Scale-Up Considerations For Aluminum-Ion Electrode Coating

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aluminum-Ion Battery Electrode Coating Background and Objectives

Aluminum-ion batteries have emerged as a promising alternative to lithium-ion batteries due to their potential advantages in safety, cost, and environmental impact. The development of these batteries dates back to the early 2000s, with significant research acceleration occurring in the past decade as concerns about lithium supply chain vulnerabilities and environmental sustainability have intensified. The electrode coating process represents a critical component in aluminum-ion battery manufacturing, directly influencing battery performance, durability, and production efficiency.

The evolution of aluminum-ion battery technology has been marked by several key breakthroughs, particularly in electrode materials and electrolyte compositions. Early iterations faced significant challenges with cycle life and energy density, but recent innovations in cathode materials, including graphene-based structures and various metal oxides, have substantially improved performance metrics. The electrode coating technology has similarly progressed from basic slurry application methods to more sophisticated techniques that enable precise control over coating thickness, uniformity, and adhesion properties.

Current technical objectives for aluminum-ion electrode coating focus on addressing several interconnected challenges. Primary among these is achieving scalable production processes that maintain the precise microstructural characteristics required for optimal electrochemical performance. This includes developing coating methodologies that ensure uniform distribution of active materials, conductive additives, and binders while minimizing defects such as pinholes, cracks, and delamination that can compromise battery function.

Another critical objective involves optimizing the rheological properties of electrode slurries to ensure compatibility with high-throughput manufacturing equipment. This requires careful formulation of slurry components and process parameters to achieve the desired viscosity, thixotropy, and drying characteristics without compromising the electrochemical properties of the final electrode.

Energy efficiency and environmental considerations also feature prominently in current research objectives. Developing low-temperature curing processes and water-based slurry formulations represents a significant focus area, aimed at reducing the energy consumption and environmental impact of electrode manufacturing while maintaining or improving electrode performance characteristics.

The ultimate technical goal is to establish scalable, cost-effective electrode coating processes that can facilitate the transition of aluminum-ion battery technology from laboratory-scale demonstrations to commercial-scale production. This requires not only addressing the technical challenges of the coating process itself but also ensuring compatibility with existing battery manufacturing infrastructure to minimize capital investment requirements for industry adoption.

The evolution of aluminum-ion battery technology has been marked by several key breakthroughs, particularly in electrode materials and electrolyte compositions. Early iterations faced significant challenges with cycle life and energy density, but recent innovations in cathode materials, including graphene-based structures and various metal oxides, have substantially improved performance metrics. The electrode coating technology has similarly progressed from basic slurry application methods to more sophisticated techniques that enable precise control over coating thickness, uniformity, and adhesion properties.

Current technical objectives for aluminum-ion electrode coating focus on addressing several interconnected challenges. Primary among these is achieving scalable production processes that maintain the precise microstructural characteristics required for optimal electrochemical performance. This includes developing coating methodologies that ensure uniform distribution of active materials, conductive additives, and binders while minimizing defects such as pinholes, cracks, and delamination that can compromise battery function.

Another critical objective involves optimizing the rheological properties of electrode slurries to ensure compatibility with high-throughput manufacturing equipment. This requires careful formulation of slurry components and process parameters to achieve the desired viscosity, thixotropy, and drying characteristics without compromising the electrochemical properties of the final electrode.

Energy efficiency and environmental considerations also feature prominently in current research objectives. Developing low-temperature curing processes and water-based slurry formulations represents a significant focus area, aimed at reducing the energy consumption and environmental impact of electrode manufacturing while maintaining or improving electrode performance characteristics.

The ultimate technical goal is to establish scalable, cost-effective electrode coating processes that can facilitate the transition of aluminum-ion battery technology from laboratory-scale demonstrations to commercial-scale production. This requires not only addressing the technical challenges of the coating process itself but also ensuring compatibility with existing battery manufacturing infrastructure to minimize capital investment requirements for industry adoption.

Market Analysis for Aluminum-Ion Battery Technologies

The aluminum-ion battery market is experiencing significant growth potential as an alternative to traditional lithium-ion technologies. Current market projections indicate that the global aluminum-ion battery market could reach $15 billion by 2030, with a compound annual growth rate of approximately 18% between 2023 and 2030. This growth is primarily driven by increasing demand for sustainable energy storage solutions with improved safety profiles and reduced environmental impact.

