Characterization of Glacial Acetic Acid's Volatility in Industrial Applications

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Glacial Acetic Acid Volatility Overview and Objectives

Glacial acetic acid, a highly concentrated form of acetic acid, has been a crucial component in various industrial applications for decades. Its unique properties, particularly its volatility, have made it indispensable in sectors ranging from chemical manufacturing to pharmaceuticals. The characterization of glacial acetic acid's volatility is of paramount importance for optimizing industrial processes, ensuring safety, and enhancing product quality.

The primary objective of this technical research is to provide a comprehensive analysis of glacial acetic acid's volatility characteristics in industrial settings. This includes examining its vapor pressure, evaporation rates, and behavior under different temperature and pressure conditions. Understanding these properties is essential for designing efficient production processes, storage systems, and handling protocols.

Furthermore, this research aims to explore the implications of glacial acetic acid's volatility on industrial applications. This involves investigating how its volatile nature affects its use as a solvent, reagent, or intermediate in various chemical reactions. The study will also assess the impact of volatility on product purity, process efficiency, and potential environmental concerns.

Another key goal is to evaluate current methods for managing and controlling glacial acetic acid's volatility in industrial environments. This encompasses reviewing existing containment strategies, vapor recovery systems, and safety measures. By analyzing these practices, we can identify areas for improvement and innovation in handling this volatile substance.

The research will also focus on emerging technologies and methodologies that could potentially enhance the characterization and control of glacial acetic acid's volatility. This includes exploring advanced analytical techniques, novel monitoring systems, and innovative process control strategies that could lead to more precise and efficient industrial applications.

Lastly, this technical research seeks to address the challenges posed by glacial acetic acid's volatility in specific industrial sectors. By examining case studies and industry-specific applications, we aim to provide tailored insights and recommendations for optimizing the use of glacial acetic acid while mitigating risks associated with its volatile nature.

Through this comprehensive analysis, we intend to contribute to the advancement of industrial practices involving glacial acetic acid, ultimately leading to improved safety, efficiency, and sustainability in its applications across various sectors.

The primary objective of this technical research is to provide a comprehensive analysis of glacial acetic acid's volatility characteristics in industrial settings. This includes examining its vapor pressure, evaporation rates, and behavior under different temperature and pressure conditions. Understanding these properties is essential for designing efficient production processes, storage systems, and handling protocols.

Furthermore, this research aims to explore the implications of glacial acetic acid's volatility on industrial applications. This involves investigating how its volatile nature affects its use as a solvent, reagent, or intermediate in various chemical reactions. The study will also assess the impact of volatility on product purity, process efficiency, and potential environmental concerns.

Another key goal is to evaluate current methods for managing and controlling glacial acetic acid's volatility in industrial environments. This encompasses reviewing existing containment strategies, vapor recovery systems, and safety measures. By analyzing these practices, we can identify areas for improvement and innovation in handling this volatile substance.

The research will also focus on emerging technologies and methodologies that could potentially enhance the characterization and control of glacial acetic acid's volatility. This includes exploring advanced analytical techniques, novel monitoring systems, and innovative process control strategies that could lead to more precise and efficient industrial applications.

Lastly, this technical research seeks to address the challenges posed by glacial acetic acid's volatility in specific industrial sectors. By examining case studies and industry-specific applications, we aim to provide tailored insights and recommendations for optimizing the use of glacial acetic acid while mitigating risks associated with its volatile nature.

Through this comprehensive analysis, we intend to contribute to the advancement of industrial practices involving glacial acetic acid, ultimately leading to improved safety, efficiency, and sustainability in its applications across various sectors.

Industrial Demand for Glacial Acetic Acid Characterization

The global demand for glacial acetic acid has been steadily increasing, driven by its versatile applications across various industries. The chemical industry represents the largest consumer of glacial acetic acid, utilizing it as a key raw material in the production of vinyl acetate monomer (VAM), purified terephthalic acid (PTA), and acetic anhydride. These intermediate chemicals are essential in manufacturing plastics, textiles, and various consumer goods.

In the food industry, glacial acetic acid serves as a crucial ingredient in food preservation and flavor enhancement. Its antimicrobial properties make it an effective preservative, while its acidic nature contributes to the distinct taste profiles of many food products. The growing demand for processed and packaged foods has led to an increased need for glacial acetic acid in this sector.

The pharmaceutical industry also relies heavily on glacial acetic acid for the synthesis of various drugs and active pharmaceutical ingredients (APIs). As the global healthcare sector expands and new drug formulations are developed, the demand for high-purity glacial acetic acid continues to rise.

