Separator Selection And Compatibility In Aluminum-Ion Systems

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aluminum-Ion Battery Technology Background and Objectives

Aluminum-ion batteries (AIBs) have emerged as a promising alternative to lithium-ion batteries due to their potential advantages in safety, cost, and resource abundance. The development of AIBs can be traced back to the early 2000s, with significant acceleration in research efforts over the past decade. This technology leverages the trivalent nature of aluminum ions, theoretically enabling higher energy densities compared to monovalent lithium-ion systems.

The evolution of aluminum-ion battery technology has been marked by several key milestones, including the development of various cathode materials, electrolyte formulations, and cell architectures. Initially, researchers focused on simple aluminum metal anodes paired with graphite cathodes in ionic liquid electrolytes. Recent advancements have expanded the material options significantly, with novel cathode materials such as vanadium oxide, manganese oxide, and various transition metal compounds showing promising results.

A critical component in the aluminum-ion battery system is the separator, which plays a multifaceted role in ensuring proper cell function. The separator must facilitate efficient aluminum ion transport while preventing electrical contact between electrodes. The unique chemistry of aluminum-ion systems, particularly the use of chloroaluminate-based electrolytes, presents specific challenges for separator selection and compatibility that differ substantially from those in lithium-ion systems.

The technical objectives for aluminum-ion battery development center around addressing several key limitations. These include improving energy density, which currently lags behind commercial lithium-ion batteries, enhancing cycle life, which is often limited by electrode degradation mechanisms, and developing separators that can withstand the highly corrosive nature of chloroaluminate electrolytes commonly used in AIBs.

Separator technology specifically aims to achieve several critical performance metrics: chemical stability in chloroaluminate environments, mechanical integrity under repeated cycling, optimal porosity and tortuosity for efficient ion transport, and minimal resistance to aluminum ion diffusion. Current research indicates that conventional polyolefin separators used in lithium-ion batteries often fail prematurely in aluminum-ion systems due to chemical degradation.

The trajectory of aluminum-ion technology suggests a growing focus on system-level optimization, with separator development representing a crucial but often overlooked aspect. As the field progresses toward practical applications, understanding the complex interactions between separators and other cell components becomes increasingly important for realizing the full potential of aluminum-ion battery technology.

The evolution of aluminum-ion battery technology has been marked by several key milestones, including the development of various cathode materials, electrolyte formulations, and cell architectures. Initially, researchers focused on simple aluminum metal anodes paired with graphite cathodes in ionic liquid electrolytes. Recent advancements have expanded the material options significantly, with novel cathode materials such as vanadium oxide, manganese oxide, and various transition metal compounds showing promising results.

A critical component in the aluminum-ion battery system is the separator, which plays a multifaceted role in ensuring proper cell function. The separator must facilitate efficient aluminum ion transport while preventing electrical contact between electrodes. The unique chemistry of aluminum-ion systems, particularly the use of chloroaluminate-based electrolytes, presents specific challenges for separator selection and compatibility that differ substantially from those in lithium-ion systems.

The technical objectives for aluminum-ion battery development center around addressing several key limitations. These include improving energy density, which currently lags behind commercial lithium-ion batteries, enhancing cycle life, which is often limited by electrode degradation mechanisms, and developing separators that can withstand the highly corrosive nature of chloroaluminate electrolytes commonly used in AIBs.

Separator technology specifically aims to achieve several critical performance metrics: chemical stability in chloroaluminate environments, mechanical integrity under repeated cycling, optimal porosity and tortuosity for efficient ion transport, and minimal resistance to aluminum ion diffusion. Current research indicates that conventional polyolefin separators used in lithium-ion batteries often fail prematurely in aluminum-ion systems due to chemical degradation.

The trajectory of aluminum-ion technology suggests a growing focus on system-level optimization, with separator development representing a crucial but often overlooked aspect. As the field progresses toward practical applications, understanding the complex interactions between separators and other cell components becomes increasingly important for realizing the full potential of aluminum-ion battery technology.

