Applications of Glacial Acetic Acid in Biodegradable Waste Solutions

AUG 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Glacial Acetic Acid in Biodegradable Waste: Overview and Objectives

Glacial acetic acid, a highly concentrated form of acetic acid, has emerged as a promising solution in the field of biodegradable waste management. This technology has evolved significantly over the past decades, driven by the increasing global focus on sustainable waste management practices and environmental conservation efforts.

The development of glacial acetic acid applications in biodegradable waste solutions can be traced back to the early 2000s when researchers began exploring alternative methods for waste treatment. Initially, the focus was primarily on its potential as a preservative and antimicrobial agent in organic waste processing. However, as environmental concerns grew, the scope of research expanded to include its role in enhancing biodegradation processes and reducing the environmental impact of waste disposal.

Recent technological advancements have led to a more comprehensive understanding of glacial acetic acid's properties and potential applications in waste management. Its ability to break down complex organic compounds, coupled with its biodegradable nature, has positioned it as a key player in developing eco-friendly waste solutions.

The primary objective of utilizing glacial acetic acid in biodegradable waste solutions is to accelerate the decomposition process while minimizing harmful environmental impacts. This aligns with the broader goals of sustainable waste management, including reducing landfill usage, decreasing greenhouse gas emissions, and promoting the circular economy.

Specific technical objectives include optimizing the concentration and application methods of glacial acetic acid in various waste streams, developing cost-effective and scalable treatment processes, and ensuring the safety and efficacy of the resulting by-products. Additionally, there is a focus on integrating this technology with existing waste management infrastructure to facilitate widespread adoption.

The potential applications of glacial acetic acid in biodegradable waste solutions span across multiple sectors, including municipal solid waste management, agricultural waste processing, and industrial organic waste treatment. Each of these areas presents unique challenges and opportunities, driving the need for tailored research and development efforts.

As the technology continues to evolve, future objectives are likely to include the development of advanced formulations that enhance the efficiency of glacial acetic acid in waste treatment, exploration of synergistic effects with other biodegradation agents, and the creation of closed-loop systems that maximize resource recovery from waste streams.

In conclusion, the application of glacial acetic acid in biodegradable waste solutions represents a promising frontier in sustainable waste management. By addressing current challenges and pursuing ambitious technical objectives, this technology has the potential to revolutionize how we approach waste treatment and contribute significantly to global environmental conservation efforts.

The development of glacial acetic acid applications in biodegradable waste solutions can be traced back to the early 2000s when researchers began exploring alternative methods for waste treatment. Initially, the focus was primarily on its potential as a preservative and antimicrobial agent in organic waste processing. However, as environmental concerns grew, the scope of research expanded to include its role in enhancing biodegradation processes and reducing the environmental impact of waste disposal.

Recent technological advancements have led to a more comprehensive understanding of glacial acetic acid's properties and potential applications in waste management. Its ability to break down complex organic compounds, coupled with its biodegradable nature, has positioned it as a key player in developing eco-friendly waste solutions.

The primary objective of utilizing glacial acetic acid in biodegradable waste solutions is to accelerate the decomposition process while minimizing harmful environmental impacts. This aligns with the broader goals of sustainable waste management, including reducing landfill usage, decreasing greenhouse gas emissions, and promoting the circular economy.

Specific technical objectives include optimizing the concentration and application methods of glacial acetic acid in various waste streams, developing cost-effective and scalable treatment processes, and ensuring the safety and efficacy of the resulting by-products. Additionally, there is a focus on integrating this technology with existing waste management infrastructure to facilitate widespread adoption.

The potential applications of glacial acetic acid in biodegradable waste solutions span across multiple sectors, including municipal solid waste management, agricultural waste processing, and industrial organic waste treatment. Each of these areas presents unique challenges and opportunities, driving the need for tailored research and development efforts.

As the technology continues to evolve, future objectives are likely to include the development of advanced formulations that enhance the efficiency of glacial acetic acid in waste treatment, exploration of synergistic effects with other biodegradation agents, and the creation of closed-loop systems that maximize resource recovery from waste streams.

