Safety Assessment And Abuse Testing Of Aluminum-Ion Cells

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aluminum-Ion Battery Safety Background and Objectives

Aluminum-ion batteries have emerged as a promising alternative to conventional lithium-ion batteries due to their potential advantages in safety, cost, and environmental impact. The development of aluminum-ion technology traces back to the early 2000s, with significant acceleration in research occurring over the past decade. This technology leverages the abundance of aluminum as the third most common element in the Earth's crust, offering a sustainable alternative to lithium, which faces resource constraints and geopolitical supply challenges.

The evolution of aluminum-ion battery technology has been marked by several breakthrough moments, particularly in electrolyte formulation and cathode material development. Early iterations suffered from rapid capacity fading and limited cycle life, but recent advancements in ionic liquid electrolytes and three-dimensional graphene cathodes have substantially improved performance metrics. The technology trajectory suggests continued improvements in energy density and cycle stability in the coming years.

Safety considerations have been a primary driver in aluminum-ion battery development, especially as the industry seeks alternatives to lithium-ion systems that have demonstrated thermal runaway risks. Aluminum's inherent properties—including lower reactivity with air and moisture compared to lithium—present fundamental safety advantages that warrant systematic investigation and quantification.

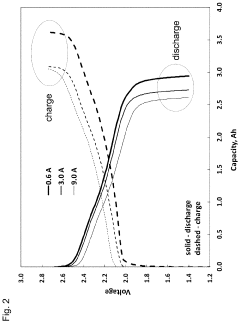

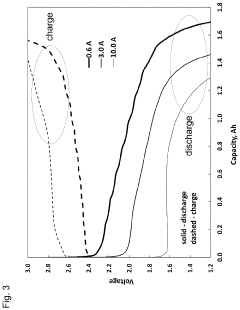

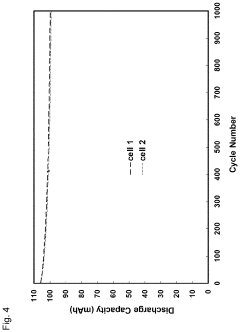

The primary technical objectives of safety assessment and abuse testing for aluminum-ion cells include establishing standardized protocols specific to this chemistry, quantifying thermal stability under various abuse conditions, and determining failure modes that may differ significantly from those observed in lithium-ion systems. Additionally, there is a need to evaluate the impact of cell design parameters on safety performance and to develop predictive models for risk assessment.

Understanding the relationship between electrochemical performance and safety characteristics represents another critical objective. As researchers push the boundaries of energy density and power capability, corresponding changes in safety profiles must be thoroughly evaluated to ensure that performance improvements do not come at the expense of safety margins.

The ultimate goal of this technical investigation is to establish a comprehensive safety framework for aluminum-ion technology that can guide both further research and eventual commercialization efforts. This includes identifying key safety advantages that could be leveraged as market differentiators, as well as any unique risks that might require mitigation strategies specific to aluminum-ion chemistry.

The evolution of aluminum-ion battery technology has been marked by several breakthrough moments, particularly in electrolyte formulation and cathode material development. Early iterations suffered from rapid capacity fading and limited cycle life, but recent advancements in ionic liquid electrolytes and three-dimensional graphene cathodes have substantially improved performance metrics. The technology trajectory suggests continued improvements in energy density and cycle stability in the coming years.

Safety considerations have been a primary driver in aluminum-ion battery development, especially as the industry seeks alternatives to lithium-ion systems that have demonstrated thermal runaway risks. Aluminum's inherent properties—including lower reactivity with air and moisture compared to lithium—present fundamental safety advantages that warrant systematic investigation and quantification.

The primary technical objectives of safety assessment and abuse testing for aluminum-ion cells include establishing standardized protocols specific to this chemistry, quantifying thermal stability under various abuse conditions, and determining failure modes that may differ significantly from those observed in lithium-ion systems. Additionally, there is a need to evaluate the impact of cell design parameters on safety performance and to develop predictive models for risk assessment.

Understanding the relationship between electrochemical performance and safety characteristics represents another critical objective. As researchers push the boundaries of energy density and power capability, corresponding changes in safety profiles must be thoroughly evaluated to ensure that performance improvements do not come at the expense of safety margins.

