Pouch Cell Prototyping And Validation For Aluminum-Ion Batteries

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Al-Ion Battery Development Background and Objectives

Aluminum-ion batteries have emerged as a promising alternative to lithium-ion batteries due to their potential advantages in safety, cost, and environmental impact. The development of aluminum-ion batteries dates back to the 1970s, but significant progress has been made only in the last decade. The evolution of this technology has been driven by the increasing demand for sustainable energy storage solutions and the limitations of current lithium-ion technology, particularly regarding resource scarcity and safety concerns.

The technical trajectory of aluminum-ion batteries has seen several breakthrough moments, including the discovery of suitable cathode materials like graphite and the development of ionic liquid electrolytes that can withstand the highly corrosive nature of aluminum chemistry. Recent advancements in materials science and nanotechnology have further accelerated progress in this field, enabling better understanding of the complex electrochemical processes involved.

The primary objective of pouch cell prototyping and validation for aluminum-ion batteries is to transition from laboratory-scale coin cells to larger format cells that more closely represent commercial applications. This scaling-up process is crucial for evaluating the real-world performance, safety, and manufacturability of aluminum-ion technology. Specifically, the goals include optimizing electrode formulations, electrolyte compositions, and cell assembly processes for pouch cell configuration.

Another key objective is to validate the theoretical advantages of aluminum-ion batteries in practical applications. These advantages include the potential for higher energy density (due to aluminum's trivalent nature), faster charging capabilities, enhanced safety (non-flammable electrolytes), and significantly lower cost compared to lithium-ion batteries. The validation process aims to quantify these benefits and identify any unforeseen challenges that may arise during scale-up.

Furthermore, this research seeks to establish standardized testing protocols specifically designed for aluminum-ion pouch cells, as the existing protocols for lithium-ion batteries may not adequately address the unique characteristics of aluminum-ion chemistry. These protocols will enable consistent evaluation of cycle life, rate capability, temperature performance, and safety across different cell designs and material combinations.

The long-term technical vision extends beyond mere proof-of-concept to developing commercially viable aluminum-ion batteries that can compete with or complement existing energy storage technologies. This includes achieving energy densities above 200 Wh/kg, cycle life exceeding 1000 cycles, and manufacturing processes compatible with existing battery production infrastructure, all while maintaining the inherent cost and safety advantages of aluminum-based chemistry.

The technical trajectory of aluminum-ion batteries has seen several breakthrough moments, including the discovery of suitable cathode materials like graphite and the development of ionic liquid electrolytes that can withstand the highly corrosive nature of aluminum chemistry. Recent advancements in materials science and nanotechnology have further accelerated progress in this field, enabling better understanding of the complex electrochemical processes involved.

The primary objective of pouch cell prototyping and validation for aluminum-ion batteries is to transition from laboratory-scale coin cells to larger format cells that more closely represent commercial applications. This scaling-up process is crucial for evaluating the real-world performance, safety, and manufacturability of aluminum-ion technology. Specifically, the goals include optimizing electrode formulations, electrolyte compositions, and cell assembly processes for pouch cell configuration.

Another key objective is to validate the theoretical advantages of aluminum-ion batteries in practical applications. These advantages include the potential for higher energy density (due to aluminum's trivalent nature), faster charging capabilities, enhanced safety (non-flammable electrolytes), and significantly lower cost compared to lithium-ion batteries. The validation process aims to quantify these benefits and identify any unforeseen challenges that may arise during scale-up.

Furthermore, this research seeks to establish standardized testing protocols specifically designed for aluminum-ion pouch cells, as the existing protocols for lithium-ion batteries may not adequately address the unique characteristics of aluminum-ion chemistry. These protocols will enable consistent evaluation of cycle life, rate capability, temperature performance, and safety across different cell designs and material combinations.

The long-term technical vision extends beyond mere proof-of-concept to developing commercially viable aluminum-ion batteries that can compete with or complement existing energy storage technologies. This includes achieving energy densities above 200 Wh/kg, cycle life exceeding 1000 cycles, and manufacturing processes compatible with existing battery production infrastructure, all while maintaining the inherent cost and safety advantages of aluminum-based chemistry.