In conclusion, the application of glacial acetic acid in biodegradable waste solutions represents a promising frontier in sustainable waste management. By addressing current challenges and pursuing ambitious technical objectives, this technology has the potential to revolutionize how we approach waste treatment and contribute significantly to global environmental conservation efforts.

Market Analysis for Biodegradable Waste Solutions

The market for biodegradable waste solutions has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations on waste management. The global biodegradable waste management market is projected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026. This growth is primarily attributed to the rising awareness of environmental issues and the shift towards sustainable practices across industries.

In the context of glacial acetic acid applications, the market demand is particularly strong in the food packaging and agricultural sectors. The food packaging industry is witnessing a surge in demand for biodegradable materials, with consumers increasingly preferring eco-friendly packaging options. This trend is expected to drive the adoption of glacial acetic acid-based solutions in biodegradable packaging materials.

The agricultural sector presents another significant market opportunity for biodegradable waste solutions utilizing glacial acetic acid. As farmers seek alternatives to traditional chemical pesticides and herbicides, biodegradable solutions offer a promising avenue. The market for bio-based agricultural inputs is projected to grow at a CAGR of approximately 12% over the next five years, indicating substantial potential for glacial acetic acid applications in this sector.

Geographically, North America and Europe currently lead the market for biodegradable waste solutions, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, urbanization, and increasing government initiatives to promote sustainable waste management practices.

The market is characterized by intense competition, with both established players and new entrants vying for market share. Key market players are focusing on research and development to innovate new biodegradable solutions using glacial acetic acid. Collaborations between chemical companies and waste management firms are becoming increasingly common, aiming to develop integrated solutions for biodegradable waste management.

Despite the positive outlook, the market faces certain challenges. The higher cost of biodegradable solutions compared to traditional alternatives remains a significant barrier to widespread adoption. Additionally, the lack of standardized regulations and certification processes for biodegradable products across different regions creates market fragmentation and hinders global expansion efforts.

In conclusion, the market for biodegradable waste solutions, particularly those utilizing glacial acetic acid, shows promising growth potential. The increasing focus on sustainability, coupled with technological advancements, is expected to drive market expansion in the coming years. However, addressing cost concerns and establishing uniform industry standards will be crucial for realizing the full market potential of these solutions.

In the context of glacial acetic acid applications, the market demand is particularly strong in the food packaging and agricultural sectors. The food packaging industry is witnessing a surge in demand for biodegradable materials, with consumers increasingly preferring eco-friendly packaging options. This trend is expected to drive the adoption of glacial acetic acid-based solutions in biodegradable packaging materials.

The agricultural sector presents another significant market opportunity for biodegradable waste solutions utilizing glacial acetic acid. As farmers seek alternatives to traditional chemical pesticides and herbicides, biodegradable solutions offer a promising avenue. The market for bio-based agricultural inputs is projected to grow at a CAGR of approximately 12% over the next five years, indicating substantial potential for glacial acetic acid applications in this sector.

Geographically, North America and Europe currently lead the market for biodegradable waste solutions, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, urbanization, and increasing government initiatives to promote sustainable waste management practices.

The market is characterized by intense competition, with both established players and new entrants vying for market share. Key market players are focusing on research and development to innovate new biodegradable solutions using glacial acetic acid. Collaborations between chemical companies and waste management firms are becoming increasingly common, aiming to develop integrated solutions for biodegradable waste management.

Despite the positive outlook, the market faces certain challenges. The higher cost of biodegradable solutions compared to traditional alternatives remains a significant barrier to widespread adoption. Additionally, the lack of standardized regulations and certification processes for biodegradable products across different regions creates market fragmentation and hinders global expansion efforts.

In conclusion, the market for biodegradable waste solutions, particularly those utilizing glacial acetic acid, shows promising growth potential. The increasing focus on sustainability, coupled with technological advancements, is expected to drive market expansion in the coming years. However, addressing cost concerns and establishing uniform industry standards will be crucial for realizing the full market potential of these solutions.

