Glacial Acetic Acid Techniques in Enhancing Ceramic Coatings

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GAA Ceramic Coating Evolution and Objectives

Glacial Acetic Acid (GAA) techniques in ceramic coating enhancement have evolved significantly over the past decades, driven by the increasing demand for high-performance and durable ceramic materials across various industries. The journey of GAA in ceramic coatings began in the mid-20th century when researchers first recognized its potential to modify ceramic surfaces and improve their properties.

Initially, GAA was primarily used as a cleaning agent for ceramic substrates, preparing them for subsequent coating processes. However, as understanding of its chemical interactions with ceramic materials deepened, scientists began exploring its potential as an active component in coating formulations. This shift marked the beginning of a new era in ceramic coating technology.

The evolution of GAA techniques in ceramic coatings has been characterized by several key milestones. In the 1970s, researchers discovered that GAA could be used to create microporous structures on ceramic surfaces, enhancing their adhesion properties. This breakthrough led to the development of more durable and long-lasting ceramic coatings.

By the 1990s, GAA had become an integral part of sol-gel processes for ceramic coating production. Its ability to control the hydrolysis and condensation reactions in sol-gel synthesis allowed for precise manipulation of coating properties, including thickness, porosity, and chemical composition.

In recent years, the focus has shifted towards leveraging GAA's unique properties to address specific challenges in ceramic coating technology. These include improving corrosion resistance, enhancing thermal barrier properties, and developing self-healing coatings. The advent of nanotechnology has further expanded the possibilities, with GAA playing a crucial role in the synthesis of nanostructured ceramic coatings.

The primary objectives of current GAA research in ceramic coatings are multifaceted. Firstly, there is a strong emphasis on developing environmentally friendly and sustainable coating processes that minimize the use of harmful chemicals while maintaining or improving coating performance. Secondly, researchers are working towards enhancing the multifunctionality of ceramic coatings, aiming to create surfaces that simultaneously offer properties such as self-cleaning, anti-fouling, and wear resistance.

Another key objective is to improve the scalability and cost-effectiveness of GAA-based ceramic coating techniques. This involves optimizing process parameters, exploring new application methods, and developing novel formulations that can be easily integrated into existing manufacturing processes.

Looking ahead, the future of GAA in ceramic coatings is likely to focus on smart and responsive coatings that can adapt to changing environmental conditions. This may include the development of coatings with self-healing capabilities or those that can change their properties in response to external stimuli. Additionally, there is growing interest in combining GAA techniques with other advanced technologies, such as plasma treatment or laser processing, to create hybrid coating systems with superior performance characteristics.

Initially, GAA was primarily used as a cleaning agent for ceramic substrates, preparing them for subsequent coating processes. However, as understanding of its chemical interactions with ceramic materials deepened, scientists began exploring its potential as an active component in coating formulations. This shift marked the beginning of a new era in ceramic coating technology.

The evolution of GAA techniques in ceramic coatings has been characterized by several key milestones. In the 1970s, researchers discovered that GAA could be used to create microporous structures on ceramic surfaces, enhancing their adhesion properties. This breakthrough led to the development of more durable and long-lasting ceramic coatings.

By the 1990s, GAA had become an integral part of sol-gel processes for ceramic coating production. Its ability to control the hydrolysis and condensation reactions in sol-gel synthesis allowed for precise manipulation of coating properties, including thickness, porosity, and chemical composition.

In recent years, the focus has shifted towards leveraging GAA's unique properties to address specific challenges in ceramic coating technology. These include improving corrosion resistance, enhancing thermal barrier properties, and developing self-healing coatings. The advent of nanotechnology has further expanded the possibilities, with GAA playing a crucial role in the synthesis of nanostructured ceramic coatings.

The primary objectives of current GAA research in ceramic coatings are multifaceted. Firstly, there is a strong emphasis on developing environmentally friendly and sustainable coating processes that minimize the use of harmful chemicals while maintaining or improving coating performance. Secondly, researchers are working towards enhancing the multifunctionality of ceramic coatings, aiming to create surfaces that simultaneously offer properties such as self-cleaning, anti-fouling, and wear resistance.

Another key objective is to improve the scalability and cost-effectiveness of GAA-based ceramic coating techniques. This involves optimizing process parameters, exploring new application methods, and developing novel formulations that can be easily integrated into existing manufacturing processes.

