Evaluating Bioplastic Production Using Glacial Acetic Acid

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bioplastic Evolution

The evolution of bioplastics represents a significant shift in material science and environmental sustainability. Initially developed in the early 20th century, bioplastics have undergone substantial transformations, driven by the growing need for eco-friendly alternatives to conventional petroleum-based plastics. The journey began with the creation of cellophane in 1912, marking the first commercially viable bioplastic.

In the 1970s and 1980s, environmental concerns sparked renewed interest in bioplastics. This period saw the development of polyhydroxyalkanoates (PHAs) and polylactic acid (PLA), two key bioplastic materials that continue to play crucial roles in the industry today. PHAs, produced by bacterial fermentation, offered biodegradability and versatility, while PLA, derived from renewable resources like corn starch, provided a more sustainable alternative to traditional plastics.

The 1990s and early 2000s witnessed significant advancements in bioplastic technology. Improved production processes and the introduction of new biopolymers expanded the range of applications for bioplastics. During this time, companies began incorporating bioplastics into packaging, disposable cutlery, and even automotive components.

Recent years have seen a surge in innovation within the bioplastics sector. The introduction of novel feedstocks, such as algae and agricultural waste, has broadened the scope of bioplastic production. Additionally, advancements in genetic engineering have enabled the creation of more efficient microorganisms for biopolymer synthesis, leading to improved yields and reduced production costs.

The use of glacial acetic acid in bioplastic production represents a promising development in this evolutionary timeline. This approach offers potential advantages in terms of process efficiency and material properties. As research in this area progresses, it may lead to new classes of bioplastics with enhanced performance characteristics and environmental benefits.

Looking forward, the bioplastics industry is poised for further growth and innovation. Emerging technologies, such as CRISPR gene editing and artificial intelligence-driven material design, are expected to accelerate the development of next-generation bioplastics. These advancements may result in materials that not only match but potentially surpass the performance of traditional plastics while maintaining their eco-friendly attributes.

The evolution of bioplastics continues to be driven by a combination of environmental concerns, technological advancements, and market demands. As the industry matures, we can anticipate further improvements in biodegradability, durability, and cost-effectiveness, solidifying bioplastics' position as a viable and sustainable alternative to conventional plastics across various sectors.

In the 1970s and 1980s, environmental concerns sparked renewed interest in bioplastics. This period saw the development of polyhydroxyalkanoates (PHAs) and polylactic acid (PLA), two key bioplastic materials that continue to play crucial roles in the industry today. PHAs, produced by bacterial fermentation, offered biodegradability and versatility, while PLA, derived from renewable resources like corn starch, provided a more sustainable alternative to traditional plastics.

The 1990s and early 2000s witnessed significant advancements in bioplastic technology. Improved production processes and the introduction of new biopolymers expanded the range of applications for bioplastics. During this time, companies began incorporating bioplastics into packaging, disposable cutlery, and even automotive components.

Recent years have seen a surge in innovation within the bioplastics sector. The introduction of novel feedstocks, such as algae and agricultural waste, has broadened the scope of bioplastic production. Additionally, advancements in genetic engineering have enabled the creation of more efficient microorganisms for biopolymer synthesis, leading to improved yields and reduced production costs.

The use of glacial acetic acid in bioplastic production represents a promising development in this evolutionary timeline. This approach offers potential advantages in terms of process efficiency and material properties. As research in this area progresses, it may lead to new classes of bioplastics with enhanced performance characteristics and environmental benefits.

Looking forward, the bioplastics industry is poised for further growth and innovation. Emerging technologies, such as CRISPR gene editing and artificial intelligence-driven material design, are expected to accelerate the development of next-generation bioplastics. These advancements may result in materials that not only match but potentially surpass the performance of traditional plastics while maintaining their eco-friendly attributes.

The evolution of bioplastics continues to be driven by a combination of environmental concerns, technological advancements, and market demands. As the industry matures, we can anticipate further improvements in biodegradability, durability, and cost-effectiveness, solidifying bioplastics' position as a viable and sustainable alternative to conventional plastics across various sectors.