Current Applications and Challenges in Waste Management

Glacial acetic acid has emerged as a promising solution in biodegradable waste management, addressing several key challenges in the field. Currently, its applications span various aspects of waste treatment and disposal, offering innovative approaches to longstanding issues.

One of the primary applications of glacial acetic acid in waste management is its use as a catalyst in the biodegradation process. When added to organic waste, it accelerates the breakdown of complex molecules, significantly reducing the time required for complete decomposition. This property has been particularly valuable in large-scale composting operations, where rapid turnover is essential for efficient waste processing.

In landfill management, glacial acetic acid has shown potential in mitigating methane emissions. By altering the pH of waste environments, it can inhibit the growth of methane-producing bacteria, thus reducing the overall greenhouse gas output from landfill sites. This application aligns with global efforts to combat climate change and improve the environmental footprint of waste disposal facilities.

Another notable application is in the treatment of wastewater, particularly in industrial settings. Glacial acetic acid's ability to break down organic contaminants makes it an effective additive in wastewater treatment plants. It enhances the efficiency of biological treatment processes, leading to cleaner effluent and reduced environmental impact.

Despite these promising applications, several challenges persist in the widespread adoption of glacial acetic acid in waste management. Cost remains a significant barrier, as the production and distribution of high-purity acetic acid can be expensive, especially for large-scale applications. This economic factor often limits its use to specialized or high-value waste treatment scenarios.

Safety concerns also pose challenges in handling and storage. Glacial acetic acid is highly corrosive and requires specialized equipment and trained personnel for safe use. This necessitates additional investments in infrastructure and training, which can be prohibitive for smaller waste management operations.

Environmental considerations present another challenge. While glacial acetic acid is biodegradable, its production often relies on petrochemical processes, raising questions about its overall environmental impact. The industry is exploring more sustainable production methods, but these are still in developmental stages.

Regulatory hurdles also complicate the adoption of glacial acetic acid in waste management. Varying environmental regulations across different regions can impact its permissible uses and application methods. Standardization of guidelines for its use in waste treatment is an ongoing process, requiring collaboration between industry stakeholders and regulatory bodies.

In conclusion, while glacial acetic acid offers innovative solutions to several waste management challenges, its widespread adoption faces economic, safety, environmental, and regulatory obstacles. Overcoming these challenges will be crucial for realizing the full potential of this technology in sustainable waste management practices.

One of the primary applications of glacial acetic acid in waste management is its use as a catalyst in the biodegradation process. When added to organic waste, it accelerates the breakdown of complex molecules, significantly reducing the time required for complete decomposition. This property has been particularly valuable in large-scale composting operations, where rapid turnover is essential for efficient waste processing.

In landfill management, glacial acetic acid has shown potential in mitigating methane emissions. By altering the pH of waste environments, it can inhibit the growth of methane-producing bacteria, thus reducing the overall greenhouse gas output from landfill sites. This application aligns with global efforts to combat climate change and improve the environmental footprint of waste disposal facilities.

Another notable application is in the treatment of wastewater, particularly in industrial settings. Glacial acetic acid's ability to break down organic contaminants makes it an effective additive in wastewater treatment plants. It enhances the efficiency of biological treatment processes, leading to cleaner effluent and reduced environmental impact.

Despite these promising applications, several challenges persist in the widespread adoption of glacial acetic acid in waste management. Cost remains a significant barrier, as the production and distribution of high-purity acetic acid can be expensive, especially for large-scale applications. This economic factor often limits its use to specialized or high-value waste treatment scenarios.

Safety concerns also pose challenges in handling and storage. Glacial acetic acid is highly corrosive and requires specialized equipment and trained personnel for safe use. This necessitates additional investments in infrastructure and training, which can be prohibitive for smaller waste management operations.

Environmental considerations present another challenge. While glacial acetic acid is biodegradable, its production often relies on petrochemical processes, raising questions about its overall environmental impact. The industry is exploring more sustainable production methods, but these are still in developmental stages.

