End-Of-Life And Recycling Pathways For Aluminum-Ion Cells

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aluminum-Ion Battery EOL Technology Background and Objectives

Aluminum-ion batteries have emerged as a promising alternative to conventional lithium-ion batteries due to their potential advantages in safety, cost, and environmental impact. The development of aluminum-ion battery technology can be traced back to the early 2000s, with significant advancements occurring in the past decade. These batteries utilize aluminum as the anode material, which is the third most abundant element in the Earth's crust, making it considerably more accessible and less expensive than lithium.

The evolution of aluminum-ion battery technology has been characterized by continuous improvements in electrode materials, electrolytes, and cell designs. Early iterations faced significant challenges related to cycle life, energy density, and stability. However, recent breakthroughs in cathode materials, particularly graphene-based structures and various transition metal compounds, have substantially enhanced performance metrics.

The primary technical objective in the end-of-life (EOL) and recycling domain for aluminum-ion cells is to develop efficient, economically viable, and environmentally sustainable processes for recovering valuable materials from spent batteries. This includes aluminum, electrolyte components, and cathode materials, which often contain valuable metals and compounds.

Current EOL management for aluminum-ion batteries remains largely underdeveloped compared to lithium-ion battery recycling technologies. This gap presents both a challenge and an opportunity as the aluminum-ion battery market continues to grow. The technical goals include minimizing energy consumption during recycling processes, maximizing material recovery rates, and ensuring that recovered materials maintain sufficient purity for reuse in new battery production.

Another critical objective is to design aluminum-ion batteries with recycling considerations integrated from the outset—a concept known as "design for recyclability." This approach aims to simplify disassembly processes, reduce the variety of materials used, and avoid difficult-to-separate components, thereby enhancing the economic feasibility of recycling operations.

The development of standardized testing protocols and classification systems for end-of-life aluminum-ion batteries represents another important technical goal. These standards would facilitate more efficient sorting and processing of spent batteries, leading to improved recovery rates and reduced environmental impact.

As aluminum-ion battery technology continues to mature and potentially gain market share, establishing comprehensive recycling infrastructure and technologies becomes increasingly urgent. The technical trajectory suggests a focus on hydrometallurgical and direct recycling methods, which offer potentially lower environmental impacts compared to pyrometallurgical approaches commonly used for lithium-ion batteries.

The evolution of aluminum-ion battery technology has been characterized by continuous improvements in electrode materials, electrolytes, and cell designs. Early iterations faced significant challenges related to cycle life, energy density, and stability. However, recent breakthroughs in cathode materials, particularly graphene-based structures and various transition metal compounds, have substantially enhanced performance metrics.

The primary technical objective in the end-of-life (EOL) and recycling domain for aluminum-ion cells is to develop efficient, economically viable, and environmentally sustainable processes for recovering valuable materials from spent batteries. This includes aluminum, electrolyte components, and cathode materials, which often contain valuable metals and compounds.

Current EOL management for aluminum-ion batteries remains largely underdeveloped compared to lithium-ion battery recycling technologies. This gap presents both a challenge and an opportunity as the aluminum-ion battery market continues to grow. The technical goals include minimizing energy consumption during recycling processes, maximizing material recovery rates, and ensuring that recovered materials maintain sufficient purity for reuse in new battery production.

Another critical objective is to design aluminum-ion batteries with recycling considerations integrated from the outset—a concept known as "design for recyclability." This approach aims to simplify disassembly processes, reduce the variety of materials used, and avoid difficult-to-separate components, thereby enhancing the economic feasibility of recycling operations.

The development of standardized testing protocols and classification systems for end-of-life aluminum-ion batteries represents another important technical goal. These standards would facilitate more efficient sorting and processing of spent batteries, leading to improved recovery rates and reduced environmental impact.

As aluminum-ion battery technology continues to mature and potentially gain market share, establishing comprehensive recycling infrastructure and technologies becomes increasingly urgent. The technical trajectory suggests a focus on hydrometallurgical and direct recycling methods, which offer potentially lower environmental impacts compared to pyrometallurgical approaches commonly used for lithium-ion batteries.