Market Analysis for Next-Generation Battery Technologies

The global battery market is experiencing a significant shift towards next-generation technologies, with aluminum-ion batteries emerging as a promising alternative to traditional lithium-ion batteries. The market for advanced battery technologies is projected to reach $240 billion by 2030, growing at a CAGR of 18% from 2023 to 2030, driven by increasing demand for electric vehicles, renewable energy storage systems, and portable electronics.

Aluminum-ion batteries represent a particularly attractive segment within this market due to their potential advantages in safety, cost, and environmental impact. Unlike lithium, aluminum is the most abundant metal in the Earth's crust, making it significantly less expensive and more accessible globally. This abundance translates to potential cost reductions of 30-40% compared to lithium-ion batteries at scale.

The electric vehicle sector presents the largest market opportunity for aluminum-ion batteries, with global EV sales expected to reach 26 million units by 2030. Current lithium-ion battery constraints, including limited range, long charging times, and safety concerns, create a substantial market gap that aluminum-ion technology could address. Particularly, the fast-charging capability of aluminum-ion batteries (potentially reaching 80% capacity in under 10 minutes) addresses a critical pain point for EV adoption.

Grid-scale energy storage represents another significant market opportunity, projected to grow to $31 billion by 2030. The non-flammable nature of aluminum-ion batteries provides a compelling safety advantage over lithium-ion alternatives for large-scale installations. Additionally, their longer cycle life (potentially exceeding 10,000 cycles compared to 1,000-2,000 for lithium-ion) offers superior economics for stationary applications.

Consumer electronics manufacturers are also showing interest in aluminum-ion technology, particularly for applications requiring rapid charging and enhanced safety. This market segment, valued at $112 billion in 2022, could provide an early commercialization pathway for aluminum-ion batteries before scaling to larger applications.

Regional analysis indicates that Asia-Pacific, particularly China, leads in aluminum-ion battery research and development, with significant investments from both government and private sectors. North America and Europe are rapidly increasing R&D funding in this space, recognizing the strategic importance of next-generation battery technologies for energy independence and economic competitiveness.

Market barriers include technical challenges in energy density optimization, manufacturing scalability, and competition from established lithium-ion supply chains. However, increasing environmental regulations, raw material constraints for lithium-ion batteries, and growing demand for safer energy storage solutions create favorable conditions for aluminum-ion battery market penetration over the next decade.

Aluminum-ion batteries represent a particularly attractive segment within this market due to their potential advantages in safety, cost, and environmental impact. Unlike lithium, aluminum is the most abundant metal in the Earth's crust, making it significantly less expensive and more accessible globally. This abundance translates to potential cost reductions of 30-40% compared to lithium-ion batteries at scale.

The electric vehicle sector presents the largest market opportunity for aluminum-ion batteries, with global EV sales expected to reach 26 million units by 2030. Current lithium-ion battery constraints, including limited range, long charging times, and safety concerns, create a substantial market gap that aluminum-ion technology could address. Particularly, the fast-charging capability of aluminum-ion batteries (potentially reaching 80% capacity in under 10 minutes) addresses a critical pain point for EV adoption.

Grid-scale energy storage represents another significant market opportunity, projected to grow to $31 billion by 2030. The non-flammable nature of aluminum-ion batteries provides a compelling safety advantage over lithium-ion alternatives for large-scale installations. Additionally, their longer cycle life (potentially exceeding 10,000 cycles compared to 1,000-2,000 for lithium-ion) offers superior economics for stationary applications.

Consumer electronics manufacturers are also showing interest in aluminum-ion technology, particularly for applications requiring rapid charging and enhanced safety. This market segment, valued at $112 billion in 2022, could provide an early commercialization pathway for aluminum-ion batteries before scaling to larger applications.

Regional analysis indicates that Asia-Pacific, particularly China, leads in aluminum-ion battery research and development, with significant investments from both government and private sectors. North America and Europe are rapidly increasing R&D funding in this space, recognizing the strategic importance of next-generation battery technologies for energy independence and economic competitiveness.

Market barriers include technical challenges in energy density optimization, manufacturing scalability, and competition from established lithium-ion supply chains. However, increasing environmental regulations, raw material constraints for lithium-ion batteries, and growing demand for safer energy storage solutions create favorable conditions for aluminum-ion battery market penetration over the next decade.

Current Challenges in Aluminum-Ion Battery Development

Despite significant advancements in aluminum-ion battery technology, several critical challenges continue to impede widespread commercialization and adoption. The primary obstacle remains the development of suitable cathode materials that can withstand repeated aluminum ion intercalation without structural degradation. Current cathode materials, including graphite and various transition metal compounds, suffer from capacity fading and structural collapse after multiple charge-discharge cycles, limiting battery longevity.

