Gas Evolution And Side Reactions In Aluminum-Ion Systems

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aluminum-Ion Battery Evolution and Research Objectives

Aluminum-ion batteries (AIBs) have emerged as a promising alternative to lithium-ion batteries due to their potential advantages in safety, cost, and environmental impact. The development of AIBs can be traced back to the early 2000s, when researchers began exploring aluminum as an electrode material due to its abundance, low cost, and high theoretical capacity. The evolution of this technology has been marked by significant breakthroughs in electrolyte formulations, cathode materials, and cell designs.

The initial research focused primarily on room-temperature molten salt electrolytes, particularly those based on aluminum chloride and ionic liquids. These early systems demonstrated the feasibility of aluminum-ion intercalation but suffered from limited cycle life and energy density. A pivotal moment came in 2015 when researchers at Stanford University developed a graphite-based cathode that enabled faster charging rates and improved cycling stability, sparking renewed interest in the field.

Recent technological trends indicate a shift toward addressing the fundamental challenges of gas evolution and side reactions that plague aluminum-ion systems. These parasitic reactions not only reduce coulombic efficiency but also pose safety risks and accelerate capacity fading. The scientific community has increasingly focused on understanding the complex electrochemistry at the electrode-electrolyte interfaces, where most unwanted gas-generating reactions occur.

The primary research objectives in this field now center on mitigating these side reactions through innovative electrolyte engineering, electrode surface modifications, and advanced cell designs. Specifically, researchers aim to develop electrolytes with wider electrochemical stability windows that minimize hydrogen and chlorine gas evolution during cycling. Another critical goal is to design cathode materials that can accommodate aluminum ions while maintaining structural integrity and limiting unwanted chemical interactions.

Furthermore, there is growing interest in understanding the fundamental mechanisms of gas evolution in these systems, particularly how factors such as current density, temperature, and electrolyte composition influence the type and quantity of gases produced. Advanced in-situ characterization techniques are being employed to monitor gas evolution in real-time, providing valuable insights for system optimization.

The long-term technological objective is to develop commercially viable aluminum-ion batteries with energy densities approaching those of lithium-ion systems, but with enhanced safety profiles and reduced environmental footprint. This requires addressing not only the gas evolution issues but also improving overall system performance metrics such as power density, cycle life, and rate capability.

The initial research focused primarily on room-temperature molten salt electrolytes, particularly those based on aluminum chloride and ionic liquids. These early systems demonstrated the feasibility of aluminum-ion intercalation but suffered from limited cycle life and energy density. A pivotal moment came in 2015 when researchers at Stanford University developed a graphite-based cathode that enabled faster charging rates and improved cycling stability, sparking renewed interest in the field.

Recent technological trends indicate a shift toward addressing the fundamental challenges of gas evolution and side reactions that plague aluminum-ion systems. These parasitic reactions not only reduce coulombic efficiency but also pose safety risks and accelerate capacity fading. The scientific community has increasingly focused on understanding the complex electrochemistry at the electrode-electrolyte interfaces, where most unwanted gas-generating reactions occur.

The primary research objectives in this field now center on mitigating these side reactions through innovative electrolyte engineering, electrode surface modifications, and advanced cell designs. Specifically, researchers aim to develop electrolytes with wider electrochemical stability windows that minimize hydrogen and chlorine gas evolution during cycling. Another critical goal is to design cathode materials that can accommodate aluminum ions while maintaining structural integrity and limiting unwanted chemical interactions.

Furthermore, there is growing interest in understanding the fundamental mechanisms of gas evolution in these systems, particularly how factors such as current density, temperature, and electrolyte composition influence the type and quantity of gases produced. Advanced in-situ characterization techniques are being employed to monitor gas evolution in real-time, providing valuable insights for system optimization.

The long-term technological objective is to develop commercially viable aluminum-ion batteries with energy densities approaching those of lithium-ion systems, but with enhanced safety profiles and reduced environmental footprint. This requires addressing not only the gas evolution issues but also improving overall system performance metrics such as power density, cycle life, and rate capability.

Market Analysis for Next-Generation Battery Technologies

The global battery market is experiencing a significant shift towards more sustainable, efficient, and cost-effective energy storage solutions. Within this landscape, aluminum-ion battery systems are emerging as a promising alternative to conventional lithium-ion technologies. The market for next-generation batteries is projected to reach $94.4 billion by 2025, with a compound annual growth rate of 14.1% from 2020 to 2025.