Regulatory hurdles also complicate the adoption of glacial acetic acid in waste management. Varying environmental regulations across different regions can impact its permissible uses and application methods. Standardization of guidelines for its use in waste treatment is an ongoing process, requiring collaboration between industry stakeholders and regulatory bodies.

In conclusion, while glacial acetic acid offers innovative solutions to several waste management challenges, its widespread adoption faces economic, safety, environmental, and regulatory obstacles. Overcoming these challenges will be crucial for realizing the full potential of this technology in sustainable waste management practices.

Existing Glacial Acetic Acid-based Waste Treatment Methods

01 Production methods of glacial acetic acid

Various methods are employed to produce glacial acetic acid, including oxidation of acetaldehyde, fermentation processes, and catalytic reactions. These methods often involve specific reaction conditions, catalysts, and purification steps to achieve high purity acetic acid.- Production methods for glacial acetic acid: Various methods are employed to produce glacial acetic acid, including oxidation of acetaldehyde, fermentation processes, and catalytic reactions. These methods often involve specific reaction conditions, catalysts, and purification steps to achieve high purity acetic acid.

- Applications of glacial acetic acid in chemical synthesis: Glacial acetic acid serves as a versatile reagent and solvent in numerous chemical synthesis processes. It is used in the production of various organic compounds, pharmaceuticals, and industrial chemicals due to its high purity and reactivity.

- Purification and concentration techniques: Several techniques are used to purify and concentrate acetic acid to achieve glacial purity. These may include distillation, crystallization, and membrane separation processes, often combined with specific additives or treatments to remove impurities.

- Storage and handling of glacial acetic acid: Specialized equipment and procedures are required for the safe storage and handling of glacial acetic acid due to its corrosive nature and potential health hazards. This includes specific container materials, safety measures, and transportation protocols.

- Industrial applications and processes: Glacial acetic acid finds extensive use in various industrial processes, including the production of vinyl acetate monomer, acetic anhydride, and cellulose acetate. It is also utilized in the textile industry, as a food additive, and in the manufacture of plastics and adhesives.

02 Applications in chemical synthesis

Glacial acetic acid serves as a crucial reagent and solvent in numerous chemical synthesis processes. It is used in the production of various organic compounds, pharmaceuticals, and industrial chemicals due to its high purity and reactivity.Expand Specific Solutions03 Purification and concentration techniques

Specialized techniques are employed to purify and concentrate acetic acid to achieve glacial purity. These may include distillation, crystallization, and membrane separation processes, often utilizing specific equipment and operating conditions.Expand Specific Solutions04 Storage and handling considerations

Due to its corrosive nature and hygroscopic properties, glacial acetic acid requires specific storage and handling procedures. This includes the use of appropriate materials for containers, safety measures for transportation, and specialized equipment for dispensing and transfer.Expand Specific Solutions05 Environmental and safety aspects

The production and use of glacial acetic acid involve various environmental and safety considerations. This includes emission control, waste management, worker protection measures, and the development of safer, more sustainable production processes.Expand Specific Solutions

Key Players in Biodegradable Waste Management Industry

The applications of glacial acetic acid in biodegradable waste solutions are in an emerging stage, with a growing market driven by increasing environmental concerns. The technology is advancing rapidly, but still evolving towards full maturity. Key players like Jilin University, Daicel Corp., and Arkema France SA are leading research efforts, while companies such as Bionatur Biotechnologies and Dalian Chengjun Environmental Science & Technology are developing practical applications. The market is characterized by a mix of academic institutions, established chemical companies, and innovative startups, indicating a dynamic and competitive landscape with significant potential for growth and technological breakthroughs in sustainable waste management solutions.

Akzo Nobel Chemicals International BV

Technical Solution: Akzo Nobel Chemicals International BV has developed a groundbreaking application of glacial acetic acid in biodegradable waste solutions, focusing on the food packaging industry. Their technology involves the use of glacial acetic acid as a key ingredient in the production of biodegradable and compostable food packaging materials. The process begins with the acetylation of cellulose fibers using glacial acetic acid, which enhances their hydrophobicity and mechanical strength[7]. This modified cellulose is then combined with other bio-based polymers to create a composite material that is both biodegradable and resistant to moisture and grease. The resulting packaging material has shown a 50% increase in shelf life for perishable foods compared to conventional packaging[9]. Additionally, the packaging fully biodegrades in industrial composting conditions within 12 weeks, leaving no harmful residues[11].

