Manufacturing Dry-Room Requirements For Aluminum-Ion Production

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aluminum-Ion Battery Manufacturing Environment Background and Objectives

Aluminum-ion batteries represent a promising alternative to conventional lithium-ion technology, offering potential advantages in safety, cost, and environmental impact. The development of these batteries has gained significant momentum over the past decade as researchers and manufacturers seek more sustainable energy storage solutions. The evolution of aluminum-ion battery technology has progressed from early conceptual designs to functional prototypes, with recent breakthroughs addressing previous limitations in cycle life and energy density.

The manufacturing environment for aluminum-ion batteries presents unique challenges and requirements, particularly regarding moisture control. Unlike lithium-ion production, which demands ultra-low humidity environments (typically below 1% relative humidity), aluminum-ion battery production may offer more flexibility in this regard. However, precise environmental parameters must still be established to ensure optimal performance and longevity of these batteries.

The primary objective of investigating dry-room requirements for aluminum-ion production is to determine the optimal manufacturing conditions that balance product quality with production costs. This includes identifying the critical humidity thresholds that affect electrode materials, electrolyte stability, and overall battery performance. Additionally, this research aims to establish whether existing lithium-ion manufacturing infrastructure can be adapted for aluminum-ion production, potentially reducing capital investment requirements.

Current technical goals include defining specific relative humidity ranges for different stages of the manufacturing process, from material preparation to cell assembly and sealing. Research suggests that aluminum-ion batteries may tolerate higher humidity levels than their lithium counterparts, potentially allowing for less stringent environmental controls and consequently reduced production costs.

The technological trajectory indicates a growing interest in room-temperature ionic liquid electrolytes for aluminum-ion batteries, which may exhibit different sensitivities to atmospheric moisture compared to conventional electrolytes. Understanding these interactions is crucial for establishing appropriate manufacturing protocols and environmental specifications.

Furthermore, as aluminum-ion technology advances toward commercialization, standardizing manufacturing environments becomes increasingly important. This standardization will facilitate scaling production from laboratory to industrial levels while maintaining consistent product quality and performance characteristics.

Recent developments in aluminum-ion chemistry, particularly regarding cathode materials and electrolyte formulations, necessitate a reevaluation of traditional dry-room specifications. The relationship between environmental conditions and battery degradation mechanisms specific to aluminum-ion systems requires thorough investigation to inform manufacturing facility design and operational parameters.

The manufacturing environment for aluminum-ion batteries presents unique challenges and requirements, particularly regarding moisture control. Unlike lithium-ion production, which demands ultra-low humidity environments (typically below 1% relative humidity), aluminum-ion battery production may offer more flexibility in this regard. However, precise environmental parameters must still be established to ensure optimal performance and longevity of these batteries.

The primary objective of investigating dry-room requirements for aluminum-ion production is to determine the optimal manufacturing conditions that balance product quality with production costs. This includes identifying the critical humidity thresholds that affect electrode materials, electrolyte stability, and overall battery performance. Additionally, this research aims to establish whether existing lithium-ion manufacturing infrastructure can be adapted for aluminum-ion production, potentially reducing capital investment requirements.

Current technical goals include defining specific relative humidity ranges for different stages of the manufacturing process, from material preparation to cell assembly and sealing. Research suggests that aluminum-ion batteries may tolerate higher humidity levels than their lithium counterparts, potentially allowing for less stringent environmental controls and consequently reduced production costs.

The technological trajectory indicates a growing interest in room-temperature ionic liquid electrolytes for aluminum-ion batteries, which may exhibit different sensitivities to atmospheric moisture compared to conventional electrolytes. Understanding these interactions is crucial for establishing appropriate manufacturing protocols and environmental specifications.

Furthermore, as aluminum-ion technology advances toward commercialization, standardizing manufacturing environments becomes increasingly important. This standardization will facilitate scaling production from laboratory to industrial levels while maintaining consistent product quality and performance characteristics.

Recent developments in aluminum-ion chemistry, particularly regarding cathode materials and electrolyte formulations, necessitate a reevaluation of traditional dry-room specifications. The relationship between environmental conditions and battery degradation mechanisms specific to aluminum-ion systems requires thorough investigation to inform manufacturing facility design and operational parameters.

