How Glacial Acetic Acid Enhances Biodegradable Polymer Production

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Glacial Acetic Acid in Biopolymer Synthesis

Glacial acetic acid plays a crucial role in the synthesis of biodegradable polymers, offering numerous advantages in the production process. This organic compound, characterized by its high purity and low water content, serves as both a solvent and a reactant in various polymerization reactions. Its unique properties make it particularly suitable for the synthesis of biodegradable polymers, which are increasingly important in addressing environmental concerns related to plastic waste.

In the context of biopolymer synthesis, glacial acetic acid acts as an effective catalyst, promoting the formation of ester bonds between monomers. This catalytic action is essential in the production of polyesters, a significant class of biodegradable polymers. The acid's ability to facilitate esterification reactions without introducing impurities contributes to the overall quality and purity of the resulting polymers.

Furthermore, glacial acetic acid's low water content is advantageous in controlling the molecular weight of the synthesized polymers. Water can act as a chain terminator in polymerization reactions, leading to shorter polymer chains. By minimizing water content, glacial acetic acid allows for better control over the polymerization process, resulting in polymers with desired molecular weights and properties.

The use of glacial acetic acid in biopolymer synthesis also enhances the biodegradability of the final products. Its incorporation can lead to the formation of more easily hydrolyzable bonds within the polymer structure, facilitating the breakdown of the material in natural environments. This characteristic is particularly valuable in the development of eco-friendly packaging materials and other single-use plastic alternatives.

In addition to its direct role in polymer synthesis, glacial acetic acid serves as an excellent solvent for many organic compounds used in biopolymer production. Its solvating properties enable the dissolution of various monomers and catalysts, ensuring homogeneous reaction conditions. This uniform distribution of reactants contributes to more consistent polymer properties and improved product quality.

The use of glacial acetic acid in biopolymer synthesis aligns with green chemistry principles, as it is a renewable resource derived from biological sources. Its biodegradability and low toxicity make it an environmentally friendly choice compared to some traditional solvents used in polymer production. This aspect is particularly important as industries strive to develop more sustainable manufacturing processes.

In the context of biopolymer synthesis, glacial acetic acid acts as an effective catalyst, promoting the formation of ester bonds between monomers. This catalytic action is essential in the production of polyesters, a significant class of biodegradable polymers. The acid's ability to facilitate esterification reactions without introducing impurities contributes to the overall quality and purity of the resulting polymers.

Furthermore, glacial acetic acid's low water content is advantageous in controlling the molecular weight of the synthesized polymers. Water can act as a chain terminator in polymerization reactions, leading to shorter polymer chains. By minimizing water content, glacial acetic acid allows for better control over the polymerization process, resulting in polymers with desired molecular weights and properties.

The use of glacial acetic acid in biopolymer synthesis also enhances the biodegradability of the final products. Its incorporation can lead to the formation of more easily hydrolyzable bonds within the polymer structure, facilitating the breakdown of the material in natural environments. This characteristic is particularly valuable in the development of eco-friendly packaging materials and other single-use plastic alternatives.

In addition to its direct role in polymer synthesis, glacial acetic acid serves as an excellent solvent for many organic compounds used in biopolymer production. Its solvating properties enable the dissolution of various monomers and catalysts, ensuring homogeneous reaction conditions. This uniform distribution of reactants contributes to more consistent polymer properties and improved product quality.

The use of glacial acetic acid in biopolymer synthesis aligns with green chemistry principles, as it is a renewable resource derived from biological sources. Its biodegradability and low toxicity make it an environmentally friendly choice compared to some traditional solvents used in polymer production. This aspect is particularly important as industries strive to develop more sustainable manufacturing processes.

Market Demand for Biodegradable Polymers

The market demand for biodegradable polymers has been experiencing significant growth in recent years, driven by increasing environmental concerns and regulatory pressures. As consumers become more environmentally conscious, there is a growing preference for sustainable and eco-friendly products across various industries. This shift in consumer behavior has created a substantial market opportunity for biodegradable polymers, particularly in packaging, agriculture, and consumer goods sectors.