Market Analysis for Aluminum-Ion Battery Recycling

The global market for aluminum-ion battery recycling is currently in its nascent stage but shows promising growth potential as aluminum-ion battery technology advances toward commercialization. Unlike the well-established lithium-ion battery recycling market, which was valued at approximately $6.5 billion in 2022, the aluminum-ion battery recycling sector remains largely undeveloped due to the limited commercial deployment of these batteries.

Market projections indicate that as aluminum-ion batteries gain traction in energy storage applications, the recycling market could experience significant growth starting from 2025-2030. This growth trajectory is expected to parallel the adoption curve of the batteries themselves, with initial recycling demand emerging from research facilities and early commercial implementations.

The primary market drivers for aluminum-ion battery recycling include increasing environmental regulations regarding battery disposal, the strategic value of aluminum as a resource, and the relatively straightforward recycling process compared to lithium-ion batteries. The European Union's Battery Directive and similar regulations in North America and Asia are creating regulatory frameworks that will necessitate end-of-life solutions for all battery technologies, including emerging ones like aluminum-ion cells.

From a regional perspective, countries with strong aluminum production industries such as China, Russia, Australia, and the Middle East are positioned to become key players in the aluminum-ion battery recycling market. These regions have existing aluminum recycling infrastructure that could be adapted for battery-specific processes, providing them with a competitive advantage.

The economic value proposition of aluminum-ion battery recycling is compelling. Aluminum has a well-established recycling value chain with recovery rates exceeding 90% in many developed markets. The metal's high recyclability and the lower energy requirements for recycling compared to primary production (requiring only about 5% of the energy) create favorable economics for recycling operations.

Market segmentation for aluminum-ion battery recycling is expected to develop along several lines: by recycling process (hydrometallurgical, pyrometallurgical, and direct recycling), by battery component (aluminum, electrolyte, cathode materials), and by end-use application (consumer electronics, electric vehicles, grid storage).

Challenges facing market development include the current lack of standardization in aluminum-ion battery design, limited waste volumes to achieve economies of scale, and competition from the well-established aluminum recycling industry which may not initially differentiate battery-grade aluminum from other sources.

Market projections indicate that as aluminum-ion batteries gain traction in energy storage applications, the recycling market could experience significant growth starting from 2025-2030. This growth trajectory is expected to parallel the adoption curve of the batteries themselves, with initial recycling demand emerging from research facilities and early commercial implementations.

The primary market drivers for aluminum-ion battery recycling include increasing environmental regulations regarding battery disposal, the strategic value of aluminum as a resource, and the relatively straightforward recycling process compared to lithium-ion batteries. The European Union's Battery Directive and similar regulations in North America and Asia are creating regulatory frameworks that will necessitate end-of-life solutions for all battery technologies, including emerging ones like aluminum-ion cells.

From a regional perspective, countries with strong aluminum production industries such as China, Russia, Australia, and the Middle East are positioned to become key players in the aluminum-ion battery recycling market. These regions have existing aluminum recycling infrastructure that could be adapted for battery-specific processes, providing them with a competitive advantage.

The economic value proposition of aluminum-ion battery recycling is compelling. Aluminum has a well-established recycling value chain with recovery rates exceeding 90% in many developed markets. The metal's high recyclability and the lower energy requirements for recycling compared to primary production (requiring only about 5% of the energy) create favorable economics for recycling operations.

Market segmentation for aluminum-ion battery recycling is expected to develop along several lines: by recycling process (hydrometallurgical, pyrometallurgical, and direct recycling), by battery component (aluminum, electrolyte, cathode materials), and by end-use application (consumer electronics, electric vehicles, grid storage).

Challenges facing market development include the current lack of standardization in aluminum-ion battery design, limited waste volumes to achieve economies of scale, and competition from the well-established aluminum recycling industry which may not initially differentiate battery-grade aluminum from other sources.

