Electrochemical Diagnostics Of Cathode Slippage In Al-Ion Batteries

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Al-Ion Battery Technology Background and Objectives

Aluminum-ion (Al-ion) batteries have emerged as a promising alternative to lithium-ion batteries due to their potential advantages in cost, safety, and environmental impact. The development of Al-ion battery technology can be traced back to the early 2000s, with significant advancements occurring in the past decade. These batteries utilize aluminum as the anode material, which is the third most abundant element in the Earth's crust, making it considerably less expensive than lithium.

The evolution of Al-ion battery technology has been marked by continuous improvements in cathode materials, electrolytes, and overall cell design. Initially, the technology faced significant challenges related to limited cycle life, low energy density, and rapid capacity fading. However, recent breakthroughs in cathode materials, particularly graphitic carbon structures and various transition metal compounds, have substantially improved performance metrics.

A critical aspect of Al-ion battery development has been understanding and addressing the phenomenon of cathode slippage. This refers to the gradual displacement or structural degradation of cathode materials during repeated charge-discharge cycles, which significantly impacts battery performance and longevity. The electrochemical diagnostics of cathode slippage has become a focal point for researchers aiming to enhance the stability and durability of Al-ion batteries.

Current technological objectives in this field include developing more sensitive and accurate diagnostic methods to detect early signs of cathode slippage, understanding the fundamental mechanisms driving this phenomenon, and designing novel cathode materials that resist slippage effects. Researchers are particularly interested in in-situ and operando electrochemical techniques that can provide real-time insights into structural changes within the battery during operation.

The advancement of electrochemical diagnostic tools for Al-ion batteries aligns with broader industry goals of creating energy storage solutions that combine high performance with sustainability. These objectives include achieving energy densities comparable to commercial lithium-ion batteries (>200 Wh/kg), extending cycle life beyond 1000 cycles, and maintaining capacity retention above 80% throughout the battery's operational lifetime.

Furthermore, there is growing interest in integrating advanced computational modeling with experimental electrochemical diagnostics to predict cathode behavior under various operating conditions. This integrated approach aims to accelerate the development cycle by identifying promising material combinations and operational parameters without extensive physical testing.

The ultimate goal of research in electrochemical diagnostics of cathode slippage is to enable the commercial viability of Al-ion batteries as a sustainable alternative in applications ranging from grid-scale energy storage to electric vehicles, thereby contributing to global efforts in reducing carbon emissions and dependence on critical materials with limited supply.

The evolution of Al-ion battery technology has been marked by continuous improvements in cathode materials, electrolytes, and overall cell design. Initially, the technology faced significant challenges related to limited cycle life, low energy density, and rapid capacity fading. However, recent breakthroughs in cathode materials, particularly graphitic carbon structures and various transition metal compounds, have substantially improved performance metrics.

A critical aspect of Al-ion battery development has been understanding and addressing the phenomenon of cathode slippage. This refers to the gradual displacement or structural degradation of cathode materials during repeated charge-discharge cycles, which significantly impacts battery performance and longevity. The electrochemical diagnostics of cathode slippage has become a focal point for researchers aiming to enhance the stability and durability of Al-ion batteries.

Current technological objectives in this field include developing more sensitive and accurate diagnostic methods to detect early signs of cathode slippage, understanding the fundamental mechanisms driving this phenomenon, and designing novel cathode materials that resist slippage effects. Researchers are particularly interested in in-situ and operando electrochemical techniques that can provide real-time insights into structural changes within the battery during operation.

The advancement of electrochemical diagnostic tools for Al-ion batteries aligns with broader industry goals of creating energy storage solutions that combine high performance with sustainability. These objectives include achieving energy densities comparable to commercial lithium-ion batteries (>200 Wh/kg), extending cycle life beyond 1000 cycles, and maintaining capacity retention above 80% throughout the battery's operational lifetime.

Furthermore, there is growing interest in integrating advanced computational modeling with experimental electrochemical diagnostics to predict cathode behavior under various operating conditions. This integrated approach aims to accelerate the development cycle by identifying promising material combinations and operational parameters without extensive physical testing.

