Glacial Acetic Acid in Electrochemical Sensor Development

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Glacial Acetic Acid in Electrochemical Sensors: Background

Glacial acetic acid has emerged as a crucial component in the development of electrochemical sensors, playing a significant role in enhancing their performance and expanding their applications. This concentrated form of acetic acid, with its unique properties, has become an integral part of sensor fabrication and operation.

The journey of glacial acetic acid in electrochemical sensor development began in the late 20th century when researchers recognized its potential as an electrolyte and solvent. Its high purity and low water content made it an ideal candidate for creating stable and sensitive sensor environments. As the field of electrochemistry advanced, so did the understanding of glacial acetic acid's role in sensor technology.

Initially, glacial acetic acid was primarily used as a supporting electrolyte in voltammetric studies. Its ability to dissolve a wide range of organic and inorganic compounds while maintaining electrical conductivity made it valuable for various sensing applications. Over time, researchers discovered that glacial acetic acid could also serve as a medium for electrode modification, opening up new possibilities for sensor design.

The evolution of glacial acetic acid's use in electrochemical sensors has been marked by several key milestones. In the 1990s, it was found to be particularly effective in the development of sensors for heavy metal detection, offering improved sensitivity and selectivity compared to aqueous-based systems. This discovery led to a surge in research focused on optimizing acetic acid-based sensor platforms for environmental monitoring.

As nanotechnology gained prominence in the early 2000s, glacial acetic acid found new applications in the synthesis of nanomaterials for sensor fabrication. Its role in controlling the size and morphology of nanoparticles and nanostructures became crucial in creating high-performance sensing interfaces. This synergy between glacial acetic acid and nanomaterials has been a driving force in the miniaturization and enhancement of electrochemical sensors.

Recent years have seen an expansion in the use of glacial acetic acid for developing biosensors. Its compatibility with various biomolecules and its ability to maintain their stability have made it an attractive choice for creating sensors capable of detecting specific proteins, enzymes, and other biomarkers. This has opened up new avenues in medical diagnostics and point-of-care testing.

The current research landscape surrounding glacial acetic acid in electrochemical sensors is focused on addressing challenges such as long-term stability, interference reduction, and expanding the range of detectable analytes. Scientists are exploring novel electrode materials and sensor architectures that can fully leverage the properties of glacial acetic acid to push the boundaries of sensor performance.

As we look to the future, the role of glacial acetic acid in electrochemical sensor development is expected to continue evolving. Emerging trends suggest its integration with advanced materials like graphene and metal-organic frameworks, as well as its application in flexible and wearable sensor technologies. The ongoing research promises to unlock new potentials for glacial acetic acid, further cementing its importance in the field of electrochemical sensing.

The journey of glacial acetic acid in electrochemical sensor development began in the late 20th century when researchers recognized its potential as an electrolyte and solvent. Its high purity and low water content made it an ideal candidate for creating stable and sensitive sensor environments. As the field of electrochemistry advanced, so did the understanding of glacial acetic acid's role in sensor technology.

Initially, glacial acetic acid was primarily used as a supporting electrolyte in voltammetric studies. Its ability to dissolve a wide range of organic and inorganic compounds while maintaining electrical conductivity made it valuable for various sensing applications. Over time, researchers discovered that glacial acetic acid could also serve as a medium for electrode modification, opening up new possibilities for sensor design.

The evolution of glacial acetic acid's use in electrochemical sensors has been marked by several key milestones. In the 1990s, it was found to be particularly effective in the development of sensors for heavy metal detection, offering improved sensitivity and selectivity compared to aqueous-based systems. This discovery led to a surge in research focused on optimizing acetic acid-based sensor platforms for environmental monitoring.

As nanotechnology gained prominence in the early 2000s, glacial acetic acid found new applications in the synthesis of nanomaterials for sensor fabrication. Its role in controlling the size and morphology of nanoparticles and nanostructures became crucial in creating high-performance sensing interfaces. This synergy between glacial acetic acid and nanomaterials has been a driving force in the miniaturization and enhancement of electrochemical sensors.