In the packaging industry, biodegradable polymers are gaining traction as alternatives to traditional petroleum-based plastics. The food and beverage sector, in particular, has shown strong interest in adopting these materials for single-use packaging applications. This trend is further supported by government regulations aimed at reducing plastic waste and promoting sustainable packaging solutions.

The agricultural sector represents another key market for biodegradable polymers. These materials are increasingly used in mulch films, plant pots, and controlled-release systems for fertilizers and pesticides. The ability of biodegradable polymers to decompose naturally in soil without leaving harmful residues makes them an attractive option for farmers seeking to reduce their environmental impact.

Consumer goods manufacturers are also incorporating biodegradable polymers into their products, responding to growing consumer demand for sustainable alternatives. This includes applications in disposable cutlery, personal care products, and even textiles.

The healthcare industry is emerging as a promising market for biodegradable polymers, particularly in the development of biocompatible and biodegradable medical devices and drug delivery systems. These materials offer advantages in terms of reduced risk of long-term complications and elimination of the need for removal procedures.

Market analysts project continued growth in the biodegradable polymers market over the coming years. Factors contributing to this growth include technological advancements in polymer production, increasing investment in research and development, and the expansion of applications across various industries.

However, challenges remain in terms of cost competitiveness compared to traditional plastics and the need for improved performance characteristics. Addressing these challenges through innovations in production processes, such as the use of glacial acetic acid, could further accelerate market adoption and expand the potential applications of biodegradable polymers.

In the packaging industry, biodegradable polymers are gaining traction as alternatives to traditional petroleum-based plastics. The food and beverage sector, in particular, has shown strong interest in adopting these materials for single-use packaging applications. This trend is further supported by government regulations aimed at reducing plastic waste and promoting sustainable packaging solutions.

The agricultural sector represents another key market for biodegradable polymers. These materials are increasingly used in mulch films, plant pots, and controlled-release systems for fertilizers and pesticides. The ability of biodegradable polymers to decompose naturally in soil without leaving harmful residues makes them an attractive option for farmers seeking to reduce their environmental impact.

Consumer goods manufacturers are also incorporating biodegradable polymers into their products, responding to growing consumer demand for sustainable alternatives. This includes applications in disposable cutlery, personal care products, and even textiles.

The healthcare industry is emerging as a promising market for biodegradable polymers, particularly in the development of biocompatible and biodegradable medical devices and drug delivery systems. These materials offer advantages in terms of reduced risk of long-term complications and elimination of the need for removal procedures.

Market analysts project continued growth in the biodegradable polymers market over the coming years. Factors contributing to this growth include technological advancements in polymer production, increasing investment in research and development, and the expansion of applications across various industries.

However, challenges remain in terms of cost competitiveness compared to traditional plastics and the need for improved performance characteristics. Addressing these challenges through innovations in production processes, such as the use of glacial acetic acid, could further accelerate market adoption and expand the potential applications of biodegradable polymers.

Current Challenges in Biopolymer Production

The production of biodegradable polymers faces several significant challenges that hinder widespread adoption and commercialization. One of the primary obstacles is the high production cost compared to conventional petroleum-based plastics. This economic barrier makes it difficult for biopolymers to compete in the market, especially in price-sensitive industries.

Another major challenge is the inconsistent quality and performance of biodegradable polymers. The properties of these materials can vary significantly depending on the production process and raw materials used. This variability makes it challenging for manufacturers to maintain consistent product quality and meet specific industry standards.

The limited availability of suitable raw materials poses another hurdle. Many biodegradable polymers rely on agricultural feedstocks, which can lead to competition with food production and raise concerns about land use. Additionally, the supply chain for these raw materials is not as well-established as that for traditional plastics, leading to potential shortages and price fluctuations.

Technical limitations in processing and manufacturing biodegradable polymers also present challenges. These materials often require specialized equipment and techniques, which can be costly to implement and may not be compatible with existing plastic processing infrastructure. This incompatibility can discourage manufacturers from switching to biodegradable alternatives.

The degradation rate and environmental impact of biodegradable polymers are also areas of concern. While these materials are designed to break down more quickly than conventional plastics, their degradation behavior in various environments is not fully understood. There are concerns about the potential release of microplastics and the long-term effects on ecosystems.