The ultimate goal of this technical investigation is to establish a comprehensive safety framework for aluminum-ion technology that can guide both further research and eventual commercialization efforts. This includes identifying key safety advantages that could be leveraged as market differentiators, as well as any unique risks that might require mitigation strategies specific to aluminum-ion chemistry.

Market Analysis for Safe Energy Storage Solutions

The global energy storage market is witnessing unprecedented growth, driven by increasing renewable energy integration and electrification trends across various sectors. The market for safe energy storage solutions is projected to reach $546 billion by 2035, with a compound annual growth rate of 12.3% between 2023 and 2035. Within this landscape, aluminum-ion technology represents an emerging segment with significant potential to disrupt traditional lithium-ion dominance due to its enhanced safety profile.

Safety concerns have become paramount in energy storage applications following numerous high-profile thermal runaway incidents involving lithium-ion batteries. These incidents have resulted in costly recalls, property damage, and in some cases, loss of life. Consequently, regulatory bodies worldwide are implementing stricter safety standards, creating market demand for inherently safer battery chemistries like aluminum-ion cells.

Consumer electronics represents the largest current market segment for safe energy storage solutions, accounting for approximately 38% of the total market share. However, electric vehicles and grid-scale storage are experiencing the fastest growth rates at 24% and 19% respectively. These high-growth segments particularly value safety attributes due to the catastrophic consequences of failure in these applications.

Aluminum-ion cells are positioned to capture significant market share in safety-critical applications where traditional lithium-ion batteries face limitations. The inherent non-flammability of aluminum-ion electrolytes addresses a fundamental safety concern, potentially eliminating the need for complex battery management systems that add cost and weight to current solutions.

Regional analysis indicates that Asia-Pacific dominates the market with 42% share, followed by North America (28%) and Europe (23%). China leads aluminum-ion cell research and development activities, with substantial government funding supporting commercialization efforts. Meanwhile, North American and European markets show strong demand for safer alternatives driven by stringent regulatory frameworks and consumer awareness.

Market research indicates that consumers and industrial buyers are willing to pay a premium of 15-20% for energy storage solutions with demonstrably superior safety profiles. This price tolerance creates a viable commercialization pathway for aluminum-ion technology despite current cost disadvantages in manufacturing scale compared to established lithium-ion production.

The competitive landscape for safe energy storage is intensifying, with both established battery manufacturers and startups investing in aluminum-ion technology. Strategic partnerships between material suppliers, cell manufacturers, and end-product integrators are accelerating commercialization timelines. Industry analysts predict that aluminum-ion cells could capture up to 8% of the total energy storage market by 2030, primarily in applications where safety considerations outweigh energy density requirements.

Safety concerns have become paramount in energy storage applications following numerous high-profile thermal runaway incidents involving lithium-ion batteries. These incidents have resulted in costly recalls, property damage, and in some cases, loss of life. Consequently, regulatory bodies worldwide are implementing stricter safety standards, creating market demand for inherently safer battery chemistries like aluminum-ion cells.

Consumer electronics represents the largest current market segment for safe energy storage solutions, accounting for approximately 38% of the total market share. However, electric vehicles and grid-scale storage are experiencing the fastest growth rates at 24% and 19% respectively. These high-growth segments particularly value safety attributes due to the catastrophic consequences of failure in these applications.

Aluminum-ion cells are positioned to capture significant market share in safety-critical applications where traditional lithium-ion batteries face limitations. The inherent non-flammability of aluminum-ion electrolytes addresses a fundamental safety concern, potentially eliminating the need for complex battery management systems that add cost and weight to current solutions.

Regional analysis indicates that Asia-Pacific dominates the market with 42% share, followed by North America (28%) and Europe (23%). China leads aluminum-ion cell research and development activities, with substantial government funding supporting commercialization efforts. Meanwhile, North American and European markets show strong demand for safer alternatives driven by stringent regulatory frameworks and consumer awareness.

Market research indicates that consumers and industrial buyers are willing to pay a premium of 15-20% for energy storage solutions with demonstrably superior safety profiles. This price tolerance creates a viable commercialization pathway for aluminum-ion technology despite current cost disadvantages in manufacturing scale compared to established lithium-ion production.

The competitive landscape for safe energy storage is intensifying, with both established battery manufacturers and startups investing in aluminum-ion technology. Strategic partnerships between material suppliers, cell manufacturers, and end-product integrators are accelerating commercialization timelines. Industry analysts predict that aluminum-ion cells could capture up to 8% of the total energy storage market by 2030, primarily in applications where safety considerations outweigh energy density requirements.