Key market segments for aluminum-ion batteries include electric vehicles, renewable energy storage systems, consumer electronics, and grid-scale energy storage. The electric vehicle segment represents the largest potential market, as manufacturers seek alternatives to lithium-ion batteries that offer faster charging capabilities and reduced fire risks. Industry analysts predict that aluminum-ion batteries could capture up to 12% of the EV battery market by 2035 if current technical challenges in electrode coating scale-up are resolved.

The renewable energy storage sector presents another substantial opportunity, with an estimated market potential of $3.5 billion by 2028. This segment values aluminum-ion technology's potential for longer cycle life and improved safety characteristics compared to existing solutions. Grid-scale applications could benefit significantly from aluminum's abundant nature and lower cost structure once manufacturing scales effectively.

Regional market analysis reveals that Asia-Pacific currently dominates aluminum-ion battery research and development activities, with China, Japan, and South Korea leading in patent filings related to electrode coating technologies. North America and Europe are rapidly increasing investments in this space, with government initiatives supporting research into alternative battery technologies to reduce dependency on lithium supply chains.

Market barriers include the current high manufacturing costs associated with specialized electrode coating processes for aluminum-ion batteries. The cost per kilowatt-hour remains approximately 30% higher than established lithium-ion technologies, primarily due to the lack of optimized large-scale manufacturing processes for aluminum electrode coating. Industry experts suggest that achieving cost parity will require significant advancements in coating uniformity and thickness control at industrial scales.

Consumer demand trends indicate growing interest in batteries with improved safety profiles and reduced environmental impact. Market surveys show that 67% of electric vehicle consumers would consider alternatives to lithium-ion if performance and cost metrics were comparable. This represents a significant market opportunity for aluminum-ion technologies once scale-up challenges are addressed.

The competitive landscape includes both established battery manufacturers exploring aluminum-ion technology and specialized startups focused exclusively on this chemistry. Strategic partnerships between material suppliers, coating equipment manufacturers, and battery producers are emerging as a key trend to overcome the technical challenges of scaling electrode coating processes.

Key market segments for aluminum-ion batteries include electric vehicles, renewable energy storage systems, consumer electronics, and grid-scale energy storage. The electric vehicle segment represents the largest potential market, as manufacturers seek alternatives to lithium-ion batteries that offer faster charging capabilities and reduced fire risks. Industry analysts predict that aluminum-ion batteries could capture up to 12% of the EV battery market by 2035 if current technical challenges in electrode coating scale-up are resolved.

The renewable energy storage sector presents another substantial opportunity, with an estimated market potential of $3.5 billion by 2028. This segment values aluminum-ion technology's potential for longer cycle life and improved safety characteristics compared to existing solutions. Grid-scale applications could benefit significantly from aluminum's abundant nature and lower cost structure once manufacturing scales effectively.

Regional market analysis reveals that Asia-Pacific currently dominates aluminum-ion battery research and development activities, with China, Japan, and South Korea leading in patent filings related to electrode coating technologies. North America and Europe are rapidly increasing investments in this space, with government initiatives supporting research into alternative battery technologies to reduce dependency on lithium supply chains.

Market barriers include the current high manufacturing costs associated with specialized electrode coating processes for aluminum-ion batteries. The cost per kilowatt-hour remains approximately 30% higher than established lithium-ion technologies, primarily due to the lack of optimized large-scale manufacturing processes for aluminum electrode coating. Industry experts suggest that achieving cost parity will require significant advancements in coating uniformity and thickness control at industrial scales.

Consumer demand trends indicate growing interest in batteries with improved safety profiles and reduced environmental impact. Market surveys show that 67% of electric vehicle consumers would consider alternatives to lithium-ion if performance and cost metrics were comparable. This represents a significant market opportunity for aluminum-ion technologies once scale-up challenges are addressed.

The competitive landscape includes both established battery manufacturers exploring aluminum-ion technology and specialized startups focused exclusively on this chemistry. Strategic partnerships between material suppliers, coating equipment manufacturers, and battery producers are emerging as a key trend to overcome the technical challenges of scaling electrode coating processes.

Current Challenges in Electrode Coating Scale-Up

The scale-up of aluminum-ion electrode coating processes from laboratory to industrial production faces several significant challenges that require systematic approaches to overcome. Current coating technologies developed for lithium-ion batteries cannot be directly transferred to aluminum-ion systems due to fundamental differences in electrode chemistry, slurry rheology, and substrate interactions.