The ultimate goal of research in electrochemical diagnostics of cathode slippage is to enable the commercial viability of Al-ion batteries as a sustainable alternative in applications ranging from grid-scale energy storage to electric vehicles, thereby contributing to global efforts in reducing carbon emissions and dependence on critical materials with limited supply.

Market Analysis for Al-Ion Battery Applications

The aluminum-ion battery market is experiencing significant growth as industries seek alternatives to lithium-ion technologies. Current market valuations place the global Al-ion battery sector at approximately $57 million in 2023, with projections indicating a compound annual growth rate of 6.8% through 2030, potentially reaching $89 million. This growth trajectory is driven by increasing demand for sustainable energy storage solutions across multiple sectors.

The electric vehicle (EV) market represents the most promising application area for Al-ion batteries. With global EV sales exceeding 10 million units in 2022 and continuing to grow at double-digit rates, manufacturers are actively seeking battery technologies that offer improved safety profiles and reduced dependency on critical materials. Al-ion batteries with optimized cathode performance could capture up to 5% of the EV battery market by 2028 if current technical challenges are addressed.

Grid-scale energy storage presents another substantial market opportunity, valued at $8.5 billion globally and growing at 24% annually. Utility companies are particularly interested in Al-ion technology due to its potential for longer cycle life and enhanced safety compared to current solutions. The ability to diagnose and prevent cathode slippage would significantly improve the reliability metrics that utility customers demand.

Consumer electronics manufacturers have also expressed interest in Al-ion batteries, particularly for applications where safety is paramount. This segment represents a $3.2 billion opportunity for advanced battery technologies, with companies willing to pay premium prices for solutions that eliminate thermal runaway risks associated with lithium-ion batteries.

Industrial applications, including backup power systems and material handling equipment, constitute a growing market segment valued at $4.7 billion. These applications prioritize operational reliability and maintenance predictability, making advanced diagnostic capabilities for issues like cathode slippage particularly valuable.

Military and aerospace sectors are investing heavily in next-generation battery technologies, with dedicated research budgets exceeding $320 million annually for aluminum-based energy storage. These high-value applications can tolerate higher costs in exchange for performance advantages and supply chain security that Al-ion batteries potentially offer.

Market adoption barriers include price sensitivity in mass-market applications, with current Al-ion battery production costs approximately 2.3 times higher than lithium-ion equivalents. However, analysis indicates that solving technical challenges like cathode slippage could reduce this premium to 1.4 times, potentially accelerating market penetration across all identified segments.

The electric vehicle (EV) market represents the most promising application area for Al-ion batteries. With global EV sales exceeding 10 million units in 2022 and continuing to grow at double-digit rates, manufacturers are actively seeking battery technologies that offer improved safety profiles and reduced dependency on critical materials. Al-ion batteries with optimized cathode performance could capture up to 5% of the EV battery market by 2028 if current technical challenges are addressed.

Grid-scale energy storage presents another substantial market opportunity, valued at $8.5 billion globally and growing at 24% annually. Utility companies are particularly interested in Al-ion technology due to its potential for longer cycle life and enhanced safety compared to current solutions. The ability to diagnose and prevent cathode slippage would significantly improve the reliability metrics that utility customers demand.

Consumer electronics manufacturers have also expressed interest in Al-ion batteries, particularly for applications where safety is paramount. This segment represents a $3.2 billion opportunity for advanced battery technologies, with companies willing to pay premium prices for solutions that eliminate thermal runaway risks associated with lithium-ion batteries.

Industrial applications, including backup power systems and material handling equipment, constitute a growing market segment valued at $4.7 billion. These applications prioritize operational reliability and maintenance predictability, making advanced diagnostic capabilities for issues like cathode slippage particularly valuable.

Military and aerospace sectors are investing heavily in next-generation battery technologies, with dedicated research budgets exceeding $320 million annually for aluminum-based energy storage. These high-value applications can tolerate higher costs in exchange for performance advantages and supply chain security that Al-ion batteries potentially offer.