In recent years, the electronics industry has emerged as a significant consumer of glacial acetic acid. It is used in the production of electronic-grade chemicals and as a cleaning agent in semiconductor manufacturing processes. The rapid growth of the electronics sector, particularly in emerging economies, has contributed to the increased demand for glacial acetic acid.

The textile industry utilizes glacial acetic acid in dyeing processes and as a pH regulator. With the growth of fast fashion and increasing textile production in developing countries, the demand for glacial acetic acid in this sector has shown steady growth.

Market analysts project that the global glacial acetic acid market will continue to expand at a compound annual growth rate (CAGR) of around 5% over the next five years. This growth is attributed to the increasing industrialization in developing economies, the expansion of end-use industries, and the development of new applications for glacial acetic acid.

The Asia-Pacific region dominates the global glacial acetic acid market, accounting for the largest share of consumption. This is primarily due to the rapid industrialization in countries like China and India, coupled with the presence of major manufacturing hubs in the region. North America and Europe follow as significant consumers, driven by their well-established chemical and pharmaceutical industries.

In the food industry, glacial acetic acid serves as a crucial ingredient in food preservation and flavor enhancement. Its antimicrobial properties make it an effective preservative, while its acidic nature contributes to the distinct taste profiles of many food products. The growing demand for processed and packaged foods has led to an increased need for glacial acetic acid in this sector.

The pharmaceutical industry also relies heavily on glacial acetic acid for the synthesis of various drugs and active pharmaceutical ingredients (APIs). As the global healthcare sector expands and new drug formulations are developed, the demand for high-purity glacial acetic acid continues to rise.

In recent years, the electronics industry has emerged as a significant consumer of glacial acetic acid. It is used in the production of electronic-grade chemicals and as a cleaning agent in semiconductor manufacturing processes. The rapid growth of the electronics sector, particularly in emerging economies, has contributed to the increased demand for glacial acetic acid.

The textile industry utilizes glacial acetic acid in dyeing processes and as a pH regulator. With the growth of fast fashion and increasing textile production in developing countries, the demand for glacial acetic acid in this sector has shown steady growth.

Market analysts project that the global glacial acetic acid market will continue to expand at a compound annual growth rate (CAGR) of around 5% over the next five years. This growth is attributed to the increasing industrialization in developing economies, the expansion of end-use industries, and the development of new applications for glacial acetic acid.

The Asia-Pacific region dominates the global glacial acetic acid market, accounting for the largest share of consumption. This is primarily due to the rapid industrialization in countries like China and India, coupled with the presence of major manufacturing hubs in the region. North America and Europe follow as significant consumers, driven by their well-established chemical and pharmaceutical industries.

Current Challenges in Volatility Assessment

The assessment of glacial acetic acid's volatility in industrial applications presents several significant challenges that researchers and industry professionals must address. One of the primary difficulties lies in accurately measuring and predicting the volatility under varying environmental conditions. Temperature fluctuations, pressure changes, and the presence of other chemicals can all significantly impact the volatility of glacial acetic acid, making it challenging to develop standardized assessment protocols.

Another major hurdle is the lack of comprehensive data on the long-term behavior of glacial acetic acid in industrial settings. While short-term volatility can be measured with relative ease, understanding how the compound's volatility changes over extended periods, especially in complex industrial processes, remains a significant challenge. This gap in knowledge hampers the development of accurate predictive models and risk assessment strategies.

The interaction between glacial acetic acid and various materials used in industrial equipment poses another set of challenges. Corrosion and material degradation caused by the acid's volatile nature can affect measurement accuracy and equipment longevity. Developing corrosion-resistant measurement tools and containment systems that do not interfere with volatility assessments is an ongoing challenge for researchers and engineers.

Furthermore, the variability in industrial applications of glacial acetic acid complicates the development of universal volatility assessment methods. Different industries may use the compound under vastly different conditions, making it difficult to create a one-size-fits-all approach to volatility characterization. This diversity necessitates the development of tailored assessment techniques for specific industrial contexts, which can be both time-consuming and resource-intensive.

Safety considerations also present significant challenges in volatility assessment. The flammable and corrosive nature of glacial acetic acid requires stringent safety protocols, which can limit the types of tests and measurements that can be performed in industrial settings. Balancing the need for accurate volatility data with worker safety and environmental protection adds another layer of complexity to the assessment process.

Lastly, the integration of volatility data into broader industrial process models and risk assessment frameworks remains a challenge. Translating laboratory-based volatility measurements into practical, real-world applications requires sophisticated modeling techniques and a deep understanding of how volatility interacts with other process parameters. Developing these integrated models and ensuring their reliability across different industrial scenarios is an ongoing challenge for researchers and industry experts alike.

