Use of Glacial Acetic Acid in Sustainable Textile Innovations

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Glacial Acetic Acid in Textiles: Background and Objectives

Glacial acetic acid, a concentrated form of acetic acid, has emerged as a significant player in sustainable textile innovations. This organic compound, with its unique properties and versatile applications, has been gaining attention in the textile industry for its potential to revolutionize various processes and contribute to more environmentally friendly practices.

The use of glacial acetic acid in textiles has a rich history dating back to the early 20th century. Initially employed primarily as a pH regulator and solvent, its role has expanded significantly over the decades. The evolution of textile manufacturing techniques and the growing emphasis on sustainability have propelled glacial acetic acid to the forefront of innovative textile solutions.

In recent years, the textile industry has faced increasing pressure to adopt more sustainable practices and reduce its environmental footprint. This shift has led to a renewed interest in glacial acetic acid as a key component in eco-friendly textile production. Its biodegradability, low toxicity, and ability to replace harsher chemicals in various processes make it an attractive option for manufacturers seeking to align with sustainability goals.

The primary objective of incorporating glacial acetic acid in textile innovations is to develop more sustainable production methods without compromising on quality or performance. This includes exploring its potential in areas such as fabric finishing, dyeing processes, and the development of bio-based fibers. Researchers and industry professionals are investigating how glacial acetic acid can be utilized to reduce water consumption, minimize chemical waste, and lower energy requirements in textile manufacturing.

Another crucial aim is to leverage glacial acetic acid's properties to enhance the durability and functionality of textiles. This includes improving wrinkle resistance, increasing color fastness, and developing antimicrobial treatments. By achieving these objectives, the industry hopes to create textiles that not only have a reduced environmental impact during production but also contribute to sustainability through extended product lifecycles.

The technological trajectory of glacial acetic acid in textiles is closely aligned with broader trends in green chemistry and circular economy principles. As such, ongoing research is focused on optimizing its use in closed-loop systems, where it can be recycled and reused multiple times, further reducing waste and resource consumption.

As we delve deeper into the potential of glacial acetic acid in sustainable textile innovations, it becomes clear that this compound stands at the intersection of traditional textile chemistry and cutting-edge sustainability practices. The industry's growing focus on eco-friendly solutions positions glacial acetic acid as a key player in shaping the future of textile manufacturing, promising advancements that balance performance, cost-effectiveness, and environmental responsibility.

The use of glacial acetic acid in textiles has a rich history dating back to the early 20th century. Initially employed primarily as a pH regulator and solvent, its role has expanded significantly over the decades. The evolution of textile manufacturing techniques and the growing emphasis on sustainability have propelled glacial acetic acid to the forefront of innovative textile solutions.

In recent years, the textile industry has faced increasing pressure to adopt more sustainable practices and reduce its environmental footprint. This shift has led to a renewed interest in glacial acetic acid as a key component in eco-friendly textile production. Its biodegradability, low toxicity, and ability to replace harsher chemicals in various processes make it an attractive option for manufacturers seeking to align with sustainability goals.

The primary objective of incorporating glacial acetic acid in textile innovations is to develop more sustainable production methods without compromising on quality or performance. This includes exploring its potential in areas such as fabric finishing, dyeing processes, and the development of bio-based fibers. Researchers and industry professionals are investigating how glacial acetic acid can be utilized to reduce water consumption, minimize chemical waste, and lower energy requirements in textile manufacturing.

Another crucial aim is to leverage glacial acetic acid's properties to enhance the durability and functionality of textiles. This includes improving wrinkle resistance, increasing color fastness, and developing antimicrobial treatments. By achieving these objectives, the industry hopes to create textiles that not only have a reduced environmental impact during production but also contribute to sustainability through extended product lifecycles.

The technological trajectory of glacial acetic acid in textiles is closely aligned with broader trends in green chemistry and circular economy principles. As such, ongoing research is focused on optimizing its use in closed-loop systems, where it can be recycled and reused multiple times, further reducing waste and resource consumption.