Current Recycling Challenges and Technical Limitations

The recycling of aluminum-ion cells presents significant technical challenges despite the theoretical recyclability of their components. Current industrial recycling infrastructure is predominantly designed for lithium-ion batteries, creating a substantial gap in processing capabilities for aluminum-ion technology. The absence of standardized recycling protocols specifically tailored for aluminum-ion cells hampers efficient end-of-life management.

A primary technical limitation involves the separation of aluminum from the cathode materials, which often include graphite or other carbon-based structures. The strong bonding between aluminum ions and these materials necessitates energy-intensive processes for effective separation. Conventional hydrometallurgical and pyrometallurgical methods developed for other battery chemistries demonstrate limited efficiency when applied to aluminum-ion cells, resulting in material loss and reduced recovery rates.

Electrolyte handling presents another significant challenge. The ionic liquids commonly used in aluminum-ion cells, such as AlCl3-[EMIm]Cl, are highly reactive and corrosive, requiring specialized containment and processing equipment. Current recycling facilities lack the necessary safety protocols and technical capabilities to manage these substances effectively, increasing the risk of environmental contamination and worker exposure to hazardous materials.

The multi-material composition of aluminum-ion cells further complicates recycling efforts. The presence of various metals, polymers, and composite materials necessitates complex sorting and separation processes. Current automated sorting technologies demonstrate insufficient precision in distinguishing between these components, leading to contaminated material streams and diminished recycling yields.

Energy consumption during recycling processes represents another substantial limitation. The high temperatures required for pyrometallurgical recovery methods contribute significantly to the carbon footprint of recycling operations, potentially offsetting the environmental benefits of aluminum-ion technology. Alternative low-energy recovery methods remain in early development stages and have not yet achieved commercial viability.

Scale presents an additional challenge. The relatively low market penetration of aluminum-ion cells has limited investment in dedicated recycling infrastructure. Without sufficient volume, recyclers cannot justify the capital expenditure required for specialized equipment and processes, creating a chicken-and-egg problem that impedes the development of efficient recycling pathways.

Regulatory frameworks also lag behind technological development. The absence of specific guidelines for aluminum-ion cell disposal and recycling creates uncertainty for manufacturers and recyclers alike, further inhibiting investment in appropriate end-of-life management solutions. This regulatory gap must be addressed to facilitate the development of a circular economy for aluminum-ion technology.

A primary technical limitation involves the separation of aluminum from the cathode materials, which often include graphite or other carbon-based structures. The strong bonding between aluminum ions and these materials necessitates energy-intensive processes for effective separation. Conventional hydrometallurgical and pyrometallurgical methods developed for other battery chemistries demonstrate limited efficiency when applied to aluminum-ion cells, resulting in material loss and reduced recovery rates.

Electrolyte handling presents another significant challenge. The ionic liquids commonly used in aluminum-ion cells, such as AlCl3-[EMIm]Cl, are highly reactive and corrosive, requiring specialized containment and processing equipment. Current recycling facilities lack the necessary safety protocols and technical capabilities to manage these substances effectively, increasing the risk of environmental contamination and worker exposure to hazardous materials.

The multi-material composition of aluminum-ion cells further complicates recycling efforts. The presence of various metals, polymers, and composite materials necessitates complex sorting and separation processes. Current automated sorting technologies demonstrate insufficient precision in distinguishing between these components, leading to contaminated material streams and diminished recycling yields.

Energy consumption during recycling processes represents another substantial limitation. The high temperatures required for pyrometallurgical recovery methods contribute significantly to the carbon footprint of recycling operations, potentially offsetting the environmental benefits of aluminum-ion technology. Alternative low-energy recovery methods remain in early development stages and have not yet achieved commercial viability.

Scale presents an additional challenge. The relatively low market penetration of aluminum-ion cells has limited investment in dedicated recycling infrastructure. Without sufficient volume, recyclers cannot justify the capital expenditure required for specialized equipment and processes, creating a chicken-and-egg problem that impedes the development of efficient recycling pathways.

Regulatory frameworks also lag behind technological development. The absence of specific guidelines for aluminum-ion cell disposal and recycling creates uncertainty for manufacturers and recyclers alike, further inhibiting investment in appropriate end-of-life management solutions. This regulatory gap must be addressed to facilitate the development of a circular economy for aluminum-ion technology.