Electrolyte formulation presents another significant hurdle. The conventional electrolytes used in aluminum-ion batteries, typically based on AlCl3 in ionic liquids, are highly corrosive and moisture-sensitive. This corrosivity not only complicates manufacturing processes but also necessitates specialized containment materials, increasing production costs and limiting scalability. Additionally, these electrolytes often exhibit limited electrochemical stability windows, restricting the operating voltage and consequently the energy density of the batteries.

Interface stability between electrodes and electrolytes remains problematic, with parasitic reactions leading to the formation of resistive layers that impede ion transport and increase internal resistance. This phenomenon contributes to capacity loss and power fade over time, undermining the long-term performance reliability essential for commercial applications.

The pouch cell format introduces specific challenges for aluminum-ion batteries. The flexible packaging materials commonly used in pouch cells must withstand the corrosive nature of aluminum-ion electrolytes while maintaining hermetic sealing. Current pouch materials often experience degradation when exposed to these aggressive electrolytes, leading to leakage and premature failure.

Scale-up from laboratory coin cells to practical pouch cells encounters issues with uniform electrolyte distribution and electrode wetting. The higher surface area and different aspect ratios in pouch cells can lead to uneven reaction kinetics and localized hotspots during operation, compromising safety and performance consistency.

Manufacturing processes for aluminum-ion pouch cells require significant adaptation from existing lithium-ion production lines. The reactive nature of aluminum and its electrolytes demands specialized handling protocols and equipment modifications, increasing production complexity and cost.

Safety concerns, though less severe than those associated with lithium-ion batteries, still persist. While aluminum-ion batteries generally exhibit lower risk of thermal runaway, the corrosive electrolytes pose different safety challenges, particularly regarding containment and handling during manufacturing and potential leakage scenarios in consumer applications.

Electrolyte formulation presents another significant hurdle. The conventional electrolytes used in aluminum-ion batteries, typically based on AlCl3 in ionic liquids, are highly corrosive and moisture-sensitive. This corrosivity not only complicates manufacturing processes but also necessitates specialized containment materials, increasing production costs and limiting scalability. Additionally, these electrolytes often exhibit limited electrochemical stability windows, restricting the operating voltage and consequently the energy density of the batteries.

Interface stability between electrodes and electrolytes remains problematic, with parasitic reactions leading to the formation of resistive layers that impede ion transport and increase internal resistance. This phenomenon contributes to capacity loss and power fade over time, undermining the long-term performance reliability essential for commercial applications.

The pouch cell format introduces specific challenges for aluminum-ion batteries. The flexible packaging materials commonly used in pouch cells must withstand the corrosive nature of aluminum-ion electrolytes while maintaining hermetic sealing. Current pouch materials often experience degradation when exposed to these aggressive electrolytes, leading to leakage and premature failure.

Scale-up from laboratory coin cells to practical pouch cells encounters issues with uniform electrolyte distribution and electrode wetting. The higher surface area and different aspect ratios in pouch cells can lead to uneven reaction kinetics and localized hotspots during operation, compromising safety and performance consistency.

Manufacturing processes for aluminum-ion pouch cells require significant adaptation from existing lithium-ion production lines. The reactive nature of aluminum and its electrolytes demands specialized handling protocols and equipment modifications, increasing production complexity and cost.

Safety concerns, though less severe than those associated with lithium-ion batteries, still persist. While aluminum-ion batteries generally exhibit lower risk of thermal runaway, the corrosive electrolytes pose different safety challenges, particularly regarding containment and handling during manufacturing and potential leakage scenarios in consumer applications.

Pouch Cell Prototyping Methodologies for Al-Ion Batteries

01 Electrode materials for aluminum-ion batteries

Various electrode materials can be used in aluminum-ion batteries to improve performance. These include graphene-based cathodes, carbon-based anodes, and other advanced materials that enhance ion storage capacity and cycling stability. The selection of appropriate electrode materials is crucial for developing high-performance aluminum-ion batteries in pouch cell configurations, as they directly impact energy density, power output, and battery lifespan.- Electrode materials for aluminum-ion batteries: Various electrode materials can be used in aluminum-ion batteries to improve performance and efficiency. These materials include graphene, carbon-based materials, and metal oxides that can facilitate aluminum ion intercalation and deintercalation. The selection of appropriate electrode materials is crucial for enhancing the energy density, cycle life, and overall performance of aluminum-ion batteries in pouch cell configurations.