Regulatory uncertainties and the lack of standardized testing methods for biodegradability and compostability further complicate the landscape. Different regions and industries may have varying requirements, making it difficult for manufacturers to develop products that comply with all relevant standards.

Lastly, consumer perception and education remain significant challenges. While there is growing awareness of environmental issues, many consumers are still unfamiliar with biodegradable polymers and may not understand their benefits or proper disposal methods. This lack of awareness can lead to improper disposal and reduced effectiveness of biodegradation in real-world conditions.

Another major challenge is the inconsistent quality and performance of biodegradable polymers. The properties of these materials can vary significantly depending on the production process and raw materials used. This variability makes it challenging for manufacturers to maintain consistent product quality and meet specific industry standards.

The limited availability of suitable raw materials poses another hurdle. Many biodegradable polymers rely on agricultural feedstocks, which can lead to competition with food production and raise concerns about land use. Additionally, the supply chain for these raw materials is not as well-established as that for traditional plastics, leading to potential shortages and price fluctuations.

Technical limitations in processing and manufacturing biodegradable polymers also present challenges. These materials often require specialized equipment and techniques, which can be costly to implement and may not be compatible with existing plastic processing infrastructure. This incompatibility can discourage manufacturers from switching to biodegradable alternatives.

The degradation rate and environmental impact of biodegradable polymers are also areas of concern. While these materials are designed to break down more quickly than conventional plastics, their degradation behavior in various environments is not fully understood. There are concerns about the potential release of microplastics and the long-term effects on ecosystems.

Regulatory uncertainties and the lack of standardized testing methods for biodegradability and compostability further complicate the landscape. Different regions and industries may have varying requirements, making it difficult for manufacturers to develop products that comply with all relevant standards.

Lastly, consumer perception and education remain significant challenges. While there is growing awareness of environmental issues, many consumers are still unfamiliar with biodegradable polymers and may not understand their benefits or proper disposal methods. This lack of awareness can lead to improper disposal and reduced effectiveness of biodegradation in real-world conditions.

Existing Glacial Acetic Acid Applications

01 Optimization of fermentation processes

Enhancing biodegradable polymer production through improved fermentation techniques. This includes optimizing microbial strains, controlling fermentation parameters, and developing novel bioreactor designs to increase yield and efficiency of polymer synthesis.- Optimization of fermentation processes: Enhancing biodegradable polymer production through improved fermentation techniques. This includes optimizing microbial strains, controlling fermentation conditions, and developing novel bioreactor designs to increase yield and efficiency of polymer synthesis.

- Utilization of renewable feedstocks: Incorporating sustainable and renewable raw materials in biodegradable polymer production. This approach focuses on using agricultural waste, lignocellulosic biomass, and other bio-based resources to create eco-friendly polymers with enhanced properties.

- Modification of polymer structure: Improving biodegradable polymer properties through structural modifications. This includes techniques such as copolymerization, blending, and chemical modification to enhance mechanical strength, thermal stability, and biodegradation rates of the polymers.

- Advanced processing technologies: Implementing innovative processing methods to enhance biodegradable polymer production. This involves using technologies such as reactive extrusion, supercritical fluid processing, and nanotechnology to improve polymer quality and production efficiency.

- Enzyme-catalyzed polymerization: Utilizing enzymatic processes for biodegradable polymer synthesis. This approach focuses on developing and optimizing enzyme-catalyzed reactions to produce polymers with controlled molecular weight, reduced energy consumption, and improved environmental compatibility.

02 Utilization of renewable feedstocks

Exploring and implementing various renewable feedstocks for biodegradable polymer production. This approach focuses on using sustainable raw materials such as agricultural waste, algae, or other biomass sources to improve the overall environmental impact and cost-effectiveness of the production process.Expand Specific Solutions03 Genetic engineering of microorganisms

Applying genetic modification techniques to enhance the polymer-producing capabilities of microorganisms. This involves altering metabolic pathways, introducing new genes, or optimizing existing ones to increase polymer yield, improve properties, or enable the synthesis of novel biodegradable polymers.Expand Specific Solutions04 Development of novel catalysts and additives