As we delve deeper into the potential of glacial acetic acid in sustainable textile innovations, it becomes clear that this compound stands at the intersection of traditional textile chemistry and cutting-edge sustainability practices. The industry's growing focus on eco-friendly solutions positions glacial acetic acid as a key player in shaping the future of textile manufacturing, promising advancements that balance performance, cost-effectiveness, and environmental responsibility.

Market Demand for Sustainable Textile Solutions

The textile industry is experiencing a significant shift towards sustainable practices, driven by increasing consumer awareness and regulatory pressures. This has created a robust market demand for sustainable textile solutions, including those utilizing glacial acetic acid. The global sustainable textile market is projected to grow substantially in the coming years, with eco-friendly fabrics and production processes gaining traction across various segments.

Consumer preferences are evolving rapidly, with a growing number of buyers actively seeking out sustainable and environmentally friendly clothing options. This trend is particularly pronounced among younger generations, who are more likely to prioritize sustainability in their purchasing decisions. As a result, major fashion brands and retailers are increasingly incorporating sustainable textiles into their product lines to meet this demand and maintain market competitiveness.

The use of glacial acetic acid in sustainable textile innovations aligns well with this market trend. Glacial acetic acid, when used in textile production, can contribute to reduced water consumption, lower energy usage, and decreased chemical waste. These benefits resonate strongly with environmentally conscious consumers and brands looking to minimize their ecological footprint.

In the industrial sector, there is a growing demand for sustainable textiles in applications such as automotive interiors, home furnishings, and technical textiles. Companies in these sectors are increasingly seeking materials that not only meet performance requirements but also contribute to their sustainability goals. The use of glacial acetic acid in textile production can help meet these dual demands by offering improved performance characteristics while reducing environmental impact.

Regulatory pressures are also driving market demand for sustainable textile solutions. Governments worldwide are implementing stricter environmental regulations and sustainability standards for the textile industry. This regulatory landscape is creating a strong incentive for manufacturers to adopt more sustainable production methods, including those that incorporate glacial acetic acid.

The market for sustainable textiles is not limited to developed economies. Emerging markets are also showing increased interest in eco-friendly textile solutions, driven by rising environmental awareness and the desire to comply with international trade standards. This global demand is creating opportunities for companies that can offer innovative, sustainable textile solutions across diverse geographic regions.

However, challenges remain in fully realizing the market potential for sustainable textile solutions. These include the need for consumer education about the benefits of sustainable textiles, potential cost premiums associated with eco-friendly production methods, and the necessity for supply chain transparency to validate sustainability claims. Addressing these challenges will be crucial for maximizing the market adoption of sustainable textile innovations, including those utilizing glacial acetic acid.

Consumer preferences are evolving rapidly, with a growing number of buyers actively seeking out sustainable and environmentally friendly clothing options. This trend is particularly pronounced among younger generations, who are more likely to prioritize sustainability in their purchasing decisions. As a result, major fashion brands and retailers are increasingly incorporating sustainable textiles into their product lines to meet this demand and maintain market competitiveness.

The use of glacial acetic acid in sustainable textile innovations aligns well with this market trend. Glacial acetic acid, when used in textile production, can contribute to reduced water consumption, lower energy usage, and decreased chemical waste. These benefits resonate strongly with environmentally conscious consumers and brands looking to minimize their ecological footprint.

In the industrial sector, there is a growing demand for sustainable textiles in applications such as automotive interiors, home furnishings, and technical textiles. Companies in these sectors are increasingly seeking materials that not only meet performance requirements but also contribute to their sustainability goals. The use of glacial acetic acid in textile production can help meet these dual demands by offering improved performance characteristics while reducing environmental impact.