Market Demand Analysis

The market demand for bioplastics produced using glacial acetic acid has been steadily growing in recent years, driven by increasing environmental concerns and the push for sustainable alternatives to traditional petroleum-based plastics. This trend is particularly evident in packaging, consumer goods, and automotive industries, where there is a growing preference for eco-friendly materials.

The global bioplastics market is experiencing significant expansion, with projections indicating continued growth in the coming years. This growth is fueled by stringent environmental regulations, consumer awareness, and corporate sustainability initiatives. The use of glacial acetic acid in bioplastic production offers several advantages, including improved biodegradability and reduced carbon footprint, which align well with these market drivers.

In the packaging sector, which represents a substantial portion of the bioplastics market, there is a notable shift towards sustainable solutions. Major food and beverage companies are increasingly adopting bioplastic packaging to meet consumer demands for environmentally friendly products. This trend is expected to continue, creating a robust demand for bioplastics produced using innovative methods such as those involving glacial acetic acid.

The consumer goods industry is another key market for bioplastics, with applications ranging from disposable cutlery to personal care product packaging. The demand in this sector is driven by both regulatory pressures and changing consumer preferences. As awareness of plastic pollution grows, consumers are actively seeking products made from renewable and biodegradable materials, creating a favorable market environment for bioplastics produced using glacial acetic acid.

In the automotive industry, there is an increasing focus on lightweight, sustainable materials to improve fuel efficiency and reduce environmental impact. Bioplastics offer a promising solution in this regard, with potential applications in interior components, under-the-hood parts, and exterior trims. The use of glacial acetic acid in bioplastic production could provide additional benefits in terms of material properties and environmental performance, further driving demand in this sector.

Geographically, the demand for bioplastics is particularly strong in regions with stringent environmental regulations and high consumer awareness, such as Europe and North America. However, emerging economies in Asia-Pacific are also showing significant growth potential as they implement stricter environmental policies and witness rising consumer consciousness about sustainability.

Despite the positive market outlook, challenges remain in scaling up production and achieving cost competitiveness with traditional plastics. The success of bioplastics produced using glacial acetic acid will depend on continued technological advancements, cost reduction strategies, and supportive policy frameworks. As these factors align, the market demand for this innovative approach to bioplastic production is expected to strengthen, offering significant opportunities for growth and market penetration across various industries.

The global bioplastics market is experiencing significant expansion, with projections indicating continued growth in the coming years. This growth is fueled by stringent environmental regulations, consumer awareness, and corporate sustainability initiatives. The use of glacial acetic acid in bioplastic production offers several advantages, including improved biodegradability and reduced carbon footprint, which align well with these market drivers.

In the packaging sector, which represents a substantial portion of the bioplastics market, there is a notable shift towards sustainable solutions. Major food and beverage companies are increasingly adopting bioplastic packaging to meet consumer demands for environmentally friendly products. This trend is expected to continue, creating a robust demand for bioplastics produced using innovative methods such as those involving glacial acetic acid.

The consumer goods industry is another key market for bioplastics, with applications ranging from disposable cutlery to personal care product packaging. The demand in this sector is driven by both regulatory pressures and changing consumer preferences. As awareness of plastic pollution grows, consumers are actively seeking products made from renewable and biodegradable materials, creating a favorable market environment for bioplastics produced using glacial acetic acid.

In the automotive industry, there is an increasing focus on lightweight, sustainable materials to improve fuel efficiency and reduce environmental impact. Bioplastics offer a promising solution in this regard, with potential applications in interior components, under-the-hood parts, and exterior trims. The use of glacial acetic acid in bioplastic production could provide additional benefits in terms of material properties and environmental performance, further driving demand in this sector.

Geographically, the demand for bioplastics is particularly strong in regions with stringent environmental regulations and high consumer awareness, such as Europe and North America. However, emerging economies in Asia-Pacific are also showing significant growth potential as they implement stricter environmental policies and witness rising consumer consciousness about sustainability.