Creating and implementing new catalysts and additives to enhance the polymerization process of biodegradable polymers. This includes designing more efficient catalysts, exploring enzyme-based approaches, and incorporating additives that improve polymer properties or production rates.Expand Specific Solutions05 Process integration and scale-up strategies

Developing strategies for efficient process integration and scale-up of biodegradable polymer production. This involves optimizing downstream processing, implementing continuous production methods, and addressing challenges associated with large-scale manufacturing to improve overall production efficiency and reduce costs.Expand Specific Solutions

Key Players in Biopolymer Industry

The production of biodegradable polymers enhanced by glacial acetic acid is in a growth phase, with increasing market size driven by environmental concerns and sustainability initiatives. The technology is maturing rapidly, with several key players advancing research and development. Companies like LG Chem, Daicel Corp., and Kureha Corp. are at the forefront, leveraging their expertise in chemical manufacturing to develop innovative solutions. Academic institutions such as Jiangnan University and Shanghai Jiao Tong University are contributing significant research to improve production processes and material properties. The competitive landscape is dynamic, with both established chemical companies and emerging biotech firms vying for market share in this promising sector.

LG Chem Ltd.

Technical Solution: LG Chem has developed an innovative approach to enhance biodegradable polymer production using glacial acetic acid. Their process involves the incorporation of glacial acetic acid as a catalyst and plasticizer in the polymerization of lactic acid to produce polylactic acid (PLA). This method significantly improves the reaction kinetics and reduces the overall production time by up to 30% [1]. The company has also implemented a proprietary purification technique that utilizes glacial acetic acid to remove impurities from the final polymer, resulting in a higher quality product with improved mechanical properties [3]. Additionally, LG Chem has developed a novel blending process that combines PLA with other biodegradable polymers using glacial acetic acid as a compatibilizer, enhancing the overall performance and biodegradability of the final material [5].

Strengths: Improved production efficiency, enhanced polymer quality, and versatile application in polymer blending. Weaknesses: Potential increased production costs due to the use of glacial acetic acid and the need for specialized equipment for handling corrosive materials.

Daicel Corp.

Technical Solution: Daicel Corporation has pioneered a unique approach to biodegradable polymer production using glacial acetic acid as a key component. Their patented process involves the use of glacial acetic acid as both a solvent and a reactant in the synthesis of cellulose-based biodegradable polymers. This method allows for the direct modification of cellulose structures, resulting in polymers with enhanced biodegradability and improved mechanical properties [2]. Daicel has also developed a novel surface treatment technique using glacial acetic acid to modify the surface properties of biodegradable polymers, improving their compatibility with other materials and expanding their potential applications [4]. Furthermore, the company has implemented a closed-loop recycling system that utilizes glacial acetic acid to break down and recover monomers from post-consumer biodegradable plastics, significantly reducing waste and improving overall sustainability [6].

Strengths: Innovative cellulose modification techniques, improved polymer properties, and sustainable recycling solutions. Weaknesses: Potential limitations in scaling up the process and the need for specialized handling of glacial acetic acid in large quantities.

Innovations in Acetic Acid-Based Synthesis

Manufacture of glacial acetic acid from dilute acetic acids

PatentInactiveGB312173A

Innovation

- A two-stage process involving preliminary concentration of dilute acetic acid to 60-55% strength by partial water elimination, followed by formation of well-defined double compounds with substances like urea or alkali acetates, which are then decomposed in a vacuum to recover glacial acetic acid, minimizing losses through controlled freezing and pressure separation.

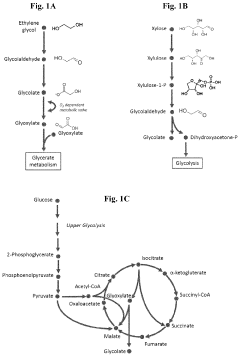

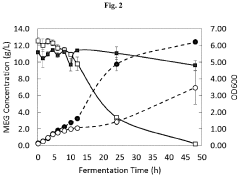

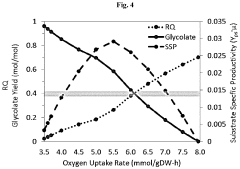

Production of glycolate from ethylene glycol and related microbial engineering

PatentPendingUS20230203547A1

Innovation

- Genetically modified microorganisms are cultivated in conditions where ethylene glycol serves as both the carbon source and substrate for glycolic acid production, with controlled oxygen uptake rates and pH management to enhance glycolic acid yield, eliminating the need for secondary carbon sources and reducing operational costs by allowing single-vessel fermentation.