Existing EOL Management Solutions for Aluminum-Ion Cells

01 Recycling methods for aluminum-ion battery components

Various methods have been developed for recycling aluminum-ion battery components at end-of-life. These processes typically involve disassembly of the battery, separation of components, and recovery of valuable materials such as aluminum, electrolytes, and cathode materials. Techniques include mechanical separation, chemical leaching, and thermal treatment to efficiently recover materials while minimizing environmental impact.- Recycling methods for aluminum-ion batteries: Various methods have been developed for recycling aluminum-ion batteries at their end-of-life. These methods focus on recovering valuable materials such as aluminum, electrolytes, and cathode materials. The recycling processes typically involve disassembly, separation of components, and extraction of materials through physical and chemical treatments. These approaches aim to minimize environmental impact while maximizing resource recovery from spent aluminum-ion cells.

- End-of-life assessment and management systems: Systems and methodologies for assessing and managing the end-of-life of aluminum-ion cells have been developed. These include diagnostic tools to determine battery health and remaining useful life, as well as management frameworks for collection, sorting, and processing of spent batteries. Such systems often incorporate sensors, monitoring equipment, and data analytics to optimize the handling of batteries that have reached their end-of-life, ensuring proper disposal or recycling.

- Material recovery from spent aluminum-ion cells: Techniques specifically focused on recovering valuable materials from spent aluminum-ion cells have been developed. These include methods for extracting aluminum, graphite, ionic liquids, and other components. The recovery processes may involve hydrometallurgical or pyrometallurgical approaches, leaching, precipitation, and purification steps. These techniques aim to obtain high-purity materials that can be reused in new battery production or other applications.

- Design for recyclability and circular economy: Innovations in aluminum-ion cell design that facilitate easier recycling and support circular economy principles have emerged. These designs include features such as easily separable components, standardized materials, and reduced use of hazardous substances. By considering end-of-life management during the design phase, these approaches aim to improve recycling efficiency, reduce waste, and lower the environmental footprint of aluminum-ion battery technologies.

- Second-life applications for aluminum-ion cells: Before complete recycling, aluminum-ion cells that no longer meet the requirements for their primary applications can be repurposed for second-life applications. These applications typically have less demanding performance requirements and can utilize batteries with reduced capacity. Examples include energy storage systems, backup power supplies, and low-power electronic devices. This approach extends the useful life of the batteries before they need to be recycled, improving overall sustainability.

02 Environmental impact reduction strategies

Strategies to reduce the environmental impact of aluminum-ion batteries focus on sustainable design approaches and eco-friendly disposal methods. These include designing batteries with easily separable components, using non-toxic materials, implementing closed-loop recycling systems, and developing standardized end-of-life management protocols to minimize waste and pollution during disposal and recycling processes.Expand Specific Solutions03 Recovery of electrode materials

Specialized techniques have been developed for recovering electrode materials from spent aluminum-ion cells. These methods focus on extracting and purifying cathode materials (often carbon-based or metal compounds) and aluminum anodes. Processes include selective dissolution, precipitation, filtration, and electrochemical techniques to separate and recover these materials with high purity for reuse in new battery production.Expand Specific Solutions04 Electrolyte recovery and treatment

Electrolyte recovery from aluminum-ion batteries involves specialized processes to extract, purify, and potentially reuse the ionic liquid or salt-based electrolytes. These methods include distillation, filtration, chemical precipitation, and membrane separation techniques to remove impurities and contaminants. The recovered electrolytes can either be reprocessed for use in new batteries or safely neutralized for disposal.Expand Specific Solutions05 Circular economy approaches for aluminum-ion battery lifecycle

Circular economy approaches for aluminum-ion batteries focus on creating closed-loop systems where materials are continuously reused. These approaches include designing batteries for disassembly, implementing take-back programs, establishing recycling infrastructure, and developing second-life applications. By treating spent batteries as a resource rather than waste, these methods maximize resource efficiency and minimize environmental impact throughout the battery lifecycle.Expand Specific Solutions