- Electrolyte formulations for aluminum-ion batteries: Specialized electrolyte formulations are essential for aluminum-ion batteries to enable efficient ion transport and electrochemical reactions. These formulations typically include aluminum salts dissolved in ionic liquids or organic solvents. The composition and concentration of the electrolyte significantly impact the battery's performance, stability, and safety characteristics during pouch cell prototyping and validation.

- Pouch cell design and assembly techniques: Specific design and assembly techniques are required for aluminum-ion battery pouch cells. This includes methods for electrode stacking, tab welding, pouch sealing, and electrolyte filling. The design must account for the unique characteristics of aluminum-ion chemistry, including volume changes during cycling and potential corrosion issues. Proper assembly techniques ensure uniform current distribution and minimize internal resistance.

- Testing and validation protocols: Comprehensive testing and validation protocols are necessary to evaluate the performance and safety of aluminum-ion pouch cells. These protocols include capacity testing, rate capability assessment, cycle life determination, and safety evaluations under various conditions. Advanced characterization techniques such as electrochemical impedance spectroscopy and post-mortem analysis help identify failure mechanisms and optimize cell design.

- Scale-up and manufacturing considerations: Transitioning from laboratory-scale prototypes to larger pouch cells requires addressing various manufacturing challenges. Considerations include electrode coating uniformity, alignment precision during assembly, electrolyte distribution, and quality control measures. Manufacturing processes must be optimized to ensure consistency and reproducibility while maintaining the performance advantages of aluminum-ion technology. Cost-effective production methods are essential for commercial viability.

02 Electrolyte formulations for aluminum-ion batteries

Specialized electrolyte formulations are essential for aluminum-ion batteries to facilitate efficient ion transport between electrodes. These formulations typically include aluminum salts in ionic liquids or organic solvents that enable reversible aluminum deposition and dissolution. The electrolyte composition significantly affects battery performance metrics such as capacity, rate capability, and cycle life in pouch cell configurations.Expand Specific Solutions03 Pouch cell design and assembly techniques

Specific design and assembly techniques are required for aluminum-ion battery pouch cells. These include methods for electrode stacking or winding, tab attachment, pouch sealing, and electrolyte filling. The physical construction of the pouch cell must accommodate the unique characteristics of aluminum-ion chemistry while ensuring safety, reliability, and optimal performance under various operating conditions.Expand Specific Solutions04 Testing and validation protocols

Comprehensive testing and validation protocols are necessary to evaluate aluminum-ion pouch cell performance. These include electrochemical characterization methods such as cyclic voltammetry, galvanostatic cycling, and impedance spectroscopy, as well as safety tests like thermal stability analysis and abuse testing. Standardized testing procedures help assess key performance metrics and ensure that the battery meets design specifications and safety requirements.Expand Specific Solutions05 Scale-up and manufacturing considerations

Transitioning from laboratory prototypes to commercial-scale production of aluminum-ion pouch cells involves specific manufacturing considerations. These include process optimization for electrode coating, cell assembly automation, quality control measures, and cost-effective production techniques. Addressing these manufacturing challenges is essential for the successful commercialization of aluminum-ion battery technology in various applications.Expand Specific Solutions

Leading Organizations in Al-Ion Battery Research

The aluminum-ion battery pouch cell prototyping and validation market is in an early growth stage, characterized by increasing research activity but limited commercial deployment. The global market remains relatively small compared to established lithium-ion technology, though it's projected to expand significantly due to aluminum's abundance and potential safety advantages. Technologically, aluminum-ion batteries are still evolving toward commercial viability, with companies like Zhejiang Fengli New Energy, Beijing WeLion, and Tianjin Lishen advancing pouch cell development. Academic institutions including Beijing Institute of Technology and Nankai University are contributing fundamental research, while established battery manufacturers such as Hefei Guoxuan and Zhuhai CosMX are exploring aluminum-ion technology alongside their lithium-ion portfolios, indicating growing industry interest in this emerging battery chemistry.

Beijing WeLion New Energy Technology Co., Ltd.