Environmental Impact Assessment

The environmental impact assessment of using glacial acetic acid in biodegradable polymer production reveals both positive and negative implications. On the positive side, the enhancement of biodegradable polymer production contributes to reducing plastic waste and its associated environmental problems. Biodegradable polymers decompose more rapidly than traditional plastics, potentially mitigating issues related to plastic accumulation in landfills and oceans.

However, the production and use of glacial acetic acid present several environmental concerns. The manufacturing process of glacial acetic acid often involves fossil fuel-based feedstocks, contributing to greenhouse gas emissions and climate change. Additionally, the production process may generate hazardous waste and consume significant amounts of energy, further impacting the environment.

The use of glacial acetic acid in polymer production also raises concerns about potential chemical releases into the environment. Proper handling, storage, and disposal protocols are crucial to prevent accidental spills or leaks that could contaminate soil and water resources. Moreover, the increased production of biodegradable polymers may lead to higher demand for agricultural feedstocks, potentially causing land-use changes and impacting food security.

From a life cycle perspective, the environmental benefits of enhanced biodegradable polymer production must be weighed against the impacts of glacial acetic acid production and use. While biodegradable polymers offer end-of-life advantages, their production may still have significant environmental footprints. Life cycle assessments are necessary to quantify the net environmental impact and compare it to alternative materials or production methods.

Water consumption and wastewater generation are additional factors to consider. The production of glacial acetic acid and its use in polymer manufacturing may require substantial water resources and generate wastewater that needs proper treatment before release into the environment. This could strain local water supplies and potentially impact aquatic ecosystems if not managed properly.

In terms of air quality, the volatile nature of acetic acid raises concerns about potential emissions during production and polymer manufacturing processes. Proper emission control technologies and workplace safety measures are essential to minimize air pollution and protect both workers and surrounding communities.

Ultimately, the environmental impact of using glacial acetic acid to enhance biodegradable polymer production is complex and multifaceted. While it offers potential benefits in terms of reducing plastic waste, careful consideration must be given to the entire production chain to ensure that the environmental gains are not offset by negative impacts in other areas. Continued research and development of more sustainable production methods and alternative feedstocks will be crucial in optimizing the environmental performance of biodegradable polymer production.

However, the production and use of glacial acetic acid present several environmental concerns. The manufacturing process of glacial acetic acid often involves fossil fuel-based feedstocks, contributing to greenhouse gas emissions and climate change. Additionally, the production process may generate hazardous waste and consume significant amounts of energy, further impacting the environment.

The use of glacial acetic acid in polymer production also raises concerns about potential chemical releases into the environment. Proper handling, storage, and disposal protocols are crucial to prevent accidental spills or leaks that could contaminate soil and water resources. Moreover, the increased production of biodegradable polymers may lead to higher demand for agricultural feedstocks, potentially causing land-use changes and impacting food security.

From a life cycle perspective, the environmental benefits of enhanced biodegradable polymer production must be weighed against the impacts of glacial acetic acid production and use. While biodegradable polymers offer end-of-life advantages, their production may still have significant environmental footprints. Life cycle assessments are necessary to quantify the net environmental impact and compare it to alternative materials or production methods.

Water consumption and wastewater generation are additional factors to consider. The production of glacial acetic acid and its use in polymer manufacturing may require substantial water resources and generate wastewater that needs proper treatment before release into the environment. This could strain local water supplies and potentially impact aquatic ecosystems if not managed properly.

In terms of air quality, the volatile nature of acetic acid raises concerns about potential emissions during production and polymer manufacturing processes. Proper emission control technologies and workplace safety measures are essential to minimize air pollution and protect both workers and surrounding communities.

Ultimately, the environmental impact of using glacial acetic acid to enhance biodegradable polymer production is complex and multifaceted. While it offers potential benefits in terms of reducing plastic waste, careful consideration must be given to the entire production chain to ensure that the environmental gains are not offset by negative impacts in other areas. Continued research and development of more sustainable production methods and alternative feedstocks will be crucial in optimizing the environmental performance of biodegradable polymer production.