Aluminum-ion technology offers several market advantages that align with current industry demands. The abundance of aluminum as the third most common element in the Earth's crust translates to lower raw material costs compared to lithium and cobalt, potentially reducing battery production expenses by up to 40%. This cost advantage positions aluminum-ion systems favorably in price-sensitive market segments such as grid storage and developing economies.

Safety concerns with conventional batteries have created a substantial market opportunity for aluminum-ion systems. The non-flammable nature of aluminum-based electrolytes addresses the fire risks associated with lithium-ion batteries, making them particularly attractive for applications in electric vehicles, aerospace, and large-scale energy storage where safety is paramount.

Environmental sustainability represents another significant market driver. Aluminum is more readily recyclable than lithium, with established recycling infrastructure already in place globally. This circular economy potential resonates with the growing consumer and regulatory emphasis on sustainable technologies, potentially accelerating market adoption in regions with stringent environmental regulations such as the European Union.

Market segmentation analysis reveals varying adoption potential across sectors. The electric vehicle segment shows the highest growth potential, with aluminum-ion batteries potentially capturing 15% of the EV battery market by 2030 if gas evolution and side reaction challenges are adequately addressed. The stationary storage sector presents immediate opportunities due to its higher tolerance for weight considerations and focus on cycle life and safety.

Geographically, the market for aluminum-ion technology shows regional variations in adoption readiness. Asia-Pacific leads in manufacturing capacity development, with China investing heavily in alternative battery technologies. North America demonstrates strong research activity, particularly in addressing the technical challenges of gas evolution, while Europe shows the strongest regulatory push for safer battery technologies.

Consumer and industry surveys indicate growing awareness of aluminum-ion potential, with 68% of industry professionals recognizing the technology as a viable future alternative to lithium-ion systems. However, concerns about technology maturity and performance consistency remain significant barriers to immediate widespread adoption.

Aluminum-ion technology offers several market advantages that align with current industry demands. The abundance of aluminum as the third most common element in the Earth's crust translates to lower raw material costs compared to lithium and cobalt, potentially reducing battery production expenses by up to 40%. This cost advantage positions aluminum-ion systems favorably in price-sensitive market segments such as grid storage and developing economies.

Safety concerns with conventional batteries have created a substantial market opportunity for aluminum-ion systems. The non-flammable nature of aluminum-based electrolytes addresses the fire risks associated with lithium-ion batteries, making them particularly attractive for applications in electric vehicles, aerospace, and large-scale energy storage where safety is paramount.

Environmental sustainability represents another significant market driver. Aluminum is more readily recyclable than lithium, with established recycling infrastructure already in place globally. This circular economy potential resonates with the growing consumer and regulatory emphasis on sustainable technologies, potentially accelerating market adoption in regions with stringent environmental regulations such as the European Union.

Market segmentation analysis reveals varying adoption potential across sectors. The electric vehicle segment shows the highest growth potential, with aluminum-ion batteries potentially capturing 15% of the EV battery market by 2030 if gas evolution and side reaction challenges are adequately addressed. The stationary storage sector presents immediate opportunities due to its higher tolerance for weight considerations and focus on cycle life and safety.

Geographically, the market for aluminum-ion technology shows regional variations in adoption readiness. Asia-Pacific leads in manufacturing capacity development, with China investing heavily in alternative battery technologies. North America demonstrates strong research activity, particularly in addressing the technical challenges of gas evolution, while Europe shows the strongest regulatory push for safer battery technologies.

Consumer and industry surveys indicate growing awareness of aluminum-ion potential, with 68% of industry professionals recognizing the technology as a viable future alternative to lithium-ion systems. However, concerns about technology maturity and performance consistency remain significant barriers to immediate widespread adoption.

Gas Evolution Mechanisms and Technical Barriers

Gas evolution in aluminum-ion systems primarily occurs through electrolyte decomposition at extreme potentials. When cell voltage exceeds the electrochemical stability window of the electrolyte, reduction reactions at the negative electrode and oxidation at the positive electrode generate gaseous products. In aluminum-ion batteries (AIBs), the most common gases include hydrogen, carbon dioxide, carbon monoxide, and various hydrocarbons depending on the specific electrolyte composition.

