Reaction Mechanism Alterations Due to Glacial Acetic Acid Introduction

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Glacial Acetic Acid Reaction Background

Glacial acetic acid, also known as anhydrous acetic acid, is a highly concentrated form of acetic acid with less than 1% water content. Its introduction into chemical reactions can significantly alter reaction mechanisms, making it a crucial component in various industrial and laboratory processes. The use of glacial acetic acid dates back to the early 19th century when it was first isolated through the distillation of wood vinegar.

The unique properties of glacial acetic acid, including its high acidity, low water content, and strong hydrogen bonding capabilities, contribute to its profound impact on reaction mechanisms. These characteristics allow it to act as both a solvent and a reactant in many organic syntheses, catalyzing reactions and modifying reaction pathways.

In organic chemistry, glacial acetic acid plays a vital role in acetylation reactions, where it serves as an acetyl group donor. This process is fundamental in the production of various pharmaceuticals, dyes, and plastics. The anhydrous nature of glacial acetic acid makes it particularly effective in these reactions, as it minimizes unwanted side reactions that could occur in the presence of water.

The introduction of glacial acetic acid can also alter the kinetics and thermodynamics of reactions. Its strong acidic properties can protonate reactants, changing their reactivity and influencing the reaction rate. Additionally, the ability of glacial acetic acid to form strong hydrogen bonds can stabilize transition states and intermediates, potentially lowering activation energies and facilitating reaction progress.

In biochemistry, the use of glacial acetic acid has been instrumental in protein research. It is commonly used in gel electrophoresis techniques for protein separation and analysis. The acid's ability to denature proteins and maintain a low pH environment is crucial for these applications.

The industrial significance of glacial acetic acid extends to the production of vinyl acetate monomer, a key precursor in the manufacture of various polymers and adhesives. In this process, the anhydrous nature of glacial acetic acid is essential for maintaining reaction efficiency and product purity.

Understanding the impact of glacial acetic acid on reaction mechanisms is crucial for optimizing chemical processes and developing new synthetic routes. Its versatility and unique properties continue to make it an indispensable tool in both academic research and industrial applications, driving innovation in fields ranging from materials science to pharmaceutical development.

The unique properties of glacial acetic acid, including its high acidity, low water content, and strong hydrogen bonding capabilities, contribute to its profound impact on reaction mechanisms. These characteristics allow it to act as both a solvent and a reactant in many organic syntheses, catalyzing reactions and modifying reaction pathways.

In organic chemistry, glacial acetic acid plays a vital role in acetylation reactions, where it serves as an acetyl group donor. This process is fundamental in the production of various pharmaceuticals, dyes, and plastics. The anhydrous nature of glacial acetic acid makes it particularly effective in these reactions, as it minimizes unwanted side reactions that could occur in the presence of water.

The introduction of glacial acetic acid can also alter the kinetics and thermodynamics of reactions. Its strong acidic properties can protonate reactants, changing their reactivity and influencing the reaction rate. Additionally, the ability of glacial acetic acid to form strong hydrogen bonds can stabilize transition states and intermediates, potentially lowering activation energies and facilitating reaction progress.

In biochemistry, the use of glacial acetic acid has been instrumental in protein research. It is commonly used in gel electrophoresis techniques for protein separation and analysis. The acid's ability to denature proteins and maintain a low pH environment is crucial for these applications.

The industrial significance of glacial acetic acid extends to the production of vinyl acetate monomer, a key precursor in the manufacture of various polymers and adhesives. In this process, the anhydrous nature of glacial acetic acid is essential for maintaining reaction efficiency and product purity.

Understanding the impact of glacial acetic acid on reaction mechanisms is crucial for optimizing chemical processes and developing new synthetic routes. Its versatility and unique properties continue to make it an indispensable tool in both academic research and industrial applications, driving innovation in fields ranging from materials science to pharmaceutical development.

Industrial Applications and Market Demand

The introduction of glacial acetic acid in reaction mechanisms has sparked significant interest across various industrial sectors due to its potential to enhance process efficiency and product quality. The market demand for this technology is driven by several factors, including the need for more sustainable and cost-effective production methods in the chemical industry.

In the pharmaceutical sector, glacial acetic acid's role in altering reaction mechanisms has shown promise in improving the synthesis of active pharmaceutical ingredients (APIs). This has led to increased interest from major pharmaceutical companies looking to optimize their production processes and reduce manufacturing costs. The global pharmaceutical market, valued at over $1.2 trillion, is constantly seeking innovative solutions to streamline drug development and production.

The food and beverage industry has also recognized the potential of glacial acetic acid in reaction mechanism alterations. Its application in food preservation and flavor enhancement has opened new avenues for product development. With the global food additives market projected to grow significantly in the coming years, the demand for advanced acetic acid-based solutions is expected to rise.