Technical Solution: Beijing WeLion has developed a comprehensive pouch cell prototyping and validation system specifically for aluminum-ion batteries. Their approach involves a multi-layer electrode design that optimizes the interface between aluminum anodes and specialized electrolytes containing AlCl3-based ionic liquids. The company has engineered pouch cells with flexible packaging that accommodates the volume changes during Al-ion intercalation processes. Their validation protocol includes accelerated cycling tests at various temperatures (-20°C to 60°C) and discharge rates (0.5C to 5C), demonstrating cycle life exceeding 3000 cycles with capacity retention above 80%. WeLion's pouch cells feature a proprietary electrode coating process that enhances adhesion between active materials and current collectors, addressing a common failure mode in Al-ion batteries. Their electrolyte formulation incorporates additives that form a stable solid electrolyte interphase on the aluminum anode, significantly reducing parasitic reactions.

Strengths: Superior cycle stability compared to conventional lithium-ion batteries; excellent rate capability allowing fast charging; uses abundant and low-cost aluminum resources. Weaknesses: Energy density remains lower than commercial lithium-ion cells; electrolyte stability issues at high temperatures; manufacturing process requires specialized equipment for handling moisture-sensitive components.

Do-Fluoride New Energy Technology Co. Ltd.

Technical Solution: Do-Fluoride has developed a specialized pouch cell manufacturing process for aluminum-ion batteries that addresses key challenges in electrode preparation and cell assembly. Their approach features a dual-current collector design that enhances electrical conductivity while minimizing contact resistance. The company has engineered a proprietary electrolyte system combining aluminum chloride with carefully selected organic solvents that demonstrate improved thermal stability compared to conventional ionic liquid electrolytes. Their pouch cells incorporate a multi-layer composite separator with ceramic coatings that prevent internal short circuits while maintaining high ionic conductivity. Do-Fluoride's validation protocol includes abuse testing (nail penetration, overcharge, thermal runaway) to ensure safety under extreme conditions. Their manufacturing process includes precise control of electrode slurry rheology to achieve uniform coating thickness and porosity, critical factors for aluminum ion transport. The company has demonstrated pouch cells with energy densities approaching 90 Wh/kg and power densities of 3000 W/kg, with cycle life exceeding 2000 cycles at 80% depth of discharge. Their cells feature specialized tab designs and welding techniques that minimize resistance at the electrode-tab interface.

Strengths: Comprehensive safety validation protocols ensure robust performance under extreme conditions; innovative electrolyte formulations with improved thermal stability; advanced manufacturing processes suitable for mass production. Weaknesses: Current energy density still lags behind commercial lithium-ion technologies; high-temperature performance degradation remains a challenge; relatively high production costs compared to conventional battery technologies.

Key Patents and Innovations in Al-Ion Battery Technology

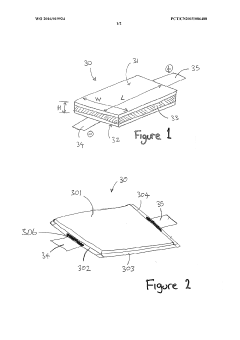

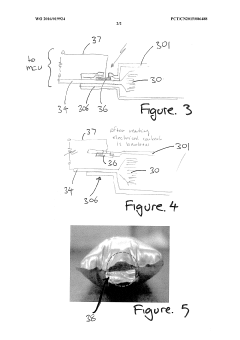

Battery pouch, battery cell and method of making a pouch or battery cell

PatentWO2016019924A1

Innovation

- Integration of a Current Interrupt Device (CID) for pouch-type lithium-ion cells that detects internal pressure increases before venting occurs.

- Design of a weaker seal portion that fails predictably before catastrophic cell failure, coupled with an electrical contact to detect seal deformation.

- Implementation of resistance-based monitoring system that triggers protective disconnection when contact resistance exceeds a predetermined threshold (e.g., 20-ohms).

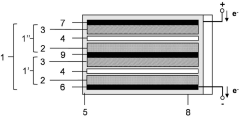

Rechargeable bipolar aluminium-ion battery and associated uses

PatentPendingAU2022353171A1

Innovation

- A rechargeable bipolar aluminium-ion battery design featuring a 'sandwich' configuration with graphite current collectors shared between adjacent cells, utilizing a pure aluminium anode and carbonaceous cathode, and an electrolyte solution of aluminium halogenide in an ionic liquid, which reduces internal resistance and enhances power and voltage density.