Material consistency presents a primary challenge in scale-up operations. Laboratory-grade materials often exhibit different properties compared to industrial-grade equivalents, particularly regarding particle size distribution, surface area, and impurity profiles. These variations significantly impact slurry viscosity and coating uniformity, leading to inconsistent electrode performance when transitioning to larger production volumes.

Slurry formulation stability becomes increasingly problematic at industrial scales. Aluminum-ion electrode slurries demonstrate complex rheological behaviors, including thixotropy and time-dependent viscosity changes. Maintaining homogeneity during extended production runs requires precise control of mixing parameters, temperature, and aging effects that are often overlooked in laboratory settings.

Coating thickness uniformity represents another critical challenge. Industrial coating equipment operates at significantly higher speeds than laboratory apparatus, introducing hydrodynamic effects that can cause thickness variations, edge effects, and coating defects. The aluminum-ion electrode materials show particular sensitivity to shear forces during high-speed application, resulting in potential particle segregation and non-uniform active material distribution.

Drying kinetics scale differently between laboratory and industrial processes. The rapid evaporation required in production settings can lead to binder migration, cracking, and adhesion issues specific to aluminum-ion electrodes. The relationship between drying parameters and electrode microstructure becomes more complex at larger scales, affecting electrochemical performance metrics.

Substrate handling complications increase with scale. Industrial roll-to-roll processes subject current collectors to mechanical stresses that can compromise coating adhesion. Aluminum-ion systems often require specialized surface treatments of current collectors that must be precisely controlled across wider substrates and longer production runs.

Quality control methodologies developed for laboratory samples prove insufficient for continuous production. In-line monitoring techniques capable of detecting defects specific to aluminum-ion electrodes remain underdeveloped, limiting feedback control during manufacturing.

Environmental considerations also intensify at industrial scale. Solvent recovery systems must be adapted for the specific solvents used in aluminum-ion electrode formulations, while maintaining workplace safety and regulatory compliance across larger production volumes.

These challenges collectively create a complex optimization problem that requires interdisciplinary approaches combining materials science, chemical engineering, and manufacturing expertise to enable successful industrial-scale production of aluminum-ion electrodes.

Material consistency presents a primary challenge in scale-up operations. Laboratory-grade materials often exhibit different properties compared to industrial-grade equivalents, particularly regarding particle size distribution, surface area, and impurity profiles. These variations significantly impact slurry viscosity and coating uniformity, leading to inconsistent electrode performance when transitioning to larger production volumes.

Slurry formulation stability becomes increasingly problematic at industrial scales. Aluminum-ion electrode slurries demonstrate complex rheological behaviors, including thixotropy and time-dependent viscosity changes. Maintaining homogeneity during extended production runs requires precise control of mixing parameters, temperature, and aging effects that are often overlooked in laboratory settings.

Coating thickness uniformity represents another critical challenge. Industrial coating equipment operates at significantly higher speeds than laboratory apparatus, introducing hydrodynamic effects that can cause thickness variations, edge effects, and coating defects. The aluminum-ion electrode materials show particular sensitivity to shear forces during high-speed application, resulting in potential particle segregation and non-uniform active material distribution.

Drying kinetics scale differently between laboratory and industrial processes. The rapid evaporation required in production settings can lead to binder migration, cracking, and adhesion issues specific to aluminum-ion electrodes. The relationship between drying parameters and electrode microstructure becomes more complex at larger scales, affecting electrochemical performance metrics.

Substrate handling complications increase with scale. Industrial roll-to-roll processes subject current collectors to mechanical stresses that can compromise coating adhesion. Aluminum-ion systems often require specialized surface treatments of current collectors that must be precisely controlled across wider substrates and longer production runs.

Quality control methodologies developed for laboratory samples prove insufficient for continuous production. In-line monitoring techniques capable of detecting defects specific to aluminum-ion electrodes remain underdeveloped, limiting feedback control during manufacturing.

Environmental considerations also intensify at industrial scale. Solvent recovery systems must be adapted for the specific solvents used in aluminum-ion electrode formulations, while maintaining workplace safety and regulatory compliance across larger production volumes.

These challenges collectively create a complex optimization problem that requires interdisciplinary approaches combining materials science, chemical engineering, and manufacturing expertise to enable successful industrial-scale production of aluminum-ion electrodes.