In the polymer and plastics industry, the introduction of glacial acetic acid has led to advancements in polymer synthesis and modification. This has resulted in improved material properties and processing techniques, driving demand from manufacturers of high-performance plastics and specialty polymers. The global plastics market, with its continuous growth trajectory, presents a substantial opportunity for the application of this technology.

The agrochemical sector has shown interest in leveraging glacial acetic acid's reaction mechanism alterations for the development of more effective and environmentally friendly pesticides and herbicides. As the global population continues to grow, the demand for increased agricultural productivity is driving innovation in this field.

Furthermore, the textile industry has found applications for glacial acetic acid in dyeing processes and fabric treatments. The ability to alter reaction mechanisms has led to improved color fastness and fabric properties, meeting the growing consumer demand for high-quality, durable textiles.

The market demand for this technology is also influenced by the increasing focus on green chemistry and sustainable production methods. Industries are seeking ways to reduce their environmental footprint while maintaining or improving product quality, making glacial acetic acid an attractive option for process optimization.

As research and development in this area continue to advance, it is anticipated that new applications and markets will emerge, further driving demand for technologies related to reaction mechanism alterations using glacial acetic acid. This presents opportunities for companies to innovate and gain a competitive edge in their respective industries.

In the pharmaceutical sector, glacial acetic acid's role in altering reaction mechanisms has shown promise in improving the synthesis of active pharmaceutical ingredients (APIs). This has led to increased interest from major pharmaceutical companies looking to optimize their production processes and reduce manufacturing costs. The global pharmaceutical market, valued at over $1.2 trillion, is constantly seeking innovative solutions to streamline drug development and production.

The food and beverage industry has also recognized the potential of glacial acetic acid in reaction mechanism alterations. Its application in food preservation and flavor enhancement has opened new avenues for product development. With the global food additives market projected to grow significantly in the coming years, the demand for advanced acetic acid-based solutions is expected to rise.

In the polymer and plastics industry, the introduction of glacial acetic acid has led to advancements in polymer synthesis and modification. This has resulted in improved material properties and processing techniques, driving demand from manufacturers of high-performance plastics and specialty polymers. The global plastics market, with its continuous growth trajectory, presents a substantial opportunity for the application of this technology.

The agrochemical sector has shown interest in leveraging glacial acetic acid's reaction mechanism alterations for the development of more effective and environmentally friendly pesticides and herbicides. As the global population continues to grow, the demand for increased agricultural productivity is driving innovation in this field.

Furthermore, the textile industry has found applications for glacial acetic acid in dyeing processes and fabric treatments. The ability to alter reaction mechanisms has led to improved color fastness and fabric properties, meeting the growing consumer demand for high-quality, durable textiles.

The market demand for this technology is also influenced by the increasing focus on green chemistry and sustainable production methods. Industries are seeking ways to reduce their environmental footprint while maintaining or improving product quality, making glacial acetic acid an attractive option for process optimization.

As research and development in this area continue to advance, it is anticipated that new applications and markets will emerge, further driving demand for technologies related to reaction mechanism alterations using glacial acetic acid. This presents opportunities for companies to innovate and gain a competitive edge in their respective industries.

Current Challenges in Acetic Acid Reactions

The introduction of glacial acetic acid into reaction systems presents several significant challenges that researchers and industry professionals are currently grappling with. One of the primary issues is the corrosive nature of glacial acetic acid, which can lead to equipment degradation and potential safety hazards. This corrosivity necessitates the use of specialized materials and protective measures, increasing operational costs and complexity.

Another challenge lies in the hygroscopic properties of glacial acetic acid. Its strong affinity for water can lead to unintended side reactions or alterations in reaction kinetics, particularly in systems sensitive to moisture. This characteristic demands stringent control over reaction conditions and careful consideration of reagent purity.

The high viscosity of glacial acetic acid at lower temperatures poses difficulties in handling and precise dosing, potentially affecting reaction stoichiometry and reproducibility. This property also impacts heat transfer efficiency, which can be critical in controlling exothermic reactions or maintaining specific temperature profiles.

Researchers are also confronted with the challenge of understanding and predicting the altered reaction mechanisms when glacial acetic acid is introduced. The strong hydrogen bonding capabilities of acetic acid can significantly influence reaction pathways, potentially leading to unexpected products or altered selectivity. This complexity requires advanced analytical techniques and computational modeling to elucidate the intricate interactions at play.

Furthermore, the environmental impact of using glacial acetic acid in large-scale processes is a growing concern. Its potential for atmospheric emissions and contribution to volatile organic compound (VOC) levels necessitates the development of more sustainable practices and efficient recovery systems.

The pharmaceutical and fine chemical industries face particular challenges in ensuring product purity when using glacial acetic acid as a reagent or solvent. Trace impurities or residual acetic acid can have significant implications for product quality and regulatory compliance, driving the need for advanced purification and analytical methods.