Market adoption barriers include price sensitivity in mass-market applications, with current Al-ion battery production costs approximately 2.3 times higher than lithium-ion equivalents. However, analysis indicates that solving technical challenges like cathode slippage could reduce this premium to 1.4 times, potentially accelerating market penetration across all identified segments.

Cathode Slippage Challenges in Al-Ion Batteries

Aluminum-ion batteries (AIBs) represent a promising alternative to lithium-ion batteries due to their potential for higher energy density, improved safety, and lower cost. However, a significant technical challenge hampering their widespread adoption is cathode slippage, a phenomenon where the cathode material undergoes structural degradation during charge-discharge cycles, leading to capacity fade and reduced battery performance.

The cathode slippage in AIBs primarily manifests as the displacement of aluminum ions from their intended intercalation sites within the cathode structure. This displacement occurs due to the strong electrostatic interactions between the trivalent aluminum ions and the host lattice, causing structural distortions and eventual breakdown of the cathode material. Unlike lithium-ion batteries, where the monovalent lithium ions cause minimal structural changes during intercalation/deintercalation, the trivalent nature of aluminum ions exerts significantly higher forces on the host structure.

Current cathode materials for AIBs, such as graphite, Prussian blue analogs, and transition metal oxides, exhibit varying degrees of susceptibility to cathode slippage. Graphitic cathodes, while demonstrating good initial performance, suffer from exfoliation and structural collapse after repeated cycling. Transition metal oxides often experience irreversible phase transformations due to the strong Al3+ interactions, leading to rapid capacity degradation.

The electrochemical diagnostics of cathode slippage involves sophisticated analytical techniques including in-situ X-ray diffraction (XRD), transmission electron microscopy (TEM), and advanced electrochemical impedance spectroscopy (EIS). These methods allow researchers to observe structural changes in real-time during battery operation, providing crucial insights into the mechanisms of cathode degradation.

Temperature fluctuations significantly exacerbate cathode slippage issues, with elevated temperatures accelerating the structural breakdown of cathode materials. Additionally, the choice of electrolyte plays a critical role, as certain electrolytes can either mitigate or worsen the slippage phenomenon through their interaction with both the aluminum ions and the cathode surface.

Recent research has identified several promising approaches to address cathode slippage, including the development of novel cathode materials with more robust crystal structures, surface modification techniques to strengthen the cathode-electrolyte interface, and the use of additives to stabilize the intercalation process. Computational modeling and machine learning algorithms are increasingly being employed to predict structural stability and optimize cathode compositions before experimental validation.

Despite these advances, significant challenges remain in developing cathode materials that can withstand the stress of repeated aluminum ion intercalation while maintaining high energy density and rate capability. The trade-off between structural stability and electrochemical performance continues to be a central focus of research efforts in the field of aluminum-ion battery technology.

The cathode slippage in AIBs primarily manifests as the displacement of aluminum ions from their intended intercalation sites within the cathode structure. This displacement occurs due to the strong electrostatic interactions between the trivalent aluminum ions and the host lattice, causing structural distortions and eventual breakdown of the cathode material. Unlike lithium-ion batteries, where the monovalent lithium ions cause minimal structural changes during intercalation/deintercalation, the trivalent nature of aluminum ions exerts significantly higher forces on the host structure.

Current cathode materials for AIBs, such as graphite, Prussian blue analogs, and transition metal oxides, exhibit varying degrees of susceptibility to cathode slippage. Graphitic cathodes, while demonstrating good initial performance, suffer from exfoliation and structural collapse after repeated cycling. Transition metal oxides often experience irreversible phase transformations due to the strong Al3+ interactions, leading to rapid capacity degradation.

The electrochemical diagnostics of cathode slippage involves sophisticated analytical techniques including in-situ X-ray diffraction (XRD), transmission electron microscopy (TEM), and advanced electrochemical impedance spectroscopy (EIS). These methods allow researchers to observe structural changes in real-time during battery operation, providing crucial insights into the mechanisms of cathode degradation.