Despite the positive market outlook, challenges remain in scaling up production and achieving cost competitiveness with traditional plastics. The success of bioplastics produced using glacial acetic acid will depend on continued technological advancements, cost reduction strategies, and supportive policy frameworks. As these factors align, the market demand for this innovative approach to bioplastic production is expected to strengthen, offering significant opportunities for growth and market penetration across various industries.

Technical Challenges

The production of bioplastics using glacial acetic acid faces several significant technical challenges that need to be addressed for successful implementation and scaling. One of the primary obstacles is the optimization of the fermentation process to efficiently convert glacial acetic acid into bioplastic precursors. This requires careful control of environmental conditions, including temperature, pH, and nutrient availability, to maximize microbial growth and product yield.

Another major challenge lies in the purification and extraction of the bioplastic materials from the fermentation broth. The presence of residual acetic acid and other byproducts can interfere with the extraction process, potentially compromising the quality and properties of the final bioplastic product. Developing efficient and cost-effective separation techniques is crucial for the commercial viability of this production method.

The polymerization process itself presents additional hurdles. Achieving consistent molecular weight distribution and desired mechanical properties in the final bioplastic product requires precise control over reaction conditions. Factors such as temperature, pressure, and catalyst selection must be carefully optimized to ensure the production of high-quality bioplastics with reproducible characteristics.

Scalability remains a significant concern in the transition from laboratory-scale production to industrial-scale manufacturing. The challenges associated with maintaining consistent quality and yield across larger production volumes need to be addressed. This includes the design and implementation of robust process control systems and the development of specialized equipment capable of handling the corrosive nature of glacial acetic acid.

Environmental and safety considerations also pose technical challenges. The use of glacial acetic acid in large quantities necessitates the implementation of stringent safety protocols and containment measures. Additionally, the development of environmentally friendly waste management strategies for handling residual acetic acid and other byproducts is essential for sustainable production practices.

The long-term stability and degradation characteristics of bioplastics produced using this method require further investigation. Ensuring that the final products meet industry standards for durability while maintaining their biodegradability is a complex balance that demands ongoing research and development efforts.

Lastly, the integration of this production method into existing manufacturing infrastructure presents logistical and technical challenges. Adapting current equipment and processes to accommodate the unique requirements of glacial acetic acid-based bioplastic production may require significant modifications and investments in new technologies.

Another major challenge lies in the purification and extraction of the bioplastic materials from the fermentation broth. The presence of residual acetic acid and other byproducts can interfere with the extraction process, potentially compromising the quality and properties of the final bioplastic product. Developing efficient and cost-effective separation techniques is crucial for the commercial viability of this production method.

The polymerization process itself presents additional hurdles. Achieving consistent molecular weight distribution and desired mechanical properties in the final bioplastic product requires precise control over reaction conditions. Factors such as temperature, pressure, and catalyst selection must be carefully optimized to ensure the production of high-quality bioplastics with reproducible characteristics.

Scalability remains a significant concern in the transition from laboratory-scale production to industrial-scale manufacturing. The challenges associated with maintaining consistent quality and yield across larger production volumes need to be addressed. This includes the design and implementation of robust process control systems and the development of specialized equipment capable of handling the corrosive nature of glacial acetic acid.

Environmental and safety considerations also pose technical challenges. The use of glacial acetic acid in large quantities necessitates the implementation of stringent safety protocols and containment measures. Additionally, the development of environmentally friendly waste management strategies for handling residual acetic acid and other byproducts is essential for sustainable production practices.

The long-term stability and degradation characteristics of bioplastics produced using this method require further investigation. Ensuring that the final products meet industry standards for durability while maintaining their biodegradability is a complex balance that demands ongoing research and development efforts.

Lastly, the integration of this production method into existing manufacturing infrastructure presents logistical and technical challenges. Adapting current equipment and processes to accommodate the unique requirements of glacial acetic acid-based bioplastic production may require significant modifications and investments in new technologies.