Current Safety Challenges in Aluminum-Ion Technology

Despite the promising potential of aluminum-ion battery technology, several critical safety challenges currently impede its widespread commercial adoption. The primary concern revolves around electrolyte stability, as most aluminum-ion cells utilize ionic liquid electrolytes that can be corrosive and potentially reactive under extreme conditions. These electrolytes may generate hazardous gases when subjected to high temperatures or during electrical abuse scenarios, creating significant safety risks in consumer applications.

Thermal management represents another substantial challenge, as aluminum-ion cells can experience thermal runaway under certain abuse conditions, albeit less severe than lithium-ion counterparts. Research indicates that while aluminum-ion cells generally demonstrate better thermal stability than lithium-ion batteries, they still require robust thermal management systems to prevent cascading failure events in multi-cell configurations.

Mechanical integrity issues also plague current aluminum-ion technology. The chloroaluminate-based electrolytes commonly used can cause corrosion of cell components and packaging materials over time, potentially compromising structural integrity. This corrosion risk increases under elevated temperature conditions or when cells experience physical damage, raising concerns about long-term safety and reliability.

Electrical abuse tolerance remains insufficiently characterized across various aluminum-ion cell chemistries. Limited standardized testing protocols exist specifically for aluminum-ion technology, creating uncertainty regarding their behavior during overcharge, over-discharge, or external short-circuit events. The industry lacks comprehensive data on failure modes and safety thresholds specific to aluminum-ion chemistry.

Regulatory frameworks present additional challenges, as existing battery safety standards were primarily developed for lithium-ion and lead-acid technologies. The unique characteristics of aluminum-ion cells, including different thermal profiles and failure mechanisms, necessitate the development of specialized testing methodologies and safety criteria. This regulatory gap creates uncertainty for manufacturers and delays commercial implementation.

Environmental and health considerations also merit attention, as the long-term environmental impact and toxicity profiles of aluminum-ion cell components remain incompletely understood. While aluminum itself presents fewer environmental concerns than lithium, the ionic liquid electrolytes used in many aluminum-ion formulations may pose unique disposal and recycling challenges that require further investigation.

Addressing these safety challenges requires coordinated efforts across academia, industry, and regulatory bodies to develop standardized testing protocols, improve cell design, and establish appropriate safety guidelines specific to aluminum-ion technology.

Thermal management represents another substantial challenge, as aluminum-ion cells can experience thermal runaway under certain abuse conditions, albeit less severe than lithium-ion counterparts. Research indicates that while aluminum-ion cells generally demonstrate better thermal stability than lithium-ion batteries, they still require robust thermal management systems to prevent cascading failure events in multi-cell configurations.

Mechanical integrity issues also plague current aluminum-ion technology. The chloroaluminate-based electrolytes commonly used can cause corrosion of cell components and packaging materials over time, potentially compromising structural integrity. This corrosion risk increases under elevated temperature conditions or when cells experience physical damage, raising concerns about long-term safety and reliability.

Electrical abuse tolerance remains insufficiently characterized across various aluminum-ion cell chemistries. Limited standardized testing protocols exist specifically for aluminum-ion technology, creating uncertainty regarding their behavior during overcharge, over-discharge, or external short-circuit events. The industry lacks comprehensive data on failure modes and safety thresholds specific to aluminum-ion chemistry.

Regulatory frameworks present additional challenges, as existing battery safety standards were primarily developed for lithium-ion and lead-acid technologies. The unique characteristics of aluminum-ion cells, including different thermal profiles and failure mechanisms, necessitate the development of specialized testing methodologies and safety criteria. This regulatory gap creates uncertainty for manufacturers and delays commercial implementation.

Environmental and health considerations also merit attention, as the long-term environmental impact and toxicity profiles of aluminum-ion cell components remain incompletely understood. While aluminum itself presents fewer environmental concerns than lithium, the ionic liquid electrolytes used in many aluminum-ion formulations may pose unique disposal and recycling challenges that require further investigation.

Addressing these safety challenges requires coordinated efforts across academia, industry, and regulatory bodies to develop standardized testing protocols, improve cell design, and establish appropriate safety guidelines specific to aluminum-ion technology.