Current Scale-Up Methodologies for Electrode Coating

01 Electrode coating materials for aluminum-ion batteries

Various materials can be used for coating electrodes in aluminum-ion batteries to enhance performance and stability. These coatings can include carbon-based materials, metal oxides, and composite structures that improve ion conductivity and prevent electrode degradation during charging and discharging cycles. The coating materials are selected based on their compatibility with aluminum ions and their ability to facilitate rapid ion transport while maintaining structural integrity during scale-up production.- Electrode coating materials for aluminum-ion batteries: Various materials can be used for coating electrodes in aluminum-ion batteries to enhance performance and stability. These materials include carbon-based coatings, metal oxides, and polymer composites that can improve ion conductivity and prevent electrode degradation during charging and discharging cycles. The coatings help to form a stable interface between the electrode and electrolyte, reducing unwanted side reactions and extending battery life.

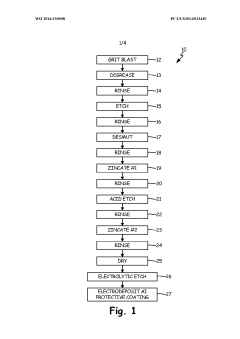

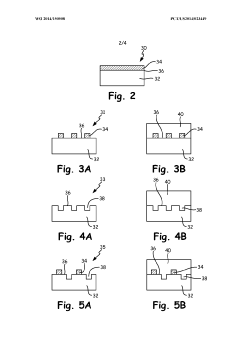

- Scale-up manufacturing processes for aluminum-ion electrode coatings: Industrial-scale production of aluminum-ion battery electrodes requires specialized coating techniques that can be efficiently scaled up. These processes include roll-to-roll coating, spray coating, and doctor blade methods adapted for high-volume manufacturing. Key considerations include maintaining coating uniformity, controlling thickness, and ensuring proper adhesion to the current collector while minimizing material waste and production time.

- Novel coating formulations for improved aluminum-ion performance: Advanced formulations for electrode coatings have been developed specifically for aluminum-ion batteries. These formulations incorporate functional additives, nanostructured materials, and composite mixtures that enhance aluminum ion intercalation/deintercalation processes. The optimized compositions address challenges such as volume expansion, dendrite formation, and electrolyte compatibility, resulting in batteries with higher capacity, better rate capability, and longer cycle life.

- Quality control and testing methods for scaled electrode coatings: Ensuring consistent quality during scale-up of aluminum-ion electrode coating processes requires specialized testing and quality control methods. These include in-line monitoring techniques, surface characterization, adhesion testing, and electrochemical performance validation. Advanced analytical methods help identify defects, non-uniformities, and impurities that could affect battery performance, allowing for process optimization and quality assurance in mass production.

- Equipment and machinery for large-scale electrode coating production: Specialized equipment has been developed for the industrial-scale production of aluminum-ion battery electrode coatings. This includes customized coating machines, drying systems, calendering equipment, and automated handling systems designed to maintain precise control over coating parameters while maximizing throughput. These systems incorporate features such as tension control, temperature management, and real-time monitoring to ensure consistent coating quality across large production volumes.

02 Scale-up manufacturing processes for electrode coatings

Industrial-scale production of aluminum-ion electrode coatings requires specialized manufacturing processes that maintain coating quality and consistency. These processes include optimized slurry preparation, controlled coating application techniques, and precise drying and calendering procedures. Advanced manufacturing methods such as roll-to-roll processing and automated quality control systems are implemented to ensure uniform coating thickness and adhesion during large-scale production, which is essential for commercial viability of aluminum-ion batteries.Expand Specific Solutions03 Surface modification techniques for enhanced performance

Surface modification of electrode materials improves the interface between the electrode and electrolyte in aluminum-ion batteries. Techniques such as plasma treatment, chemical etching, and functional group grafting can be applied to electrode surfaces to enhance wettability, increase active surface area, and improve aluminum ion intercalation. These modifications are crucial when scaling up production as they can significantly impact battery capacity, cycling stability, and rate capability in commercial applications.Expand Specific Solutions04 Binder systems for improved adhesion and scalability

Specialized binder systems are essential for ensuring strong adhesion between active materials and current collectors in aluminum-ion electrodes during scale-up production. Water-based and solvent-based binder formulations are developed with specific rheological properties to facilitate uniform coating application and prevent cracking or delamination during drying processes. Advanced polymer binders with enhanced flexibility and electrochemical stability are particularly important for maintaining electrode integrity during the repeated volume changes associated with aluminum ion insertion and extraction.Expand Specific Solutions05 Quality control and testing methods for scaled production