Glacial Acetic Methods

01 Biodegradable polymer compositions

Development of bioplastic compositions using biodegradable polymers derived from renewable resources. These compositions often include blends of different biopolymers or additives to enhance properties such as strength, flexibility, and degradation rate. The focus is on creating materials that can replace conventional plastics while reducing environmental impact.- Biodegradable polymer compositions: Development of bioplastic compositions using biodegradable polymers derived from renewable resources. These compositions often include blends of different biopolymers or additives to enhance properties such as strength, flexibility, and degradation rate. The focus is on creating materials that can decompose naturally in the environment while maintaining performance characteristics similar to traditional plastics.

- Production methods for bioplastics: Innovative manufacturing processes for bioplastic production, including fermentation techniques, chemical synthesis, and extraction methods from biomass. These processes aim to improve efficiency, reduce costs, and scale up production to make bioplastics more competitive with conventional plastics. Some methods focus on utilizing waste materials or agricultural byproducts as feedstock.

- Bioplastic packaging solutions: Development of bioplastic materials specifically tailored for packaging applications. This includes food packaging, beverage containers, and other consumer goods packaging. The focus is on creating materials that provide adequate barrier properties, durability, and shelf life while being environmentally friendly and compostable.

- Bioplastic composites and blends: Creation of composite materials and blends that incorporate bioplastics with other materials to enhance specific properties. This may include reinforcing bioplastics with natural fibers, blending with other biodegradable polymers, or incorporating nanoparticles to improve mechanical, thermal, or barrier properties. The goal is to expand the range of applications for bioplastics.

- Bioplastic modification and functionalization: Methods for modifying and functionalizing bioplastics to improve their properties or add new functionalities. This includes chemical modifications, surface treatments, and the incorporation of additives to enhance characteristics such as water resistance, flame retardancy, or antimicrobial properties. The aim is to broaden the applicability of bioplastics in various industries.

02 Production methods for bioplastics

Innovative manufacturing processes for bioplastic production, including fermentation techniques, chemical synthesis, and extraction methods from biomass. These methods aim to improve efficiency, reduce costs, and scale up production to make bioplastics more competitive with traditional plastics.Expand Specific Solutions03 Bioplastic applications in packaging

Development of bioplastic materials specifically tailored for packaging applications. This includes food packaging, beverage containers, and other consumer goods packaging. The focus is on creating materials that offer similar performance to conventional plastics in terms of barrier properties, durability, and shelf life, while being biodegradable or compostable.Expand Specific Solutions04 Bioplastic composites and blends

Creation of composite materials and blends that incorporate bioplastics with other materials to enhance properties or reduce costs. This may include blending biopolymers with natural fibers, minerals, or even small amounts of conventional plastics to achieve desired characteristics for specific applications.Expand Specific Solutions05 Modification and functionalization of bioplastics

Chemical and physical modification techniques to improve the properties of bioplastics. This includes grafting, crosslinking, and surface treatments to enhance characteristics such as water resistance, thermal stability, and mechanical strength. The goal is to expand the range of applications for bioplastics and make them more competitive with petroleum-based plastics.Expand Specific Solutions

Industry Leaders

The bioplastic production using glacial acetic acid is in an emerging phase, with growing market potential due to increasing environmental concerns. The global bioplastics market is expected to expand significantly, driven by sustainability initiatives and regulatory pressures. Technologically, the field is still evolving, with companies like Nantong Cellulose Fibers Co. Ltd., Zhuhai Cellulose Fibers Co. Ltd., and Kunming Acetate Fiber Co. Ltd. leading in cellulose-based materials. Research institutions such as MIT and Qingdao University of Science & Technology are contributing to advancements. Companies like METabolic EXplorer SA and Roquette Frères SA are exploring innovative bio-based solutions, while established players like LG Chem Ltd. and Kao Corp. are investing in sustainable alternatives, indicating a competitive and dynamic landscape.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a novel approach for bioplastic production using glacial acetic acid as a key component. Their method involves a two-step process: first, the conversion of glacial acetic acid into a biobased monomer through microbial fermentation, and second, the polymerization of this monomer into a biodegradable plastic. The process utilizes engineered bacteria strains capable of metabolizing acetic acid efficiently, resulting in a high yield of the desired monomer. The polymerization step is optimized for energy efficiency and minimal waste production. MIT's research has shown that this method can reduce greenhouse gas emissions by up to 30% compared to traditional petroleum-based plastic production [1][3].