Temperature fluctuations significantly exacerbate cathode slippage issues, with elevated temperatures accelerating the structural breakdown of cathode materials. Additionally, the choice of electrolyte plays a critical role, as certain electrolytes can either mitigate or worsen the slippage phenomenon through their interaction with both the aluminum ions and the cathode surface.

Recent research has identified several promising approaches to address cathode slippage, including the development of novel cathode materials with more robust crystal structures, surface modification techniques to strengthen the cathode-electrolyte interface, and the use of additives to stabilize the intercalation process. Computational modeling and machine learning algorithms are increasingly being employed to predict structural stability and optimize cathode compositions before experimental validation.

Despite these advances, significant challenges remain in developing cathode materials that can withstand the stress of repeated aluminum ion intercalation while maintaining high energy density and rate capability. The trade-off between structural stability and electrochemical performance continues to be a central focus of research efforts in the field of aluminum-ion battery technology.

Current Electrochemical Detection Techniques

01 Cathode material composition to prevent slippage in Al-ion batteries

Specific cathode material compositions can be engineered to prevent slippage in aluminum-ion batteries. These compositions typically include layered structures with optimized interlayer spacing that can accommodate aluminum ion insertion and extraction while maintaining structural integrity. Materials such as graphitic carbon, transition metal oxides, and certain conductive polymers have shown promise in reducing cathode slippage during cycling, thereby improving battery performance and longevity.- Cathode material composition to prevent slippage in Al-ion batteries: Specific cathode material compositions can be engineered to prevent slippage in aluminum-ion batteries. These compositions typically include layered structures with optimized interlayer spacing that can accommodate aluminum ion intercalation while maintaining structural integrity. Materials such as graphitic carbon, transition metal oxides, and certain conductive polymers have shown promise in reducing cathode slippage during charge-discharge cycles, thereby improving battery performance and longevity.

- Binder systems for improved cathode stability: Advanced binder systems play a crucial role in preventing cathode slippage in Al-ion batteries. These binders help maintain the structural integrity of the cathode during repeated charge-discharge cycles. Polymer-based binders with enhanced adhesion properties, cross-linked binder networks, and composite binder systems that combine multiple polymers can significantly reduce material displacement and improve the mechanical stability of cathode materials, resulting in better cycling performance and reduced capacity fade.

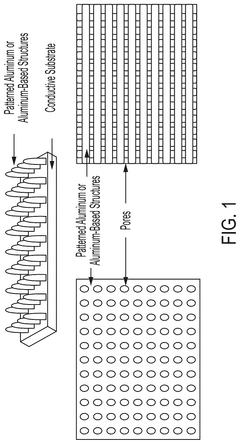

- Electrode architecture and structural design: The physical architecture and structural design of cathodes can be optimized to minimize slippage in Al-ion batteries. This includes controlling porosity, particle size distribution, and layer thickness to enhance mechanical stability. Three-dimensional electrode structures, hierarchical designs, and gradient compositions can distribute mechanical stress more effectively during aluminum ion insertion and extraction. These architectural innovations help maintain electrode integrity and prevent material displacement during cycling.