Market Analysis for Aluminum-Ion Energy Storage Systems

The aluminum-ion battery market is experiencing significant growth as a promising alternative to lithium-ion technology. Current market valuations estimate the global aluminum-ion battery sector at approximately $35 million in 2023, with projections indicating a compound annual growth rate (CAGR) of 6.8% through 2030. This growth trajectory is driven by increasing demand for sustainable energy storage solutions across multiple sectors.

The automotive industry represents the largest potential market segment, with electric vehicle manufacturers actively seeking alternatives to traditional lithium-ion batteries. Aluminum-ion systems offer compelling advantages including faster charging capabilities, enhanced safety profiles, and potentially lower production costs. Market research indicates that by 2028, aluminum-ion batteries could capture up to 5% of the EV battery market, representing a value of $2.1 billion.

Grid-scale energy storage presents another substantial market opportunity, currently valued at $7.9 billion globally and growing at 24% annually. Aluminum-ion technology is particularly well-positioned in this segment due to its non-flammable electrolytes and longer cycle life compared to some competing technologies. Utility companies in North America and Europe have begun pilot programs incorporating aluminum-ion systems, with initial results demonstrating promising performance metrics.

Consumer electronics manufacturers are also exploring aluminum-ion technology for applications requiring rapid charging and enhanced safety. This segment is expected to adopt aluminum-ion batteries more quickly than others, with market penetration potentially reaching 8% by 2026. The total addressable market for aluminum-ion batteries in consumer electronics is estimated at $12 billion by 2030.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, with China leading in production capacity development. North America and Europe are focusing more on research and development, with significant investments in aluminum-ion technology startups. Government initiatives supporting sustainable energy storage solutions are accelerating market growth, particularly in regions with aggressive carbon reduction targets.

Key market challenges include scaling production to commercial levels, reducing manufacturing costs, and establishing supply chains for specialized materials including advanced separators. Current production costs remain 30-40% higher than lithium-ion equivalents, though this gap is expected to narrow as manufacturing processes mature and economies of scale are realized.

The automotive industry represents the largest potential market segment, with electric vehicle manufacturers actively seeking alternatives to traditional lithium-ion batteries. Aluminum-ion systems offer compelling advantages including faster charging capabilities, enhanced safety profiles, and potentially lower production costs. Market research indicates that by 2028, aluminum-ion batteries could capture up to 5% of the EV battery market, representing a value of $2.1 billion.

Grid-scale energy storage presents another substantial market opportunity, currently valued at $7.9 billion globally and growing at 24% annually. Aluminum-ion technology is particularly well-positioned in this segment due to its non-flammable electrolytes and longer cycle life compared to some competing technologies. Utility companies in North America and Europe have begun pilot programs incorporating aluminum-ion systems, with initial results demonstrating promising performance metrics.

Consumer electronics manufacturers are also exploring aluminum-ion technology for applications requiring rapid charging and enhanced safety. This segment is expected to adopt aluminum-ion batteries more quickly than others, with market penetration potentially reaching 8% by 2026. The total addressable market for aluminum-ion batteries in consumer electronics is estimated at $12 billion by 2030.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, with China leading in production capacity development. North America and Europe are focusing more on research and development, with significant investments in aluminum-ion technology startups. Government initiatives supporting sustainable energy storage solutions are accelerating market growth, particularly in regions with aggressive carbon reduction targets.

Key market challenges include scaling production to commercial levels, reducing manufacturing costs, and establishing supply chains for specialized materials including advanced separators. Current production costs remain 30-40% higher than lithium-ion equivalents, though this gap is expected to narrow as manufacturing processes mature and economies of scale are realized.

Current Separator Technologies and Challenges in Al-Ion Batteries

Separators in aluminum-ion batteries (AIBs) serve as critical components that physically isolate the electrodes while facilitating ion transport. Current separator technologies predominantly include glass fiber, polymer-based, and ceramic-based materials, each offering distinct advantages and limitations in AIB applications.

Glass fiber separators remain widely used in laboratory-scale AIB research due to their excellent chemical stability in chloroaluminate electrolytes and high porosity that enables efficient ion diffusion. However, these separators suffer from mechanical fragility and thickness constraints that limit their application in compact battery designs.