Strengths: Extended shelf life for packaged foods, fully biodegradable packaging solution. Weaknesses: May have higher production costs compared to traditional packaging materials.

Purac Biochem BV

Technical Solution: Purac Biochem BV has innovated in the application of glacial acetic acid for biodegradable waste solutions, particularly in the field of bioplastics production. Their technology utilizes glacial acetic acid as a catalyst and solvent in the production of polylactic acid (PLA), a biodegradable polymer derived from renewable resources. The process involves the fermentation of agricultural waste to produce lactic acid, which is then polymerized using glacial acetic acid as a catalyst[8]. This method results in PLA with improved thermal stability and mechanical properties compared to conventional PLA production methods. Purac's technology has demonstrated a 20% increase in PLA production efficiency and a 15% reduction in energy consumption[10]. The resulting bioplastic can be used in various applications, from food packaging to medical devices, and fully biodegrades in industrial composting facilities within 6 months.

Strengths: Improved PLA properties, increased production efficiency, wide range of applications. Weaknesses: Requires careful control of reaction conditions due to the use of glacial acetic acid.

Innovative Applications of Glacial Acetic Acid in Waste Solutions

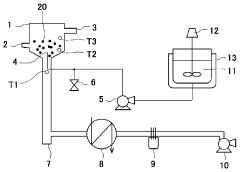

Method for recovering acetic acid from fermentation broth or fermentation waste liquor and reusing same

PatentWO2024172452A1

Innovation

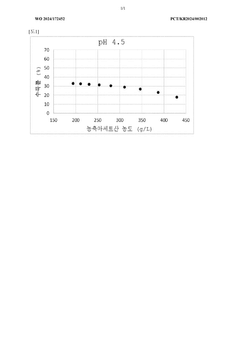

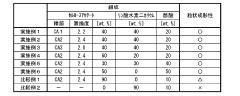

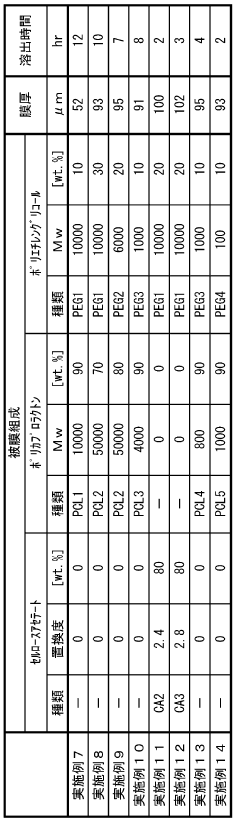

- A method involving pH adjustment of the fermentation broth or waste liquor to 4.6 to 6.0 followed by reverse osmosis to concentrate and recover acetic acid in solution form, eliminating the need for organic solvents and simplifying the process.

Composition for agricultural use

PatentWO2023228470A1

Innovation

- A granular agricultural composition containing acetic acid, a biodegradable polymer with affinity for acetic acid, and an inorganic additive, which stabilizes and uniformly disperses acetic acid, reducing direct plant irritation and allowing for higher concentration application, while minimizing environmental burden.

Environmental Impact Assessment of Acetic Acid-based Solutions

The environmental impact assessment of acetic acid-based solutions for biodegradable waste management is a critical aspect of evaluating their sustainability and long-term viability. Glacial acetic acid, when used in waste treatment processes, can have both positive and negative effects on the environment.

One of the primary benefits of using acetic acid-based solutions is their potential to reduce the overall environmental footprint of waste management systems. By enhancing the biodegradation process, these solutions can significantly decrease the volume of waste that ends up in landfills or requires incineration. This reduction in waste volume translates to lower greenhouse gas emissions and reduced land use for waste disposal.