Market Analysis for Aluminum-Ion Battery Production

The aluminum-ion battery market is experiencing significant growth as an emerging alternative to traditional lithium-ion batteries. Current market projections indicate that the global aluminum-ion battery market could reach $15 billion by 2030, with a compound annual growth rate of approximately 18% between 2023 and 2030. This growth is primarily driven by increasing demand for sustainable energy storage solutions with improved safety profiles and reduced environmental impact.

Key market segments for aluminum-ion batteries include electric vehicles, renewable energy storage systems, consumer electronics, and grid-scale energy storage. The electric vehicle segment represents the largest potential market, with automotive manufacturers actively seeking alternatives to lithium-ion batteries due to concerns about lithium supply chain vulnerabilities and safety issues. Industry analysts predict that aluminum-ion batteries could capture up to 12% of the EV battery market by 2035.

The renewable energy storage sector presents another substantial opportunity, particularly for stationary applications where energy density is less critical than cost, safety, and longevity. With global renewable energy capacity expanding at unprecedented rates, the demand for efficient energy storage solutions is projected to grow by 25% annually through 2028.

Regional market analysis reveals that Asia-Pacific currently dominates aluminum-ion battery research and development activities, with China, Japan, and South Korea leading in patent filings and commercial initiatives. North America and Europe are rapidly increasing investments in this technology, with several startups securing significant venture capital funding in the past two years.

Market barriers include the current high production costs compared to established lithium-ion technology, with aluminum-ion batteries currently costing approximately 30% more per kWh. However, this gap is expected to narrow as manufacturing scales up and processes are optimized. The requirement for specialized dry-room facilities represents approximately 15-20% of initial capital expenditure for production facilities.

Customer demand analysis indicates growing interest from industries prioritizing safety and sustainability over maximum energy density. Survey data shows that 68% of industrial energy storage customers would consider aluminum-ion technology if it demonstrated comparable performance at competitive prices.

The competitive landscape includes established battery manufacturers expanding their portfolios to include aluminum-ion technology, as well as specialized startups focused exclusively on advancing this chemistry. Strategic partnerships between material suppliers, battery manufacturers, and end-users are becoming increasingly common as the industry works to accelerate commercialization and market adoption.

Key market segments for aluminum-ion batteries include electric vehicles, renewable energy storage systems, consumer electronics, and grid-scale energy storage. The electric vehicle segment represents the largest potential market, with automotive manufacturers actively seeking alternatives to lithium-ion batteries due to concerns about lithium supply chain vulnerabilities and safety issues. Industry analysts predict that aluminum-ion batteries could capture up to 12% of the EV battery market by 2035.

The renewable energy storage sector presents another substantial opportunity, particularly for stationary applications where energy density is less critical than cost, safety, and longevity. With global renewable energy capacity expanding at unprecedented rates, the demand for efficient energy storage solutions is projected to grow by 25% annually through 2028.

Regional market analysis reveals that Asia-Pacific currently dominates aluminum-ion battery research and development activities, with China, Japan, and South Korea leading in patent filings and commercial initiatives. North America and Europe are rapidly increasing investments in this technology, with several startups securing significant venture capital funding in the past two years.

Market barriers include the current high production costs compared to established lithium-ion technology, with aluminum-ion batteries currently costing approximately 30% more per kWh. However, this gap is expected to narrow as manufacturing scales up and processes are optimized. The requirement for specialized dry-room facilities represents approximately 15-20% of initial capital expenditure for production facilities.

Customer demand analysis indicates growing interest from industries prioritizing safety and sustainability over maximum energy density. Survey data shows that 68% of industrial energy storage customers would consider aluminum-ion technology if it demonstrated comparable performance at competitive prices.

The competitive landscape includes established battery manufacturers expanding their portfolios to include aluminum-ion technology, as well as specialized startups focused exclusively on advancing this chemistry. Strategic partnerships between material suppliers, battery manufacturers, and end-users are becoming increasingly common as the industry works to accelerate commercialization and market adoption.