Polymer-based separators, particularly those made from polypropylene (PP) and polyethylene (PE), offer superior mechanical properties and manufacturing scalability. Modified versions with enhanced wettability have shown promising performance in AIBs. Nevertheless, these materials face significant challenges regarding chemical stability when exposed to highly corrosive chloroaluminate electrolytes, often resulting in degradation over extended cycling periods.

Ceramic-based separators represent an emerging alternative with exceptional thermal stability and chemical resistance. Materials such as aluminum oxide and silicon dioxide have demonstrated compatibility with AIB systems. Their inherent rigidity, however, creates integration challenges in flexible battery configurations, and their higher production costs currently limit widespread commercial adoption.

A significant challenge across all separator types is the unique ionic transport mechanism in AIBs. Unlike lithium-ion batteries, AIBs involve complex chloroaluminate anions (Al₂Cl₇⁻) that require larger pore structures for efficient diffusion. Current separator designs often fail to optimize this balance between pore size, mechanical integrity, and electrochemical stability.

Electrolyte compatibility presents another major hurdle, as the highly corrosive nature of chloroaluminate electrolytes progressively degrades many separator materials. This degradation can lead to increased internal resistance, capacity fading, and potential safety hazards through separator breakdown.

Recent research has explored composite separators that combine the advantages of different materials, such as ceramic-coated polymers or glass fiber-polymer hybrids. These approaches show promise in addressing multiple challenges simultaneously but require further optimization for commercial viability.

The development of specialized separators specifically engineered for AIB systems remains in its infancy compared to lithium-ion technology. Addressing these challenges will require interdisciplinary approaches combining materials science, electrochemistry, and manufacturing innovation to create separators that can withstand the unique chemical environment while maintaining optimal ion transport properties.

Glass fiber separators remain widely used in laboratory-scale AIB research due to their excellent chemical stability in chloroaluminate electrolytes and high porosity that enables efficient ion diffusion. However, these separators suffer from mechanical fragility and thickness constraints that limit their application in compact battery designs.

Polymer-based separators, particularly those made from polypropylene (PP) and polyethylene (PE), offer superior mechanical properties and manufacturing scalability. Modified versions with enhanced wettability have shown promising performance in AIBs. Nevertheless, these materials face significant challenges regarding chemical stability when exposed to highly corrosive chloroaluminate electrolytes, often resulting in degradation over extended cycling periods.

Ceramic-based separators represent an emerging alternative with exceptional thermal stability and chemical resistance. Materials such as aluminum oxide and silicon dioxide have demonstrated compatibility with AIB systems. Their inherent rigidity, however, creates integration challenges in flexible battery configurations, and their higher production costs currently limit widespread commercial adoption.

A significant challenge across all separator types is the unique ionic transport mechanism in AIBs. Unlike lithium-ion batteries, AIBs involve complex chloroaluminate anions (Al₂Cl₇⁻) that require larger pore structures for efficient diffusion. Current separator designs often fail to optimize this balance between pore size, mechanical integrity, and electrochemical stability.

Electrolyte compatibility presents another major hurdle, as the highly corrosive nature of chloroaluminate electrolytes progressively degrades many separator materials. This degradation can lead to increased internal resistance, capacity fading, and potential safety hazards through separator breakdown.

Recent research has explored composite separators that combine the advantages of different materials, such as ceramic-coated polymers or glass fiber-polymer hybrids. These approaches show promise in addressing multiple challenges simultaneously but require further optimization for commercial viability.

The development of specialized separators specifically engineered for AIB systems remains in its infancy compared to lithium-ion technology. Addressing these challenges will require interdisciplinary approaches combining materials science, electrochemistry, and manufacturing innovation to create separators that can withstand the unique chemical environment while maintaining optimal ion transport properties.