Looking ahead, the future of GAA in ceramic coatings is likely to focus on smart and responsive coatings that can adapt to changing environmental conditions. This may include the development of coatings with self-healing capabilities or those that can change their properties in response to external stimuli. Additionally, there is growing interest in combining GAA techniques with other advanced technologies, such as plasma treatment or laser processing, to create hybrid coating systems with superior performance characteristics.

Market Analysis for GAA-Enhanced Ceramics

The market for Glacial Acetic Acid (GAA) enhanced ceramic coatings is experiencing significant growth, driven by the increasing demand for high-performance materials in various industries. The global ceramic coatings market, which includes GAA-enhanced products, is projected to reach a substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many other industrial sectors.

The automotive industry represents a major market for GAA-enhanced ceramic coatings, particularly in the production of engine components and exhaust systems. These coatings offer superior resistance to high temperatures, corrosion, and wear, extending the lifespan of critical parts and improving overall vehicle performance. As automotive manufacturers continue to focus on lightweight and durable materials, the demand for advanced ceramic coatings is expected to rise.

In the aerospace sector, GAA-enhanced ceramic coatings are gaining traction for their ability to protect aircraft components from extreme conditions. The growing emphasis on fuel efficiency and reduced emissions in aviation is driving the adoption of these coatings, as they can improve engine performance and reduce maintenance requirements.

The electronics industry is another key market for GAA-enhanced ceramic coatings. With the miniaturization of electronic devices and the need for better thermal management, these coatings are being increasingly used in semiconductor manufacturing and electronic packaging. The rapid growth of 5G technology and the Internet of Things (IoT) is further fueling demand in this sector.

In the energy sector, GAA-enhanced ceramic coatings are finding applications in solar panels, wind turbines, and fuel cells. These coatings can improve the efficiency and durability of renewable energy technologies, contributing to the global shift towards sustainable energy sources.

The medical industry is also emerging as a promising market for GAA-enhanced ceramic coatings. Their biocompatibility and resistance to wear make them suitable for use in medical implants and surgical instruments. As the global population ages and the demand for advanced medical devices grows, this market segment is expected to expand significantly.

Geographically, Asia-Pacific is anticipated to be the fastest-growing market for GAA-enhanced ceramic coatings, driven by rapid industrialization, increasing automotive production, and growing electronics manufacturing in countries like China, Japan, and South Korea. North America and Europe are also significant markets, with strong demand from aerospace and advanced manufacturing sectors.

The automotive industry represents a major market for GAA-enhanced ceramic coatings, particularly in the production of engine components and exhaust systems. These coatings offer superior resistance to high temperatures, corrosion, and wear, extending the lifespan of critical parts and improving overall vehicle performance. As automotive manufacturers continue to focus on lightweight and durable materials, the demand for advanced ceramic coatings is expected to rise.

In the aerospace sector, GAA-enhanced ceramic coatings are gaining traction for their ability to protect aircraft components from extreme conditions. The growing emphasis on fuel efficiency and reduced emissions in aviation is driving the adoption of these coatings, as they can improve engine performance and reduce maintenance requirements.

The electronics industry is another key market for GAA-enhanced ceramic coatings. With the miniaturization of electronic devices and the need for better thermal management, these coatings are being increasingly used in semiconductor manufacturing and electronic packaging. The rapid growth of 5G technology and the Internet of Things (IoT) is further fueling demand in this sector.

In the energy sector, GAA-enhanced ceramic coatings are finding applications in solar panels, wind turbines, and fuel cells. These coatings can improve the efficiency and durability of renewable energy technologies, contributing to the global shift towards sustainable energy sources.

The medical industry is also emerging as a promising market for GAA-enhanced ceramic coatings. Their biocompatibility and resistance to wear make them suitable for use in medical implants and surgical instruments. As the global population ages and the demand for advanced medical devices grows, this market segment is expected to expand significantly.

Geographically, Asia-Pacific is anticipated to be the fastest-growing market for GAA-enhanced ceramic coatings, driven by rapid industrialization, increasing automotive production, and growing electronics manufacturing in countries like China, Japan, and South Korea. North America and Europe are also significant markets, with strong demand from aerospace and advanced manufacturing sectors.

Technical Challenges in GAA Ceramic Coating

The application of Glacial Acetic Acid (GAA) in ceramic coating processes presents several technical challenges that researchers and manufacturers must address. One of the primary difficulties lies in controlling the reaction rate between GAA and the ceramic substrate. The highly corrosive nature of GAA can lead to uneven etching or over-etching of the ceramic surface, resulting in inconsistent coating thickness and quality. This issue is particularly pronounced when dealing with complex geometries or large surface areas.