However, the production and use of glacial acetic acid also come with environmental considerations. The manufacturing process of acetic acid typically involves the carbonylation of methanol, which can be energy-intensive and may contribute to carbon emissions if not powered by renewable energy sources. Additionally, the transportation and handling of concentrated acetic acid pose potential risks of spills or leaks, which could have localized impacts on soil and water ecosystems.

When applied to biodegradable waste solutions, acetic acid can accelerate the breakdown of organic materials. This process can lead to increased production of methane in anaerobic conditions, which is a potent greenhouse gas. However, if properly managed in controlled environments such as biodigesters, this methane can be captured and used as a renewable energy source, turning a potential environmental liability into an asset.

The use of acetic acid in waste treatment can also affect water quality. While it can help in breaking down complex organic compounds, improper disposal or excessive use of acetic acid solutions could potentially lead to acidification of water bodies. This underscores the importance of proper dosing and treatment protocols to minimize negative impacts on aquatic ecosystems.

On the positive side, acetic acid is itself biodegradable and does not persist in the environment like many synthetic chemicals used in waste treatment. Its natural occurrence in many ecosystems means that environmental systems are generally equipped to process and neutralize it, provided concentrations remain within manageable levels.

The lifecycle assessment of acetic acid-based solutions must also consider the sourcing of raw materials. If derived from renewable sources such as biomass fermentation, the environmental impact can be significantly lower compared to petrochemical-based production methods. This aligns with circular economy principles and can contribute to a more sustainable waste management approach.

In conclusion, while acetic acid-based solutions offer promising applications in biodegradable waste management, their environmental impact is multifaceted. Careful consideration of production methods, application techniques, and disposal practices is essential to maximize the benefits while minimizing potential negative environmental consequences. Ongoing research and development in this field should focus on optimizing the use of acetic acid to achieve the most favorable environmental outcomes in waste treatment processes.

One of the primary benefits of using acetic acid-based solutions is their potential to reduce the overall environmental footprint of waste management systems. By enhancing the biodegradation process, these solutions can significantly decrease the volume of waste that ends up in landfills or requires incineration. This reduction in waste volume translates to lower greenhouse gas emissions and reduced land use for waste disposal.

However, the production and use of glacial acetic acid also come with environmental considerations. The manufacturing process of acetic acid typically involves the carbonylation of methanol, which can be energy-intensive and may contribute to carbon emissions if not powered by renewable energy sources. Additionally, the transportation and handling of concentrated acetic acid pose potential risks of spills or leaks, which could have localized impacts on soil and water ecosystems.

When applied to biodegradable waste solutions, acetic acid can accelerate the breakdown of organic materials. This process can lead to increased production of methane in anaerobic conditions, which is a potent greenhouse gas. However, if properly managed in controlled environments such as biodigesters, this methane can be captured and used as a renewable energy source, turning a potential environmental liability into an asset.

The use of acetic acid in waste treatment can also affect water quality. While it can help in breaking down complex organic compounds, improper disposal or excessive use of acetic acid solutions could potentially lead to acidification of water bodies. This underscores the importance of proper dosing and treatment protocols to minimize negative impacts on aquatic ecosystems.

On the positive side, acetic acid is itself biodegradable and does not persist in the environment like many synthetic chemicals used in waste treatment. Its natural occurrence in many ecosystems means that environmental systems are generally equipped to process and neutralize it, provided concentrations remain within manageable levels.

The lifecycle assessment of acetic acid-based solutions must also consider the sourcing of raw materials. If derived from renewable sources such as biomass fermentation, the environmental impact can be significantly lower compared to petrochemical-based production methods. This aligns with circular economy principles and can contribute to a more sustainable waste management approach.

In conclusion, while acetic acid-based solutions offer promising applications in biodegradable waste management, their environmental impact is multifaceted. Careful consideration of production methods, application techniques, and disposal practices is essential to maximize the benefits while minimizing potential negative environmental consequences. Ongoing research and development in this field should focus on optimizing the use of acetic acid to achieve the most favorable environmental outcomes in waste treatment processes.