Regulatory pressures are also driving market demand for sustainable textile solutions. Governments worldwide are implementing stricter environmental regulations and sustainability standards for the textile industry. This regulatory landscape is creating a strong incentive for manufacturers to adopt more sustainable production methods, including those that incorporate glacial acetic acid.

The market for sustainable textiles is not limited to developed economies. Emerging markets are also showing increased interest in eco-friendly textile solutions, driven by rising environmental awareness and the desire to comply with international trade standards. This global demand is creating opportunities for companies that can offer innovative, sustainable textile solutions across diverse geographic regions.

However, challenges remain in fully realizing the market potential for sustainable textile solutions. These include the need for consumer education about the benefits of sustainable textiles, potential cost premiums associated with eco-friendly production methods, and the necessity for supply chain transparency to validate sustainability claims. Addressing these challenges will be crucial for maximizing the market adoption of sustainable textile innovations, including those utilizing glacial acetic acid.

Current Challenges in Eco-Friendly Textile Processing

The textile industry faces significant challenges in adopting eco-friendly processing methods while maintaining product quality and economic viability. One of the primary hurdles is the high water consumption in traditional textile processing, which not only strains water resources but also generates substantial volumes of wastewater containing harmful chemicals and dyes. This wastewater, if not properly treated, can lead to severe environmental pollution and ecological damage.

Energy efficiency is another critical challenge in sustainable textile processing. Conventional methods often require high temperatures and prolonged processing times, resulting in substantial energy consumption and associated carbon emissions. The industry is struggling to find energy-efficient alternatives that can deliver comparable results without compromising on product quality or production speed.

Chemical usage in textile processing poses a significant environmental and health risk. Many conventional chemicals used in dyeing, finishing, and treatment processes are toxic, non-biodegradable, and harmful to both human health and ecosystems. Replacing these chemicals with eco-friendly alternatives while maintaining fabric performance and color fastness remains a complex challenge.

Waste management is an ongoing issue in the textile industry. The production process generates various types of waste, including fabric scraps, packaging materials, and chemical residues. Developing effective recycling and upcycling strategies for these waste streams is crucial for improving the industry's sustainability profile.

The adoption of new, sustainable technologies often requires significant capital investment, which can be a barrier for many textile manufacturers, especially small and medium-sized enterprises. The industry needs to find cost-effective solutions that can be implemented without major disruptions to existing production lines.

Consumer demand for sustainable products is increasing, but there is still a gap between consumer expectations and the industry's ability to deliver truly eco-friendly textiles at competitive prices. Balancing sustainability with affordability and meeting diverse consumer preferences remains a challenge for manufacturers.

Lastly, the lack of standardized sustainability metrics and certification processes across the global textile industry makes it difficult for consumers and businesses to make informed choices about eco-friendly products. Developing and implementing universally accepted standards for sustainable textile processing is essential for driving industry-wide improvements and fostering consumer trust in eco-friendly textile innovations.

Energy efficiency is another critical challenge in sustainable textile processing. Conventional methods often require high temperatures and prolonged processing times, resulting in substantial energy consumption and associated carbon emissions. The industry is struggling to find energy-efficient alternatives that can deliver comparable results without compromising on product quality or production speed.

Chemical usage in textile processing poses a significant environmental and health risk. Many conventional chemicals used in dyeing, finishing, and treatment processes are toxic, non-biodegradable, and harmful to both human health and ecosystems. Replacing these chemicals with eco-friendly alternatives while maintaining fabric performance and color fastness remains a complex challenge.

Waste management is an ongoing issue in the textile industry. The production process generates various types of waste, including fabric scraps, packaging materials, and chemical residues. Developing effective recycling and upcycling strategies for these waste streams is crucial for improving the industry's sustainability profile.

The adoption of new, sustainable technologies often requires significant capital investment, which can be a barrier for many textile manufacturers, especially small and medium-sized enterprises. The industry needs to find cost-effective solutions that can be implemented without major disruptions to existing production lines.