Current Dry-Room Technology Challenges in Al-Ion Manufacturing

The manufacturing of aluminum-ion batteries presents unique challenges related to dry-room environments, which are critical for ensuring product quality and performance. Current dry-room technologies face several significant limitations that impede efficient and cost-effective production of Al-ion batteries at scale.

Moisture sensitivity remains the primary challenge in Al-ion battery manufacturing. Unlike lithium-ion batteries that require humidity levels below 1% RH (relative humidity), aluminum-ion batteries typically need even stricter conditions—often below 0.5% RH—due to the highly reactive nature of aluminum electrolytes with moisture. This extreme dryness requirement increases operational complexity and energy consumption.

Energy efficiency presents another major hurdle. Conventional dry rooms utilize massive dehumidification systems that consume substantial amounts of electricity, accounting for up to 30-40% of a battery manufacturing facility's total energy usage. This high energy demand significantly impacts production costs and carbon footprint, making sustainable manufacturing difficult to achieve.

Current air handling systems also struggle with stability issues. Fluctuations in humidity levels can occur during personnel entry/exit or material transfers, potentially compromising battery components. Most existing systems lack the rapid response capabilities needed to maintain ultra-low humidity levels consistently during these operational disturbances.

Space utilization efficiency represents another significant challenge. Traditional dry rooms require extensive support infrastructure, including large air handling units, desiccant wheels, and cooling systems. This ancillary equipment can occupy up to 40% of the total facility footprint, reducing the space available for actual production activities and increasing capital expenditure requirements.

Personnel comfort and productivity issues further complicate operations. Workers in ultra-dry environments experience significant discomfort, including dry skin, respiratory irritation, and dehydration. Current personal protective equipment (PPE) solutions are often bulky and restrictive, limiting dexterity and extending task completion times by an estimated 15-25%.

Monitoring and control systems present technological gaps as well. Many existing humidity sensors lack the precision required for ultra-low humidity environments, with error margins becoming proportionally significant at sub-1% RH levels. This measurement uncertainty complicates quality control and process validation efforts.

Scalability remains problematic for emerging manufacturers. Current dry-room technologies often employ proprietary designs that are difficult to scale linearly, creating bottlenecks when transitioning from pilot to commercial production. The lack of modular, standardized solutions increases both capital and operational expenses for expanding production capacity.

Moisture sensitivity remains the primary challenge in Al-ion battery manufacturing. Unlike lithium-ion batteries that require humidity levels below 1% RH (relative humidity), aluminum-ion batteries typically need even stricter conditions—often below 0.5% RH—due to the highly reactive nature of aluminum electrolytes with moisture. This extreme dryness requirement increases operational complexity and energy consumption.

Energy efficiency presents another major hurdle. Conventional dry rooms utilize massive dehumidification systems that consume substantial amounts of electricity, accounting for up to 30-40% of a battery manufacturing facility's total energy usage. This high energy demand significantly impacts production costs and carbon footprint, making sustainable manufacturing difficult to achieve.

Current air handling systems also struggle with stability issues. Fluctuations in humidity levels can occur during personnel entry/exit or material transfers, potentially compromising battery components. Most existing systems lack the rapid response capabilities needed to maintain ultra-low humidity levels consistently during these operational disturbances.

Space utilization efficiency represents another significant challenge. Traditional dry rooms require extensive support infrastructure, including large air handling units, desiccant wheels, and cooling systems. This ancillary equipment can occupy up to 40% of the total facility footprint, reducing the space available for actual production activities and increasing capital expenditure requirements.

Personnel comfort and productivity issues further complicate operations. Workers in ultra-dry environments experience significant discomfort, including dry skin, respiratory irritation, and dehydration. Current personal protective equipment (PPE) solutions are often bulky and restrictive, limiting dexterity and extending task completion times by an estimated 15-25%.

Monitoring and control systems present technological gaps as well. Many existing humidity sensors lack the precision required for ultra-low humidity environments, with error margins becoming proportionally significant at sub-1% RH levels. This measurement uncertainty complicates quality control and process validation efforts.

Scalability remains problematic for emerging manufacturers. Current dry-room technologies often employ proprietary designs that are difficult to scale linearly, creating bottlenecks when transitioning from pilot to commercial production. The lack of modular, standardized solutions increases both capital and operational expenses for expanding production capacity.