Another major hurdle is the lack of comprehensive data on the long-term behavior of glacial acetic acid in industrial settings. While short-term volatility can be measured with relative ease, understanding how the compound's volatility changes over extended periods, especially in complex industrial processes, remains a significant challenge. This gap in knowledge hampers the development of accurate predictive models and risk assessment strategies.

The interaction between glacial acetic acid and various materials used in industrial equipment poses another set of challenges. Corrosion and material degradation caused by the acid's volatile nature can affect measurement accuracy and equipment longevity. Developing corrosion-resistant measurement tools and containment systems that do not interfere with volatility assessments is an ongoing challenge for researchers and engineers.

Furthermore, the variability in industrial applications of glacial acetic acid complicates the development of universal volatility assessment methods. Different industries may use the compound under vastly different conditions, making it difficult to create a one-size-fits-all approach to volatility characterization. This diversity necessitates the development of tailored assessment techniques for specific industrial contexts, which can be both time-consuming and resource-intensive.

Safety considerations also present significant challenges in volatility assessment. The flammable and corrosive nature of glacial acetic acid requires stringent safety protocols, which can limit the types of tests and measurements that can be performed in industrial settings. Balancing the need for accurate volatility data with worker safety and environmental protection adds another layer of complexity to the assessment process.

Lastly, the integration of volatility data into broader industrial process models and risk assessment frameworks remains a challenge. Translating laboratory-based volatility measurements into practical, real-world applications requires sophisticated modeling techniques and a deep understanding of how volatility interacts with other process parameters. Developing these integrated models and ensuring their reliability across different industrial scenarios is an ongoing challenge for researchers and industry experts alike.

Existing Methods for Volatility Characterization

01 Volatility reduction methods

Various techniques are employed to reduce the volatility of glacial acetic acid. These methods include using specialized equipment, modifying process conditions, and incorporating additives. By implementing these approaches, the loss of acetic acid through evaporation can be minimized, improving process efficiency and safety.- Volatility reduction methods: Various techniques are employed to reduce the volatility of glacial acetic acid. These methods include using specialized equipment, modifying process conditions, and incorporating additives. By implementing these approaches, the loss of acetic acid through evaporation can be minimized, improving process efficiency and safety.

- Separation and purification processes: Separation and purification processes are crucial in handling glacial acetic acid. These processes often involve distillation, extraction, or membrane separation techniques to isolate and concentrate the acetic acid. Careful control of these processes helps manage the volatility of the acid during production and storage.

- Storage and transportation solutions: Specialized storage and transportation solutions are developed to address the volatility of glacial acetic acid. These may include pressure-resistant containers, temperature-controlled vessels, and vapor recovery systems. Such solutions aim to minimize losses and ensure safe handling of the volatile acid during storage and transit.