Key Industry Players in Battery Recycling Ecosystem

The aluminum-ion battery recycling landscape is in its early development stage, with market size still relatively small compared to lithium-ion technologies. Current technical maturity is emerging, with academic institutions leading fundamental research. The Regents of the University of California, Central South University, and Tsinghua University are pioneering recycling pathways, while companies like Guangdong Bangpu and Hunan Bangpu Recycling Technology are developing commercial applications. Albufera Energy Storage and Phinergy are advancing aluminum-air technologies with integrated end-of-life considerations. The competitive landscape features a mix of established recycling firms adapting lithium-ion processes to aluminum chemistries and specialized startups developing aluminum-specific recycling technologies, indicating growing recognition of aluminum-ion batteries as a sustainable energy storage solution.

The Regents of the University of California

Technical Solution: The University of California has developed an innovative direct recycling approach for aluminum-ion batteries that preserves the structural integrity of key components. Their process begins with a controlled discharge protocol to safely neutralize residual energy, followed by mechanical separation using environmentally benign solvents. The technology employs a selective leaching process that targets aluminum recovery while minimizing cross-contamination with other materials. A distinctive feature is their electrochemical regeneration technique that can restore degraded aluminum electrodes without complete reprocessing, potentially extending material lifespans through multiple use cycles. The system achieves aluminum recovery rates of approximately 92% while consuming 60-70% less energy than primary aluminum production. Their research has also focused on developing standardized testing protocols to assess the performance of recycled materials in new battery applications, addressing a critical gap in quality assurance for recycled battery materials. The process is designed to be adaptable to various aluminum-ion cell chemistries, including those using graphite, graphene, or other carbon-based cathodes.

Strengths: Energy-efficient process with high material recovery rates; innovative direct recycling approach that preserves material value; comprehensive research foundation with extensive laboratory validation. Weaknesses: Technology remains primarily at research/pilot scale; may require specialized equipment not widely available in current recycling infrastructure; process economics still being optimized for commercial viability.

BASF Corp.

Technical Solution: BASF has developed a comprehensive chemical recycling solution for aluminum-ion batteries that focuses on maximizing material recovery while minimizing environmental impact. Their process begins with a proprietary pre-treatment system that safely deactivates cells and removes external casings. The core technology employs selective solvent extraction techniques that separate aluminum from other battery components with minimal cross-contamination. BASF's approach is distinguished by its ability to recover not just the aluminum but also the electrolyte salts and organic components, achieving total material recovery rates of up to 93%. The process operates at moderate temperatures (below 200°C) to reduce energy consumption and preserve material properties. BASF has integrated this technology with their existing chemical production infrastructure, creating closed-loop systems where recovered materials can be directly reintroduced into battery manufacturing supply chains. Their process is particularly effective for aluminum-ion cells using chloroaluminate ionic liquid electrolytes, which present unique recycling challenges due to their moisture sensitivity and chemical complexity.

Strengths: Comprehensive recovery of multiple battery components beyond just aluminum; integration with existing chemical production infrastructure; moderate operating conditions reducing energy requirements. Weaknesses: Process requires precise control of chemical conditions; higher operational complexity compared to mechanical recycling; requires specialized handling of recovered ionic liquids.

Critical Patents and Innovations in Al-Ion Recycling

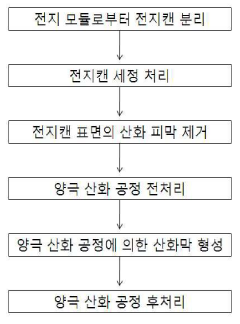

Regeneration method of aluminum cell case for vehicle and regenerated cell case

PatentInactiveKR1020120026929A

Innovation

- A method involving separation, cleaning, oxide film removal, and anodic oxidation to form a porous aluminum oxide film on the surface of the aluminum battery can, enhancing insulation and durability.