Current Dry-Room Design Solutions for Aluminum-Ion Production

01 Moisture control requirements for aluminum-ion battery production

Aluminum-ion batteries require strict moisture control during manufacturing to prevent degradation of components and ensure optimal performance. Dry rooms with controlled humidity levels (typically below 1% relative humidity) are essential for handling moisture-sensitive materials like aluminum anodes and electrolytes. These controlled environments help prevent unwanted reactions that could compromise battery safety and efficiency.- Humidity control requirements for aluminum-ion battery production: Aluminum-ion batteries require strict humidity control during manufacturing to prevent moisture-induced degradation of components. Dry rooms typically need to maintain relative humidity levels below 1% to ensure optimal battery performance and safety. Advanced dehumidification systems are essential to create and maintain these ultra-low humidity environments, which help prevent unwanted reactions between moisture and the aluminum electrodes or electrolytes.

- Temperature control specifications in dry rooms for aluminum-ion batteries: Temperature control is critical in dry rooms for aluminum-ion battery production. The environment typically requires stable temperatures between 20-25°C to ensure consistent manufacturing conditions. Temperature fluctuations can affect electrolyte stability and electrode performance in aluminum-ion batteries. Integrated HVAC systems with precise temperature control capabilities are necessary to maintain these conditions while simultaneously managing the low humidity requirements.

- Airflow and filtration systems for aluminum-ion battery dry rooms: Specialized airflow and filtration systems are required in dry rooms for aluminum-ion battery production to maintain clean manufacturing environments. These systems must provide laminar airflow to prevent particle contamination while maintaining the strict humidity levels. HEPA and ULPA filtration systems are commonly employed to remove particulates down to submicron levels, as contaminants can significantly impact the electrochemical performance of aluminum-ion batteries and lead to manufacturing defects.

- Material handling and personnel requirements in aluminum-ion battery dry rooms: Specific protocols for material handling and personnel movement are essential in aluminum-ion battery dry rooms. Materials must be properly dried and stored before entering the controlled environment. Personnel typically need to pass through air showers and wear specialized clean room garments to prevent moisture introduction. Airlocks and material transfer systems are designed to minimize humidity fluctuations during the movement of components and finished batteries in and out of the dry room environment.

- Monitoring and control systems for aluminum-ion battery dry rooms: Advanced monitoring and control systems are required to maintain the strict environmental conditions in aluminum-ion battery dry rooms. These systems continuously measure humidity, temperature, pressure, and particle counts, with automated responses to maintain specifications. Real-time monitoring with alarm systems ensures immediate notification of any deviations from required parameters. Data logging capabilities are essential for quality control and regulatory compliance, tracking environmental conditions throughout the battery manufacturing process.

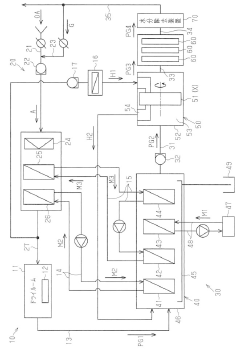

02 Dry room infrastructure and equipment specifications

Specialized infrastructure is required for aluminum-ion battery dry rooms, including advanced dehumidification systems, airlocks, and continuous monitoring equipment. The dry room facilities need precise temperature control systems, specialized ventilation, and air filtration to maintain ultra-low humidity levels. Equipment specifications often include specialized materials that don't outgas or introduce contaminants into the controlled environment.Expand Specific Solutions03 Personnel and material handling protocols in dry environments

Strict protocols govern personnel entry/exit and material transfer in aluminum-ion battery dry rooms. Workers typically use specialized clothing, undergo air showers, and follow specific procedures to minimize moisture introduction. Materials entering the dry room must be properly dried and sealed, with specific transfer protocols through airlocks or pass-through chambers to maintain environmental integrity during manufacturing processes.Expand Specific Solutions04 Monitoring and quality control systems for dry rooms