Another significant challenge is maintaining the stability of the GAA solution during the coating process. Environmental factors such as temperature and humidity can affect the concentration and reactivity of the acid, leading to variations in coating performance. Ensuring a consistent and controlled application environment is crucial but often difficult to achieve in industrial settings.

The porosity of ceramic materials poses an additional hurdle in GAA-based coating techniques. The acid may penetrate deep into the ceramic structure, potentially weakening the material or creating undesirable subsurface reactions. Developing methods to limit acid penetration while still achieving the desired surface modification is an ongoing area of research and development.

Safety concerns also present technical challenges in GAA ceramic coating processes. The volatile and corrosive nature of GAA requires specialized handling equipment and stringent safety protocols. Designing efficient and safe production systems that minimize worker exposure while maintaining coating quality is a complex engineering task.

Furthermore, the disposal and environmental impact of GAA waste products from ceramic coating processes pose significant technical and regulatory challenges. Developing closed-loop systems or effective neutralization techniques to mitigate environmental risks is essential but technically demanding.

Achieving uniform coating thickness across varied ceramic surfaces remains a persistent challenge. The reactivity of GAA can lead to preferential etching or coating in certain areas, resulting in non-uniform surface properties. Advanced application techniques and precise control mechanisms are needed to ensure consistent coating distribution.

Lastly, the long-term stability and durability of GAA-enhanced ceramic coatings under various environmental conditions and stresses present ongoing technical challenges. Researchers must develop accelerated testing methods and predictive models to assess coating performance over extended periods, considering factors such as thermal cycling, chemical exposure, and mechanical stress.

Another significant challenge is maintaining the stability of the GAA solution during the coating process. Environmental factors such as temperature and humidity can affect the concentration and reactivity of the acid, leading to variations in coating performance. Ensuring a consistent and controlled application environment is crucial but often difficult to achieve in industrial settings.

The porosity of ceramic materials poses an additional hurdle in GAA-based coating techniques. The acid may penetrate deep into the ceramic structure, potentially weakening the material or creating undesirable subsurface reactions. Developing methods to limit acid penetration while still achieving the desired surface modification is an ongoing area of research and development.

Safety concerns also present technical challenges in GAA ceramic coating processes. The volatile and corrosive nature of GAA requires specialized handling equipment and stringent safety protocols. Designing efficient and safe production systems that minimize worker exposure while maintaining coating quality is a complex engineering task.

Furthermore, the disposal and environmental impact of GAA waste products from ceramic coating processes pose significant technical and regulatory challenges. Developing closed-loop systems or effective neutralization techniques to mitigate environmental risks is essential but technically demanding.

Achieving uniform coating thickness across varied ceramic surfaces remains a persistent challenge. The reactivity of GAA can lead to preferential etching or coating in certain areas, resulting in non-uniform surface properties. Advanced application techniques and precise control mechanisms are needed to ensure consistent coating distribution.

Lastly, the long-term stability and durability of GAA-enhanced ceramic coatings under various environmental conditions and stresses present ongoing technical challenges. Researchers must develop accelerated testing methods and predictive models to assess coating performance over extended periods, considering factors such as thermal cycling, chemical exposure, and mechanical stress.

Current GAA Ceramic Coating Methodologies

01 Synthesis of acetic acid using ceramic catalysts

Ceramic catalysts are used in the synthesis of acetic acid. These catalysts, often containing metal oxides, facilitate the conversion of precursors into acetic acid under specific reaction conditions. The use of ceramic catalysts can improve the efficiency and selectivity of acetic acid production.- Synthesis of acetic acid using ceramic catalysts: Ceramic catalysts are used in the synthesis of acetic acid. These catalysts, often containing metal oxides, facilitate the conversion of precursors into acetic acid under specific reaction conditions. The use of ceramic catalysts can improve the efficiency and selectivity of acetic acid production.

- Ceramic coatings for acetic acid production equipment: Ceramic coatings are applied to equipment used in acetic acid production to protect against corrosion and improve durability. These coatings can withstand the harsh acidic environment and high temperatures associated with acetic acid manufacturing processes, extending the lifespan of the equipment and reducing maintenance costs.

- Ceramic membranes for acetic acid purification: Ceramic membranes are utilized in the purification of acetic acid. These membranes can effectively separate acetic acid from other components in the mixture, such as water or impurities. The use of ceramic membranes can improve the purity of the final product and enhance the overall efficiency of the purification process.