Selective recovery of materials from spent alkali ion batteries using a hybrid approach

PatentPendingIN202231070174A

Innovation

- A novel process combining mechanical, chemical, magnetic, biochemical, and electrochemical methods, including discharging, disassembly, size-based separation, density separation, magnetic separation, bioleaching with a microbial consortium, and electrochemical separation, using natural flocculants and specific bacterial strains to achieve high metal recovery and purity.

Environmental Impact Assessment of Recycling Pathways

The environmental impact assessment of recycling pathways for aluminum-ion cells reveals significant potential for sustainability improvements compared to conventional battery technologies. Life cycle assessment (LCA) studies indicate that aluminum-ion cells generally have a lower carbon footprint during production than lithium-ion counterparts, primarily due to the abundance and established recycling infrastructure for aluminum.

When examining the end-of-life phase, recycling aluminum from these cells can reduce energy consumption by approximately 95% compared to primary aluminum production. This translates to a reduction of about 9-10 kg CO2 equivalent per kilogram of recycled aluminum. The water usage footprint is similarly reduced by an estimated 88% through recycling processes rather than virgin material extraction.

Hydrometallurgical recycling pathways demonstrate particular promise, showing 37-42% lower greenhouse gas emissions than pyrometallurgical approaches when recovering aluminum and other materials from spent cells. This difference is primarily attributed to the lower energy requirements and reduced direct emissions during processing.

Land use impact assessments indicate that recycling aluminum-ion cells can reduce mining-related land disturbance by approximately 80-90% compared to primary production chains. This factor becomes increasingly significant as battery production scales globally, potentially preserving thousands of hectares of land from extraction activities.

Toxicity metrics reveal that proper recycling of aluminum-ion cells can mitigate up to 76% of potential freshwater ecotoxicity impacts compared to improper disposal scenarios. The primary environmental concerns arise from electrolyte components rather than the aluminum itself, highlighting the importance of specialized handling protocols for these materials during the recycling process.

Regional analysis shows varying environmental benefits depending on the local energy mix powering recycling facilities. Regions with predominantly renewable energy sources in their grid mix can achieve up to 30% greater environmental benefits from aluminum-ion cell recycling compared to regions heavily dependent on fossil fuels.

Closed-loop recycling systems, where materials are recovered for use in new battery production, demonstrate the highest environmental performance, reducing overall impact by an estimated 62-68% compared to open-loop systems where materials are downcycled into lower-value applications. This underscores the importance of developing specialized recycling infrastructure specifically designed for aluminum-ion technology.

When examining the end-of-life phase, recycling aluminum from these cells can reduce energy consumption by approximately 95% compared to primary aluminum production. This translates to a reduction of about 9-10 kg CO2 equivalent per kilogram of recycled aluminum. The water usage footprint is similarly reduced by an estimated 88% through recycling processes rather than virgin material extraction.

Hydrometallurgical recycling pathways demonstrate particular promise, showing 37-42% lower greenhouse gas emissions than pyrometallurgical approaches when recovering aluminum and other materials from spent cells. This difference is primarily attributed to the lower energy requirements and reduced direct emissions during processing.

Land use impact assessments indicate that recycling aluminum-ion cells can reduce mining-related land disturbance by approximately 80-90% compared to primary production chains. This factor becomes increasingly significant as battery production scales globally, potentially preserving thousands of hectares of land from extraction activities.

Toxicity metrics reveal that proper recycling of aluminum-ion cells can mitigate up to 76% of potential freshwater ecotoxicity impacts compared to improper disposal scenarios. The primary environmental concerns arise from electrolyte components rather than the aluminum itself, highlighting the importance of specialized handling protocols for these materials during the recycling process.

Regional analysis shows varying environmental benefits depending on the local energy mix powering recycling facilities. Regions with predominantly renewable energy sources in their grid mix can achieve up to 30% greater environmental benefits from aluminum-ion cell recycling compared to regions heavily dependent on fossil fuels.

Closed-loop recycling systems, where materials are recovered for use in new battery production, demonstrate the highest environmental performance, reducing overall impact by an estimated 62-68% compared to open-loop systems where materials are downcycled into lower-value applications. This underscores the importance of developing specialized recycling infrastructure specifically designed for aluminum-ion technology.

