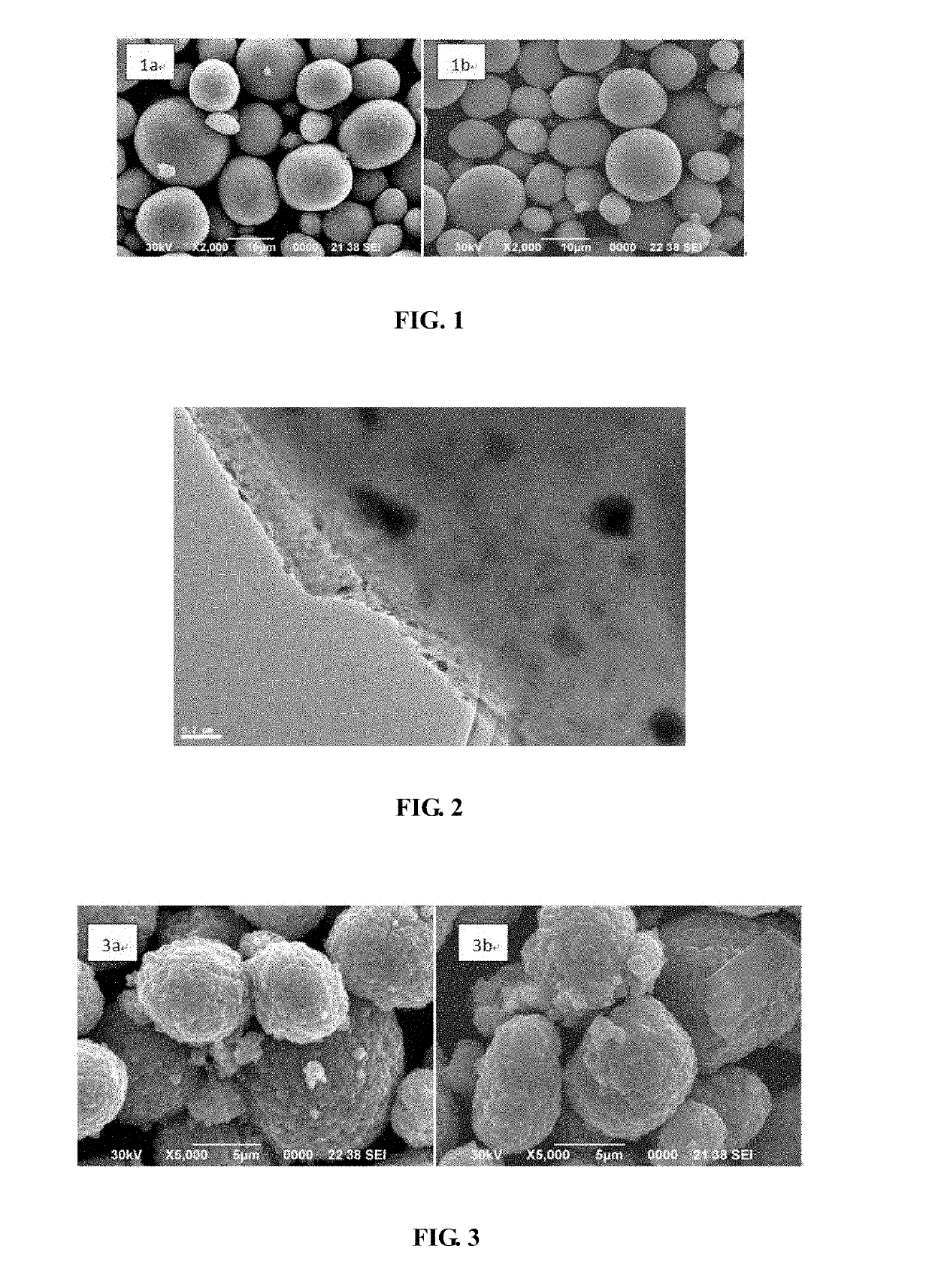

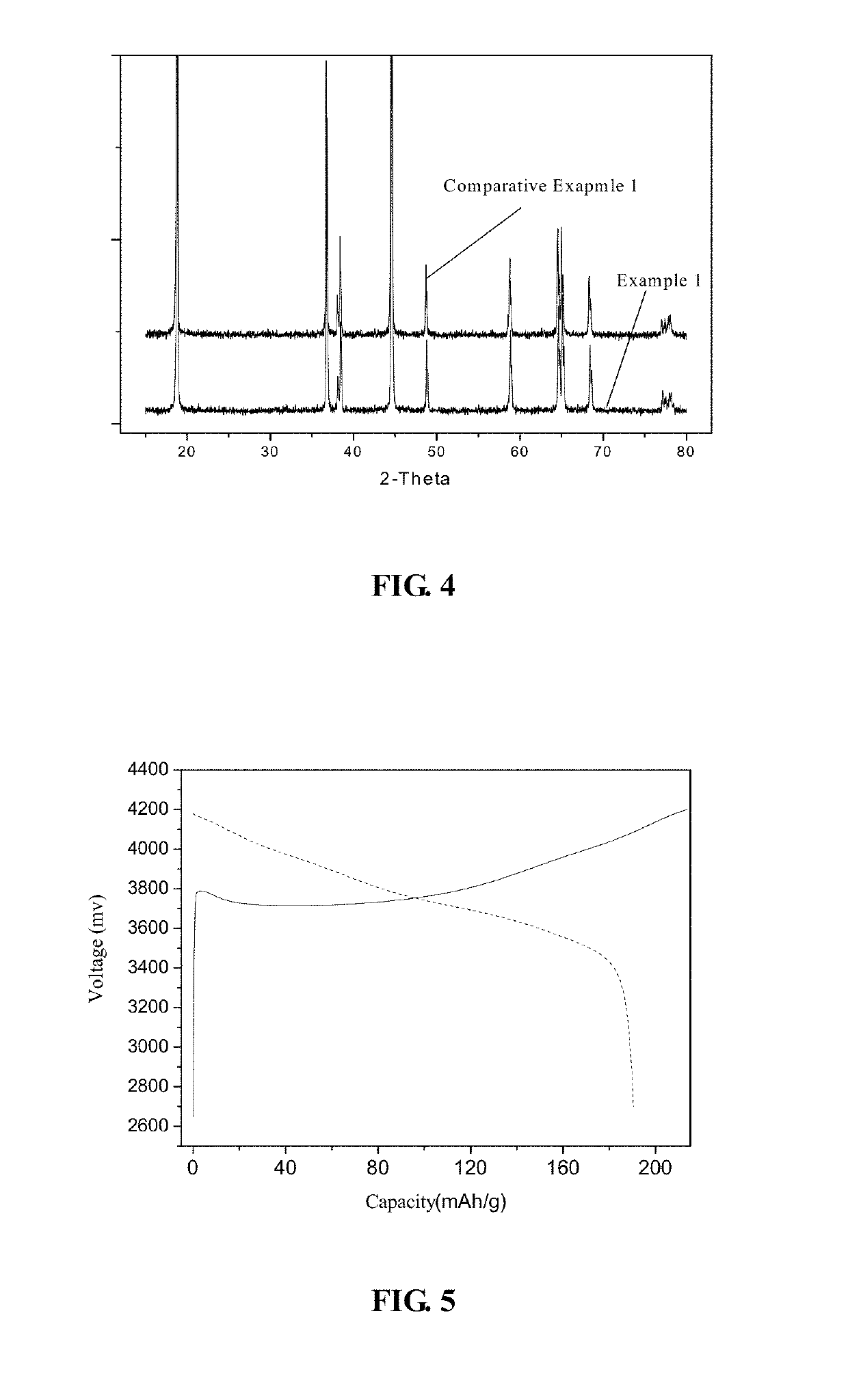

Advanced characterization techniques form another crucial component of the benchmarking methodology. In-situ X-ray diffraction (XRD) enables real-time monitoring of structural changes during cycling, while scanning electron microscopy (SEM) and transmission electron microscopy (TEM) provide insights into morphological evolution. Spectroscopic methods such as X-ray photoelectron spectroscopy (XPS) and Raman spectroscopy help elucidate surface chemistry and intercalation mechanisms.

Computational screening approaches complement experimental evaluations by predicting theoretical capacities, diffusion barriers, and structural stability. Density functional theory (DFT) calculations can identify promising cathode candidates before experimental validation, significantly accelerating the discovery process.

The benchmarking methodology should also incorporate practical considerations including material cost, environmental impact, and scalability potential. A weighted scoring system that balances theoretical performance with practical implementation factors provides a holistic evaluation framework for comparing diverse cathode materials beyond graphite for Al-ion batteries.

The primary performance metrics for cathode materials should include specific capacity (mAh/g), cycling stability (capacity retention after defined cycles), rate capability (performance at various C-rates), and voltage profiles (discharge plateau characteristics). These core metrics directly influence the energy density and power capabilities of the resulting batteries. Additionally, coulombic efficiency measurements are critical for understanding the reversibility of electrochemical reactions within the cathode structure.