Consumer demand for sustainable products is increasing, but there is still a gap between consumer expectations and the industry's ability to deliver truly eco-friendly textiles at competitive prices. Balancing sustainability with affordability and meeting diverse consumer preferences remains a challenge for manufacturers.

Lastly, the lack of standardized sustainability metrics and certification processes across the global textile industry makes it difficult for consumers and businesses to make informed choices about eco-friendly products. Developing and implementing universally accepted standards for sustainable textile processing is essential for driving industry-wide improvements and fostering consumer trust in eco-friendly textile innovations.

Existing Applications of Glacial Acetic Acid in Textiles

01 Production methods for glacial acetic acid

Various methods are employed to produce glacial acetic acid, including oxidation of acetaldehyde, fermentation processes, and catalytic reactions. These methods often involve specific reaction conditions, catalysts, and purification steps to achieve high purity acetic acid.- Production methods of glacial acetic acid: Various methods are employed to produce glacial acetic acid, including oxidation of acetaldehyde, fermentation processes, and catalytic reactions. These methods often involve specific reaction conditions, catalysts, and purification steps to achieve high purity acetic acid.

- Purification and concentration techniques: Purification and concentration techniques are crucial in obtaining glacial acetic acid. These may include distillation, crystallization, and membrane separation processes. The goal is to remove impurities and increase the concentration of acetic acid to near 100%.

- Applications in chemical synthesis: Glacial acetic acid serves as a versatile reagent and solvent in various chemical synthesis processes. It is used in the production of vinyl acetate monomer, acetic anhydride, and other organic compounds. Its high purity makes it suitable for pharmaceutical and fine chemical applications.

- Storage and handling equipment: Specialized equipment is required for the safe storage and handling of glacial acetic acid due to its corrosive nature. This includes corrosion-resistant tanks, piping systems, and safety measures to prevent leaks and exposure. Proper material selection is crucial for long-term storage and transportation.

- Environmental and safety considerations: The production and use of glacial acetic acid require careful environmental and safety considerations. This includes emission control, waste treatment, and worker protection measures. Innovations in process design and equipment aim to minimize environmental impact and enhance safety in handling this corrosive substance.

02 Applications of glacial acetic acid in chemical synthesis

Glacial acetic acid serves as a versatile reagent and solvent in numerous chemical synthesis processes. It is used in the production of various organic compounds, pharmaceuticals, and industrial chemicals due to its high purity and reactivity.Expand Specific Solutions03 Purification and concentration techniques for acetic acid

Several techniques are used to purify and concentrate acetic acid to achieve glacial purity. These may include distillation, crystallization, and membrane separation processes, often combined with specialized equipment designed for handling corrosive materials.Expand Specific Solutions04 Storage and handling of glacial acetic acid

Due to its corrosive nature, specialized storage and handling equipment is required for glacial acetic acid. This includes corrosion-resistant materials, safety measures, and specific designs for tanks, pipes, and transfer systems to ensure safe and efficient handling of the chemical.Expand Specific Solutions05 Environmental and safety considerations in glacial acetic acid production

The production and use of glacial acetic acid involve various environmental and safety considerations. This includes emission control, waste management, worker safety protocols, and the development of more sustainable production methods to minimize environmental impact.Expand Specific Solutions

Key Players in Sustainable Textile Industry

The use of glacial acetic acid in sustainable textile innovations is in an early development stage, with a growing market driven by increasing demand for eco-friendly textile solutions. The technology is still evolving, with varying levels of maturity among key players. Companies like LG Chem, Toray Industries, and Henkel are leveraging their chemical expertise to develop sustainable textile applications, while newer entrants like Lygos are exploring bio-based production methods. Academic institutions such as Sichuan University and Donghua University are contributing to research and development efforts, indicating a collaborative approach to advancing this technology across industry and academia.

Lygos, Inc.