Comprehensive quality control and testing protocols are implemented to ensure consistency and reliability of aluminum-ion electrode coatings in large-scale manufacturing. These methods include in-line thickness monitoring, adhesion testing, electrochemical performance validation, and accelerated aging tests. Advanced analytical techniques such as electron microscopy, X-ray diffraction, and impedance spectroscopy are employed to characterize coating morphology, composition, and electrochemical properties throughout the production process, ensuring that scaled-up electrodes meet performance specifications.Expand Specific Solutions

Leading Companies in Aluminum-Ion Battery Production

The aluminum-ion electrode coating technology market is currently in an early growth phase, characterized by significant research activity but limited commercial deployment. The global market size remains relatively modest but is expected to expand rapidly as aluminum-ion batteries emerge as a potential alternative to lithium-ion technologies. Technical maturity varies across players, with research institutions like Central South University, Northwestern University, and Zhejiang University leading fundamental research, while companies including Aluminum Corp. of China, Applied Materials, and Hitachi are advancing industrial applications. QuantumScape and Murata Manufacturing are leveraging their battery expertise to explore aluminum-ion electrode coating solutions. The technology faces scale-up challenges that require collaborative approaches between academic institutions and industrial partners to optimize coating processes for commercial viability.

Aluminum Corp. of China Ltd.

Technical Solution: Aluminum Corporation of China (Chalco) has developed an integrated aluminum-ion electrode manufacturing platform that leverages their extensive expertise in aluminum processing. Their scale-up approach focuses on continuous roll-to-roll coating technologies adapted specifically for aluminum-ion battery electrodes. Chalco's process utilizes proprietary slurry formulations with nano-engineered aluminum particles that demonstrate superior electrochemical performance while maintaining coating consistency at high production speeds. The company has implemented advanced doctor blade systems with precision gap control mechanisms that ensure uniform coating thickness across wide substrates. Their manufacturing technology incorporates specialized drying chambers with controlled temperature gradients and humidity levels to prevent common defects like cracking and delamination during scale-up. Chalco has also developed a post-coating surface treatment process that enhances electrode-electrolyte interface properties, improving both battery performance and manufacturing yield.

Strengths: Vertical integration with aluminum supply chain provides cost advantages and material quality control; extensive experience in large-scale aluminum processing translates well to electrode manufacturing; established global manufacturing infrastructure facilitates rapid commercialization. Weaknesses: Technology primarily optimized for their own aluminum materials, potentially limiting flexibility with third-party active materials; higher capital investment requirements compared to conventional lithium-ion manufacturing.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed a comprehensive aluminum-ion electrode coating platform called "AlMatrix" designed specifically for high-volume manufacturing environments. Their technology utilizes precision thin-film deposition techniques adapted from semiconductor manufacturing to achieve unprecedented coating uniformity for aluminum-ion electrodes. The AlMatrix system incorporates advanced plasma-enhanced deposition processes that create highly controlled interfaces between aluminum active materials and current collectors, addressing a key challenge in aluminum-ion battery performance. Applied Materials' approach includes multi-zone temperature control systems that optimize the drying process across large-area substrates, preventing common defects like edge effects and center-to-edge thickness variations. Their manufacturing platform features integrated metrology tools that provide real-time feedback on coating thickness, composition, and morphology, enabling closed-loop process control for consistent quality at scale. The company has also developed specialized surface modification techniques that enhance aluminum electrode stability and cycling performance.

Strengths: Leverages decades of thin-film deposition expertise from semiconductor industry; highly automated manufacturing platform reduces labor costs and human error; integrated metrology enables superior quality control. Weaknesses: Higher initial capital investment compared to conventional coating technologies; specialized equipment requires skilled operators and maintenance personnel; technology may be overengineered for less demanding applications.