Advanced monitoring systems are essential for aluminum-ion battery dry rooms, including distributed humidity sensors, automated alarm systems, and continuous data logging. Quality control measures include regular calibration of monitoring equipment, periodic validation of environmental parameters, and documentation of any deviations. These systems ensure the manufacturing environment remains within specified parameters to maintain battery quality and safety.Expand Specific Solutions05 Alternative approaches to traditional dry room requirements

Innovative approaches are being developed to reduce dependency on expensive dry room facilities for aluminum-ion battery production. These include encapsulation technologies, specialized coating processes that protect moisture-sensitive components, and modular dry chambers that provide localized controlled environments. Some manufacturing processes incorporate in-line drying steps or use moisture-scavenging additives to mitigate humidity effects without requiring full dry room conditions.Expand Specific Solutions

Leading Manufacturers and Equipment Suppliers in Dry-Room Technology

The aluminum-ion battery production market is in an early growth phase, characterized by increasing R&D investments but limited commercial deployment. The global market size remains relatively small compared to lithium-ion technology but is projected to expand significantly due to aluminum's abundance and safety advantages. From a technical maturity perspective, the industry is still evolving, with key players at different development stages. Contemporary Amperex Technology (CATL) leads with substantial resources and manufacturing expertise, while specialized companies like Altris AB and PolyPlus Battery focus on innovative electrode materials. Traditional aluminum manufacturers including UACJ Corp., Kobe Steel, and Constellium provide essential materials expertise. Equipment suppliers such as Axcelis Technologies and Espec Corp. are developing specialized dry-room solutions critical for aluminum-ion battery production, as humidity control represents a significant manufacturing challenge.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed specialized dry-room technology for aluminum-ion battery production with humidity control systems maintaining dew points below -40°C. Their manufacturing facilities implement multi-stage dehumidification processes combining desiccant wheels and refrigeration systems to achieve ultra-low moisture environments (below 100ppm water content). CATL's dry rooms feature advanced air handling units with HEPA filtration to remove particulates while maintaining precise temperature (21±1°C) and humidity control. The company utilizes real-time monitoring systems with distributed sensor networks to ensure consistent environmental conditions throughout production areas, with automated adjustment capabilities to compensate for personnel entry/exit and seasonal variations.

Strengths: Industry-leading humidity control precision; integrated monitoring systems; scalable design for mass production. Weaknesses: High energy consumption for maintaining ultra-dry conditions; significant capital investment requirements; complex maintenance procedures for dehumidification systems.

Altris AB

Technical Solution: Altris has pioneered specialized dry-room technology for aluminum-ion battery production focusing on energy efficiency. Their system employs a cascaded dehumidification approach with primary desiccant-based moisture removal followed by molecular sieve technology to achieve dew points below -45°C while consuming approximately 30% less energy than conventional systems. The company's dry rooms feature modular construction with airlocks and material transfer systems specifically designed to minimize moisture ingress during component handling. Altris implements continuous monitoring with multiple redundant humidity sensors and automated control systems that adjust dehumidification intensity based on production volume and external weather conditions, optimizing energy usage while maintaining required specifications.

Strengths: Superior energy efficiency; modular design allowing for production scaling; advanced moisture ingress prevention. Weaknesses: Higher initial capital costs; requires specialized maintenance expertise; system complexity increases vulnerability to component failures.

Critical Patents and Innovations in Moisture Control Systems

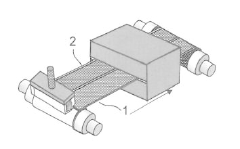

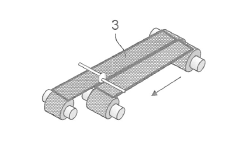

Dry box for lithium-ion battery production

PatentInactiveJPWO2015186367A1

Innovation

- A dry box system with separate chambers for pouch packaging and liquid injection processes, allowing production in small and medium-sized facilities, and includes features like independent drying spaces, ventilation, and vacuum chambers to maintain cleanliness and dryness.

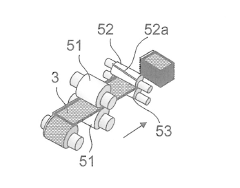

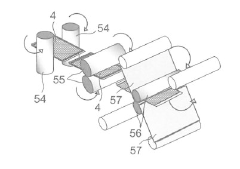

Gas treatment equipment

PatentInactiveJP2019029254A

Innovation

- A gas treatment apparatus comprising an organic solvent removal device, water removal device, and static eliminator to treat gas discharged from the manufacturing environment, neutralizing the gas to suppress static electricity.