Current Separator Selection Methodologies and Compatibility Solutions

01 Polymer-based separators for aluminum-ion batteries

Polymer-based separators are widely used in aluminum-ion battery systems due to their excellent chemical stability and mechanical properties. These separators typically consist of materials such as polyethylene (PE), polypropylene (PP), or their combinations, which provide good ionic conductivity while preventing direct contact between electrodes. The polymer structure can be modified with functional groups to enhance compatibility with aluminum-ion electrolytes, improving overall battery performance and cycle life.- Polymer-based separators for aluminum-ion batteries: Polymer-based separators are widely used in aluminum-ion battery systems due to their excellent mechanical properties and chemical stability. These separators typically consist of materials such as polyethylene (PE), polypropylene (PP), or their combinations, which provide good ionic conductivity while preventing direct contact between electrodes. The polymer structure can be modified to enhance compatibility with aluminum-ion electrolytes, improving overall battery performance and cycle life.

- Ceramic-coated separators for enhanced stability: Ceramic-coated separators offer improved thermal and chemical stability in aluminum-ion systems. The ceramic coating, typically consisting of materials like aluminum oxide or silicon dioxide, provides protection against aluminum dendrite formation and prevents separator degradation in the highly corrosive electrolyte environment. These hybrid separators combine the flexibility of polymer substrates with the stability of ceramic materials, resulting in enhanced safety and extended battery lifespan.

- Electrolyte-separator compatibility optimization: The compatibility between the separator and the electrolyte is crucial for aluminum-ion battery performance. Separators must maintain structural integrity when exposed to the typically corrosive chloroaluminate-based electrolytes. Optimization strategies include surface modifications, functional group additions, and porosity control to enhance wettability and ion transport while minimizing unwanted side reactions. Proper electrolyte-separator compatibility reduces internal resistance and improves the overall efficiency of the battery system.

- Glass fiber and composite separators: Glass fiber and composite separators provide excellent thermal stability and chemical resistance in aluminum-ion systems. These separators typically consist of borosilicate glass fibers or combinations of glass fibers with polymeric materials. The high porosity and interconnected pore structure facilitate efficient ion transport while maintaining dimensional stability. The inherent resistance to corrosion makes these separators particularly suitable for the harsh chemical environment of aluminum-ion batteries.

- Separator surface treatments for aluminum-ion compatibility: Various surface treatment methods can be applied to separators to enhance their compatibility with aluminum-ion systems. These treatments include plasma modification, chemical grafting, and coating with functional materials that improve wettability and ion conductivity. Surface-treated separators exhibit reduced interfacial resistance and enhanced electrochemical stability, leading to improved cycling performance. The treatments can also help mitigate aluminum deposition on the separator surface, preventing internal short circuits.

02 Ceramic-coated separators for enhanced stability

Ceramic-coated separators offer improved thermal and chemical stability in aluminum-ion systems. The ceramic coating, typically comprising materials like aluminum oxide, silicon dioxide, or titanium dioxide, provides protection against aluminum dendrite formation and prevents separator degradation in the highly corrosive electrolyte environment. These composite separators maintain dimensional stability at high temperatures and extend battery lifespan by reducing unwanted side reactions between the separator and aluminum-containing electrolytes.Expand Specific Solutions03 Electrolyte-separator compatibility optimization

The compatibility between electrolytes and separators is crucial for aluminum-ion battery performance. Optimizing this interface involves selecting separator materials that resist degradation by the typically corrosive chloroaluminate-based electrolytes. Modifications to the separator surface wettability and pore structure can enhance electrolyte uptake and ion transport. Additives incorporated into either the separator or electrolyte can form protective interfaces that mitigate unwanted reactions while maintaining efficient aluminum ion conductivity.Expand Specific Solutions04 Glass fiber and composite separators

Glass fiber and composite separators provide excellent thermal stability and electrolyte retention for aluminum-ion systems. These separators typically feature a porous structure that allows for high electrolyte uptake while maintaining mechanical integrity. The inorganic nature of glass fibers makes them particularly resistant to degradation in the presence of aluminum-containing electrolytes. Composite designs incorporating glass fibers with polymeric binders offer a balance of mechanical flexibility and chemical resistance needed for long-term operation in aluminum-ion batteries.Expand Specific Solutions05 Separator surface treatments and modifications