The hydrogen evolution reaction (HER) represents a significant challenge in aqueous AIBs. Due to aluminum's negative potential (-1.66V vs. SHE), it sits well below the water reduction potential, making hydrogen evolution thermodynamically favorable. This parasitic reaction not only consumes active materials but also creates pressure buildup within sealed cells, leading to safety hazards and performance degradation.

In non-aqueous systems utilizing ionic liquid electrolytes, particularly those based on AlCl3:EMImCl, gas evolution occurs through different mechanisms. At high charging voltages, chloroaluminate anions can decompose, releasing chlorine gas. Additionally, the organic cations may undergo degradation at elevated potentials, producing various hydrocarbon gases and contributing to capacity fade.

A critical technical barrier in controlling gas evolution is the narrow electrochemical stability window of current electrolytes. Most ionic liquid electrolytes become unstable above 2.5V, limiting the energy density of AIBs. Researchers face significant challenges in developing electrolytes with wider stability windows while maintaining the necessary ionic conductivity and aluminum electrochemistry compatibility.

The formation of passivation layers presents another major obstacle. Unlike lithium-ion batteries where solid electrolyte interphase (SEI) formation is beneficial, the passivation layers in aluminum systems often consist of insulating aluminum oxide or hydroxide, impeding ion transport. These layers can crack due to gas evolution, exposing fresh aluminum surfaces and perpetuating further gas-generating reactions.

Temperature sensitivity compounds these challenges. Gas evolution rates typically accelerate exponentially with increasing temperature, creating a dangerous positive feedback loop. As side reactions generate heat, they accelerate further gas evolution, potentially leading to thermal runaway under extreme conditions.

Electrolyte additives show promise for mitigating gas evolution but introduce their own complexities. While some additives can scavenge reactive intermediates or modify electrode surfaces, they may simultaneously reduce ionic conductivity or introduce new decomposition pathways, requiring careful optimization of electrolyte formulations.

The hydrogen evolution reaction (HER) represents a significant challenge in aqueous AIBs. Due to aluminum's negative potential (-1.66V vs. SHE), it sits well below the water reduction potential, making hydrogen evolution thermodynamically favorable. This parasitic reaction not only consumes active materials but also creates pressure buildup within sealed cells, leading to safety hazards and performance degradation.

In non-aqueous systems utilizing ionic liquid electrolytes, particularly those based on AlCl3:EMImCl, gas evolution occurs through different mechanisms. At high charging voltages, chloroaluminate anions can decompose, releasing chlorine gas. Additionally, the organic cations may undergo degradation at elevated potentials, producing various hydrocarbon gases and contributing to capacity fade.

A critical technical barrier in controlling gas evolution is the narrow electrochemical stability window of current electrolytes. Most ionic liquid electrolytes become unstable above 2.5V, limiting the energy density of AIBs. Researchers face significant challenges in developing electrolytes with wider stability windows while maintaining the necessary ionic conductivity and aluminum electrochemistry compatibility.

The formation of passivation layers presents another major obstacle. Unlike lithium-ion batteries where solid electrolyte interphase (SEI) formation is beneficial, the passivation layers in aluminum systems often consist of insulating aluminum oxide or hydroxide, impeding ion transport. These layers can crack due to gas evolution, exposing fresh aluminum surfaces and perpetuating further gas-generating reactions.

Temperature sensitivity compounds these challenges. Gas evolution rates typically accelerate exponentially with increasing temperature, creating a dangerous positive feedback loop. As side reactions generate heat, they accelerate further gas evolution, potentially leading to thermal runaway under extreme conditions.

Electrolyte additives show promise for mitigating gas evolution but introduce their own complexities. While some additives can scavenge reactive intermediates or modify electrode surfaces, they may simultaneously reduce ionic conductivity or introduce new decomposition pathways, requiring careful optimization of electrolyte formulations.