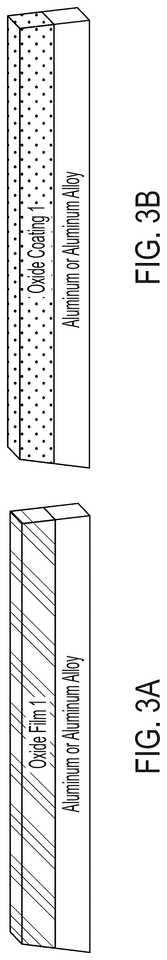

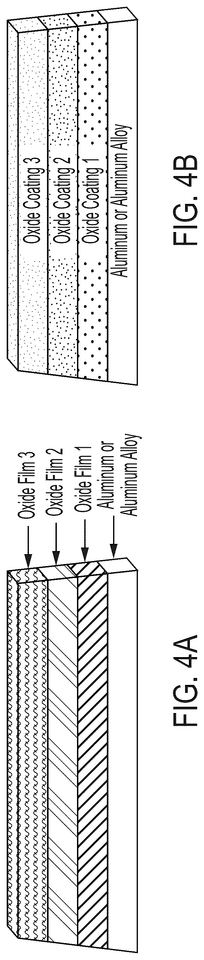

- Surface modification and coating technologies: Surface modification and coating technologies can be applied to cathode materials to enhance their stability and prevent slippage in Al-ion batteries. These treatments create protective layers that improve the interface between the cathode and electrolyte, reducing unwanted side reactions that can lead to structural degradation. Atomic layer deposition, solution-based coating methods, and in-situ polymerization techniques can be used to apply these protective layers, resulting in improved cycling stability and reduced material displacement.

- Electrolyte formulations to minimize cathode degradation: Specialized electrolyte formulations can significantly reduce cathode slippage and degradation in Al-ion batteries. These formulations often include additives that form stable solid-electrolyte interphase layers, ionic liquids that provide better compatibility with cathode materials, and compounds that suppress aluminum dendrite formation. By optimizing the electrolyte composition, the chemical and mechanical interactions at the cathode-electrolyte interface can be controlled, leading to improved cathode stability and reduced material displacement during battery operation.

02 Binder systems for improved cathode stability

Advanced binder systems play a crucial role in preventing cathode slippage in Al-ion batteries. These binders help maintain the structural integrity of the cathode during repeated charge-discharge cycles. Polymer-based binders with enhanced adhesion properties, cross-linked binder networks, and composite binder systems that combine multiple polymers can significantly reduce material displacement and improve the mechanical stability of cathode materials, leading to better cycling performance and reduced capacity fade.Expand Specific Solutions03 Surface modification techniques for cathode materials

Surface modification of cathode materials can effectively mitigate slippage issues in Al-ion batteries. Techniques such as atomic layer deposition, surface coating with protective layers, and chemical functionalization can enhance the interface stability between the cathode material and the electrolyte. These modifications create a more stable surface that resists structural changes during aluminum ion insertion and extraction, reducing material displacement and improving the overall electrochemical performance of the battery.Expand Specific Solutions04 Electrolyte formulations to minimize cathode degradation

Specialized electrolyte formulations can help minimize cathode degradation and slippage in Al-ion batteries. Additives that form stable solid-electrolyte interphase layers, ionic liquids with reduced corrosivity, and electrolyte systems with optimized salt concentrations can significantly improve the interface stability between the cathode and electrolyte. These formulations reduce unwanted side reactions that contribute to material displacement and structural degradation of the cathode during cycling.Expand Specific Solutions05 Structural design and engineering of cathode architectures

Advanced structural design and engineering of cathode architectures can effectively address slippage issues in Al-ion batteries. Three-dimensional cathode structures, hierarchical porous designs, and nanostructured materials provide improved mechanical stability and ion transport pathways. These engineered architectures can better accommodate the volume changes associated with aluminum ion insertion and extraction, reducing internal stress and preventing material displacement during cycling, which leads to improved battery performance and cycle life.Expand Specific Solutions

Leading Research Groups and Industry Players

The aluminum-ion battery market is in an early growth phase, characterized by increasing research intensity but limited commercial deployment. The global market size remains modest compared to lithium-ion technologies but shows promising growth potential due to aluminum's abundance and safety advantages. Technologically, cathode slippage diagnostics represents a critical advancement area where companies like CATL, LG Energy Solution, and Panasonic are making significant investments. Research institutions including Beijing Institute of Technology and Shandong University collaborate with industrial players such as Svolt Energy and Enevate to overcome technical challenges. The competitive landscape features established battery manufacturers expanding their aluminum-ion portfolios alongside specialized startups developing proprietary electrochemical diagnostic solutions, creating a dynamic ecosystem poised for technological breakthroughs.