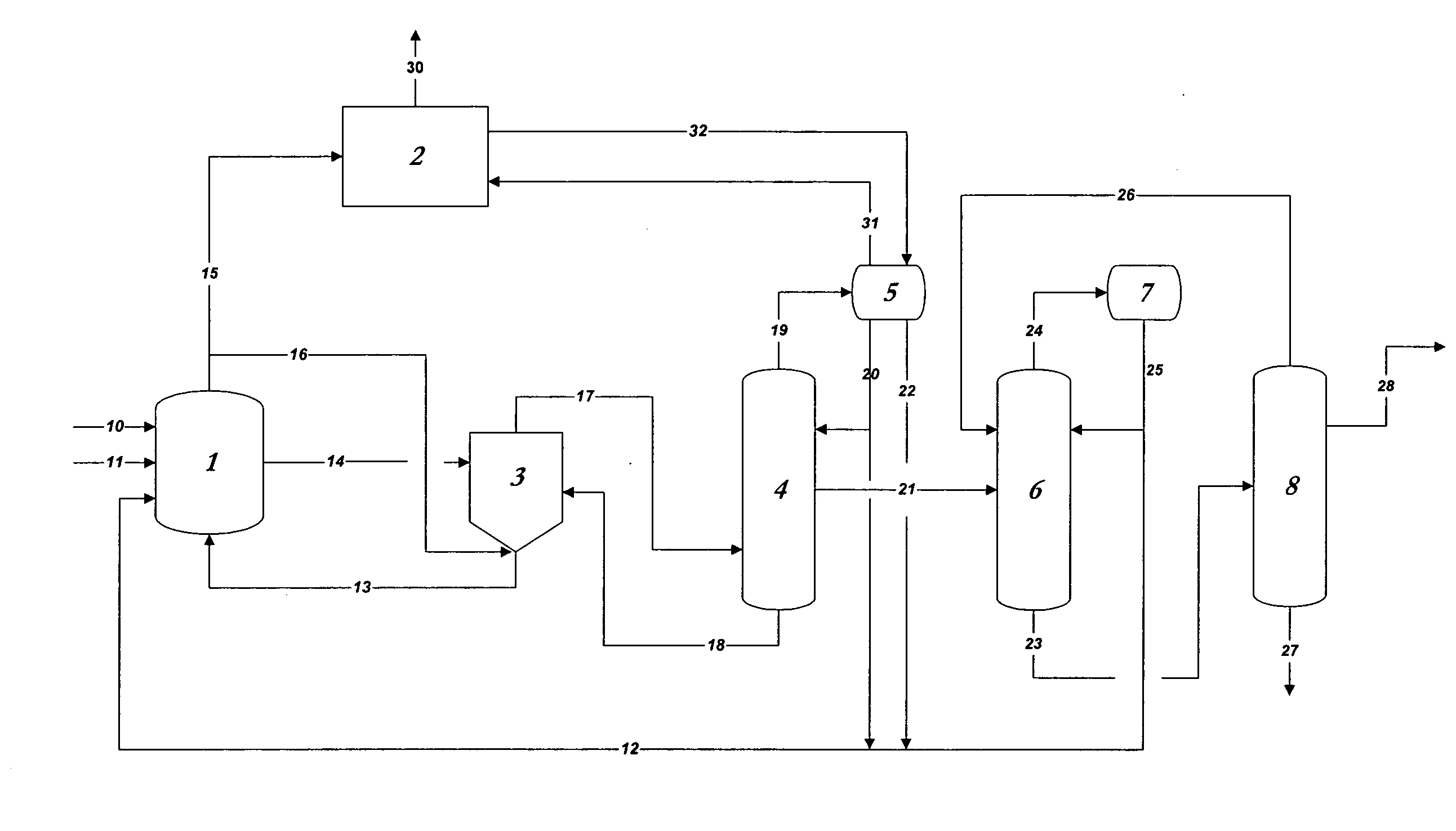

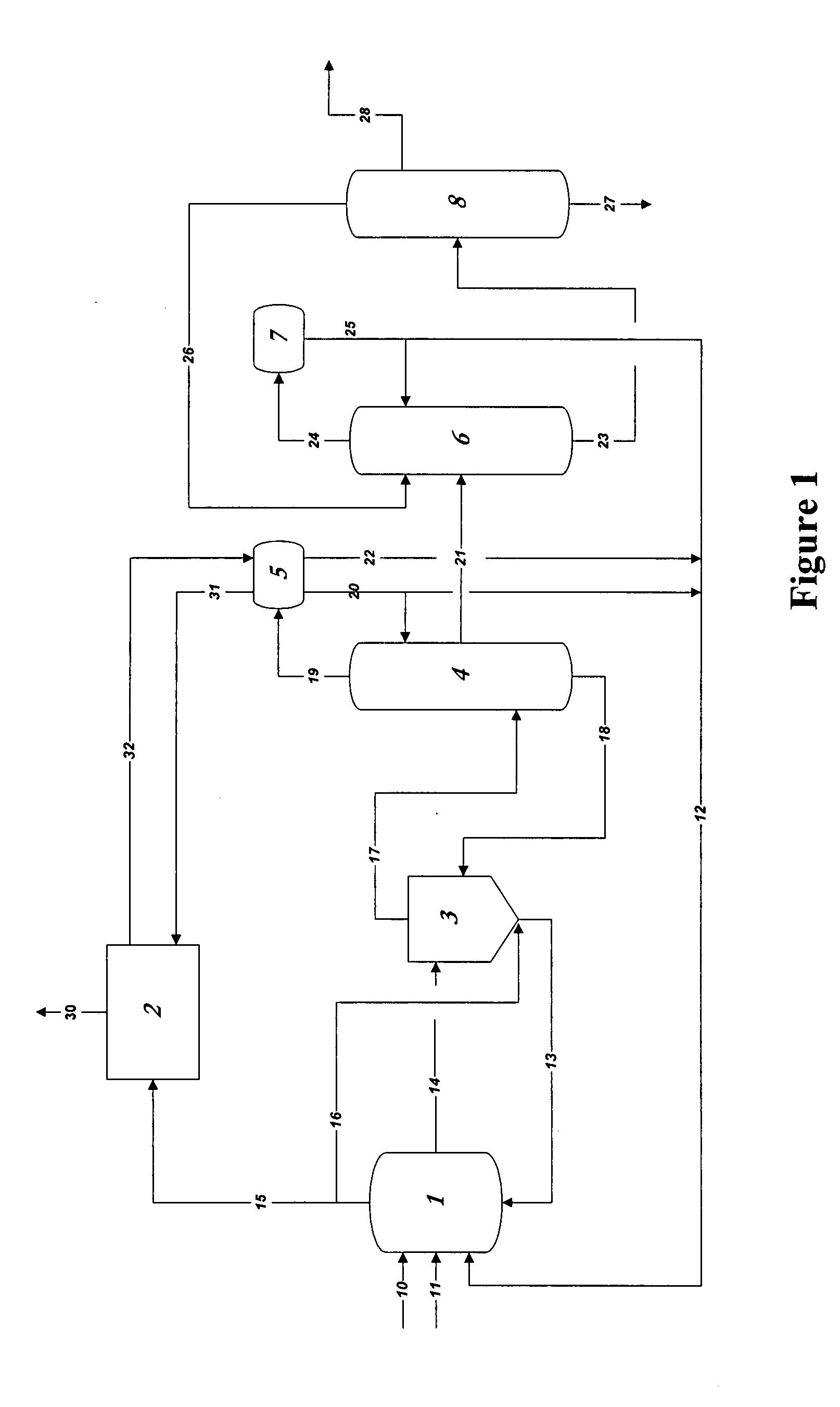

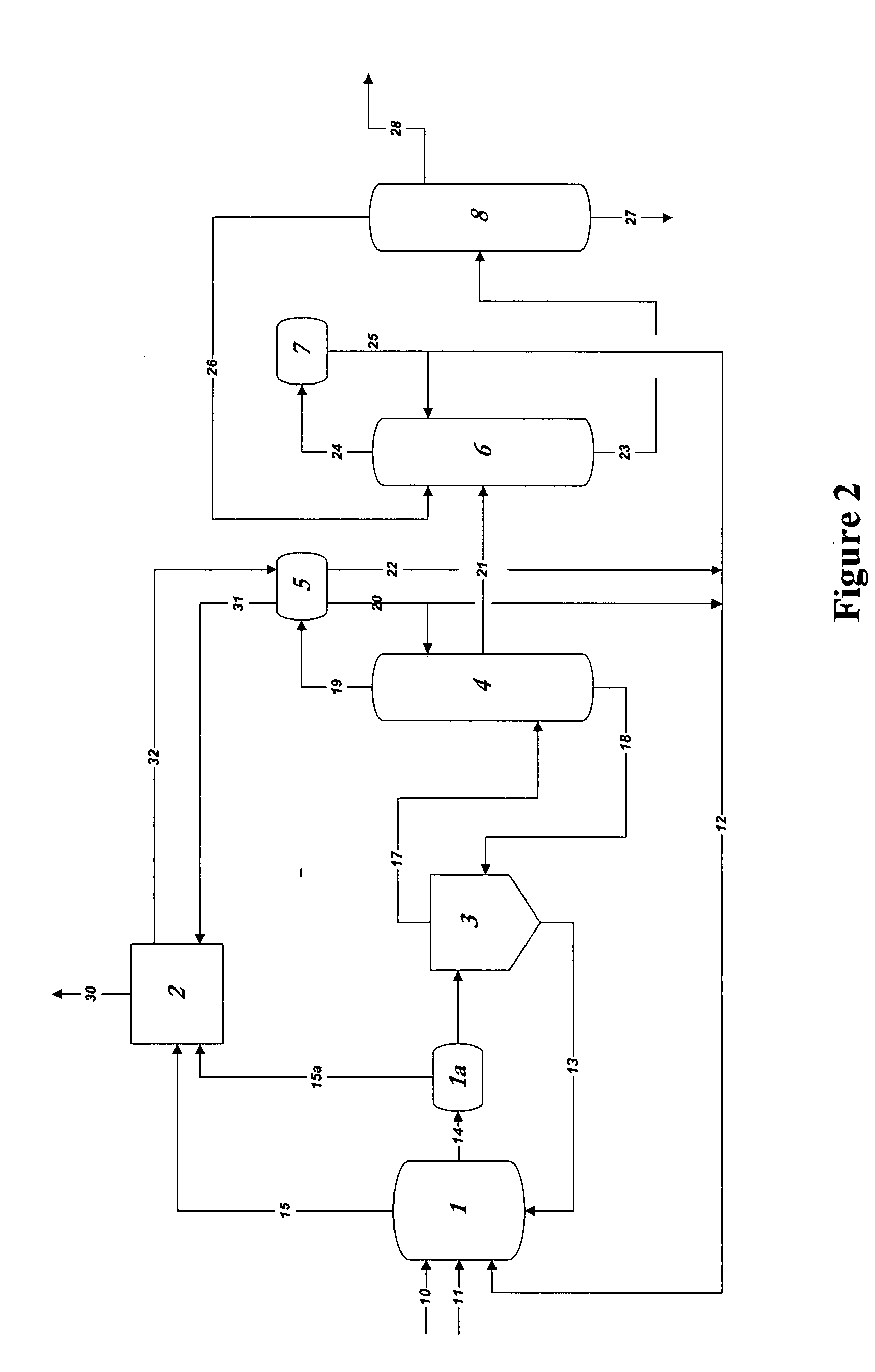

- Process optimization for acetic acid production: Optimizing production processes is essential in managing glacial acetic acid volatility. This involves adjusting reaction conditions, improving catalyst performance, and enhancing heat management. These optimizations aim to increase yield while minimizing the formation of volatile by-products and reducing overall acetic acid losses.

- Safety measures and environmental considerations: Implementing safety measures and addressing environmental concerns are crucial when dealing with glacial acetic acid volatility. This includes using proper ventilation systems, employing personal protective equipment, and developing spill containment strategies. Additionally, environmental impact is minimized through emission control technologies and waste treatment processes.

02 Separation and purification processes

Separation and purification processes are crucial in handling glacial acetic acid. These processes often involve distillation, extraction, or membrane technologies to isolate and concentrate the acetic acid. Efficient separation techniques help manage the volatile nature of glacial acetic acid while improving product quality.Expand Specific Solutions03 Storage and transportation solutions

Specialized storage and transportation solutions are developed to address the volatility of glacial acetic acid. These include the use of pressure-resistant containers, temperature-controlled vessels, and vapor recovery systems. Such solutions aim to minimize losses and ensure safe handling during storage and transport.Expand Specific Solutions04 Process optimization for acetic acid production