Strengths: Highly innovative approach, potential for significant environmental impact, and leverages MIT's expertise in biotechnology. Weaknesses: May require substantial investment for scaling up, and market acceptance of new bioplastics could be challenging.

METabolic EXplorer SA

Technical Solution: METabolic EXplorer has developed a proprietary technology for bioplastic production using glacial acetic acid as a feedstock. Their process involves a unique bacterial strain that can efficiently convert acetic acid into biobased monomers. These monomers are then polymerized using a catalytic process that requires less energy compared to traditional methods. The company has reported a 40% reduction in carbon footprint compared to conventional plastic production [2]. METabolic EXplorer's technology also allows for the production of various types of bioplastics with different properties, catering to diverse market needs. They have successfully scaled up their process to pilot plant level, demonstrating its potential for industrial application [4].

Strengths: Versatile technology capable of producing various bioplastics, proven scalability to pilot level. Weaknesses: May face competition from established petrochemical companies, and the cost of production could be higher than traditional plastics initially.

Key Innovations

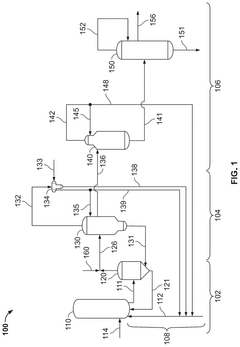

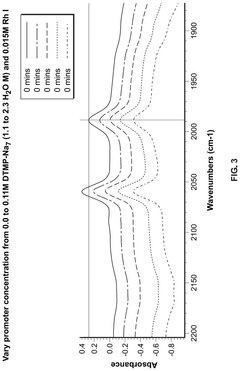

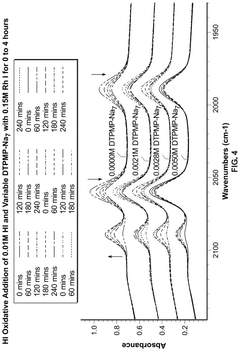

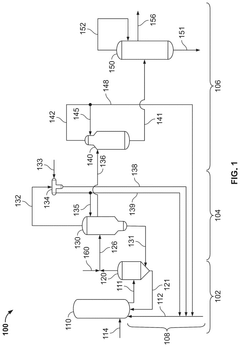

Polyphoshates and polyphosphonates as rate promoters for the glacial acetic acid process

PatentPendingUS20250074856A1

Innovation

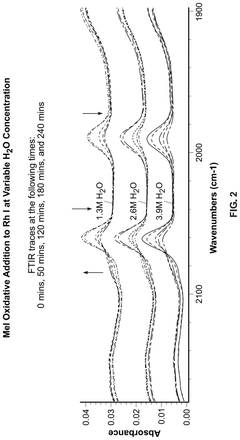

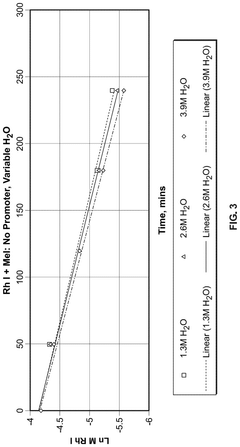

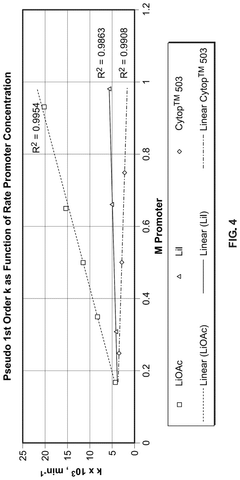

- The process involves using a reaction mixture comprising a carbonylation catalyst, water, and specific rate-promoting compounds such as Group I and Group II polyphosphate and polyphosphonate salts, which are added at an iodide to promoter molar ratio greater than 2, to enhance the rate of acetic acid formation while reducing the amount of water required.