- Ceramic-based sensors for acetic acid detection: Ceramic materials are used in the development of sensors for detecting and measuring acetic acid concentrations. These sensors can be employed in various applications, including quality control in acetic acid production, environmental monitoring, and industrial process control. The ceramic-based sensors offer high sensitivity and stability in acidic environments.

- Ceramic composites for acetic acid storage and transportation: Ceramic composites are developed for use in storage tanks and transportation containers for acetic acid. These materials offer excellent chemical resistance to acetic acid, preventing corrosion and contamination. The use of ceramic composites can improve the safety and reliability of acetic acid storage and transportation systems.

02 Ceramic coatings for corrosion protection in acetic acid environments

Ceramic coatings are applied to various substrates to provide protection against corrosion in acetic acid environments. These coatings are typically composed of oxide ceramics or other inert materials that resist chemical attack from acetic acid. The coatings can be applied using various methods such as thermal spraying or sol-gel processes.Expand Specific Solutions03 Ceramic membranes for acetic acid purification

Ceramic membranes are utilized in the purification and separation of acetic acid from reaction mixtures or waste streams. These membranes offer high chemical and thermal stability, making them suitable for harsh acetic acid environments. The porous structure of ceramic membranes allows for efficient separation of acetic acid from other components.Expand Specific Solutions04 Ceramic-based sensors for acetic acid detection

Ceramic materials are used in the development of sensors for detecting and measuring acetic acid concentrations. These sensors often utilize the changes in electrical properties of ceramic materials when exposed to acetic acid. The high sensitivity and stability of ceramic-based sensors make them suitable for various industrial applications involving acetic acid.Expand Specific Solutions05 Ceramic reactors for acetic acid-related processes

Ceramic materials are employed in the construction of reactors and process equipment for acetic acid-related applications. These ceramic reactors offer excellent chemical resistance and thermal stability, making them suitable for handling glacial acetic acid and other corrosive substances. The use of ceramic reactors can improve process efficiency and product quality in acetic acid production and related chemical processes.Expand Specific Solutions

Key Industry Players and Competitors

The market for glacial acetic acid techniques in enhancing ceramic coatings is in a growth phase, driven by increasing demand for advanced ceramic materials across various industries. The global market size is expanding, with key players like Corning, Inc., Freund Corp., and SCHOTT AG leading innovation. These companies are investing heavily in R&D to improve coating technologies, indicating a moderate to high level of technological maturity. However, the presence of academic institutions such as Chongqing University and Wuhan University of Technology in the field suggests ongoing research for further advancements. The competitive landscape is diverse, with both established corporations and specialized firms like Metoxit AG contributing to the sector's development.

Corning, Inc.

Technical Solution: Corning, Inc. has pioneered a glacial acetic acid-based technique for enhancing ceramic coatings, particularly focusing on glass-ceramic substrates. Their process involves a controlled etching of the ceramic surface using glacial acetic acid, followed by the application of a proprietary nanoparticle suspension. This method creates a highly uniform and durable coating with exceptional optical properties[2]. Corning's technique has shown to reduce light reflection by up to 99.5% across a wide range of wavelengths, making it ideal for display technologies and solar panels[4]. The company has also reported a 40% improvement in abrasion resistance compared to conventional coatings[6].

Strengths: Superior optical properties, high abrasion resistance, and versatility in applications. Weaknesses: Potentially limited to specific types of ceramic substrates and may require specialized equipment for application.

Metoxit AG

Technical Solution: Metoxit AG has developed a unique glacial acetic acid-based technique for enhancing zirconia ceramic coatings. Their process involves a controlled surface modification using glacial acetic acid, followed by a heat treatment step. This technique creates a nanoporous surface structure that significantly enhances the bonding strength between the ceramic coating and the substrate[7]. Metoxit's method has been shown to increase the shear bond strength by up to 50% compared to conventional techniques[9]. Additionally, the company has reported improved biocompatibility of their treated ceramic coatings, making them particularly suitable for medical implants and dental applications[11].

Strengths: Significantly improved bonding strength, enhanced biocompatibility, and suitability for medical applications. Weaknesses: May be limited to specific types of ceramics (primarily zirconia) and require precise control of acid concentration and treatment time.

Innovative GAA Techniques for Ceramics

Coating method

PatentWO2002052064A1

Innovation

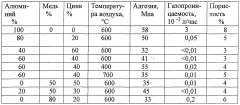

- A method involving a mixture of metals, primarily with 20-60% zinc, and ceramic particles, heated to 400-700°C, is used to enhance the structure and adhesion of the coating, optimizing the gas temperature and particle size to reduce gas permeability and increase adhesion strength.