Energy Efficiency Considerations in Dry-Room Operations

Energy efficiency represents a critical factor in the operation of dry rooms for aluminum-ion battery production, directly impacting both environmental sustainability and economic viability. The maintenance of ultra-low humidity levels (typically below 1% relative humidity) requires significant energy consumption, primarily through dehumidification systems that continuously remove moisture from the environment. These systems typically account for 60-70% of the total energy consumption in dry room operations.

Advanced energy recovery systems have emerged as essential components in modern dry room designs. Heat exchangers can recover up to 75% of the thermal energy from exhaust air, which would otherwise be wasted. This recovered energy can then be utilized to pre-condition incoming air, substantially reducing the overall energy requirements for maintaining the desired temperature and humidity conditions.

Variable frequency drives (VFDs) for air handling units represent another significant advancement in energy efficiency. By allowing precise control of fan speeds based on actual demand rather than operating at constant speeds, VFDs can reduce energy consumption by 20-30% compared to conventional systems. This adaptive approach ensures optimal energy utilization while maintaining required environmental parameters.

Smart monitoring and control systems have revolutionized dry room energy management. AI-driven predictive algorithms can anticipate changes in humidity levels based on production schedules, personnel movements, and external weather conditions. These systems optimize dehumidification cycles, reducing unnecessary operation and associated energy consumption by up to 15-25% compared to traditional time-based control systems.

Thermal insulation technologies specifically designed for dry room applications have evolved significantly. Advanced materials with extremely low thermal conductivity and vapor transmission rates create highly efficient building envelopes that minimize energy losses. Multi-layer insulation systems incorporating vacuum panels and aerogel-based materials can reduce thermal transfer by up to 40% compared to conventional insulation approaches.

Alternative dehumidification technologies present promising opportunities for energy reduction. Desiccant wheel systems combined with solar thermal regeneration can decrease electrical energy consumption by up to 50% in suitable climates. Similarly, membrane-based dehumidification systems operate at lower energy intensities than conventional refrigerant-based systems, potentially reducing energy requirements by 30-40% while maintaining the stringent humidity levels necessary for aluminum-ion battery production.

Advanced energy recovery systems have emerged as essential components in modern dry room designs. Heat exchangers can recover up to 75% of the thermal energy from exhaust air, which would otherwise be wasted. This recovered energy can then be utilized to pre-condition incoming air, substantially reducing the overall energy requirements for maintaining the desired temperature and humidity conditions.

Variable frequency drives (VFDs) for air handling units represent another significant advancement in energy efficiency. By allowing precise control of fan speeds based on actual demand rather than operating at constant speeds, VFDs can reduce energy consumption by 20-30% compared to conventional systems. This adaptive approach ensures optimal energy utilization while maintaining required environmental parameters.

Smart monitoring and control systems have revolutionized dry room energy management. AI-driven predictive algorithms can anticipate changes in humidity levels based on production schedules, personnel movements, and external weather conditions. These systems optimize dehumidification cycles, reducing unnecessary operation and associated energy consumption by up to 15-25% compared to traditional time-based control systems.

Thermal insulation technologies specifically designed for dry room applications have evolved significantly. Advanced materials with extremely low thermal conductivity and vapor transmission rates create highly efficient building envelopes that minimize energy losses. Multi-layer insulation systems incorporating vacuum panels and aerogel-based materials can reduce thermal transfer by up to 40% compared to conventional insulation approaches.

Alternative dehumidification technologies present promising opportunities for energy reduction. Desiccant wheel systems combined with solar thermal regeneration can decrease electrical energy consumption by up to 50% in suitable climates. Similarly, membrane-based dehumidification systems operate at lower energy intensities than conventional refrigerant-based systems, potentially reducing energy requirements by 30-40% while maintaining the stringent humidity levels necessary for aluminum-ion battery production.