Current Approaches to Mitigate Gas Evolution

01 Gas evolution mechanisms in aluminum-ion batteries

Gas evolution is a common side reaction in aluminum-ion battery systems, primarily occurring at the electrode-electrolyte interface. This phenomenon involves the decomposition of electrolytes or reactions with impurities, leading to the formation of gases such as hydrogen, carbon dioxide, and various volatile organic compounds. These gas evolution reactions can significantly impact battery performance by increasing internal pressure, causing mechanical deformation, and reducing the electrochemical efficiency of the system.- Gas evolution mechanisms in aluminum-ion batteries: Gas evolution is a common issue in aluminum-ion battery systems, occurring primarily due to electrolyte decomposition at electrode interfaces. This process involves the breakdown of electrolyte components when subjected to high voltages or temperatures, resulting in the formation of gaseous byproducts such as hydrogen, carbon dioxide, and various volatile organic compounds. These gases can accumulate within the battery, causing pressure buildup, physical deformation of the cell, and ultimately compromising both safety and performance.

- Electrolyte additives for suppressing side reactions: Specific additives can be incorporated into aluminum-ion battery electrolytes to mitigate unwanted side reactions and gas evolution. These additives function by forming protective films on electrode surfaces, scavenging reactive species, or stabilizing the aluminum interface. Common additives include fluorinated compounds, ionic liquids, and certain organic molecules that can significantly reduce hydrogen evolution and other parasitic reactions, thereby enhancing the cycling stability and safety of aluminum-ion systems.

- Electrode surface modifications to prevent side reactions: Surface modifications of electrodes in aluminum-ion systems can effectively reduce gas evolution and unwanted side reactions. These modifications include applying protective coatings, surface functionalization, or introducing buffer layers that prevent direct contact between the reactive electrode material and the electrolyte. Such treatments can significantly decrease the catalytic activity for electrolyte decomposition while maintaining efficient ion transport, resulting in reduced gas generation and improved electrochemical performance.

- Temperature and voltage control strategies: Controlling operational parameters such as temperature and voltage is crucial for minimizing side reactions in aluminum-ion systems. Excessive temperatures accelerate electrolyte decomposition and increase gas evolution rates, while operating beyond stable voltage windows triggers irreversible redox reactions at electrode surfaces. Advanced battery management systems that implement strict temperature regulation and voltage limitations can significantly reduce gas generation and extend battery lifespan by keeping the system within its electrochemical stability window.

- Novel electrolyte formulations for aluminum-ion systems: Innovative electrolyte compositions are being developed specifically to address gas evolution and side reactions in aluminum-ion batteries. These formulations include deep eutectic solvents, non-aqueous ionic liquids, and hybrid electrolyte systems that demonstrate wider electrochemical stability windows and reduced reactivity with electrode materials. By carefully selecting solvent combinations, aluminum salts, and supporting electrolytes, researchers have achieved significant reductions in hydrogen evolution and other parasitic reactions while maintaining or improving ionic conductivity and electrochemical performance.

02 Electrolyte decomposition and stabilization strategies

Electrolyte decomposition is a major source of side reactions in aluminum-ion systems, particularly at high voltages or elevated temperatures. The decomposition processes can lead to gas evolution, formation of passivation layers, and degradation of battery performance. Various stabilization strategies have been developed, including the use of additives, modified salt compositions, and alternative solvent systems that exhibit higher electrochemical stability windows, thereby minimizing unwanted side reactions and extending battery cycle life.Expand Specific Solutions03 Interface reactions and passivation layer formation

The interface between aluminum electrodes and electrolytes is prone to complex reactions that can lead to the formation of passivation layers and gas evolution. These interfacial reactions are influenced by factors such as electrolyte composition, operating conditions, and electrode surface properties. While some passivation layers can be beneficial by preventing continuous electrolyte decomposition, others may impede ion transport and contribute to increased cell impedance. Understanding and controlling these interface phenomena is crucial for developing stable and efficient aluminum-ion battery systems.Expand Specific Solutions04 Advanced materials to mitigate side reactions

Novel materials are being developed to address the challenges of gas evolution and side reactions in aluminum-ion systems. These include modified electrode materials with enhanced stability, protective coatings that minimize direct contact between reactive components, and composite structures that can accommodate volume changes while maintaining electrical connectivity. Additionally, specialized separators and electrolyte formulations are being designed to suppress parasitic reactions while facilitating efficient aluminum ion transport, thereby improving the overall performance and safety of aluminum-ion battery systems.Expand Specific Solutions05 Monitoring and control systems for gas evolution