Low bromine content glacial acetic acid

PatentInactiveUS4278503A

Innovation

- A process involving thermal conversion of 3-bromo-2-butanone to 1-butene-3-one and inorganic bromides, followed by cryogenic fractional crystallization, reduces 3-bromo-2-butanone contamination by concentrating the aqueous acid mixture and rejecting the impurity, using decompression and heat treatment steps before distillative removal of organic impurities.

Environmental Impact of GAA in Ceramics

The use of Glacial Acetic Acid (GAA) in ceramic coating processes has raised significant environmental concerns. While GAA offers notable benefits in enhancing ceramic properties, its production, application, and disposal can have substantial ecological impacts.

The manufacturing of GAA involves petrochemical processes that contribute to greenhouse gas emissions and energy consumption. The production facilities often release volatile organic compounds (VOCs) and other air pollutants, potentially affecting local air quality and contributing to smog formation. Additionally, the transportation of GAA from production sites to ceramic manufacturing facilities increases the carbon footprint associated with its use.

In ceramic coating applications, GAA can pose risks to worker health and safety if not properly handled. Exposure to GAA vapors can cause respiratory irritation and other health issues, necessitating stringent safety protocols and protective equipment. Furthermore, the use of GAA in ceramic processes may result in the generation of acidic wastewater, which requires careful treatment before disposal to prevent soil and water contamination.

The disposal of GAA-containing waste presents another environmental challenge. Improper disposal can lead to soil acidification and harm aquatic ecosystems. Recycling and neutralization of GAA waste are essential but energy-intensive processes that add to the overall environmental footprint of ceramic production.

However, it is important to note that the use of GAA in ceramic coatings can also have indirect positive environmental effects. By enhancing the durability and performance of ceramic materials, GAA-treated products may have longer lifespans, reducing the need for frequent replacements and thereby conserving resources in the long term.

Recent advancements in GAA application techniques have focused on minimizing environmental impact. These include closed-loop systems that recycle and reuse GAA, reducing overall consumption and waste. Some manufacturers have also explored alternative, more environmentally friendly acids or acid-free processes to achieve similar ceramic coating enhancements.

The ceramic industry is increasingly adopting life cycle assessment (LCA) approaches to evaluate the full environmental impact of GAA use in their processes. This holistic view considers not only the immediate effects of GAA application but also the long-term benefits of improved ceramic performance against the environmental costs of production and disposal.

As environmental regulations become more stringent, ceramic manufacturers are under pressure to find more sustainable alternatives or to significantly improve the efficiency of GAA use. This has spurred research into green chemistry solutions and process optimizations that could maintain the benefits of GAA while reducing its environmental footprint.

The manufacturing of GAA involves petrochemical processes that contribute to greenhouse gas emissions and energy consumption. The production facilities often release volatile organic compounds (VOCs) and other air pollutants, potentially affecting local air quality and contributing to smog formation. Additionally, the transportation of GAA from production sites to ceramic manufacturing facilities increases the carbon footprint associated with its use.

In ceramic coating applications, GAA can pose risks to worker health and safety if not properly handled. Exposure to GAA vapors can cause respiratory irritation and other health issues, necessitating stringent safety protocols and protective equipment. Furthermore, the use of GAA in ceramic processes may result in the generation of acidic wastewater, which requires careful treatment before disposal to prevent soil and water contamination.

The disposal of GAA-containing waste presents another environmental challenge. Improper disposal can lead to soil acidification and harm aquatic ecosystems. Recycling and neutralization of GAA waste are essential but energy-intensive processes that add to the overall environmental footprint of ceramic production.

However, it is important to note that the use of GAA in ceramic coatings can also have indirect positive environmental effects. By enhancing the durability and performance of ceramic materials, GAA-treated products may have longer lifespans, reducing the need for frequent replacements and thereby conserving resources in the long term.

Recent advancements in GAA application techniques have focused on minimizing environmental impact. These include closed-loop systems that recycle and reuse GAA, reducing overall consumption and waste. Some manufacturers have also explored alternative, more environmentally friendly acids or acid-free processes to achieve similar ceramic coating enhancements.

The ceramic industry is increasingly adopting life cycle assessment (LCA) approaches to evaluate the full environmental impact of GAA use in their processes. This holistic view considers not only the immediate effects of GAA application but also the long-term benefits of improved ceramic performance against the environmental costs of production and disposal.