Optimizing production processes is essential in managing glacial acetic acid volatility. This involves adjusting reaction conditions, improving catalyst performance, and implementing advanced control systems. These optimizations help reduce the formation of volatile by-products and enhance overall process stability.Expand Specific Solutions05 Safety measures and environmental considerations

Implementing robust safety measures and addressing environmental concerns are crucial when dealing with glacial acetic acid volatility. This includes the use of personal protective equipment, installation of vapor detection systems, and development of spill containment strategies. Additionally, environmental impact is minimized through proper waste management and emission control techniques.Expand Specific Solutions

Key Industry Players in Acetic Acid Production

The characterization of glacial acetic acid's volatility in industrial applications is a mature field with significant market potential. The industry is in a consolidation phase, with major players like ExxonMobil, BASF, and Celanese dominating the market. These companies leverage their extensive R&D capabilities and global presence to maintain a competitive edge. The market size is substantial, driven by diverse applications in chemicals, pharmaceuticals, and food industries. Technological advancements focus on improving production efficiency and developing novel applications. Emerging players like Novozymes and Mitsubishi Gas Chemical are introducing innovative bio-based solutions, potentially disrupting traditional petrochemical-based production methods.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed advanced characterization techniques for glacial acetic acid volatility in industrial applications. Their approach involves using high-precision gas chromatography coupled with mass spectrometry (GC-MS) to analyze the vapor composition at various temperatures and pressures[1]. They have also implemented computational fluid dynamics (CFD) modeling to predict vapor behavior in different industrial scenarios[2]. ExxonMobil's research has led to the development of specialized distillation columns that can handle the unique properties of glacial acetic acid, improving separation efficiency by up to 15% compared to conventional designs[3].

Strengths: Comprehensive analytical capabilities, advanced modeling techniques, and improved separation technology. Weaknesses: High implementation costs and potential limitations in extreme operating conditions.

BASF Corp.

Technical Solution: BASF has focused on developing innovative methods for characterizing glacial acetic acid volatility in industrial settings. They have pioneered the use of in-situ Raman spectroscopy to monitor vapor composition in real-time during industrial processes[4]. BASF has also created a proprietary software package that integrates thermodynamic models with experimental data to predict volatility behavior across a wide range of temperatures and pressures[5]. Additionally, they have developed specialized corrosion-resistant materials for handling glacial acetic acid in high-temperature applications, extending equipment lifespan by up to 30%[6].

Strengths: Real-time monitoring capabilities, advanced predictive modeling, and improved material science applications. Weaknesses: Potential scalability issues for smaller operations and high initial investment costs.