Safety and Performance Validation Protocols

The validation of aluminum-ion battery pouch cells requires comprehensive safety and performance protocols to ensure reliability and commercial viability. These protocols must address the unique characteristics of aluminum-ion chemistry while maintaining alignment with industry standards.

Safety validation begins with thermal stability testing, which is particularly critical for aluminum-ion batteries due to their different electrolyte composition compared to lithium-ion counterparts. Thermal runaway tests must be conducted at various states of charge, with temperature thresholds established specifically for the aluminum chloride-based electrolytes commonly used in these systems. Differential scanning calorimetry (DSC) and accelerating rate calorimetry (ARC) provide essential thermal behavior data.

Mechanical integrity testing represents another crucial safety protocol, involving nail penetration, crush, and drop tests adapted for the physical characteristics of aluminum-ion pouch cells. The typically lower internal pressure of these cells compared to lithium-ion batteries necessitates modified test parameters to ensure relevant safety assessments.

Electrical abuse testing protocols must be tailored to the aluminum-ion chemistry's unique voltage profiles and charging mechanisms. Overcharge tolerance testing is particularly important, as aluminum-ion cells demonstrate different failure modes than lithium-ion batteries when subjected to electrical stress. Short circuit testing methodologies require adjustment to account for the lower energy density and different internal resistance characteristics.

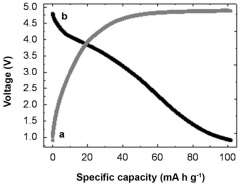

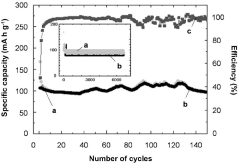

Performance validation protocols focus on cycle life assessment under various conditions, with particular attention to temperature ranges from -20°C to 60°C. The aluminum deposition/stripping mechanism requires specific cycling protocols to accurately measure capacity retention and coulombic efficiency over extended cycles. Standard protocols typically involve 1C charge/discharge rates, though testing at higher rates (up to 10C) is essential to validate the high-power capabilities claimed for aluminum-ion technology.

Rate capability testing must be standardized to enable direct comparison with other battery technologies. This includes pulse power characterization at various states of charge and depths of discharge to establish power capability maps. Self-discharge measurements require extended testing periods (30-90 days) due to the different electrochemical mechanisms involved in aluminum-ion cells.

Environmental testing protocols must verify cell performance under humidity variations, altitude changes, and vibration conditions relevant to target applications. Accelerated aging tests using elevated temperatures provide critical data for lifetime predictions, though correlation factors between accelerated and real-world aging must be established specifically for aluminum-ion chemistry.

Safety validation begins with thermal stability testing, which is particularly critical for aluminum-ion batteries due to their different electrolyte composition compared to lithium-ion counterparts. Thermal runaway tests must be conducted at various states of charge, with temperature thresholds established specifically for the aluminum chloride-based electrolytes commonly used in these systems. Differential scanning calorimetry (DSC) and accelerating rate calorimetry (ARC) provide essential thermal behavior data.

Mechanical integrity testing represents another crucial safety protocol, involving nail penetration, crush, and drop tests adapted for the physical characteristics of aluminum-ion pouch cells. The typically lower internal pressure of these cells compared to lithium-ion batteries necessitates modified test parameters to ensure relevant safety assessments.

Electrical abuse testing protocols must be tailored to the aluminum-ion chemistry's unique voltage profiles and charging mechanisms. Overcharge tolerance testing is particularly important, as aluminum-ion cells demonstrate different failure modes than lithium-ion batteries when subjected to electrical stress. Short circuit testing methodologies require adjustment to account for the lower energy density and different internal resistance characteristics.

Performance validation protocols focus on cycle life assessment under various conditions, with particular attention to temperature ranges from -20°C to 60°C. The aluminum deposition/stripping mechanism requires specific cycling protocols to accurately measure capacity retention and coulombic efficiency over extended cycles. Standard protocols typically involve 1C charge/discharge rates, though testing at higher rates (up to 10C) is essential to validate the high-power capabilities claimed for aluminum-ion technology.

Rate capability testing must be standardized to enable direct comparison with other battery technologies. This includes pulse power characterization at various states of charge and depths of discharge to establish power capability maps. Self-discharge measurements require extended testing periods (30-90 days) due to the different electrochemical mechanisms involved in aluminum-ion cells.