As environmental regulations become more stringent, ceramic manufacturers are under pressure to find more sustainable alternatives or to significantly improve the efficiency of GAA use. This has spurred research into green chemistry solutions and process optimizations that could maintain the benefits of GAA while reducing its environmental footprint.

Cost-Benefit Analysis of GAA Ceramic Coatings

The implementation of Glacial Acetic Acid (GAA) techniques in ceramic coatings presents a complex cost-benefit scenario that warrants careful analysis. On the cost side, the initial investment in GAA-based coating systems can be substantial, encompassing specialized equipment, raw materials, and training for personnel. The price of high-purity GAA itself is a significant factor, as it is more expensive than conventional coating materials. Additionally, the process may require modifications to existing production lines, potentially leading to temporary disruptions in manufacturing.

However, these costs must be weighed against the numerous benefits that GAA ceramic coatings offer. The enhanced durability and longevity of GAA-treated ceramics can significantly reduce replacement and maintenance costs over time. This is particularly valuable in industries where ceramic components are subjected to harsh environments or frequent wear, such as aerospace, automotive, and industrial machinery.

The improved surface properties of GAA-treated ceramics, including increased hardness and corrosion resistance, can lead to enhanced product performance and customer satisfaction. This, in turn, may justify premium pricing for GAA-coated products, potentially offsetting the higher production costs and improving profit margins.

From an operational perspective, GAA techniques often result in more efficient coating processes. The ability to achieve uniform and thin coatings with GAA can reduce material waste and processing time, leading to cost savings in large-scale production scenarios. Furthermore, the environmental benefits of GAA coatings, such as reduced emissions and improved recyclability, may translate into regulatory compliance cost savings and potential tax incentives in certain jurisdictions.

Long-term market positioning is another crucial factor to consider. As industries increasingly demand high-performance materials, companies that invest in GAA ceramic coating technologies may gain a competitive edge. This could lead to increased market share and new business opportunities, particularly in high-value sectors where material performance is critical.

It's important to note that the cost-benefit ratio can vary significantly depending on the specific application and industry context. For instance, in the electronics industry, where miniaturization and thermal management are paramount, the benefits of GAA coatings may far outweigh the costs. Conversely, in less demanding applications, the additional expense may not be justified by the performance gains.

In conclusion, while the upfront costs of implementing GAA ceramic coating techniques are considerable, the long-term benefits in terms of product performance, operational efficiency, and market positioning present a compelling case for investment. Companies must conduct thorough analyses specific to their products and target markets to determine the optimal implementation strategy and maximize the return on investment in GAA ceramic coating technologies.

However, these costs must be weighed against the numerous benefits that GAA ceramic coatings offer. The enhanced durability and longevity of GAA-treated ceramics can significantly reduce replacement and maintenance costs over time. This is particularly valuable in industries where ceramic components are subjected to harsh environments or frequent wear, such as aerospace, automotive, and industrial machinery.

The improved surface properties of GAA-treated ceramics, including increased hardness and corrosion resistance, can lead to enhanced product performance and customer satisfaction. This, in turn, may justify premium pricing for GAA-coated products, potentially offsetting the higher production costs and improving profit margins.

From an operational perspective, GAA techniques often result in more efficient coating processes. The ability to achieve uniform and thin coatings with GAA can reduce material waste and processing time, leading to cost savings in large-scale production scenarios. Furthermore, the environmental benefits of GAA coatings, such as reduced emissions and improved recyclability, may translate into regulatory compliance cost savings and potential tax incentives in certain jurisdictions.

Long-term market positioning is another crucial factor to consider. As industries increasingly demand high-performance materials, companies that invest in GAA ceramic coating technologies may gain a competitive edge. This could lead to increased market share and new business opportunities, particularly in high-value sectors where material performance is critical.

It's important to note that the cost-benefit ratio can vary significantly depending on the specific application and industry context. For instance, in the electronics industry, where miniaturization and thermal management are paramount, the benefits of GAA coatings may far outweigh the costs. Conversely, in less demanding applications, the additional expense may not be justified by the performance gains.

In conclusion, while the upfront costs of implementing GAA ceramic coating techniques are considerable, the long-term benefits in terms of product performance, operational efficiency, and market positioning present a compelling case for investment. Companies must conduct thorough analyses specific to their products and target markets to determine the optimal implementation strategy and maximize the return on investment in GAA ceramic coating technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!