Lastly, the optimization of reaction conditions in the presence of glacial acetic acid remains a complex task. Balancing factors such as reaction rate, yield, selectivity, and process safety requires a multifaceted approach, often involving extensive experimentation and the application of advanced process analytical technologies (PAT).

Another challenge lies in the hygroscopic properties of glacial acetic acid. Its strong affinity for water can lead to unintended side reactions or alterations in reaction kinetics, particularly in systems sensitive to moisture. This characteristic demands stringent control over reaction conditions and careful consideration of reagent purity.

The high viscosity of glacial acetic acid at lower temperatures poses difficulties in handling and precise dosing, potentially affecting reaction stoichiometry and reproducibility. This property also impacts heat transfer efficiency, which can be critical in controlling exothermic reactions or maintaining specific temperature profiles.

Researchers are also confronted with the challenge of understanding and predicting the altered reaction mechanisms when glacial acetic acid is introduced. The strong hydrogen bonding capabilities of acetic acid can significantly influence reaction pathways, potentially leading to unexpected products or altered selectivity. This complexity requires advanced analytical techniques and computational modeling to elucidate the intricate interactions at play.

Furthermore, the environmental impact of using glacial acetic acid in large-scale processes is a growing concern. Its potential for atmospheric emissions and contribution to volatile organic compound (VOC) levels necessitates the development of more sustainable practices and efficient recovery systems.

The pharmaceutical and fine chemical industries face particular challenges in ensuring product purity when using glacial acetic acid as a reagent or solvent. Trace impurities or residual acetic acid can have significant implications for product quality and regulatory compliance, driving the need for advanced purification and analytical methods.

Lastly, the optimization of reaction conditions in the presence of glacial acetic acid remains a complex task. Balancing factors such as reaction rate, yield, selectivity, and process safety requires a multifaceted approach, often involving extensive experimentation and the application of advanced process analytical technologies (PAT).

Existing Reaction Mechanisms with Glacial Acetic Acid

01 Enzymatic reaction mechanism alterations

This approach involves modifying the reaction mechanisms of enzymes to achieve desired outcomes. By altering the catalytic properties or substrate specificity of enzymes, researchers can enhance their performance or create novel functionalities. These alterations can be achieved through various methods, including protein engineering, directed evolution, or rational design.- Enzymatic reaction mechanism alterations: This approach involves modifying the reaction mechanisms of enzymes to enhance their catalytic efficiency or alter their substrate specificity. By introducing mutations or chemical modifications to the enzyme's active site or regulatory regions, researchers can fine-tune the enzyme's performance for specific applications in biotechnology and pharmaceutical industries.

- Molecular dynamics simulations for reaction mechanism studies: Computational methods, particularly molecular dynamics simulations, are employed to study and predict reaction mechanism alterations. These simulations provide insights into the atomic-level interactions and energy landscapes of chemical reactions, allowing researchers to design and optimize reaction conditions or catalysts for desired outcomes.

- Photochemical reaction mechanism modifications: This area focuses on altering the mechanisms of photochemical reactions by manipulating light-sensitive compounds or introducing photocatalysts. By controlling the wavelength, intensity, or duration of light exposure, researchers can influence reaction pathways and product distributions in various applications, including materials science and organic synthesis.

- Electrochemical reaction mechanism control: Electrochemical techniques are used to modify reaction mechanisms by applying controlled electrical potentials or currents. This approach allows for the selective activation or inhibition of specific reaction pathways, enabling the development of more efficient and selective chemical processes in areas such as energy storage, corrosion prevention, and materials synthesis.

- Reaction mechanism alterations in biological systems: This field explores modifications to reaction mechanisms in living organisms, often through genetic engineering or the introduction of synthetic biological components. By altering metabolic pathways or introducing novel enzymatic reactions, researchers can enhance the production of valuable compounds or create new biological functions for applications in medicine, agriculture, and biotechnology.

02 Chemical reaction mechanism modifications

This category focuses on altering the mechanisms of chemical reactions to improve efficiency, selectivity, or yield. Techniques may include the use of catalysts, changes in reaction conditions, or the introduction of new reagents. These modifications can lead to the development of more sustainable processes or the synthesis of novel compounds.Expand Specific Solutions03 Genetic and molecular biology alterations

This approach involves modifying genetic material or molecular processes to alter reaction mechanisms at the cellular level. Techniques such as gene editing, recombinant DNA technology, or RNA interference can be used to manipulate biological pathways and create new reaction mechanisms or modify existing ones.Expand Specific Solutions04 Computational modeling and simulation of reaction mechanisms

This category involves the use of advanced computational techniques to model and simulate reaction mechanisms. By employing algorithms, machine learning, or quantum mechanical calculations, researchers can predict and analyze potential alterations to reaction mechanisms, guiding experimental design and accelerating the discovery process.Expand Specific Solutions05 Photochemical and electrochemical reaction mechanism alterations