Aminopolycarboxylates as rate promoters for the glacial acetic acid process

PatentPendingUS20250074857A1

Innovation

- The process involves using a reaction mixture comprising a carbonylation catalyst, water, and specific rate-promoting compounds, such as Group I and Group II aminopolycarboxylate salts, to enhance the rate of acetic acid formation while reducing the amount of water required and suppressing undesirable oxidative addition reactions.

Environmental Impact

The production of bioplastics using glacial acetic acid presents both opportunities and challenges in terms of environmental impact. This process offers a potential alternative to conventional petroleum-based plastics, which are known for their significant environmental footprint. By utilizing renewable resources and biodegradable materials, bioplastics have the potential to reduce greenhouse gas emissions and minimize plastic pollution in ecosystems.

One of the primary environmental benefits of bioplastic production using glacial acetic acid is the reduction of carbon dioxide emissions. Unlike traditional plastics derived from fossil fuels, bioplastics can be produced from renewable biomass sources, such as corn starch or sugarcane. This shift towards bio-based raw materials can lead to a lower carbon footprint throughout the product lifecycle, from production to disposal.

However, the environmental impact of bioplastic production is not entirely positive. The cultivation of crops for bioplastic feedstock may lead to increased land use, potentially competing with food production and contributing to deforestation. Additionally, the agricultural practices involved in growing these crops may require significant water resources and the use of fertilizers and pesticides, which can have negative impacts on soil and water quality.

The use of glacial acetic acid in the production process also warrants careful consideration. While acetic acid is generally considered less harmful than many other industrial chemicals, its production and handling still require energy and resources. The environmental impact of acetic acid production, including potential emissions and waste generation, must be factored into the overall assessment of bioplastic sustainability.

Biodegradability is another crucial aspect of bioplastics' environmental profile. Many bioplastics are designed to break down more readily than conventional plastics, potentially reducing long-term pollution in landfills and marine environments. However, the actual biodegradation rates can vary significantly depending on environmental conditions, and some bioplastics may require industrial composting facilities to degrade effectively.

End-of-life management of bioplastics presents both opportunities and challenges. While biodegradable bioplastics offer the potential for reduced environmental persistence, they may complicate existing recycling streams if not properly sorted and processed. Developing appropriate waste management infrastructure and consumer education programs is essential to maximize the environmental benefits of bioplastics.

In conclusion, the environmental impact of bioplastic production using glacial acetic acid is complex and multifaceted. While offering potential benefits in terms of reduced carbon emissions and plastic pollution, careful consideration must be given to land use, agricultural practices, and end-of-life management to ensure a net positive environmental outcome. Ongoing research and life cycle assessments are crucial to fully understand and optimize the environmental performance of this emerging technology.

One of the primary environmental benefits of bioplastic production using glacial acetic acid is the reduction of carbon dioxide emissions. Unlike traditional plastics derived from fossil fuels, bioplastics can be produced from renewable biomass sources, such as corn starch or sugarcane. This shift towards bio-based raw materials can lead to a lower carbon footprint throughout the product lifecycle, from production to disposal.

However, the environmental impact of bioplastic production is not entirely positive. The cultivation of crops for bioplastic feedstock may lead to increased land use, potentially competing with food production and contributing to deforestation. Additionally, the agricultural practices involved in growing these crops may require significant water resources and the use of fertilizers and pesticides, which can have negative impacts on soil and water quality.

The use of glacial acetic acid in the production process also warrants careful consideration. While acetic acid is generally considered less harmful than many other industrial chemicals, its production and handling still require energy and resources. The environmental impact of acetic acid production, including potential emissions and waste generation, must be factored into the overall assessment of bioplastic sustainability.

Biodegradability is another crucial aspect of bioplastics' environmental profile. Many bioplastics are designed to break down more readily than conventional plastics, potentially reducing long-term pollution in landfills and marine environments. However, the actual biodegradation rates can vary significantly depending on environmental conditions, and some bioplastics may require industrial composting facilities to degrade effectively.