Surface treatments and modifications of separators can significantly improve their compatibility with aluminum-ion systems. Techniques such as plasma treatment, chemical grafting, and coating with functional materials can enhance the wettability, ion conductivity, and chemical stability of separators. These modifications create favorable interfaces between the separator and electrolyte, reducing interfacial resistance and preventing aluminum deposition on the separator surface. Additionally, surface-modified separators can help suppress unwanted side reactions that would otherwise lead to capacity fading and shortened battery life.Expand Specific Solutions

Leading Companies and Research Institutions in Al-Ion Separator Development

The aluminum-ion battery technology market is currently in an early development stage, characterized by significant research activity but limited commercial deployment. The global market size remains relatively small compared to established lithium-ion technologies, though projections indicate substantial growth potential as technical challenges are overcome. From a technical maturity perspective, key players demonstrate varying levels of advancement. CATL and Ningde Amperex Technology are leveraging their lithium-ion expertise to accelerate aluminum-ion development, while academic institutions like Caltech, MIT, and Nanyang Technological University are pioneering fundamental research. Established materials companies including BASF, Sumitomo Chemical, and Asahi Kasei are developing specialized separator technologies critical for aluminum-ion performance. LG Energy Solution and Panasonic are also investing in this space, recognizing its potential as a complementary technology to their existing battery portfolios.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: Contemporary Amperex Technology (CATL) has developed advanced separator technologies specifically for aluminum-ion battery systems, focusing on glass fiber-based separators with modified surface properties. Their approach involves creating hierarchical porous structures that effectively manage aluminum ion transport while preventing dendrite formation. CATL's separators incorporate aluminum-philic functional groups to enhance ion conductivity and employ specialized coatings that resist corrosion from chloroaluminate electrolytes. Their research has demonstrated that these engineered separators can maintain stability in highly acidic electrolyte environments while providing the mechanical strength needed for long-term cycling. CATL has also pioneered composite separator designs that combine polymeric materials with inorganic components to optimize the balance between ion transport and mechanical integrity in aluminum-ion systems.

Strengths: Superior ion conductivity and excellent mechanical stability in chloroaluminate electrolytes. Their hierarchical porous structure effectively prevents dendrite formation while maintaining high ionic flux. Weaknesses: Higher manufacturing costs compared to conventional separators and potential challenges in scaling production to commercial levels.

LG Chem Ltd.

Technical Solution: LG Chem has developed proprietary separator technology for aluminum-ion batteries focusing on polymer-based separators with specialized coatings. Their approach utilizes modified polyolefin materials with tailored pore structures optimized for aluminum ion transport. The company has engineered separators with asymmetric pore distributions that facilitate directional ion movement while maintaining mechanical integrity. LG Chem's separators incorporate surface modifications with functional groups that enhance wettability with ionic liquid electrolytes commonly used in aluminum-ion systems. Their research has demonstrated that these separators can effectively mitigate aluminum dendrite formation while maintaining high ionic conductivity. Additionally, LG Chem has developed multi-layer separator designs that combine different materials to achieve optimal performance characteristics for aluminum-ion battery applications.

Strengths: Excellent compatibility with ionic liquid electrolytes and superior thermal stability under operating conditions. Their multi-layer design provides enhanced safety features. Weaknesses: Relatively high production costs and potential limitations in extremely low-temperature environments.

Key Patents and Research on Al-Ion Compatible Separator Materials

Separator comprising a porous layer and method for producing said separator

PatentInactiveEP2805366A1

Innovation

- A separator comprising a porous layer made from a block copolymer with three or more polymer blocks and aluminum oxide or hydroxide, with a weight ratio of 2.5:1 to 8:1, which provides high porosity, low thermal shrinkage, and excellent mechanical properties, including high elongation at break, and can be produced using a cost-effective coating process.