Established Abuse Testing Protocols for Aluminum-Ion Cells

01 Electrolyte safety enhancements for aluminum-ion cells

Safety of aluminum-ion cells can be improved through specialized electrolyte formulations. These include non-flammable ionic liquid electrolytes, solid-state electrolytes, and electrolyte additives that suppress dendrite formation. These formulations help prevent thermal runaway, reduce fire hazards, and improve the overall safety profile of aluminum-ion batteries while maintaining electrochemical performance.- Safety mechanisms for aluminum-ion cells: Various safety mechanisms can be implemented in aluminum-ion cells to prevent hazards such as overheating, short circuits, and thermal runaway. These include protective circuits, temperature sensors, pressure relief valves, and structural designs that isolate components in case of failure. These safety features help maintain cell integrity during normal operation and fault conditions, reducing the risk of catastrophic failures.

- Electrolyte formulations for improved safety: The electrolyte composition plays a crucial role in aluminum-ion cell safety. Non-flammable or flame-retardant electrolytes can significantly reduce fire hazards. Ionic liquids and certain additives can enhance thermal stability and reduce reactivity with electrode materials. Optimized electrolyte formulations can prevent dendrite formation and minimize gas generation during cycling, which are common safety concerns in battery technologies.

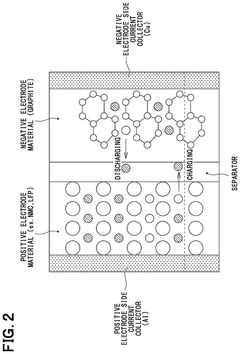

- Electrode materials and design for safer operation: The selection of electrode materials significantly impacts aluminum-ion cell safety. Materials with high thermal stability, low reactivity, and resistance to structural degradation can prevent catastrophic failures. Electrode designs that accommodate volume changes during cycling and prevent internal short circuits enhance safety. Coatings and dopants can be applied to electrode surfaces to improve stability and reduce unwanted side reactions at the electrode-electrolyte interface.

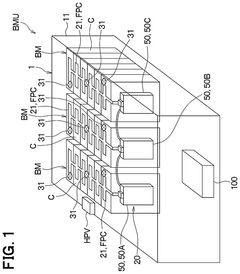

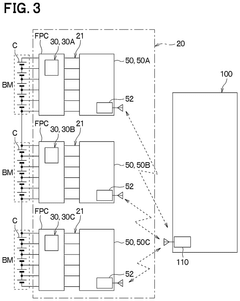

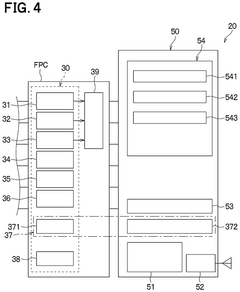

- Battery management systems for aluminum-ion cells: Advanced battery management systems (BMS) are essential for monitoring and controlling aluminum-ion cells to ensure safe operation. These systems track parameters such as voltage, current, and temperature to prevent operation outside safe limits. BMS can implement protective measures like current limitation, cell balancing, and emergency shutdown procedures. Smart algorithms can detect early signs of potential failures and take preventive actions before safety issues arise.

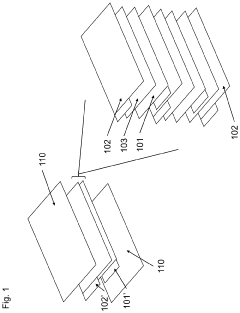

- Structural and packaging innovations for enhanced safety: The physical construction and packaging of aluminum-ion cells significantly impact their safety performance. Robust cell casings, internal separators with thermal shutdown properties, and mechanical reinforcements can prevent physical damage and contain failures. Multi-layer safety designs incorporate redundant protective features. Advanced thermal management systems help dissipate heat efficiently, preventing temperature-related safety incidents. Innovative cell and pack designs can isolate failures to prevent propagation throughout the battery system.