End-of-life management of bioplastics presents both opportunities and challenges. While biodegradable bioplastics offer the potential for reduced environmental persistence, they may complicate existing recycling streams if not properly sorted and processed. Developing appropriate waste management infrastructure and consumer education programs is essential to maximize the environmental benefits of bioplastics.

In conclusion, the environmental impact of bioplastic production using glacial acetic acid is complex and multifaceted. While offering potential benefits in terms of reduced carbon emissions and plastic pollution, careful consideration must be given to land use, agricultural practices, and end-of-life management to ensure a net positive environmental outcome. Ongoing research and life cycle assessments are crucial to fully understand and optimize the environmental performance of this emerging technology.

Regulatory Framework

The regulatory framework surrounding bioplastic production using glacial acetic acid is a complex and evolving landscape that significantly impacts the development and commercialization of this technology. At the international level, organizations such as the United Nations Environment Programme (UNEP) and the European Union (EU) have established guidelines and directives aimed at promoting sustainable practices in plastic production and waste management.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the production and use of bioplastics. The Toxic Substances Control Act (TSCA) requires manufacturers to submit premanufacture notices for new chemical substances, including those used in bioplastic production. Additionally, the Food and Drug Administration (FDA) oversees the safety of bioplastics used in food packaging and medical devices.

The EU has implemented stringent regulations through its Waste Framework Directive and Packaging and Packaging Waste Directive, which set targets for recycling and recovery of plastic waste. These directives also encourage the use of biodegradable and compostable materials, potentially favoring bioplastics produced using glacial acetic acid.

Many countries have introduced or are considering legislation to reduce single-use plastics, which could create opportunities for bioplastic alternatives. For instance, Japan's Plastic Resource Circulation Act aims to promote the recycling and sustainable use of plastic resources, potentially benefiting bioplastic producers.

Certification systems, such as those provided by the Biodegradable Products Institute (BPI) and TÜV Austria, play a crucial role in verifying the biodegradability and compostability of bioplastics. These certifications are often required for market access and consumer acceptance.

Safety regulations concerning the use of glacial acetic acid in bioplastic production are also critical. Occupational Safety and Health Administration (OSHA) standards in the U.S. and similar regulations in other countries set exposure limits and safety protocols for handling this chemical in industrial settings.

As the bioplastics industry evolves, regulatory frameworks are likely to adapt. Policymakers are increasingly focusing on life cycle assessments and circular economy principles, which may lead to new regulations favoring bioplastics with lower environmental impacts. However, producers must navigate a complex landscape of varying regional and national regulations, which can pose challenges for global market expansion.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the production and use of bioplastics. The Toxic Substances Control Act (TSCA) requires manufacturers to submit premanufacture notices for new chemical substances, including those used in bioplastic production. Additionally, the Food and Drug Administration (FDA) oversees the safety of bioplastics used in food packaging and medical devices.

The EU has implemented stringent regulations through its Waste Framework Directive and Packaging and Packaging Waste Directive, which set targets for recycling and recovery of plastic waste. These directives also encourage the use of biodegradable and compostable materials, potentially favoring bioplastics produced using glacial acetic acid.

Many countries have introduced or are considering legislation to reduce single-use plastics, which could create opportunities for bioplastic alternatives. For instance, Japan's Plastic Resource Circulation Act aims to promote the recycling and sustainable use of plastic resources, potentially benefiting bioplastic producers.

Certification systems, such as those provided by the Biodegradable Products Institute (BPI) and TÜV Austria, play a crucial role in verifying the biodegradability and compostability of bioplastics. These certifications are often required for market access and consumer acceptance.

Safety regulations concerning the use of glacial acetic acid in bioplastic production are also critical. Occupational Safety and Health Administration (OSHA) standards in the U.S. and similar regulations in other countries set exposure limits and safety protocols for handling this chemical in industrial settings.

As the bioplastics industry evolves, regulatory frameworks are likely to adapt. Policymakers are increasingly focusing on life cycle assessments and circular economy principles, which may lead to new regulations favoring bioplastics with lower environmental impacts. However, producers must navigate a complex landscape of varying regional and national regulations, which can pose challenges for global market expansion.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!