This approach focuses on modifying reaction mechanisms through the use of light or electrical energy. By manipulating photochemical or electrochemical processes, researchers can achieve unique transformations, control reaction pathways, or develop novel energy conversion systems. These alterations can lead to more efficient and sustainable chemical processes.Expand Specific Solutions

Key Players in Acetic Acid Industry

The competitive landscape for "Reaction Mechanism Alterations Due to Glacial Acetic Acid Introduction" is in an early development stage, with a relatively small market size but growing interest from both academic and industrial sectors. The technology is still evolving, with varying levels of maturity across different applications. Key players like The Scripps Research Institute, Centre National de la Recherche Scientifique, and University of Kansas Medical Center are leading academic research efforts, while companies such as Kyowa Kirin Co., Ltd., Daicel Corp., and Evonik Operations GmbH are exploring industrial applications. The field is characterized by interdisciplinary collaboration and a focus on understanding fundamental reaction mechanisms, with potential applications in pharmaceuticals, chemical manufacturing, and materials science.

Daicel Corp.

Technical Solution: Daicel Corp. has developed an innovative solution to address reaction mechanism alterations caused by glacial acetic acid introduction. Their approach involves a unique solvent system that mitigates the effects of glacial acetic acid on reaction kinetics. By utilizing a carefully designed mixture of polar aprotic solvents, Daicel has created an environment that stabilizes reactive intermediates and maintains desired reaction pathways[2]. The company has also implemented advanced in-situ spectroscopic monitoring techniques to track reaction progress and adjust conditions as needed. Furthermore, Daicel has developed a novel workup procedure that efficiently separates the product from the acetic acid-containing reaction mixture, minimizing downstream processing issues[4].

Strengths: Unique solvent system, advanced monitoring techniques, efficient workup procedure. Weaknesses: May require specialized equipment, potential limitations in scalability for certain reactions.

Evonik Operations GmbH

Technical Solution: Evonik has developed a comprehensive approach to manage reaction mechanism alterations due to glacial acetic acid introduction. Their strategy involves using specially designed heterogeneous catalysts that maintain activity and selectivity in acidic environments. These catalysts feature acid-resistant support materials and carefully tailored active sites that minimize side reactions induced by glacial acetic acid[5]. Evonik has also implemented advanced reactor designs with precise temperature control and mixing patterns to optimize mass transfer and heat dissipation in the presence of glacial acetic acid. Additionally, the company has developed a suite of analytical tools for real-time monitoring of reaction progress and acid concentration, allowing for dynamic adjustments to reaction conditions[6].

Strengths: Specialized heterogeneous catalysts, advanced reactor designs, real-time monitoring capabilities. Weaknesses: Potentially higher catalyst costs, may require specific expertise for catalyst handling and regeneration.