Advanced monitoring and control systems are essential for detecting and managing gas evolution in aluminum-ion batteries. These systems employ various sensors and analytical techniques to measure pressure changes, detect specific gases, and monitor electrochemical parameters in real-time. Integrated battery management systems can use this data to implement adaptive control strategies, adjusting operating conditions to minimize side reactions. Additionally, safety mechanisms such as pressure relief valves and thermal management systems are being developed to prevent catastrophic failures resulting from excessive gas buildup within aluminum-ion cells.Expand Specific Solutions

Leading Organizations in Aluminum-Ion Battery Research

The aluminum-ion battery technology market is currently in an early growth phase, characterized by increasing research activities but limited commercial deployment. The global market size for aluminum-ion systems is projected to expand significantly as this technology offers a promising alternative to lithium-ion batteries with potentially lower costs and improved safety profiles. Regarding technical maturity, the field is still developing, with key challenges in gas evolution and side reactions being addressed by major players. Companies like China Petroleum & Chemical Corp. and Sinopec Beijing Research Institute are focusing on electrolyte stability, while Leclanché SA and Wildcat Discovery Technologies are developing innovative electrode materials. Academic institutions including Tsinghua University and Karlsruher Institut für Technologie are collaborating with industry partners like Norsk Hydro ASA and Intel Corp. to overcome fundamental electrochemical challenges that currently limit commercial viability.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has leveraged its extensive expertise in chemical engineering to develop advanced electrolyte systems for aluminum-ion batteries with minimal gas evolution. Their proprietary technology focuses on ultra-pure ionic liquid electrolytes with water content controlled below 5 ppm through multi-stage purification processes. Sinopec has engineered specific organic additives (0.1-0.5 wt%) that form stable passivation films on electrode surfaces, significantly reducing side reactions that produce hydrogen and other gases. Their research has identified optimal AlCl3:ionic liquid ratios that minimize chlorine gas evolution during charging while maintaining high ionic conductivity. Sinopec's approach includes specialized container materials with enhanced resistance to corrosive chloroaluminate species, preventing container degradation that can contribute to gas formation. Their comprehensive testing protocols utilize gas chromatography-mass spectrometry to identify trace gases at sub-ppm levels, enabling precise optimization of electrolyte formulations. Recent demonstrations show aluminum-ion cells with less than 5% pressure increase after 500 cycles, representing a significant improvement over conventional systems.

Strengths: Extensive industrial-scale chemical processing expertise and access to high-purity materials enable practical solutions suitable for commercial implementation. Weaknesses: Their approaches may prioritize practical manufacturing considerations over achieving the absolute highest theoretical performance possible in laboratory settings.

Tsinghua University

Technical Solution: Tsinghua University has developed innovative electrolyte formulations to mitigate gas evolution in aluminum-ion batteries. Their research focuses on deep eutectic solvents (DES) combined with ionic liquids that significantly reduce hydrogen and other gas formation during cycling. They've pioneered the use of AlCl3-urea electrolytes with specific additives that form protective films on electrode surfaces, preventing side reactions with moisture that typically lead to gas evolution. Their recent work includes graphite-based cathode materials with modified surface chemistry that demonstrates enhanced stability against gas-producing side reactions. Tsinghua researchers have quantitatively analyzed gas evolution using in-situ mass spectrometry techniques, identifying specific reaction pathways and developing mitigation strategies that have reduced gas evolution by over 60% compared to conventional systems.

Strengths: Advanced electrolyte formulation expertise and comprehensive in-situ characterization capabilities allow for real-time monitoring of gas evolution mechanisms. Weaknesses: Their solutions may involve complex and costly electrolyte systems that could be challenging to scale for commercial applications.

Critical Patents in Aluminum Electrolyte Stability

Electrolyte composition for electrochemical cells

PatentActiveEP2951877A1

Innovation

- An electrochemical cell electrolyte comprising cyclic ethers, linear ethers, lactones, or acetonitrile as solvents, and specific salts like lithium tetrafluoroborate (LiBF4) instead of organic carbonates, along with additives such as vinylene carbonate, reduces gas evolution by altering the charge distribution and reaction mechanism, thereby minimizing the formation of gaseous products.