02 Thermal management systems for aluminum-ion batteries

Effective thermal management is crucial for aluminum-ion cell safety. Specialized cooling systems, heat dissipation structures, and temperature monitoring devices help maintain optimal operating temperatures and prevent overheating. These systems can include phase change materials, liquid cooling circuits, or thermally conductive components that efficiently remove excess heat from the battery pack, reducing the risk of thermal runaway incidents.Expand Specific Solutions03 Protective housing and structural safety features

Aluminum-ion cells incorporate specialized protective housings and structural features to enhance safety. These include pressure relief mechanisms, reinforced casings, and isolation components that prevent short circuits. The designs often feature multi-layer protection systems that can contain internal failures, prevent electrolyte leakage, and minimize the impact of mechanical damage, thereby improving overall battery safety and reliability.Expand Specific Solutions04 Battery management systems for safety monitoring

Advanced battery management systems (BMS) are essential for aluminum-ion cell safety. These systems continuously monitor critical parameters such as voltage, current, and temperature across individual cells and the entire battery pack. The BMS can detect abnormal conditions, implement protective measures like current limitation or circuit disconnection, and provide early warning of potential safety issues, preventing catastrophic failures through proactive management.Expand Specific Solutions05 Electrode design and materials for enhanced safety

Safety of aluminum-ion cells is significantly influenced by electrode design and materials selection. Advanced electrode formulations incorporate materials that resist dendrite formation, maintain structural integrity during cycling, and exhibit improved thermal stability. These designs often feature specialized coatings, novel composite structures, or engineered interfaces that prevent internal short circuits and enhance the overall safety performance of the battery under various operating conditions.Expand Specific Solutions

Leading Organizations in Aluminum-Ion Battery Development

The aluminum-ion battery technology market is currently in an early development stage, characterized by significant research activity but limited commercial deployment. The global market size remains relatively small compared to established lithium-ion technology, though projections indicate substantial growth potential as safety advantages become more recognized. From a technical maturity perspective, companies like Robert Bosch GmbH, Samsung SDI, and LG Chem are leading industrial research efforts, while academic institutions including Beijing Institute of Technology and University of Maryland contribute fundamental research. Specialized players such as Faradion and CAMX Power are developing proprietary aluminum-ion cell technologies with enhanced safety profiles. The competitive landscape features both established battery manufacturers expanding their portfolios and startups focused exclusively on aluminum-ion technology, creating a dynamic environment where safety assessment methodologies are becoming key differentiators.

University of Science & Technology of China

Technical Solution: The University of Science & Technology of China (USTC) has established a comprehensive research program on aluminum-ion cell safety assessment with particular focus on novel electrolyte formulations and their behavior under abuse conditions. Their approach integrates computational modeling with experimental validation to predict and characterize failure mechanisms specific to aluminum-ion chemistry. USTC researchers have developed specialized testing methodologies that evaluate the thermal stability of chloroaluminate electrolytes and their interaction with cathode materials during overcharging and thermal runaway scenarios. Their work includes detailed analysis of gas evolution during abuse testing using mass spectrometry and gas chromatography to identify specific decomposition products and their associated hazards. USTC has pioneered non-destructive testing techniques using acoustic emission and thermal imaging to detect early warning signs of aluminum-ion cell failure before catastrophic events occur, establishing new safety monitoring protocols specific to this emerging battery technology.

Strengths: Strong fundamental research capabilities in electrochemistry and materials science; innovative approach to safety assessment methodologies. Weaknesses: Limited experience with large-format cells and commercial battery designs; gap between laboratory research and industrial implementation requirements.

Xiamen University

Technical Solution: Xiamen University has developed innovative safety assessment methodologies for aluminum-ion cells focusing on fundamental electrochemical stability mechanisms. Their research team has pioneered specialized testing protocols that evaluate the unique failure modes of aluminum-ion chemistry, particularly regarding the chloroaluminate electrolyte behavior under abuse conditions. The university's approach combines electrochemical testing with advanced materials characterization techniques including in-situ Raman spectroscopy and transmission electron microscopy to monitor structural and chemical changes during thermal and electrical abuse scenarios. Their research has identified critical safety parameters specific to aluminum-ion cells, including electrolyte decomposition pathways and aluminum anode passivation mechanisms under extreme conditions. Xiamen University has established correlations between cell design parameters and safety performance, providing valuable insights for optimizing aluminum-ion cell construction for enhanced abuse tolerance.

Strengths: Deep scientific understanding of aluminum-ion electrochemistry; access to advanced analytical equipment for detailed failure analysis. Weaknesses: Limited industrial-scale testing capabilities compared to commercial entities; research findings require additional validation in commercial-format cells.