Innovative Approaches in Acetic Acid Reactions

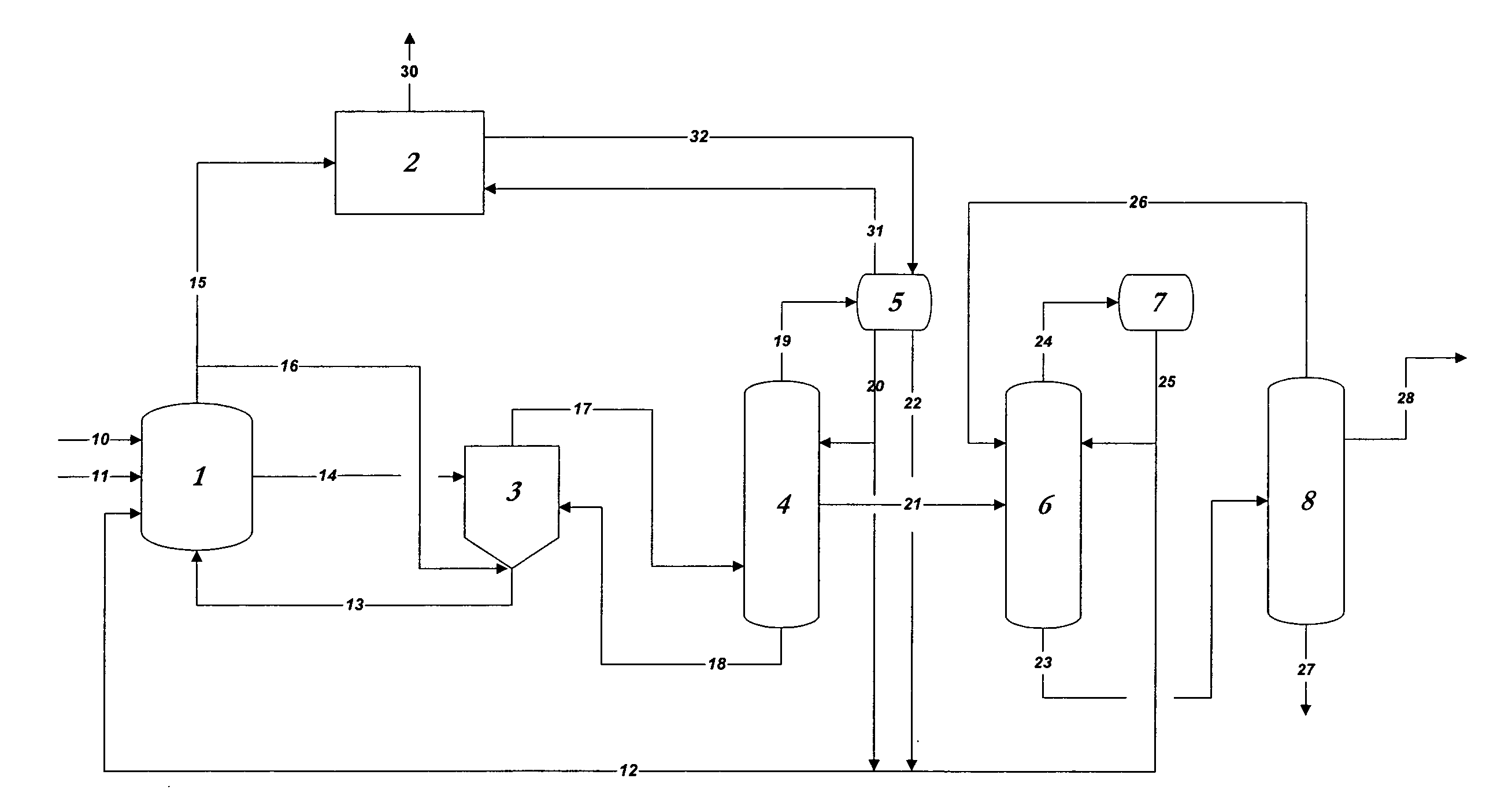

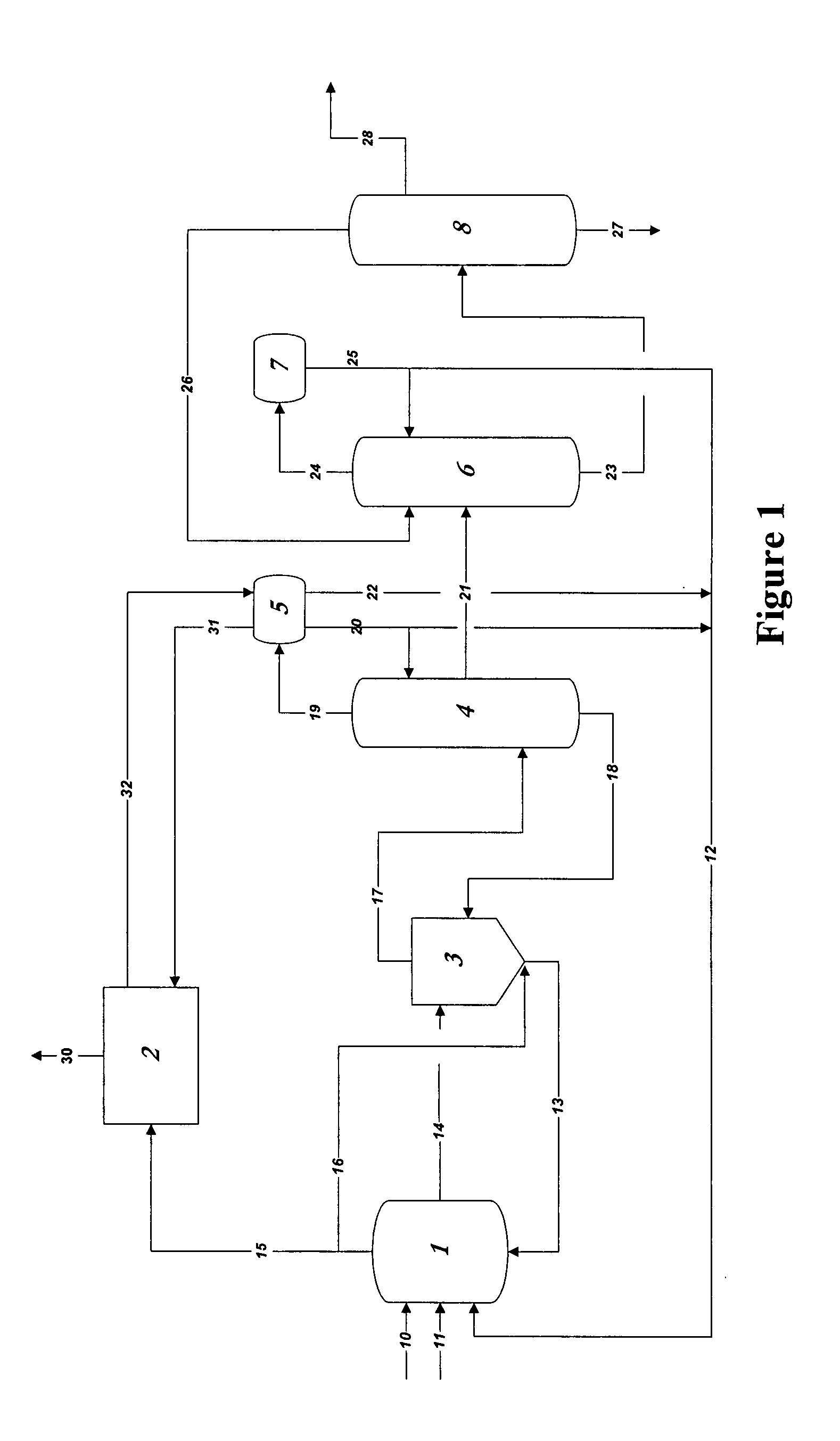