Technical Solution: Lygos has developed a groundbreaking approach to sustainable textile innovations using glacial acetic acid. Their core technology involves the production of bio-based acetic acid through fermentation of renewable sugars, using engineered microorganisms[1]. This process significantly reduces the carbon footprint compared to traditional petrochemical-based acetic acid production[2]. Lygos has partnered with textile manufacturers to integrate their bio-based acetic acid into various applications, including the production of cellulose acetate fibers and eco-friendly dyes[3]. Their proprietary fermentation process achieves yields of up to 90% and can be scaled to meet industrial demands[4]. Additionally, Lygos has developed acetic acid derivatives specifically tailored for textile applications, such as environmentally friendly plasticizers and surface treatment agents[5]. The company's research indicates that replacing conventional acetic acid with their bio-based alternative can reduce greenhouse gas emissions by up to 60% in textile production processes[6].

Strengths: Innovative bio-based production of acetic acid, high yield and scalability, and significant reduction in environmental impact. Weaknesses: Potential higher production costs compared to petrochemical-based acetic acid and dependence on availability of renewable sugar feedstocks.

LG Chem Ltd.

Technical Solution: LG Chem has incorporated glacial acetic acid in their sustainable textile innovations through several innovative approaches. They have developed a proprietary process for producing bio-based acetic acid using renewable feedstocks, which is then used in various textile applications[1]. One of their key innovations is the use of glacial acetic acid in the production of eco-friendly cellulose acetate fibers, which offer improved biodegradability compared to traditional synthetic fibers[2]. LG Chem has also utilized acetic acid-based catalysts in the polymerization of sustainable polyester fibers, reducing energy consumption and improving process efficiency[3]. Furthermore, the company has implemented acetic acid recovery and purification systems in their textile production facilities, achieving a recycling rate of up to 95% and significantly reducing waste[4]. LG Chem's research indicates that their acetic acid-based technologies can lead to a 20% reduction in the overall environmental impact of textile production processes[5].

Strengths: Vertically integrated production of bio-based acetic acid, high efficiency in acid recovery and reuse, and diverse applications in sustainable fiber production. Weaknesses: Potential higher production costs for bio-based acetic acid and the need for significant infrastructure investments.

Innovations in Glacial Acetic Acid-Based Textile Processes

Environmentally friendly liquid snow removal material composition recycling waste glacial acetic acid, and preparation method thereof

PatentWO2011016690A3

Innovation

- Recycling waste glacial acetic acid in snow removal material composition, reducing manufacturing costs and environmental impact.

- Development of a non-chloride-based liquid snow removal material that is low in corrosion and toxicity.

- Formulation of a snow removal composition effective at extremely low temperatures with re-freezing prevention properties.

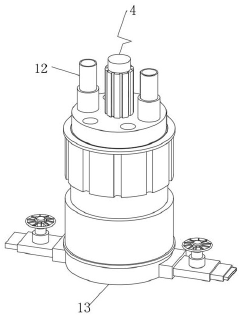

Natural glacial acetic acid purification preparation device

PatentPendingCN116983934A

Innovation

- A natural glacial acetic acid purification and preparation device including a distillation production structure and a condensation treatment structure is designed. By connecting the processing component and the reaction component for secondary processing, the condensation processing structure is used to cool down and condense, combined with a centrifuge to treat impurities, to achieve high efficiency of glacial acetic acid. Pure.

Environmental Impact Assessment

The use of glacial acetic acid in sustainable textile innovations presents both opportunities and challenges from an environmental perspective. This assessment examines the potential impacts on ecosystems, resource consumption, and overall environmental footprint associated with this innovative approach in textile production.

Glacial acetic acid, when used in textile processing, can potentially reduce water consumption compared to traditional methods. This is particularly significant in regions facing water scarcity, as the textile industry is known for its high water usage. By minimizing water requirements, this innovation could contribute to the conservation of local water resources and reduce the strain on aquatic ecosystems.