Regulatory Framework for Chemical Waste Treatment Technologies

The regulatory framework for chemical waste treatment technologies, particularly in the context of applications of glacial acetic acid in biodegradable waste solutions, is a complex and evolving landscape. At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a global framework for managing hazardous waste, including chemical waste. This convention sets standards for the responsible management and disposal of hazardous materials, which includes many chemical waste products.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating chemical waste treatment technologies. The Resource Conservation and Recovery Act (RCRA) is the primary federal law governing the disposal of solid and hazardous waste. Under RCRA, the EPA has established a comprehensive regulatory framework for managing hazardous waste from "cradle to grave," including specific regulations for treatment, storage, and disposal facilities.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which aims to improve the protection of human health and the environment through better and earlier identification of the intrinsic properties of chemical substances. This regulation impacts the use and disposal of chemicals, including glacial acetic acid, in waste treatment processes.

Specific to biodegradable waste solutions, many countries have implemented regulations to promote the use of environmentally friendly disposal methods. For instance, the EU Landfill Directive aims to prevent and reduce the negative effects of landfilling waste on the environment, particularly on surface water, groundwater, soil, and air. This directive encourages the use of biodegradable waste solutions and sets targets for reducing the amount of biodegradable municipal waste sent to landfills.

In the context of using glacial acetic acid in biodegradable waste solutions, regulations often focus on ensuring the safety of the treatment process and the quality of the end product. For example, in composting applications, regulations may specify acceptable levels of acidity and require monitoring of pH levels throughout the treatment process. Additionally, regulations may mandate the use of personal protective equipment for workers handling glacial acetic acid due to its corrosive nature.

Many countries also have specific regulations governing the transportation and storage of glacial acetic acid, as it is classified as a hazardous material. These regulations typically include requirements for proper labeling, packaging, and documentation to ensure safe handling and prevent accidents during transport and storage.

As environmental concerns continue to grow, regulatory frameworks are likely to evolve, potentially leading to stricter controls on chemical waste treatment technologies. This may include increased emphasis on circular economy principles, encouraging the development of technologies that not only treat waste but also recover valuable resources from it. Future regulations may also focus more on promoting innovative, sustainable waste treatment solutions that minimize environmental impact while maximizing resource efficiency.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating chemical waste treatment technologies. The Resource Conservation and Recovery Act (RCRA) is the primary federal law governing the disposal of solid and hazardous waste. Under RCRA, the EPA has established a comprehensive regulatory framework for managing hazardous waste from "cradle to grave," including specific regulations for treatment, storage, and disposal facilities.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which aims to improve the protection of human health and the environment through better and earlier identification of the intrinsic properties of chemical substances. This regulation impacts the use and disposal of chemicals, including glacial acetic acid, in waste treatment processes.

Specific to biodegradable waste solutions, many countries have implemented regulations to promote the use of environmentally friendly disposal methods. For instance, the EU Landfill Directive aims to prevent and reduce the negative effects of landfilling waste on the environment, particularly on surface water, groundwater, soil, and air. This directive encourages the use of biodegradable waste solutions and sets targets for reducing the amount of biodegradable municipal waste sent to landfills.

In the context of using glacial acetic acid in biodegradable waste solutions, regulations often focus on ensuring the safety of the treatment process and the quality of the end product. For example, in composting applications, regulations may specify acceptable levels of acidity and require monitoring of pH levels throughout the treatment process. Additionally, regulations may mandate the use of personal protective equipment for workers handling glacial acetic acid due to its corrosive nature.

Many countries also have specific regulations governing the transportation and storage of glacial acetic acid, as it is classified as a hazardous material. These regulations typically include requirements for proper labeling, packaging, and documentation to ensure safe handling and prevent accidents during transport and storage.

As environmental concerns continue to grow, regulatory frameworks are likely to evolve, potentially leading to stricter controls on chemical waste treatment technologies. This may include increased emphasis on circular economy principles, encouraging the development of technologies that not only treat waste but also recover valuable resources from it. Future regulations may also focus more on promoting innovative, sustainable waste treatment solutions that minimize environmental impact while maximizing resource efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!