Recent years have seen an expansion in the use of glacial acetic acid for developing biosensors. Its compatibility with various biomolecules and its ability to maintain their stability have made it an attractive choice for creating sensors capable of detecting specific proteins, enzymes, and other biomarkers. This has opened up new avenues in medical diagnostics and point-of-care testing.

The current research landscape surrounding glacial acetic acid in electrochemical sensors is focused on addressing challenges such as long-term stability, interference reduction, and expanding the range of detectable analytes. Scientists are exploring novel electrode materials and sensor architectures that can fully leverage the properties of glacial acetic acid to push the boundaries of sensor performance.

As we look to the future, the role of glacial acetic acid in electrochemical sensor development is expected to continue evolving. Emerging trends suggest its integration with advanced materials like graphene and metal-organic frameworks, as well as its application in flexible and wearable sensor technologies. The ongoing research promises to unlock new potentials for glacial acetic acid, further cementing its importance in the field of electrochemical sensing.

Market Analysis for Electrochemical Sensors

The electrochemical sensor market has experienced significant growth in recent years, driven by increasing demand across various industries such as healthcare, environmental monitoring, and industrial processes. The global electrochemical sensor market size was valued at USD 20.15 billion in 2020 and is projected to reach USD 35.82 billion by 2028, growing at a CAGR of 7.5% during the forecast period.

The healthcare sector remains the largest end-user of electrochemical sensors, accounting for approximately 40% of the market share. This is primarily due to the rising prevalence of chronic diseases and the growing need for point-of-care diagnostics. The use of electrochemical sensors in glucose monitoring devices for diabetes management has been a major contributor to market growth.

Environmental monitoring applications have also seen a surge in demand for electrochemical sensors. Stringent government regulations regarding air and water quality have led to increased adoption of these sensors for detecting pollutants and toxic gases. The industrial sector, particularly in chemical and petrochemical industries, utilizes electrochemical sensors for process control and safety monitoring.

The market for electrochemical sensors is highly competitive, with key players including Honeywell International, ABB Ltd., Emerson Electric Co., and Siemens AG. These companies are investing heavily in research and development to improve sensor performance, reliability, and miniaturization.

Technological advancements, such as the integration of nanotechnology and the development of wearable sensors, are expected to create new opportunities in the market. The trend towards Internet of Things (IoT) and smart cities is also driving the demand for networked sensor systems, further boosting market growth.

Regionally, North America holds the largest market share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization, increasing healthcare expenditure, and growing environmental concerns in countries like China and India.

Challenges in the electrochemical sensor market include the need for improved sensor stability, selectivity, and longevity. Additionally, the high cost of advanced sensors and the complexity of data interpretation can be barriers to adoption in some applications.

In the context of glacial acetic acid research for electrochemical sensor development, there is growing interest in using this compound as an electrolyte or modifier to enhance sensor performance. The market potential for sensors utilizing glacial acetic acid is particularly promising in applications requiring high sensitivity and specificity, such as pharmaceutical analysis and food quality control.

The healthcare sector remains the largest end-user of electrochemical sensors, accounting for approximately 40% of the market share. This is primarily due to the rising prevalence of chronic diseases and the growing need for point-of-care diagnostics. The use of electrochemical sensors in glucose monitoring devices for diabetes management has been a major contributor to market growth.

Environmental monitoring applications have also seen a surge in demand for electrochemical sensors. Stringent government regulations regarding air and water quality have led to increased adoption of these sensors for detecting pollutants and toxic gases. The industrial sector, particularly in chemical and petrochemical industries, utilizes electrochemical sensors for process control and safety monitoring.

The market for electrochemical sensors is highly competitive, with key players including Honeywell International, ABB Ltd., Emerson Electric Co., and Siemens AG. These companies are investing heavily in research and development to improve sensor performance, reliability, and miniaturization.