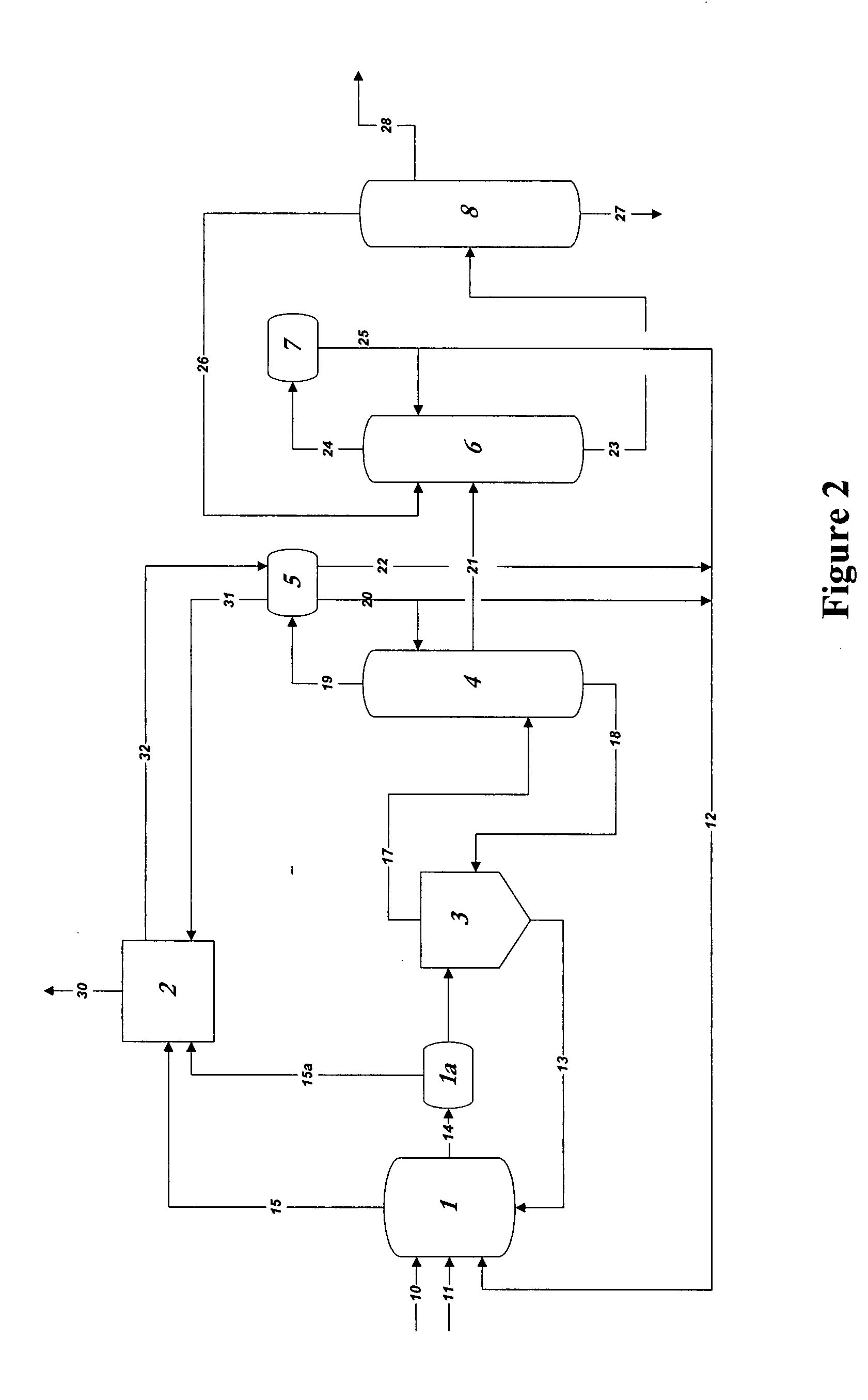

Control of impurities in reaction product of rhodium-catalyzed methanol carbonylation