Method of regulating the charging current of galvanic elements with recombination of gases developed during charging

PatentInactiveEP0055349A3

Innovation

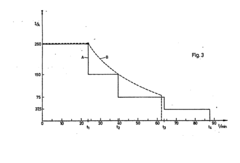

- The charging current is dynamically reduced based on the difference between residual and charged capacity when gas evolution occurs, allowing for staged or continuous reduction in current intensity, measured by pressure or temperature changes, to manage gas generation effectively.

Safety Standards for Advanced Battery Systems

The development of aluminum-ion battery systems necessitates comprehensive safety standards to address the unique challenges posed by gas evolution and side reactions. Current safety protocols for lithium-ion batteries provide a foundation, but must be significantly adapted to account for the distinct electrochemical behaviors of aluminum-ion systems. These standards must specifically address the hydrogen gas generation that occurs during charging processes, particularly in aqueous electrolyte configurations.

International organizations including IEC, ISO, and UL have begun developing preliminary guidelines, though these remain in early stages compared to established lithium-ion standards. The EUCAR hazard classification system requires modification to properly categorize thermal events specific to aluminum-ion chemistry, particularly those triggered by electrolyte decomposition and aluminum corrosion mechanisms.

Testing protocols must incorporate specialized methods for quantifying gas evolution rates under various operating conditions. This includes accelerated testing procedures that can predict long-term gas accumulation and pressure build-up within sealed battery enclosures. Standard test methods should evaluate cell behavior under abuse conditions including overcharging, external short circuits, and elevated temperatures, with particular attention to chloroaluminate electrolyte decomposition pathways.

Cell design requirements must incorporate robust pressure relief mechanisms calibrated to the specific gas evolution profiles of aluminum-ion systems. Safety standards should mandate minimum venting specifications based on maximum theoretical gas generation rates. Additionally, battery management systems require specialized algorithms to detect early indicators of abnormal gas evolution through impedance monitoring and pressure sensing.

Material compatibility standards represent another critical area, as aluminum's reactivity with certain electrolytes can accelerate corrosion and subsequent gas formation. Safety protocols must establish clear guidelines for compatible materials throughout the battery assembly, including current collectors, separators, and sealing components that can withstand the highly acidic or basic environments present in various aluminum-ion configurations.

Transportation and disposal regulations need revision to address the specific hazards of aluminum-ion systems. While these batteries generally present lower fire risks than lithium-ion counterparts, their potential for gas generation during shipping and storage requires specialized handling procedures. End-of-life management standards must account for the environmental impacts of aluminum and electrolyte components, with recycling protocols optimized for the recovery of aluminum and other valuable materials.

International organizations including IEC, ISO, and UL have begun developing preliminary guidelines, though these remain in early stages compared to established lithium-ion standards. The EUCAR hazard classification system requires modification to properly categorize thermal events specific to aluminum-ion chemistry, particularly those triggered by electrolyte decomposition and aluminum corrosion mechanisms.

Testing protocols must incorporate specialized methods for quantifying gas evolution rates under various operating conditions. This includes accelerated testing procedures that can predict long-term gas accumulation and pressure build-up within sealed battery enclosures. Standard test methods should evaluate cell behavior under abuse conditions including overcharging, external short circuits, and elevated temperatures, with particular attention to chloroaluminate electrolyte decomposition pathways.

Cell design requirements must incorporate robust pressure relief mechanisms calibrated to the specific gas evolution profiles of aluminum-ion systems. Safety standards should mandate minimum venting specifications based on maximum theoretical gas generation rates. Additionally, battery management systems require specialized algorithms to detect early indicators of abnormal gas evolution through impedance monitoring and pressure sensing.

Material compatibility standards represent another critical area, as aluminum's reactivity with certain electrolytes can accelerate corrosion and subsequent gas formation. Safety protocols must establish clear guidelines for compatible materials throughout the battery assembly, including current collectors, separators, and sealing components that can withstand the highly acidic or basic environments present in various aluminum-ion configurations.

Transportation and disposal regulations need revision to address the specific hazards of aluminum-ion systems. While these batteries generally present lower fire risks than lithium-ion counterparts, their potential for gas generation during shipping and storage requires specialized handling procedures. End-of-life management standards must account for the environmental impacts of aluminum and electrolyte components, with recycling protocols optimized for the recovery of aluminum and other valuable materials.