Technological advancements, such as the integration of nanotechnology and the development of wearable sensors, are expected to create new opportunities in the market. The trend towards Internet of Things (IoT) and smart cities is also driving the demand for networked sensor systems, further boosting market growth.

Regionally, North America holds the largest market share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization, increasing healthcare expenditure, and growing environmental concerns in countries like China and India.

Challenges in the electrochemical sensor market include the need for improved sensor stability, selectivity, and longevity. Additionally, the high cost of advanced sensors and the complexity of data interpretation can be barriers to adoption in some applications.

In the context of glacial acetic acid research for electrochemical sensor development, there is growing interest in using this compound as an electrolyte or modifier to enhance sensor performance. The market potential for sensors utilizing glacial acetic acid is particularly promising in applications requiring high sensitivity and specificity, such as pharmaceutical analysis and food quality control.

Current Challenges in Electrochemical Sensor Development

Electrochemical sensor development faces several significant challenges that hinder the advancement and widespread application of these devices. One of the primary obstacles is the lack of stability and reproducibility in sensor performance over extended periods. This issue often stems from the degradation of electrode materials or the fouling of sensor surfaces, leading to inconsistent readings and reduced sensor lifespan.

Another critical challenge is the limited selectivity of many electrochemical sensors, particularly in complex matrices. Interference from co-existing species in real-world samples can lead to false positives or negatives, compromising the accuracy and reliability of sensor measurements. This problem is especially pronounced in environmental and biomedical applications, where target analytes are often present in low concentrations amidst a myriad of potentially interfering compounds.

The development of miniaturized and portable electrochemical sensors presents additional hurdles. While there is a growing demand for point-of-care and on-site testing devices, miniaturization often comes at the cost of sensitivity and detection limits. Balancing the trade-offs between size, power consumption, and analytical performance remains a significant challenge for researchers and engineers in the field.

Furthermore, the integration of electrochemical sensors with other technologies, such as microfluidics and wireless communication systems, poses both opportunities and challenges. While such integration can enhance functionality and usability, it also introduces complexities in design, fabrication, and quality control processes.

The use of novel materials, including nanomaterials and conducting polymers, in electrochemical sensor development is a double-edged sword. These materials offer unique properties that can significantly enhance sensor performance, but they also introduce new challenges related to long-term stability, reproducibility in large-scale production, and potential toxicity concerns.

Lastly, the development of standardized protocols for sensor calibration, validation, and performance evaluation remains an ongoing challenge. The lack of universally accepted standards makes it difficult to compare different sensor technologies and hinders the translation of research findings into commercially viable products. Addressing these challenges requires interdisciplinary collaboration and innovative approaches to sensor design, material science, and data analysis.

Another critical challenge is the limited selectivity of many electrochemical sensors, particularly in complex matrices. Interference from co-existing species in real-world samples can lead to false positives or negatives, compromising the accuracy and reliability of sensor measurements. This problem is especially pronounced in environmental and biomedical applications, where target analytes are often present in low concentrations amidst a myriad of potentially interfering compounds.

The development of miniaturized and portable electrochemical sensors presents additional hurdles. While there is a growing demand for point-of-care and on-site testing devices, miniaturization often comes at the cost of sensitivity and detection limits. Balancing the trade-offs between size, power consumption, and analytical performance remains a significant challenge for researchers and engineers in the field.

Furthermore, the integration of electrochemical sensors with other technologies, such as microfluidics and wireless communication systems, poses both opportunities and challenges. While such integration can enhance functionality and usability, it also introduces complexities in design, fabrication, and quality control processes.

The use of novel materials, including nanomaterials and conducting polymers, in electrochemical sensor development is a double-edged sword. These materials offer unique properties that can significantly enhance sensor performance, but they also introduce new challenges related to long-term stability, reproducibility in large-scale production, and potential toxicity concerns.