Safety Standards and Compliance Requirements for Al-Ion Production

The implementation of aluminum-ion battery production necessitates adherence to stringent safety standards and compliance requirements due to the reactive nature of aluminum and the hazardous materials involved in the manufacturing process. International standards such as ISO 45001 for occupational health and safety management systems provide the foundational framework for establishing safe working environments in Al-ion production facilities. Additionally, IEC 62133 for secondary cells and batteries containing alkaline or other non-acid electrolytes is particularly relevant for ensuring product safety.

Regulatory bodies including OSHA in the United States, the European Chemicals Agency (ECHA), and similar organizations in Asia have established specific guidelines for handling reactive metals and electrolyte materials. These regulations mandate proper ventilation systems, emergency response protocols, and regular safety audits. For aluminum-ion battery production specifically, compliance with NFPA 70E for electrical safety and NFPA 652 for combustible dust hazards is critical due to the potential fire and explosion risks associated with aluminum particles.

Material Safety Data Sheets (MSDS) for all chemicals used in the manufacturing process must be readily available, with staff properly trained on handling procedures. This includes specific protocols for electrolyte materials, which may contain ionic liquids or other potentially hazardous substances. Personal Protective Equipment (PPE) requirements are particularly stringent in dry room environments, with specifications for anti-static clothing, respiratory protection, and chemical-resistant gloves.

Environmental compliance represents another crucial aspect of Al-ion production. Regulations such as the EU's Restriction of Hazardous Substances (RoHS) Directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) impose strict limitations on certain substances in manufacturing processes. Waste management protocols must comply with local and international standards, with particular attention to the disposal of electrolyte materials and aluminum waste.

Quality management systems conforming to ISO 9001 standards should be implemented to ensure consistent adherence to safety protocols. This includes documentation of all safety procedures, regular training programs, and continuous improvement mechanisms. For facilities seeking to export globally, compliance with UN Transportation of Dangerous Goods regulations is essential, particularly for shipping finished batteries or raw materials classified as hazardous.

Risk assessment methodologies specific to dry room environments must be developed and regularly updated. These should address the unique challenges of maintaining ultra-low humidity while ensuring worker safety, including protocols for emergency evacuation that account for airlock systems and specialized entry/exit procedures. Regular third-party audits are recommended to verify compliance with all applicable standards and identify potential areas for improvement in safety protocols.

Regulatory bodies including OSHA in the United States, the European Chemicals Agency (ECHA), and similar organizations in Asia have established specific guidelines for handling reactive metals and electrolyte materials. These regulations mandate proper ventilation systems, emergency response protocols, and regular safety audits. For aluminum-ion battery production specifically, compliance with NFPA 70E for electrical safety and NFPA 652 for combustible dust hazards is critical due to the potential fire and explosion risks associated with aluminum particles.

Material Safety Data Sheets (MSDS) for all chemicals used in the manufacturing process must be readily available, with staff properly trained on handling procedures. This includes specific protocols for electrolyte materials, which may contain ionic liquids or other potentially hazardous substances. Personal Protective Equipment (PPE) requirements are particularly stringent in dry room environments, with specifications for anti-static clothing, respiratory protection, and chemical-resistant gloves.

Environmental compliance represents another crucial aspect of Al-ion production. Regulations such as the EU's Restriction of Hazardous Substances (RoHS) Directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) impose strict limitations on certain substances in manufacturing processes. Waste management protocols must comply with local and international standards, with particular attention to the disposal of electrolyte materials and aluminum waste.

Quality management systems conforming to ISO 9001 standards should be implemented to ensure consistent adherence to safety protocols. This includes documentation of all safety procedures, regular training programs, and continuous improvement mechanisms. For facilities seeking to export globally, compliance with UN Transportation of Dangerous Goods regulations is essential, particularly for shipping finished batteries or raw materials classified as hazardous.

Risk assessment methodologies specific to dry room environments must be developed and regularly updated. These should address the unique challenges of maintaining ultra-low humidity while ensuring worker safety, including protocols for emergency evacuation that account for airlock systems and specialized entry/exit procedures. Regular third-party audits are recommended to verify compliance with all applicable standards and identify potential areas for improvement in safety protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!