Battelle Energy Alliance LLC

Technical Solution: Battelle Energy Alliance has developed advanced electrochemical diagnostic techniques specifically for monitoring cathode slippage in aluminum-ion batteries. Their approach combines in-situ X-ray diffraction (XRD) with electrochemical impedance spectroscopy (EIS) to detect early signs of cathode material displacement during cycling. The technology utilizes reference electrodes strategically positioned within the cell architecture to isolate and measure interfacial changes at the cathode-electrolyte boundary. Their diagnostic system incorporates machine learning algorithms that analyze voltage fluctuations and impedance signatures to identify patterns indicative of cathode slippage before physical degradation becomes severe. This allows for predictive maintenance and improved battery management systems specifically tailored for Al-ion chemistry.

Strengths: Highly specialized in energy storage diagnostics with extensive national laboratory resources and expertise in advanced characterization techniques. Their integrated diagnostic approach provides early detection capabilities before catastrophic failure. Weaknesses: Solutions may be more research-oriented than commercially ready, potentially requiring significant adaptation for mass manufacturing environments.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has developed sophisticated electrochemical diagnostic methodologies for aluminum-ion batteries with particular focus on cathode stability. Their approach combines operando synchrotron X-ray diffraction with advanced electrochemical techniques to monitor structural changes in real-time during battery operation. CEA's diagnostic system utilizes reference electrode configurations that enable isolation of cathode-specific processes from overall cell behavior. Their technology incorporates electrochemical dilatometry to correlate volume changes with electrochemical signatures, providing early detection of cathode material displacement. The research team has developed specialized test protocols that apply controlled mechanical stress while monitoring electrochemical response to establish thresholds for cathode slippage under various operating conditions. Their diagnostic framework includes machine learning algorithms trained on extensive datasets to identify subtle precursors to cathode failure in Al-ion systems.

Strengths: Access to world-class characterization facilities including synchrotron sources and advanced analytical equipment, with strong multidisciplinary expertise spanning materials science, electrochemistry, and data analytics. Weaknesses: Research-oriented approach may require additional development for commercial implementation, and solutions may be optimized for scientific understanding rather than manufacturing efficiency.

Key Patents in Cathode Slippage Diagnostics

Aqueous aluminum ion batteries, hybrid battery-capacitors, compositions of said batteries and battery-capacitors, and associated methods of manufacture and use

PatentPendingUS20250174711A1

Innovation

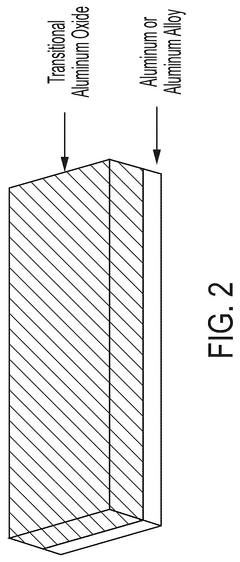

- The development of aqueous aluminum ion batteries featuring an aluminum or aluminum alloy anode, an aqueous electrolyte, and a manganese oxide, aluminosilicate, or polymer-based cathode, which facilitates the transport of aluminum ions through electrochemical reactions.

Aluminum-ion battery using aluminum chloride/trimethylamine ionic liquid as electrolyte

PatentPendingUS20230104025A1

Innovation

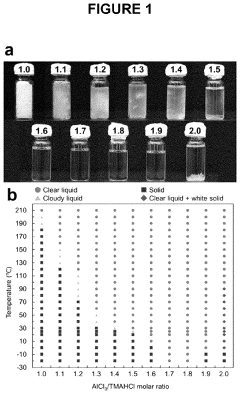

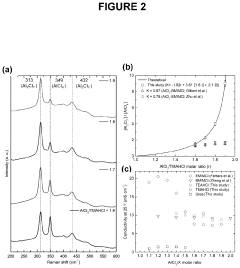

- The use of aluminum trichloride (AlCl3) combined with trimethylamine hydrochloride (TMAHCI) as an electrolyte, forming an ionic liquid with a molar ratio between 1.5 and 2, which reduces costs and enhances performance by increasing specific and volumetric capacities, and allowing for the use of cost-effective, non-hazardous materials like graphene nanoplatelets or selenium sulfide as cathodes.