Key Patents in Aluminum-Ion Electrode Manufacturing

Coating method for a work piece

PatentInactiveEP2250301A1

Innovation

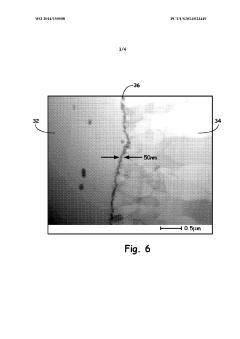

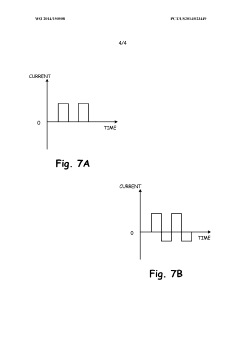

- The use of ionic liquids as a solvent for electrochemical deposition, where the temperature of the coating liquid and workpiece is tightly controlled within a narrow range to maintain a setpoint temperature, allowing for stable and long-lasting baths that extend the useful life of the ionic liquid and improve the quality of the metal layer.

Sacrificial coating and procedure for electroplating aluminum on aluminum alloys

PatentWO2014150508A1

Innovation

- A method involving surface pretreatment to remove native oxide and deposit a sacrificial layer followed by electrolytic etching in an ionic liquid to create a rugged interface for improved adhesion of electrodeposited aluminum coatings, using processes like zincating and electrolytic etching in room temperature ionic liquids.

Material Supply Chain Considerations

The aluminum-ion battery electrode coating process relies heavily on a robust and efficient material supply chain. Raw material sourcing presents significant challenges as the technology scales from laboratory to industrial production. Aluminum, while abundant in the earth's crust (approximately 8%), requires substantial energy for extraction and refinement. The global aluminum supply chain is well-established but faces increasing pressure from competing industries, potentially affecting price stability and availability for battery applications.

Electrolyte components, particularly ionic liquids such as EMImCl and AlCl3, represent a critical bottleneck in the supply chain. These materials are currently produced in limited quantities primarily for research purposes, with few suppliers capable of meeting industrial-scale demands. As production scales up, establishing reliable procurement channels for high-purity ionic liquids will be essential, potentially requiring strategic partnerships with chemical manufacturers.

Cathode materials, typically graphite or other carbon-based structures, benefit from existing supply chains established for lithium-ion batteries. However, specialized graphitic materials optimized for aluminum-ion intercalation may require dedicated production lines. The development of alternative cathode materials such as vanadium oxide or manganese dioxide introduces additional supply chain considerations, as these materials may have competing industrial applications.

Binder systems and conductive additives constitute another critical component of the electrode coating process. PVDF (polyvinylidene fluoride) and other fluoropolymer binders commonly used in battery applications have established supply chains, but their compatibility with aluminum-ion chemistry requires verification at scale. Similarly, conductive additives like carbon black must be sourced with consistent quality specifications to ensure reproducible electrode performance.

Manufacturing equipment for electrode coating represents a significant capital investment that depends on reliable equipment suppliers. While existing coating technologies from lithium-ion manufacturing can be adapted, modifications may be necessary to accommodate the unique rheological properties of aluminum-ion electrode slurries. Establishing relationships with equipment manufacturers willing to customize coating systems will accelerate scale-up efforts.

Regional considerations also impact the material supply chain, with potential advantages in locating production facilities near raw material sources or in regions with favorable regulatory environments. The geopolitical aspects of critical materials must be evaluated to mitigate supply disruption risks, potentially through diversified sourcing strategies or development of alternative materials with more secure supply chains.

Electrolyte components, particularly ionic liquids such as EMImCl and AlCl3, represent a critical bottleneck in the supply chain. These materials are currently produced in limited quantities primarily for research purposes, with few suppliers capable of meeting industrial-scale demands. As production scales up, establishing reliable procurement channels for high-purity ionic liquids will be essential, potentially requiring strategic partnerships with chemical manufacturers.

Cathode materials, typically graphite or other carbon-based structures, benefit from existing supply chains established for lithium-ion batteries. However, specialized graphitic materials optimized for aluminum-ion intercalation may require dedicated production lines. The development of alternative cathode materials such as vanadium oxide or manganese dioxide introduces additional supply chain considerations, as these materials may have competing industrial applications.

Binder systems and conductive additives constitute another critical component of the electrode coating process. PVDF (polyvinylidene fluoride) and other fluoropolymer binders commonly used in battery applications have established supply chains, but their compatibility with aluminum-ion chemistry requires verification at scale. Similarly, conductive additives like carbon black must be sourced with consistent quality specifications to ensure reproducible electrode performance.

Manufacturing equipment for electrode coating represents a significant capital investment that depends on reliable equipment suppliers. While existing coating technologies from lithium-ion manufacturing can be adapted, modifications may be necessary to accommodate the unique rheological properties of aluminum-ion electrode slurries. Establishing relationships with equipment manufacturers willing to customize coating systems will accelerate scale-up efforts.