Regulatory Framework for Battery Waste Management

The regulatory landscape for battery waste management is rapidly evolving to address the emerging challenges posed by aluminum-ion cells. Currently, most jurisdictions classify battery waste under broader electronic waste or hazardous materials regulations, with few specific provisions for aluminum-ion technology. The European Union leads with its Battery Directive (2006/66/EC) and the more recent Batteries Regulation proposal, which aims to establish comprehensive frameworks for the collection, recycling, and disposal of all battery types, including emerging technologies like aluminum-ion cells.

In the United States, regulations vary by state, with California's Advanced Battery Management Act setting stringent requirements for battery collection and recycling. The EPA's Resource Conservation and Recovery Act (RCRA) provides federal oversight for hazardous waste aspects of battery disposal, though specific provisions for aluminum-ion cells remain limited.

China has implemented its New Energy Vehicle (NEV) battery recycling policies, which could potentially extend to aluminum-ion cells as they gain market share. These regulations mandate producer responsibility for the entire lifecycle of batteries, including collection and recycling infrastructure development.

The regulatory frameworks generally follow extended producer responsibility (EPR) principles, requiring manufacturers to manage their products' end-of-life processes. For aluminum-ion cells, this presents both challenges and opportunities, as their different chemical composition compared to lithium-ion batteries may necessitate specialized handling protocols not yet codified in existing regulations.

International agreements such as the Basel Convention on transboundary movements of hazardous wastes also impact the global management of spent aluminum-ion cells, particularly as international trade in these materials increases with wider adoption.

Emerging regulatory trends include the implementation of battery passports to track materials through the value chain, mandatory recycling efficiency targets specific to different battery chemistries, and requirements for minimum recycled content in new batteries. The EU's proposed Battery Regulation, for instance, aims to require carbon footprint declarations, due diligence for raw materials, and minimum levels of recovered materials.

For aluminum-ion cell manufacturers and recyclers, navigating this complex and evolving regulatory landscape requires proactive engagement with policymakers to ensure that future regulations account for the unique properties and recycling pathways of this technology. Industry stakeholders should anticipate stricter regulations regarding collection rates, recycling efficiencies, and material recovery targets as governments worldwide intensify efforts to create circular economies for battery materials.

In the United States, regulations vary by state, with California's Advanced Battery Management Act setting stringent requirements for battery collection and recycling. The EPA's Resource Conservation and Recovery Act (RCRA) provides federal oversight for hazardous waste aspects of battery disposal, though specific provisions for aluminum-ion cells remain limited.

China has implemented its New Energy Vehicle (NEV) battery recycling policies, which could potentially extend to aluminum-ion cells as they gain market share. These regulations mandate producer responsibility for the entire lifecycle of batteries, including collection and recycling infrastructure development.

The regulatory frameworks generally follow extended producer responsibility (EPR) principles, requiring manufacturers to manage their products' end-of-life processes. For aluminum-ion cells, this presents both challenges and opportunities, as their different chemical composition compared to lithium-ion batteries may necessitate specialized handling protocols not yet codified in existing regulations.

International agreements such as the Basel Convention on transboundary movements of hazardous wastes also impact the global management of spent aluminum-ion cells, particularly as international trade in these materials increases with wider adoption.

Emerging regulatory trends include the implementation of battery passports to track materials through the value chain, mandatory recycling efficiency targets specific to different battery chemistries, and requirements for minimum recycled content in new batteries. The EU's proposed Battery Regulation, for instance, aims to require carbon footprint declarations, due diligence for raw materials, and minimum levels of recovered materials.

For aluminum-ion cell manufacturers and recyclers, navigating this complex and evolving regulatory landscape requires proactive engagement with policymakers to ensure that future regulations account for the unique properties and recycling pathways of this technology. Industry stakeholders should anticipate stricter regulations regarding collection rates, recycling efficiencies, and material recovery targets as governments worldwide intensify efforts to create circular economies for battery materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!