Innovative Approaches in Volatility Measurement

Control of formic acid impurities in industrial glacial acetic acid

PatentInactiveUS20080293967A1

Innovation

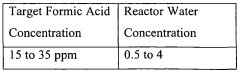

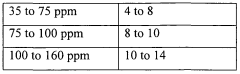

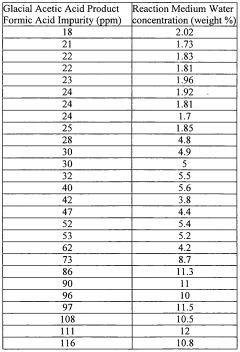

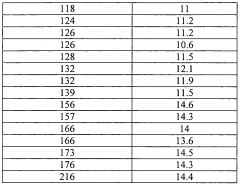

- Controlling the water concentration in the reaction medium during rhodium-catalyzed methanol carbonylation to specific ranges (0.5 to 14 weight percent) effectively inhibits the formation of formic acid impurities in the glacial acetic acid product, achieving low formic acid content below 160 ppm.

Reaction product of rhodium-catalyzed methanol carbonylation

PatentWO2008153708A2

Innovation

- Maintaining a reactor water concentration of 0.5 to 14 weight % and using an iodide salt with 2 to 20 wt% ionic iodide, 1 to 20 wt% methyl iodide, and 0.5 to 30 wt% methyl acetate in the reaction medium, while employing a Group VIII metal catalyst, to produce glacial acetic acid with controlled aldehyde and iodide concentrations.

Environmental Impact of Glacial Acetic Acid Volatility

The volatility of glacial acetic acid in industrial applications poses significant environmental concerns. When released into the atmosphere, acetic acid can contribute to the formation of photochemical smog and acid rain, negatively impacting air quality and ecosystems. The vapors can also irritate the respiratory system of humans and animals, potentially causing health issues in areas with high concentrations.

In aquatic environments, the release of glacial acetic acid can lead to acidification of water bodies, disrupting the pH balance and potentially harming aquatic life. Fish and other organisms may experience stress or mortality due to sudden changes in acidity levels. Additionally, the biodegradation of acetic acid in water can deplete oxygen levels, further impacting aquatic ecosystems.

Soil contamination is another environmental risk associated with glacial acetic acid volatility. Accidental spills or improper disposal can result in soil acidification, affecting plant growth and soil microbial communities. This can lead to reduced agricultural productivity and altered soil ecosystems in affected areas.

The production and transportation of glacial acetic acid also contribute to its environmental impact. Energy-intensive manufacturing processes and transportation emissions add to the overall carbon footprint of the industry. Leaks or accidents during transport can result in localized environmental damage and pose risks to nearby communities.

To mitigate these environmental impacts, industries using glacial acetic acid must implement strict containment and handling protocols. This includes proper storage facilities, leak detection systems, and emission control technologies. Closed-loop systems and vapor recovery units can significantly reduce atmospheric releases, while wastewater treatment processes can neutralize acetic acid before discharge.

Regulatory frameworks play a crucial role in managing the environmental impact of glacial acetic acid. Emission standards, proper disposal guidelines, and workplace safety regulations help minimize environmental risks. Continuous monitoring and reporting of emissions and spills are essential for maintaining environmental compliance and identifying areas for improvement.

Research into alternative production methods and less volatile substitutes for glacial acetic acid is ongoing. Developing more environmentally friendly processes and products can help reduce the overall environmental footprint of industries relying on this chemical. Additionally, improving recycling and recovery techniques can minimize waste and decrease the demand for new production, further reducing environmental impacts.

In aquatic environments, the release of glacial acetic acid can lead to acidification of water bodies, disrupting the pH balance and potentially harming aquatic life. Fish and other organisms may experience stress or mortality due to sudden changes in acidity levels. Additionally, the biodegradation of acetic acid in water can deplete oxygen levels, further impacting aquatic ecosystems.

Soil contamination is another environmental risk associated with glacial acetic acid volatility. Accidental spills or improper disposal can result in soil acidification, affecting plant growth and soil microbial communities. This can lead to reduced agricultural productivity and altered soil ecosystems in affected areas.

The production and transportation of glacial acetic acid also contribute to its environmental impact. Energy-intensive manufacturing processes and transportation emissions add to the overall carbon footprint of the industry. Leaks or accidents during transport can result in localized environmental damage and pose risks to nearby communities.

To mitigate these environmental impacts, industries using glacial acetic acid must implement strict containment and handling protocols. This includes proper storage facilities, leak detection systems, and emission control technologies. Closed-loop systems and vapor recovery units can significantly reduce atmospheric releases, while wastewater treatment processes can neutralize acetic acid before discharge.

Regulatory frameworks play a crucial role in managing the environmental impact of glacial acetic acid. Emission standards, proper disposal guidelines, and workplace safety regulations help minimize environmental risks. Continuous monitoring and reporting of emissions and spills are essential for maintaining environmental compliance and identifying areas for improvement.