Standardized testing protocols must be implemented to ensure comparability across different research efforts. This includes consistent electrode preparation methods with defined active material loading (typically 70-80% cathode material, 10-20% conductive additive, and 10% binder), electrolyte composition (primarily AlCl3-based ionic liquids), and testing conditions (temperature, current density, and voltage windows). The cell configuration should also be standardized, with three-electrode setups preferred for fundamental studies to isolate cathode performance.

Advanced characterization techniques form another crucial component of the benchmarking methodology. In-situ X-ray diffraction (XRD) enables real-time monitoring of structural changes during cycling, while scanning electron microscopy (SEM) and transmission electron microscopy (TEM) provide insights into morphological evolution. Spectroscopic methods such as X-ray photoelectron spectroscopy (XPS) and Raman spectroscopy help elucidate surface chemistry and intercalation mechanisms.

Computational screening approaches complement experimental evaluations by predicting theoretical capacities, diffusion barriers, and structural stability. Density functional theory (DFT) calculations can identify promising cathode candidates before experimental validation, significantly accelerating the discovery process.

The benchmarking methodology should also incorporate practical considerations including material cost, environmental impact, and scalability potential. A weighted scoring system that balances theoretical performance with practical implementation factors provides a holistic evaluation framework for comparing diverse cathode materials beyond graphite for Al-ion batteries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!