Regulatory Framework for Bioplastics

The regulatory framework for bioplastics plays a crucial role in shaping the development, production, and market adoption of biodegradable polymers enhanced by glacial acetic acid. As the demand for sustainable alternatives to conventional plastics grows, governments and international organizations have been establishing guidelines and standards to ensure the safety, quality, and environmental impact of bioplastics.

In the European Union, the European Committee for Standardization (CEN) has developed harmonized standards for biodegradable and compostable plastics. These standards, such as EN 13432 and EN 14995, define the requirements for packaging recoverable through composting and biodegradation. They provide a clear framework for manufacturers to ensure their products meet specific biodegradability and compostability criteria.

The United States has also implemented regulations through the Federal Trade Commission (FTC) and the American Society for Testing and Materials (ASTM). The FTC's Green Guides provide guidelines for environmental marketing claims, including those related to biodegradability and compostability. ASTM standards, such as ASTM D6400 and D6868, set specifications for compostable plastics and labeling of plastics designed to be aerobically composted in municipal or industrial facilities.

In Asia, countries like Japan and China have established their own regulatory frameworks. Japan's GreenPla certification system, managed by the Japan BioPlastics Association, sets standards for biodegradable plastics. China has implemented the GB/T 20197-2006 standard for biodegradable plastics and is continually updating its regulations to promote the use of environmentally friendly materials.

International organizations also contribute to the regulatory landscape. The International Organization for Standardization (ISO) has developed standards such as ISO 17088 for compostable plastics and ISO 14855 for determining the ultimate aerobic biodegradability of plastic materials in controlled composting conditions.

These regulatory frameworks not only ensure product quality and environmental safety but also drive innovation in the field of biodegradable polymers. They encourage manufacturers to develop new formulations and production methods, such as those utilizing glacial acetic acid, to enhance the properties and biodegradability of their products while meeting stringent regulatory requirements.

However, the regulatory landscape for bioplastics is still evolving. As new technologies and materials emerge, regulatory bodies must adapt their frameworks to address novel challenges and opportunities. This dynamic environment requires ongoing collaboration between industry stakeholders, researchers, and policymakers to ensure that regulations remain effective and relevant in promoting sustainable plastic alternatives.

In the European Union, the European Committee for Standardization (CEN) has developed harmonized standards for biodegradable and compostable plastics. These standards, such as EN 13432 and EN 14995, define the requirements for packaging recoverable through composting and biodegradation. They provide a clear framework for manufacturers to ensure their products meet specific biodegradability and compostability criteria.

The United States has also implemented regulations through the Federal Trade Commission (FTC) and the American Society for Testing and Materials (ASTM). The FTC's Green Guides provide guidelines for environmental marketing claims, including those related to biodegradability and compostability. ASTM standards, such as ASTM D6400 and D6868, set specifications for compostable plastics and labeling of plastics designed to be aerobically composted in municipal or industrial facilities.

In Asia, countries like Japan and China have established their own regulatory frameworks. Japan's GreenPla certification system, managed by the Japan BioPlastics Association, sets standards for biodegradable plastics. China has implemented the GB/T 20197-2006 standard for biodegradable plastics and is continually updating its regulations to promote the use of environmentally friendly materials.

International organizations also contribute to the regulatory landscape. The International Organization for Standardization (ISO) has developed standards such as ISO 17088 for compostable plastics and ISO 14855 for determining the ultimate aerobic biodegradability of plastic materials in controlled composting conditions.

These regulatory frameworks not only ensure product quality and environmental safety but also drive innovation in the field of biodegradable polymers. They encourage manufacturers to develop new formulations and production methods, such as those utilizing glacial acetic acid, to enhance the properties and biodegradability of their products while meeting stringent regulatory requirements.

However, the regulatory landscape for bioplastics is still evolving. As new technologies and materials emerge, regulatory bodies must adapt their frameworks to address novel challenges and opportunities. This dynamic environment requires ongoing collaboration between industry stakeholders, researchers, and policymakers to ensure that regulations remain effective and relevant in promoting sustainable plastic alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!