Critical Safety Mechanisms in Aluminum-Ion Technology

High power, extended temperature range-capable, highly abuse overcharge and discharge tolerant rechargeable battery cell and pack

PatentActiveUS20200328416A1

Innovation

- The development of rechargeable lithium-ion cells with a polycrystalline cathode electrochemically active material and a lithium titanate anode, both using aluminum current collectors, which provide improved safety, high power delivery, and tolerance to extreme mechanical abuse, allowing for charging and discharging at low temperatures and extended storage without damage.

Battery evaluation system and battery evaluation method

PatentPendingUS20250130287A1

Innovation

- A battery evaluation system that includes a battery monitoring unit to monitor the battery state and calculate the lithium precipitation amount, which is then used by an evaluation device to determine the safety of the storage battery based on this index.

Regulatory Compliance for Aluminum-Ion Battery Certification

The regulatory landscape for aluminum-ion battery certification is evolving rapidly as this technology advances toward commercial viability. Currently, aluminum-ion cells must comply with international standards primarily designed for lithium-ion batteries, with specific adaptations to address the unique characteristics of aluminum-ion chemistry. Key regulatory bodies include the International Electrotechnical Commission (IEC), Underwriters Laboratories (UL), and various regional certification authorities.

Safety certification for aluminum-ion cells requires compliance with IEC 62133 for portable batteries and IEC 61960 for secondary cells, though these standards require interpretation for application to aluminum-ion technology. The UN Transportation Testing (UN 38.3) is mandatory for shipping aluminum-ion batteries internationally, covering tests for altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge.

In the United States, UL 1642 for lithium batteries serves as a reference standard that certification bodies adapt for aluminum-ion cells. The European Union requires CE marking, demonstrating compliance with the Battery Directive (2006/66/EC) and its amendments, with particular attention to restricted substance regulations and end-of-life management.

Emerging regulations specifically addressing aluminum-ion technology are being developed by standards organizations. These focus on the unique safety characteristics of aluminum-ion cells, including their lower fire risk compared to lithium-ion batteries and different thermal runaway behaviors. Manufacturers must document how aluminum-ion cells meet or exceed existing safety standards, even when those standards were not explicitly designed for this chemistry.

Environmental compliance is increasingly important, with regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in Europe affecting battery certification. Aluminum-ion batteries generally have favorable environmental profiles due to abundant aluminum resources and potentially simpler recycling processes, which may facilitate regulatory approval.

For market entry, manufacturers must navigate country-specific certification requirements. Japan requires PSE certification, China mandates CCC certification, and South Korea requires KC certification. Each jurisdiction has unique testing protocols that must be satisfied before commercial deployment. Manufacturers should engage with certification bodies early in the development process to ensure compliance pathways are clearly established.

As aluminum-ion technology matures, regulatory frameworks will likely evolve to better accommodate its specific characteristics. Companies developing aluminum-ion cells should maintain active engagement with standards organizations to influence the development of technology-specific standards that appropriately address the safety profile of this emerging battery chemistry.

Safety certification for aluminum-ion cells requires compliance with IEC 62133 for portable batteries and IEC 61960 for secondary cells, though these standards require interpretation for application to aluminum-ion technology. The UN Transportation Testing (UN 38.3) is mandatory for shipping aluminum-ion batteries internationally, covering tests for altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge.

In the United States, UL 1642 for lithium batteries serves as a reference standard that certification bodies adapt for aluminum-ion cells. The European Union requires CE marking, demonstrating compliance with the Battery Directive (2006/66/EC) and its amendments, with particular attention to restricted substance regulations and end-of-life management.

Emerging regulations specifically addressing aluminum-ion technology are being developed by standards organizations. These focus on the unique safety characteristics of aluminum-ion cells, including their lower fire risk compared to lithium-ion batteries and different thermal runaway behaviors. Manufacturers must document how aluminum-ion cells meet or exceed existing safety standards, even when those standards were not explicitly designed for this chemistry.

Environmental compliance is increasingly important, with regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in Europe affecting battery certification. Aluminum-ion batteries generally have favorable environmental profiles due to abundant aluminum resources and potentially simpler recycling processes, which may facilitate regulatory approval.

For market entry, manufacturers must navigate country-specific certification requirements. Japan requires PSE certification, China mandates CCC certification, and South Korea requires KC certification. Each jurisdiction has unique testing protocols that must be satisfied before commercial deployment. Manufacturers should engage with certification bodies early in the development process to ensure compliance pathways are clearly established.