Research into alternative production methods and less volatile substitutes for glacial acetic acid is ongoing. Developing more environmentally friendly processes and products can help reduce the overall environmental footprint of industries relying on this chemical. Additionally, improving recycling and recovery techniques can minimize waste and decrease the demand for new production, further reducing environmental impacts.

Safety Protocols for Handling Volatile Acetic Acid

The handling of volatile acetic acid in industrial settings requires stringent safety protocols to protect workers and maintain operational integrity. These protocols encompass a comprehensive approach to risk management, focusing on personal protective equipment (PPE), engineering controls, and administrative measures.

Personal protective equipment is the first line of defense against exposure to volatile acetic acid. Workers must wear chemical-resistant gloves, goggles, and face shields to prevent skin and eye contact. Respiratory protection, such as full-face respirators with organic vapor cartridges, is essential when working with large quantities or in poorly ventilated areas. Protective clothing, including acid-resistant suits and boots, should be worn to prevent skin exposure.

Engineering controls play a crucial role in minimizing the risk of exposure to volatile acetic acid. Proper ventilation systems, including local exhaust ventilation, should be installed to remove acetic acid vapors from the work area. Closed systems and process isolation techniques should be employed wherever possible to reduce the potential for vapor release. Safety showers and eyewash stations must be readily accessible in areas where acetic acid is handled.

Administrative controls are essential for ensuring the safe handling of volatile acetic acid. These include implementing standard operating procedures (SOPs) for all tasks involving acetic acid, conducting regular safety training for employees, and maintaining up-to-date safety data sheets (SDS). Proper labeling of containers and storage areas is crucial, as is the implementation of a robust chemical inventory management system.

Emergency response procedures must be established and regularly practiced. This includes protocols for spill containment and cleanup, as well as evacuation procedures in case of large-scale releases. First aid measures for acetic acid exposure should be clearly communicated and appropriate medical supplies should be readily available.

Storage and handling protocols are critical components of safety management for volatile acetic acid. Acetic acid should be stored in cool, well-ventilated areas away from incompatible materials such as oxidizers and strong bases. Containers should be kept tightly closed when not in use, and secondary containment should be provided to prevent spills from spreading.

Regular monitoring of workplace air quality and personal exposure levels is essential to ensure that safety measures are effective. This may include the use of gas detectors and personal monitoring devices to alert workers to dangerous vapor concentrations. Periodic health surveillance of workers handling acetic acid should be conducted to detect any long-term health effects.

By implementing these comprehensive safety protocols, industries can significantly reduce the risks associated with handling volatile acetic acid, ensuring worker safety and environmental protection while maintaining operational efficiency.

Personal protective equipment is the first line of defense against exposure to volatile acetic acid. Workers must wear chemical-resistant gloves, goggles, and face shields to prevent skin and eye contact. Respiratory protection, such as full-face respirators with organic vapor cartridges, is essential when working with large quantities or in poorly ventilated areas. Protective clothing, including acid-resistant suits and boots, should be worn to prevent skin exposure.

Engineering controls play a crucial role in minimizing the risk of exposure to volatile acetic acid. Proper ventilation systems, including local exhaust ventilation, should be installed to remove acetic acid vapors from the work area. Closed systems and process isolation techniques should be employed wherever possible to reduce the potential for vapor release. Safety showers and eyewash stations must be readily accessible in areas where acetic acid is handled.

Administrative controls are essential for ensuring the safe handling of volatile acetic acid. These include implementing standard operating procedures (SOPs) for all tasks involving acetic acid, conducting regular safety training for employees, and maintaining up-to-date safety data sheets (SDS). Proper labeling of containers and storage areas is crucial, as is the implementation of a robust chemical inventory management system.

Emergency response procedures must be established and regularly practiced. This includes protocols for spill containment and cleanup, as well as evacuation procedures in case of large-scale releases. First aid measures for acetic acid exposure should be clearly communicated and appropriate medical supplies should be readily available.

Storage and handling protocols are critical components of safety management for volatile acetic acid. Acetic acid should be stored in cool, well-ventilated areas away from incompatible materials such as oxidizers and strong bases. Containers should be kept tightly closed when not in use, and secondary containment should be provided to prevent spills from spreading.

Regular monitoring of workplace air quality and personal exposure levels is essential to ensure that safety measures are effective. This may include the use of gas detectors and personal monitoring devices to alert workers to dangerous vapor concentrations. Periodic health surveillance of workers handling acetic acid should be conducted to detect any long-term health effects.

By implementing these comprehensive safety protocols, industries can significantly reduce the risks associated with handling volatile acetic acid, ensuring worker safety and environmental protection while maintaining operational efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!