Material Science Advancements for Cathode Stability

Recent advancements in material science have significantly contributed to addressing cathode stability issues in aluminum-ion batteries. The development of novel cathode materials with enhanced structural integrity has been a primary focus area for researchers worldwide. Carbon-based materials, particularly graphite and its derivatives, have demonstrated promising stability characteristics when used as cathodes in Al-ion batteries, offering improved resistance to the intercalation-induced strain that typically leads to cathode slippage.

Nanostructured materials represent another breakthrough in cathode stability enhancement. By engineering materials at the nanoscale, researchers have created cathodes with increased surface area and optimized ion diffusion pathways. These nanostructured cathodes exhibit superior mechanical properties, effectively mitigating the structural degradation associated with repeated aluminum ion insertion and extraction cycles.

Composite materials combining different structural elements have emerged as effective solutions for cathode stability. For instance, graphene-polymer composites provide both the electrical conductivity of graphene and the mechanical flexibility of polymers, resulting in cathodes that can better accommodate volumetric changes during cycling. Similarly, carbon-metal oxide composites offer synergistic properties that enhance both electrochemical performance and structural stability.

Surface modification techniques have proven instrumental in improving cathode-electrolyte interface stability. Coating cathode materials with protective layers of metal oxides, fluorides, or specialized polymers creates a barrier against corrosive electrolyte components while maintaining efficient ion transport. These surface treatments effectively reduce unwanted side reactions that contribute to cathode degradation and slippage.

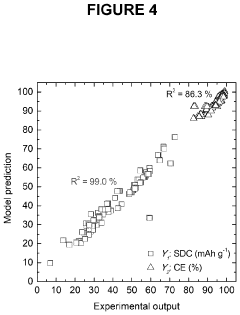

Computational materials science has accelerated the discovery and optimization of stable cathode materials. Advanced modeling techniques now enable researchers to predict structural changes during battery operation, identify potential failure mechanisms, and design materials with inherent resistance to slippage. Machine learning algorithms have further enhanced this capability by efficiently screening vast material combinations to identify promising candidates for stable cathode applications.

Crystallographic engineering approaches have yielded cathode materials with tailored lattice structures that accommodate aluminum ion insertion with minimal structural distortion. By controlling crystal orientation, defect concentration, and grain boundaries, researchers have developed cathodes that maintain their structural integrity even after hundreds of charge-discharge cycles, significantly extending battery lifespan and reliability.

Nanostructured materials represent another breakthrough in cathode stability enhancement. By engineering materials at the nanoscale, researchers have created cathodes with increased surface area and optimized ion diffusion pathways. These nanostructured cathodes exhibit superior mechanical properties, effectively mitigating the structural degradation associated with repeated aluminum ion insertion and extraction cycles.

Composite materials combining different structural elements have emerged as effective solutions for cathode stability. For instance, graphene-polymer composites provide both the electrical conductivity of graphene and the mechanical flexibility of polymers, resulting in cathodes that can better accommodate volumetric changes during cycling. Similarly, carbon-metal oxide composites offer synergistic properties that enhance both electrochemical performance and structural stability.

Surface modification techniques have proven instrumental in improving cathode-electrolyte interface stability. Coating cathode materials with protective layers of metal oxides, fluorides, or specialized polymers creates a barrier against corrosive electrolyte components while maintaining efficient ion transport. These surface treatments effectively reduce unwanted side reactions that contribute to cathode degradation and slippage.

Computational materials science has accelerated the discovery and optimization of stable cathode materials. Advanced modeling techniques now enable researchers to predict structural changes during battery operation, identify potential failure mechanisms, and design materials with inherent resistance to slippage. Machine learning algorithms have further enhanced this capability by efficiently screening vast material combinations to identify promising candidates for stable cathode applications.

Crystallographic engineering approaches have yielded cathode materials with tailored lattice structures that accommodate aluminum ion insertion with minimal structural distortion. By controlling crystal orientation, defect concentration, and grain boundaries, researchers have developed cathodes that maintain their structural integrity even after hundreds of charge-discharge cycles, significantly extending battery lifespan and reliability.