PatentInactiveUS20080293966A1

Innovation

- A method involving the reaction of methanol, methyl acetate, or dimethyl ether with carbon monoxide in the presence of a rhodium catalyst, maintaining a water concentration of 0.5 to 14 weight percent to control formic acid content in the product acetic acid to 15-160 ppm, and using a silver exchanged cationic ion exchange resin to reduce sulfur levels below 1 ppm.

Manufacture of glacial acetic acid from dilute acetic acid

PatentInactiveGB315397A

Innovation

- A two-stage process where dilute acetic acid is first concentrated to 60% strength through freezing, followed by additional concentration methods such as cold extractions, azeotropic mixtures, or absorption with high-boiling extracting agents, allowing for efficient separation of glacial acetic acid with reduced heat application.

Environmental Impact of Acetic Acid Use

The introduction of glacial acetic acid into reaction mechanisms can have significant environmental implications. Acetic acid, while widely used in various industrial processes, poses potential risks to ecosystems and human health when released into the environment. The environmental impact of acetic acid use primarily stems from its corrosive nature and its ability to alter pH levels in aquatic systems.

When acetic acid is introduced into water bodies, it can lead to acidification, causing a decrease in pH levels. This change in acidity can have detrimental effects on aquatic life, particularly on sensitive species such as fish, amphibians, and invertebrates. Prolonged exposure to acidic conditions can disrupt reproductive cycles, impair growth, and even cause mortality in these organisms. Furthermore, the altered pH can affect the solubility and bioavailability of other pollutants, potentially exacerbating their toxic effects on aquatic ecosystems.

Soil ecosystems are also vulnerable to acetic acid contamination. The introduction of acetic acid can lead to soil acidification, which may negatively impact soil fertility and microbial communities. This can result in reduced plant growth and altered nutrient cycling processes, ultimately affecting the overall health of terrestrial ecosystems.

The atmospheric release of acetic acid, although less common, can contribute to the formation of photochemical smog and acid rain. When acetic acid vapors react with other atmospheric pollutants in the presence of sunlight, they can form secondary air pollutants, such as peroxyacetyl nitrate (PAN), which is a component of photochemical smog. These secondary pollutants can have far-reaching effects on air quality and human health.

From a human health perspective, exposure to high concentrations of acetic acid can cause respiratory irritation, skin burns, and eye damage. While acute exposure risks are primarily associated with occupational settings, chronic low-level exposure through environmental contamination may pose long-term health risks to communities living near industrial facilities that use or produce acetic acid.

To mitigate these environmental impacts, stringent regulations and best practices for acetic acid handling, storage, and disposal are essential. Industries using glacial acetic acid should implement robust containment systems, proper waste management protocols, and effective treatment technologies to minimize environmental releases. Additionally, ongoing monitoring of air, water, and soil quality in areas surrounding acetic acid-using facilities is crucial for early detection and mitigation of potential environmental impacts.

Research into alternative, more environmentally friendly substances or processes that can replace or reduce the use of glacial acetic acid is an important avenue for minimizing long-term environmental risks. As awareness of the environmental impacts of chemical processes grows, there is an increasing emphasis on developing greener alternatives and optimizing existing processes to reduce the overall environmental footprint of industrial operations involving acetic acid.

When acetic acid is introduced into water bodies, it can lead to acidification, causing a decrease in pH levels. This change in acidity can have detrimental effects on aquatic life, particularly on sensitive species such as fish, amphibians, and invertebrates. Prolonged exposure to acidic conditions can disrupt reproductive cycles, impair growth, and even cause mortality in these organisms. Furthermore, the altered pH can affect the solubility and bioavailability of other pollutants, potentially exacerbating their toxic effects on aquatic ecosystems.

Soil ecosystems are also vulnerable to acetic acid contamination. The introduction of acetic acid can lead to soil acidification, which may negatively impact soil fertility and microbial communities. This can result in reduced plant growth and altered nutrient cycling processes, ultimately affecting the overall health of terrestrial ecosystems.

The atmospheric release of acetic acid, although less common, can contribute to the formation of photochemical smog and acid rain. When acetic acid vapors react with other atmospheric pollutants in the presence of sunlight, they can form secondary air pollutants, such as peroxyacetyl nitrate (PAN), which is a component of photochemical smog. These secondary pollutants can have far-reaching effects on air quality and human health.