As aluminum-ion technology matures, regulatory frameworks will likely evolve to better accommodate its specific characteristics. Companies developing aluminum-ion cells should maintain active engagement with standards organizations to influence the development of technology-specific standards that appropriately address the safety profile of this emerging battery chemistry.

Environmental Impact of Aluminum-Ion Battery Safety Features

The environmental implications of aluminum-ion battery safety features represent a significant advantage over traditional lithium-ion technologies. Aluminum-ion cells demonstrate superior thermal stability during abuse testing, with significantly lower risk of thermal runaway events that can release toxic gases and particulates into the atmosphere. This reduced fire hazard translates directly to decreased potential for environmental contamination during accidents or improper disposal.

The electrolytes used in aluminum-ion cells typically contain fewer environmentally persistent chemicals compared to lithium-ion counterparts. Safety testing reveals that even under extreme conditions, these electrolytes release substantially fewer volatile organic compounds and fluorinated gases, which are known contributors to air pollution and greenhouse effects. The environmental footprint of safety incidents is therefore considerably smaller.

Recycling processes for aluminum-ion batteries benefit from their enhanced safety profile. The reduced reactivity of damaged cells allows for safer handling during end-of-life processing, minimizing the risk of environmental contamination during the recycling chain. Additionally, the aluminum components are more readily recyclable than lithium, with established global recycling infrastructure already in place, further reducing the environmental impact.

Water contamination risks from damaged aluminum-ion cells appear significantly lower based on leachate testing of compromised cells. Safety assessments indicate that even when cell casings are breached, the electrolyte components show reduced aquatic toxicity compared to conventional battery technologies. This characteristic is particularly valuable for applications in environmentally sensitive areas or marine environments.

The manufacturing safety protocols for aluminum-ion cells may also contribute to reduced environmental impact. The lower reactivity of materials allows for less stringent containment requirements during production, potentially reducing energy consumption and associated carbon emissions in manufacturing facilities. Safety testing confirms that production accidents would have more localized environmental consequences.

Long-term environmental monitoring of disposal sites containing damaged aluminum-ion cells shows promising results regarding soil contamination and groundwater impacts. The inherent stability of these cells, even after physical damage, contributes to slower leaching rates of potentially harmful components, providing more time for remediation efforts in case of improper disposal.

The reduced need for flame-retardant additives and safety-enhancing chemicals in aluminum-ion cells further diminishes their environmental footprint. These additives, often required in lithium-ion batteries to mitigate safety risks, frequently include halogenated compounds with known environmental persistence and bioaccumulation properties.

The electrolytes used in aluminum-ion cells typically contain fewer environmentally persistent chemicals compared to lithium-ion counterparts. Safety testing reveals that even under extreme conditions, these electrolytes release substantially fewer volatile organic compounds and fluorinated gases, which are known contributors to air pollution and greenhouse effects. The environmental footprint of safety incidents is therefore considerably smaller.

Recycling processes for aluminum-ion batteries benefit from their enhanced safety profile. The reduced reactivity of damaged cells allows for safer handling during end-of-life processing, minimizing the risk of environmental contamination during the recycling chain. Additionally, the aluminum components are more readily recyclable than lithium, with established global recycling infrastructure already in place, further reducing the environmental impact.

Water contamination risks from damaged aluminum-ion cells appear significantly lower based on leachate testing of compromised cells. Safety assessments indicate that even when cell casings are breached, the electrolyte components show reduced aquatic toxicity compared to conventional battery technologies. This characteristic is particularly valuable for applications in environmentally sensitive areas or marine environments.

The manufacturing safety protocols for aluminum-ion cells may also contribute to reduced environmental impact. The lower reactivity of materials allows for less stringent containment requirements during production, potentially reducing energy consumption and associated carbon emissions in manufacturing facilities. Safety testing confirms that production accidents would have more localized environmental consequences.

Long-term environmental monitoring of disposal sites containing damaged aluminum-ion cells shows promising results regarding soil contamination and groundwater impacts. The inherent stability of these cells, even after physical damage, contributes to slower leaching rates of potentially harmful components, providing more time for remediation efforts in case of improper disposal.

The reduced need for flame-retardant additives and safety-enhancing chemicals in aluminum-ion cells further diminishes their environmental footprint. These additives, often required in lithium-ion batteries to mitigate safety risks, frequently include halogenated compounds with known environmental persistence and bioaccumulation properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!