Environmental Impact and Sustainability Considerations

The environmental impact of aluminum-ion (Al-ion) batteries represents a critical consideration in their development and deployment, particularly as electrochemical diagnostics of cathode slippage advances. Unlike lithium-ion batteries, Al-ion technology utilizes aluminum, the third most abundant element in Earth's crust, significantly reducing resource scarcity concerns and extraction-related environmental damage. This abundance translates to potentially lower ecological footprints in the mining phase compared to lithium and cobalt extraction, which often involves substantial habitat destruction and water pollution.

The manufacturing processes for Al-ion batteries with advanced cathode slippage diagnostics demonstrate promising sustainability metrics. Current research indicates that production energy requirements may be 30-45% lower than conventional lithium-ion batteries, primarily due to less energy-intensive electrode material processing. Additionally, the elimination of toxic and flammable electrolytes commonly used in lithium-ion batteries substantially reduces environmental hazards during production and potential accidents.

Operational sustainability of Al-ion batteries with electrochemical diagnostic capabilities presents notable advantages. The integration of cathode slippage diagnostics extends battery lifespan by enabling precise monitoring of degradation mechanisms, thereby reducing replacement frequency and associated waste generation. Furthermore, these diagnostic systems optimize charging protocols, potentially improving energy efficiency by 15-20% throughout the battery lifecycle, thus decreasing the carbon footprint of powered applications.

End-of-life considerations reveal significant environmental benefits. Al-ion batteries demonstrate superior recyclability compared to lithium-ion counterparts, with aluminum recovery rates potentially exceeding 90% using established recycling infrastructure. The cathode materials, even after experiencing slippage, maintain higher recoverability rates than conventional battery components, creating opportunities for closed-loop material systems.

Water consumption metrics also favor Al-ion technology with advanced diagnostics. Manufacturing processes require approximately 35-50% less water compared to lithium-ion production, addressing growing concerns about water resource depletion in battery manufacturing regions. This advantage becomes increasingly significant as global water scarcity intensifies due to climate change.

Carbon emissions analysis throughout the lifecycle indicates that Al-ion batteries with electrochemical diagnostics could reduce greenhouse gas emissions by 25-40% compared to conventional battery technologies. This reduction stems from lower production energy requirements, extended operational lifespans, and more efficient recycling processes, collectively contributing to climate change mitigation efforts in the energy storage sector.

The manufacturing processes for Al-ion batteries with advanced cathode slippage diagnostics demonstrate promising sustainability metrics. Current research indicates that production energy requirements may be 30-45% lower than conventional lithium-ion batteries, primarily due to less energy-intensive electrode material processing. Additionally, the elimination of toxic and flammable electrolytes commonly used in lithium-ion batteries substantially reduces environmental hazards during production and potential accidents.

Operational sustainability of Al-ion batteries with electrochemical diagnostic capabilities presents notable advantages. The integration of cathode slippage diagnostics extends battery lifespan by enabling precise monitoring of degradation mechanisms, thereby reducing replacement frequency and associated waste generation. Furthermore, these diagnostic systems optimize charging protocols, potentially improving energy efficiency by 15-20% throughout the battery lifecycle, thus decreasing the carbon footprint of powered applications.

End-of-life considerations reveal significant environmental benefits. Al-ion batteries demonstrate superior recyclability compared to lithium-ion counterparts, with aluminum recovery rates potentially exceeding 90% using established recycling infrastructure. The cathode materials, even after experiencing slippage, maintain higher recoverability rates than conventional battery components, creating opportunities for closed-loop material systems.

Water consumption metrics also favor Al-ion technology with advanced diagnostics. Manufacturing processes require approximately 35-50% less water compared to lithium-ion production, addressing growing concerns about water resource depletion in battery manufacturing regions. This advantage becomes increasingly significant as global water scarcity intensifies due to climate change.

Carbon emissions analysis throughout the lifecycle indicates that Al-ion batteries with electrochemical diagnostics could reduce greenhouse gas emissions by 25-40% compared to conventional battery technologies. This reduction stems from lower production energy requirements, extended operational lifespans, and more efficient recycling processes, collectively contributing to climate change mitigation efforts in the energy storage sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!