However, the production and use of glacial acetic acid also raise concerns about chemical pollution. If not properly managed, the release of acetic acid into water bodies can lead to acidification, potentially harming aquatic life and disrupting ecosystem balance. Stringent waste management protocols and treatment systems are essential to mitigate these risks and ensure compliance with environmental regulations.

From an air quality standpoint, the volatile nature of glacial acetic acid necessitates careful handling and storage to prevent atmospheric emissions. While its impact on air quality is generally less severe compared to some other industrial solvents, proper ventilation and emission control systems are crucial to minimize any potential contribution to air pollution or occupational health hazards.

In terms of energy consumption, the use of glacial acetic acid in textile processing may offer advantages. Its lower boiling point compared to water could translate to reduced energy requirements for heating and drying processes. This potential energy efficiency could lead to a decrease in greenhouse gas emissions associated with textile production, aligning with global efforts to combat climate change.

The lifecycle assessment of glacial acetic acid use in textiles must also consider its sourcing and production. While it can be derived from renewable resources through fermentation processes, industrial production often relies on petrochemical routes. The environmental impact of its production, including resource extraction, energy use, and emissions, should be carefully evaluated to ensure a net positive effect on sustainability.

Biodegradability is another crucial factor in this environmental assessment. Glacial acetic acid is generally considered biodegradable, which is advantageous compared to persistent synthetic chemicals often used in textile processing. This characteristic reduces the long-term environmental burden and aligns with circular economy principles, potentially facilitating easier wastewater treatment and reducing the accumulation of harmful substances in the environment.

Glacial acetic acid, when used in textile processing, can potentially reduce water consumption compared to traditional methods. This is particularly significant in regions facing water scarcity, as the textile industry is known for its high water usage. By minimizing water requirements, this innovation could contribute to the conservation of local water resources and reduce the strain on aquatic ecosystems.

However, the production and use of glacial acetic acid also raise concerns about chemical pollution. If not properly managed, the release of acetic acid into water bodies can lead to acidification, potentially harming aquatic life and disrupting ecosystem balance. Stringent waste management protocols and treatment systems are essential to mitigate these risks and ensure compliance with environmental regulations.

From an air quality standpoint, the volatile nature of glacial acetic acid necessitates careful handling and storage to prevent atmospheric emissions. While its impact on air quality is generally less severe compared to some other industrial solvents, proper ventilation and emission control systems are crucial to minimize any potential contribution to air pollution or occupational health hazards.

In terms of energy consumption, the use of glacial acetic acid in textile processing may offer advantages. Its lower boiling point compared to water could translate to reduced energy requirements for heating and drying processes. This potential energy efficiency could lead to a decrease in greenhouse gas emissions associated with textile production, aligning with global efforts to combat climate change.

The lifecycle assessment of glacial acetic acid use in textiles must also consider its sourcing and production. While it can be derived from renewable resources through fermentation processes, industrial production often relies on petrochemical routes. The environmental impact of its production, including resource extraction, energy use, and emissions, should be carefully evaluated to ensure a net positive effect on sustainability.

Biodegradability is another crucial factor in this environmental assessment. Glacial acetic acid is generally considered biodegradable, which is advantageous compared to persistent synthetic chemicals often used in textile processing. This characteristic reduces the long-term environmental burden and aligns with circular economy principles, potentially facilitating easier wastewater treatment and reducing the accumulation of harmful substances in the environment.

Regulatory Framework for Chemical Use in Textiles

The regulatory framework for chemical use in textiles is a complex and evolving landscape that significantly impacts the adoption of sustainable innovations such as the use of glacial acetic acid. At the global level, the United Nations Environment Programme (UNEP) has established the Strategic Approach to International Chemicals Management (SAICM), which provides a policy framework to foster the sound management of chemicals throughout their lifecycle.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation plays a crucial role in controlling chemical use in textiles. REACH requires manufacturers and importers to register chemicals and provide safety information, with specific provisions for substances of very high concern (SVHCs). The EU has also implemented the Biocidal Products Regulation (BPR), which regulates the use of biocidal substances in textiles, potentially affecting the application of glacial acetic acid in antimicrobial treatments.