Separator for lithium-ion secondary battery

PatentActiveJP2013127955A

Innovation

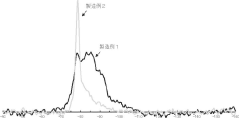

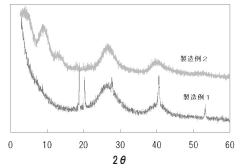

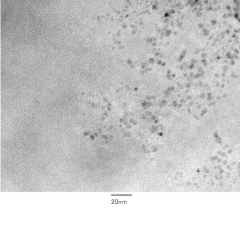

- A lithium-ion secondary battery separator incorporating a specific aluminum silicate with a Si/Al molar ratio of 0.3 to 1.0, exhibiting peaks in Al-NMR and Si-NMR spectra, and a BET specific surface area of 250 m²/g, which selectively adsorbs metal ions like nickel, manganese, and copper while minimizing lithium ion adsorption.

Environmental Impact and Sustainability of Al-Ion Battery Components

The environmental impact of aluminum-ion battery components represents a critical consideration in the advancement of this emerging energy storage technology. Unlike lithium-ion batteries, aluminum-ion systems offer significant sustainability advantages due to the abundance of aluminum in the Earth's crust, ranking as the third most abundant element. This natural abundance translates to lower extraction impacts and reduced geopolitical supply chain concerns compared to lithium and cobalt resources.

Separator materials in aluminum-ion batteries present unique environmental considerations. Traditional polymer-based separators such as polypropylene (PP) and polyethylene (PE) are petroleum-derived and non-biodegradable, contributing to plastic waste accumulation. However, research into bio-based alternatives like cellulose, chitin, and lignin-derived separators shows promise for reducing the carbon footprint of these components while maintaining electrochemical performance.

The manufacturing processes for aluminum-ion battery separators typically require less energy and fewer toxic solvents compared to those used in lithium-ion production. Ceramic-coated and composite separators, while offering enhanced performance, may introduce additional environmental considerations through more complex production methods and material combinations that could complicate end-of-life recycling.

Water consumption represents another important environmental factor in separator production. Conventional manufacturing processes can be water-intensive, particularly for ceramic-coated varieties. Emerging dry processing techniques and water recycling systems are being developed to address this concern, potentially reducing the water footprint by up to 40% according to recent industry analyses.

End-of-life management of aluminum-ion battery components offers significant advantages over lithium-ion systems. The aluminum components, including current collectors and potentially the ionic liquid electrolytes, demonstrate higher recyclability rates. Separators designed with environmental considerations can further enhance the circular economy potential of these systems, though challenges remain in developing efficient separation and recycling processes for multi-material components.

Carbon footprint assessments of various separator materials indicate that glass fiber and certain ceramic-based separators may have higher embodied energy than polymer alternatives, though their extended cycle life and enhanced safety features may offset these impacts through longer system lifetimes. Life cycle analyses suggest that separator selection can influence up to 15% of the total environmental impact of an aluminum-ion cell, highlighting the importance of this component in sustainable battery design.

Separator materials in aluminum-ion batteries present unique environmental considerations. Traditional polymer-based separators such as polypropylene (PP) and polyethylene (PE) are petroleum-derived and non-biodegradable, contributing to plastic waste accumulation. However, research into bio-based alternatives like cellulose, chitin, and lignin-derived separators shows promise for reducing the carbon footprint of these components while maintaining electrochemical performance.

The manufacturing processes for aluminum-ion battery separators typically require less energy and fewer toxic solvents compared to those used in lithium-ion production. Ceramic-coated and composite separators, while offering enhanced performance, may introduce additional environmental considerations through more complex production methods and material combinations that could complicate end-of-life recycling.

Water consumption represents another important environmental factor in separator production. Conventional manufacturing processes can be water-intensive, particularly for ceramic-coated varieties. Emerging dry processing techniques and water recycling systems are being developed to address this concern, potentially reducing the water footprint by up to 40% according to recent industry analyses.

End-of-life management of aluminum-ion battery components offers significant advantages over lithium-ion systems. The aluminum components, including current collectors and potentially the ionic liquid electrolytes, demonstrate higher recyclability rates. Separators designed with environmental considerations can further enhance the circular economy potential of these systems, though challenges remain in developing efficient separation and recycling processes for multi-material components.