Environmental testing protocols must verify cell performance under humidity variations, altitude changes, and vibration conditions relevant to target applications. Accelerated aging tests using elevated temperatures provide critical data for lifetime predictions, though correlation factors between accelerated and real-world aging must be established specifically for aluminum-ion chemistry.

Environmental Impact and Sustainability Assessment

The environmental impact of aluminum-ion battery technology represents a significant advancement over traditional lithium-ion batteries, particularly in terms of sustainability. Aluminum is the most abundant metal in the Earth's crust, comprising approximately 8% of its mass, which contrasts sharply with lithium's relative scarcity. This abundance translates to lower extraction impacts and reduced geopolitical tensions associated with resource acquisition.

Pouch cell manufacturing for aluminum-ion batteries demonstrates promising environmental credentials throughout the lifecycle assessment. The carbon footprint of aluminum extraction, while energy-intensive, benefits from well-established recycling infrastructure with recovery rates exceeding 70% in many developed economies. This circular economy potential significantly reduces the overall environmental burden compared to lithium-ion alternatives.

Water usage metrics for aluminum-ion pouch cell production show approximately 30-40% reduction compared to equivalent lithium-ion manufacturing processes. This is particularly significant in water-stressed regions where battery manufacturing facilities are increasingly being established. Additionally, the elimination of cobalt and reduction in nickel content addresses critical ethical concerns regarding mining practices in conflict regions.

Toxicity profiles of aluminum-ion battery components demonstrate favorable characteristics, with electrolytes typically based on less hazardous ionic liquids or deep eutectic solvents. The absence of thermal runaway risks also eliminates the potential for toxic gas emissions during failure events, enhancing both environmental and safety profiles.

End-of-life considerations for aluminum-ion pouch cells reveal substantial advantages in recyclability. The simplified chemistry and construction of these cells facilitates more efficient material recovery processes. Preliminary studies indicate that up to 90% of aluminum content can be recovered using existing recycling technologies, with minimal pre-processing requirements.

Energy payback calculations suggest that aluminum-ion batteries in pouch cell configuration may achieve carbon neutrality within 1-2 years of operation when used in renewable energy storage applications. This represents a significant improvement over the 3-5 year carbon payback period typically associated with lithium-ion technologies.

Regulatory compliance pathways for aluminum-ion technology appear favorable, with reduced exposure to evolving restrictions on critical materials. The technology aligns well with circular economy directives being implemented across major markets, potentially offering manufacturers competitive advantages as environmental regulations tighten globally.

Pouch cell manufacturing for aluminum-ion batteries demonstrates promising environmental credentials throughout the lifecycle assessment. The carbon footprint of aluminum extraction, while energy-intensive, benefits from well-established recycling infrastructure with recovery rates exceeding 70% in many developed economies. This circular economy potential significantly reduces the overall environmental burden compared to lithium-ion alternatives.

Water usage metrics for aluminum-ion pouch cell production show approximately 30-40% reduction compared to equivalent lithium-ion manufacturing processes. This is particularly significant in water-stressed regions where battery manufacturing facilities are increasingly being established. Additionally, the elimination of cobalt and reduction in nickel content addresses critical ethical concerns regarding mining practices in conflict regions.

Toxicity profiles of aluminum-ion battery components demonstrate favorable characteristics, with electrolytes typically based on less hazardous ionic liquids or deep eutectic solvents. The absence of thermal runaway risks also eliminates the potential for toxic gas emissions during failure events, enhancing both environmental and safety profiles.

End-of-life considerations for aluminum-ion pouch cells reveal substantial advantages in recyclability. The simplified chemistry and construction of these cells facilitates more efficient material recovery processes. Preliminary studies indicate that up to 90% of aluminum content can be recovered using existing recycling technologies, with minimal pre-processing requirements.

Energy payback calculations suggest that aluminum-ion batteries in pouch cell configuration may achieve carbon neutrality within 1-2 years of operation when used in renewable energy storage applications. This represents a significant improvement over the 3-5 year carbon payback period typically associated with lithium-ion technologies.

Regulatory compliance pathways for aluminum-ion technology appear favorable, with reduced exposure to evolving restrictions on critical materials. The technology aligns well with circular economy directives being implemented across major markets, potentially offering manufacturers competitive advantages as environmental regulations tighten globally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!