From a human health perspective, exposure to high concentrations of acetic acid can cause respiratory irritation, skin burns, and eye damage. While acute exposure risks are primarily associated with occupational settings, chronic low-level exposure through environmental contamination may pose long-term health risks to communities living near industrial facilities that use or produce acetic acid.

To mitigate these environmental impacts, stringent regulations and best practices for acetic acid handling, storage, and disposal are essential. Industries using glacial acetic acid should implement robust containment systems, proper waste management protocols, and effective treatment technologies to minimize environmental releases. Additionally, ongoing monitoring of air, water, and soil quality in areas surrounding acetic acid-using facilities is crucial for early detection and mitigation of potential environmental impacts.

Research into alternative, more environmentally friendly substances or processes that can replace or reduce the use of glacial acetic acid is an important avenue for minimizing long-term environmental risks. As awareness of the environmental impacts of chemical processes grows, there is an increasing emphasis on developing greener alternatives and optimizing existing processes to reduce the overall environmental footprint of industrial operations involving acetic acid.

Safety Considerations in Handling Glacial Acetic Acid

Glacial acetic acid is a highly corrosive and flammable substance that requires careful handling to ensure safety in laboratory and industrial settings. When working with this chemical, it is crucial to implement comprehensive safety measures to protect personnel and the environment. Personal protective equipment (PPE) is essential, including chemical-resistant gloves, safety goggles, and a lab coat or chemical-resistant apron. A properly functioning fume hood should be used to minimize exposure to vapors.

Due to its corrosive nature, glacial acetic acid can cause severe burns on contact with skin or eyes. Immediate flushing with water for at least 15 minutes is necessary in case of exposure. Eye wash stations and safety showers should be readily accessible in areas where glacial acetic acid is handled. Inhalation of vapors can irritate the respiratory system, so adequate ventilation is critical.

The flammability of glacial acetic acid poses a fire hazard, particularly when heated. It should be stored away from heat sources, sparks, and open flames. Proper grounding and bonding procedures must be followed when transferring the chemical to prevent static electricity buildup. Fire extinguishers suitable for chemical fires should be available in the vicinity.

Containment and spill control measures are vital. Secondary containment should be used during storage and transport to prevent accidental releases. Spill kits specifically designed for acid spills must be readily available, and personnel should be trained in their use. In the event of a spill, neutralization with sodium bicarbonate or other appropriate bases should be performed carefully to avoid violent reactions.

Proper storage is crucial for maintaining the stability of glacial acetic acid. It should be kept in tightly sealed containers made of compatible materials such as stainless steel or glass. Storage areas should be well-ventilated, cool, and dry. Incompatible substances, particularly strong oxidizing agents and bases, must be stored separately to prevent hazardous reactions.

Training and education are fundamental aspects of safety when handling glacial acetic acid. All personnel working with or around the chemical should receive comprehensive training on its properties, hazards, and proper handling procedures. Safety data sheets (SDS) must be readily accessible, and regular safety briefings should be conducted to reinforce best practices.

Emergency response planning is essential. Clear protocols for handling spills, fires, and personal exposure incidents should be established and regularly reviewed. Coordination with local emergency services is advisable to ensure an effective response in case of a major incident.

Due to its corrosive nature, glacial acetic acid can cause severe burns on contact with skin or eyes. Immediate flushing with water for at least 15 minutes is necessary in case of exposure. Eye wash stations and safety showers should be readily accessible in areas where glacial acetic acid is handled. Inhalation of vapors can irritate the respiratory system, so adequate ventilation is critical.

The flammability of glacial acetic acid poses a fire hazard, particularly when heated. It should be stored away from heat sources, sparks, and open flames. Proper grounding and bonding procedures must be followed when transferring the chemical to prevent static electricity buildup. Fire extinguishers suitable for chemical fires should be available in the vicinity.

Containment and spill control measures are vital. Secondary containment should be used during storage and transport to prevent accidental releases. Spill kits specifically designed for acid spills must be readily available, and personnel should be trained in their use. In the event of a spill, neutralization with sodium bicarbonate or other appropriate bases should be performed carefully to avoid violent reactions.

Proper storage is crucial for maintaining the stability of glacial acetic acid. It should be kept in tightly sealed containers made of compatible materials such as stainless steel or glass. Storage areas should be well-ventilated, cool, and dry. Incompatible substances, particularly strong oxidizing agents and bases, must be stored separately to prevent hazardous reactions.

Training and education are fundamental aspects of safety when handling glacial acetic acid. All personnel working with or around the chemical should receive comprehensive training on its properties, hazards, and proper handling procedures. Safety data sheets (SDS) must be readily accessible, and regular safety briefings should be conducted to reinforce best practices.

Emergency response planning is essential. Clear protocols for handling spills, fires, and personal exposure incidents should be established and regularly reviewed. Coordination with local emergency services is advisable to ensure an effective response in case of a major incident.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!