Carbon footprint assessments of various separator materials indicate that glass fiber and certain ceramic-based separators may have higher embodied energy than polymer alternatives, though their extended cycle life and enhanced safety features may offset these impacts through longer system lifetimes. Life cycle analyses suggest that separator selection can influence up to 15% of the total environmental impact of an aluminum-ion cell, highlighting the importance of this component in sustainable battery design.

Cost Analysis and Manufacturing Scalability of Advanced Separators

The economic viability of advanced separators for aluminum-ion batteries represents a critical factor in their commercial adoption. Current cost structures for high-performance separators range from $10-25/m² for specialized polymer membranes to $30-50/m² for ceramic-coated options, significantly higher than conventional lithium-ion battery separators ($1-5/m²). This cost differential primarily stems from the specialized materials required to withstand the corrosive aluminum electrolytes and maintain stability during repeated charge-discharge cycles.

Manufacturing scalability presents both challenges and opportunities. Traditional separator production lines would require substantial modifications to accommodate the unique requirements of aluminum-ion compatible materials. The integration of ceramic coatings or specialized polymer treatments necessitates additional processing steps, increasing production complexity and capital equipment costs. However, several manufacturers have demonstrated pilot-scale production capabilities that suggest pathways to economies of scale.

Cost reduction trajectories indicate potential for 30-40% price decreases within 3-5 years through process optimization and material innovations. Key areas for manufacturing improvement include the development of continuous coating processes for ceramic-polymer composite separators and the implementation of solvent-free production methods to reduce environmental impact and processing costs.

Material substitution strategies offer promising avenues for cost reduction. Research indicates that replacing expensive fluorinated polymers with modified polyolefins could reduce material costs by up to 50% while maintaining compatibility with aluminum electrolytes. Similarly, utilizing naturally abundant clay minerals as alternatives to synthetic ceramic coatings could significantly lower raw material expenses.

Supply chain considerations reveal potential bottlenecks in specialized polymer availability, particularly for fluorinated materials. Diversification of supplier networks and development of alternative formulations would mitigate these risks. Additionally, co-location of separator manufacturing with battery production facilities could reduce logistics costs and improve quality control.

Return on investment analysis suggests that despite higher initial capital requirements, advanced separator production facilities could achieve breakeven within 4-6 years at moderate production volumes (10-20 million m²/year). This timeline aligns with projected market growth for aluminum-ion energy storage systems, particularly in grid-scale applications where cost sensitivity is balanced against performance requirements.

Manufacturing scalability presents both challenges and opportunities. Traditional separator production lines would require substantial modifications to accommodate the unique requirements of aluminum-ion compatible materials. The integration of ceramic coatings or specialized polymer treatments necessitates additional processing steps, increasing production complexity and capital equipment costs. However, several manufacturers have demonstrated pilot-scale production capabilities that suggest pathways to economies of scale.

Cost reduction trajectories indicate potential for 30-40% price decreases within 3-5 years through process optimization and material innovations. Key areas for manufacturing improvement include the development of continuous coating processes for ceramic-polymer composite separators and the implementation of solvent-free production methods to reduce environmental impact and processing costs.

Material substitution strategies offer promising avenues for cost reduction. Research indicates that replacing expensive fluorinated polymers with modified polyolefins could reduce material costs by up to 50% while maintaining compatibility with aluminum electrolytes. Similarly, utilizing naturally abundant clay minerals as alternatives to synthetic ceramic coatings could significantly lower raw material expenses.

Supply chain considerations reveal potential bottlenecks in specialized polymer availability, particularly for fluorinated materials. Diversification of supplier networks and development of alternative formulations would mitigate these risks. Additionally, co-location of separator manufacturing with battery production facilities could reduce logistics costs and improve quality control.

Return on investment analysis suggests that despite higher initial capital requirements, advanced separator production facilities could achieve breakeven within 4-6 years at moderate production volumes (10-20 million m²/year). This timeline aligns with projected market growth for aluminum-ion energy storage systems, particularly in grid-scale applications where cost sensitivity is balanced against performance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!