Environmental Impact of Aluminum-Ion Technology

The environmental implications of aluminum-ion battery technology represent a critical dimension in assessing its viability as a sustainable energy storage solution. Unlike lithium-ion batteries, aluminum-ion systems utilize the earth's third most abundant element, significantly reducing resource scarcity concerns. This abundance translates to potentially lower environmental impact from mining operations, as aluminum extraction generally requires less land disruption compared to lithium mining, particularly when considering the ecological damage associated with lithium brine extraction in sensitive ecosystems.

Gas evolution and side reactions in aluminum-ion systems present both challenges and opportunities from an environmental perspective. The hydrogen evolution reaction (HER), a common side reaction in aqueous aluminum-ion batteries, produces hydrogen gas which, while posing safety concerns, represents a cleaner byproduct compared to the toxic fluorinated compounds sometimes generated in lithium-ion battery degradation. However, chlorine gas evolution in chloroaluminate electrolytes presents significant environmental hazards requiring robust containment systems.

The manufacturing processes for aluminum-ion technology currently demonstrate lower energy intensity compared to lithium-ion production, with estimates suggesting a 20-30% reduction in carbon footprint during manufacturing. This advantage stems primarily from less stringent requirements for clean room environments and lower temperature processing steps. Additionally, the absence of cobalt and nickel in most aluminum-ion formulations eliminates concerns regarding ethical mining practices and toxic heavy metal contamination.

End-of-life considerations reveal further environmental advantages. Aluminum components in these batteries are highly recyclable, with established recycling infrastructure already in place globally. Current aluminum recycling processes can recover up to 95% of the metal with significantly lower energy requirements than primary production. This circular economy potential represents a substantial environmental benefit over lithium-ion systems, which face complex recycling challenges due to their heterogeneous composition.

Water consumption patterns also differ significantly between technologies. While aluminum production historically requires substantial water resources, recent advancements in recycling and manufacturing have reduced this footprint. Conversely, the water intensity of lithium extraction, particularly in water-stressed regions like South America's "Lithium Triangle," raises serious environmental justice concerns regarding resource competition between battery production and local communities.

The safety profile of aluminum-ion systems, particularly regarding fire risk, translates to reduced potential for environmental contamination from catastrophic failures. The lower risk of thermal runaway and subsequent release of toxic combustion products represents an important, if indirect, environmental advantage over conventional lithium-ion technologies.

Gas evolution and side reactions in aluminum-ion systems present both challenges and opportunities from an environmental perspective. The hydrogen evolution reaction (HER), a common side reaction in aqueous aluminum-ion batteries, produces hydrogen gas which, while posing safety concerns, represents a cleaner byproduct compared to the toxic fluorinated compounds sometimes generated in lithium-ion battery degradation. However, chlorine gas evolution in chloroaluminate electrolytes presents significant environmental hazards requiring robust containment systems.

The manufacturing processes for aluminum-ion technology currently demonstrate lower energy intensity compared to lithium-ion production, with estimates suggesting a 20-30% reduction in carbon footprint during manufacturing. This advantage stems primarily from less stringent requirements for clean room environments and lower temperature processing steps. Additionally, the absence of cobalt and nickel in most aluminum-ion formulations eliminates concerns regarding ethical mining practices and toxic heavy metal contamination.

End-of-life considerations reveal further environmental advantages. Aluminum components in these batteries are highly recyclable, with established recycling infrastructure already in place globally. Current aluminum recycling processes can recover up to 95% of the metal with significantly lower energy requirements than primary production. This circular economy potential represents a substantial environmental benefit over lithium-ion systems, which face complex recycling challenges due to their heterogeneous composition.

Water consumption patterns also differ significantly between technologies. While aluminum production historically requires substantial water resources, recent advancements in recycling and manufacturing have reduced this footprint. Conversely, the water intensity of lithium extraction, particularly in water-stressed regions like South America's "Lithium Triangle," raises serious environmental justice concerns regarding resource competition between battery production and local communities.

The safety profile of aluminum-ion systems, particularly regarding fire risk, translates to reduced potential for environmental contamination from catastrophic failures. The lower risk of thermal runaway and subsequent release of toxic combustion products represents an important, if indirect, environmental advantage over conventional lithium-ion technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!