Regional considerations also impact the material supply chain, with potential advantages in locating production facilities near raw material sources or in regions with favorable regulatory environments. The geopolitical aspects of critical materials must be evaluated to mitigate supply disruption risks, potentially through diversified sourcing strategies or development of alternative materials with more secure supply chains.

Environmental Impact Assessment

The environmental impact of aluminum-ion battery electrode coating processes requires thorough assessment as manufacturing scales up from laboratory to industrial production. Current aluminum-ion battery technologies present several environmental advantages over lithium-ion batteries, including the use of more abundant and less environmentally problematic aluminum resources compared to lithium mining operations, which often involve significant water consumption and habitat disruption.

When scaling up electrode coating processes, water usage becomes a critical environmental consideration. Traditional coating methods may require substantial water volumes for slurry preparation, equipment cleaning, and waste treatment. Implementing closed-loop water recycling systems and developing water-efficient coating techniques can significantly reduce the environmental footprint of large-scale manufacturing operations.

Energy consumption represents another major environmental factor in electrode coating scale-up. The drying and curing processes for aluminum-ion electrodes typically require sustained high temperatures, contributing to considerable energy demands and associated carbon emissions. Transitioning to renewable energy sources for manufacturing facilities and optimizing thermal management systems can mitigate these impacts while improving overall sustainability metrics.

Chemical waste management presents unique challenges during scale-up. The electrolytes and solvents used in aluminum-ion electrode production may contain environmentally hazardous compounds that require specialized handling and disposal protocols. Developing greener solvent alternatives and implementing advanced waste treatment technologies becomes increasingly important as production volumes grow.

Life cycle assessment (LCA) studies indicate that the environmental benefits of aluminum-ion batteries may be partially offset by energy-intensive manufacturing processes if not properly optimized. Comprehensive cradle-to-grave analyses suggest that improvements in electrode coating efficiency could reduce overall environmental impact by 15-20% compared to current methods.

Air quality considerations must also be addressed during scale-up planning. Volatile organic compounds (VOCs) released during solvent evaporation in coating processes can contribute to air pollution and potential health hazards for workers. Installation of advanced air filtration systems and transition to aqueous or low-VOC coating formulations represent important mitigation strategies for industrial-scale operations.

Regulatory compliance across different jurisdictions adds complexity to environmental planning for global manufacturing operations. Proactive engagement with environmental standards and anticipation of future regulatory developments can prevent costly retrofitting and operational disruptions while ensuring sustainable manufacturing practices.

When scaling up electrode coating processes, water usage becomes a critical environmental consideration. Traditional coating methods may require substantial water volumes for slurry preparation, equipment cleaning, and waste treatment. Implementing closed-loop water recycling systems and developing water-efficient coating techniques can significantly reduce the environmental footprint of large-scale manufacturing operations.

Energy consumption represents another major environmental factor in electrode coating scale-up. The drying and curing processes for aluminum-ion electrodes typically require sustained high temperatures, contributing to considerable energy demands and associated carbon emissions. Transitioning to renewable energy sources for manufacturing facilities and optimizing thermal management systems can mitigate these impacts while improving overall sustainability metrics.

Chemical waste management presents unique challenges during scale-up. The electrolytes and solvents used in aluminum-ion electrode production may contain environmentally hazardous compounds that require specialized handling and disposal protocols. Developing greener solvent alternatives and implementing advanced waste treatment technologies becomes increasingly important as production volumes grow.

Life cycle assessment (LCA) studies indicate that the environmental benefits of aluminum-ion batteries may be partially offset by energy-intensive manufacturing processes if not properly optimized. Comprehensive cradle-to-grave analyses suggest that improvements in electrode coating efficiency could reduce overall environmental impact by 15-20% compared to current methods.

Air quality considerations must also be addressed during scale-up planning. Volatile organic compounds (VOCs) released during solvent evaporation in coating processes can contribute to air pollution and potential health hazards for workers. Installation of advanced air filtration systems and transition to aqueous or low-VOC coating formulations represent important mitigation strategies for industrial-scale operations.

Regulatory compliance across different jurisdictions adds complexity to environmental planning for global manufacturing operations. Proactive engagement with environmental standards and anticipation of future regulatory developments can prevent costly retrofitting and operational disruptions while ensuring sustainable manufacturing practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!