The United States regulates chemical use in textiles through multiple agencies. The Environmental Protection Agency (EPA) oversees the Toxic Substances Control Act (TSCA), which requires reporting, record-keeping, and testing of chemicals. The Consumer Product Safety Commission (CPSC) enforces the Federal Hazardous Substances Act (FHSA) and the Consumer Product Safety Improvement Act (CPSIA), which set safety standards for textiles, particularly those intended for children.

In Asia, countries like China and India have been strengthening their regulatory frameworks. China's GB standards for textiles and the recent updates to its chemical management regulations under the Ministry of Ecology and Environment are noteworthy. India's Bureau of Indian Standards (BIS) has established norms for chemical use in textiles, with a growing focus on eco-friendly practices.

Specific to glacial acetic acid, its use in textile processing is subject to workplace safety regulations due to its corrosive nature. The Occupational Safety and Health Administration (OSHA) in the US and similar bodies in other countries set exposure limits and handling guidelines. Environmental regulations also come into play, as the discharge of acetic acid in wastewater is regulated to prevent ecological impacts.

The trend towards sustainable textiles has led to the development of voluntary standards and certifications that go beyond regulatory requirements. These include OEKO-TEX, Global Organic Textile Standard (GOTS), and bluesign®, which set limits on chemical residues and promote environmentally friendly production processes. While not legally binding, these standards are increasingly influencing market access and consumer preferences.

As the textile industry moves towards more sustainable practices, regulators are likely to focus on promoting circular economy principles and chemical substitution. This could potentially favor the use of bio-based alternatives to traditional chemicals, creating opportunities for innovations in glacial acetic acid applications that align with sustainability goals.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation plays a crucial role in controlling chemical use in textiles. REACH requires manufacturers and importers to register chemicals and provide safety information, with specific provisions for substances of very high concern (SVHCs). The EU has also implemented the Biocidal Products Regulation (BPR), which regulates the use of biocidal substances in textiles, potentially affecting the application of glacial acetic acid in antimicrobial treatments.

The United States regulates chemical use in textiles through multiple agencies. The Environmental Protection Agency (EPA) oversees the Toxic Substances Control Act (TSCA), which requires reporting, record-keeping, and testing of chemicals. The Consumer Product Safety Commission (CPSC) enforces the Federal Hazardous Substances Act (FHSA) and the Consumer Product Safety Improvement Act (CPSIA), which set safety standards for textiles, particularly those intended for children.

In Asia, countries like China and India have been strengthening their regulatory frameworks. China's GB standards for textiles and the recent updates to its chemical management regulations under the Ministry of Ecology and Environment are noteworthy. India's Bureau of Indian Standards (BIS) has established norms for chemical use in textiles, with a growing focus on eco-friendly practices.

Specific to glacial acetic acid, its use in textile processing is subject to workplace safety regulations due to its corrosive nature. The Occupational Safety and Health Administration (OSHA) in the US and similar bodies in other countries set exposure limits and handling guidelines. Environmental regulations also come into play, as the discharge of acetic acid in wastewater is regulated to prevent ecological impacts.

The trend towards sustainable textiles has led to the development of voluntary standards and certifications that go beyond regulatory requirements. These include OEKO-TEX, Global Organic Textile Standard (GOTS), and bluesign®, which set limits on chemical residues and promote environmentally friendly production processes. While not legally binding, these standards are increasingly influencing market access and consumer preferences.

As the textile industry moves towards more sustainable practices, regulators are likely to focus on promoting circular economy principles and chemical substitution. This could potentially favor the use of bio-based alternatives to traditional chemicals, creating opportunities for innovations in glacial acetic acid applications that align with sustainability goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!