Lastly, the development of standardized protocols for sensor calibration, validation, and performance evaluation remains an ongoing challenge. The lack of universally accepted standards makes it difficult to compare different sensor technologies and hinders the translation of research findings into commercially viable products. Addressing these challenges requires interdisciplinary collaboration and innovative approaches to sensor design, material science, and data analysis.

Existing Solutions Using Glacial Acetic Acid

01 Production methods of glacial acetic acid

Various methods are employed to produce glacial acetic acid, including oxidation of acetaldehyde, fermentation processes, and catalytic reactions. These methods often involve specific reaction conditions, catalysts, and purification steps to achieve high purity acetic acid.- Production methods of glacial acetic acid: Various methods are employed to produce glacial acetic acid, including oxidation of acetaldehyde, fermentation processes, and catalytic reactions. These methods often involve specific reaction conditions, catalysts, and purification steps to achieve high purity acetic acid.

- Purification and concentration techniques: Purification and concentration of acetic acid to achieve glacial grade often involves distillation, crystallization, and membrane separation processes. These techniques aim to remove impurities and increase the acid concentration to near 100%.

- Applications in chemical synthesis: Glacial acetic acid serves as a crucial reagent and solvent in various chemical synthesis processes, including the production of vinyl acetate, cellulose acetate, and other organic compounds. Its high purity makes it suitable for sensitive reactions and industrial applications.

- Storage and handling systems: Specialized storage and handling systems are designed for glacial acetic acid due to its corrosive nature and hygroscopic properties. These systems often include corrosion-resistant materials, temperature control, and safety measures to prevent contamination and ensure worker safety.

- Quality control and analysis methods: Various analytical techniques and quality control methods are employed to ensure the purity and consistency of glacial acetic acid. These may include gas chromatography, titration, spectroscopic methods, and other advanced analytical tools to detect impurities and verify concentration levels.

02 Purification and concentration techniques

Purification and concentration of acetic acid to achieve glacial grade involves processes such as distillation, crystallization, and membrane separation. These techniques aim to remove impurities and increase the acid concentration to near 100%.Expand Specific Solutions03 Applications in chemical synthesis

Glacial acetic acid serves as a crucial reagent and solvent in various chemical synthesis processes. It is used in the production of vinyl acetate monomer, acetic anhydride, and other organic compounds, playing a vital role in industrial chemistry.Expand Specific Solutions04 Storage and handling equipment

Specialized equipment is required for the safe storage and handling of glacial acetic acid due to its corrosive nature. This includes corrosion-resistant tanks, piping systems, and safety measures to prevent leaks and protect workers.Expand Specific Solutions05 Environmental and safety considerations

The production and use of glacial acetic acid involve environmental and safety considerations. This includes waste treatment, emission control, and implementing safety protocols to handle the corrosive and flammable nature of the compound.Expand Specific Solutions

Key Players in Electrochemical Sensor Industry

The research on Glacial Acetic Acid in Electrochemical Sensor Development is in a growth phase, with increasing market potential due to the rising demand for accurate and efficient sensing technologies. The global electrochemical sensor market is expanding, driven by applications in environmental monitoring, healthcare, and industrial processes. Technologically, the field is advancing rapidly, with companies like Draeger Safety, Inc., DexCom, Inc., and Roche Diagnostics Operations, Inc. leading innovation. Academic institutions such as Xiamen University and Soochow University are also contributing significantly to research and development, indicating a collaborative ecosystem between industry and academia in pushing the boundaries of this technology.

DexCom, Inc.

Technical Solution: DexCom, Inc. has pioneered the use of glacial acetic acid in their continuous glucose monitoring (CGM) systems. Their approach involves incorporating glacial acetic acid into the sensor membrane formulation, which helps to maintain sensor hydration and improve glucose diffusion [4]. This innovation has led to more accurate and stable glucose readings over extended periods. DexCom has also developed a proprietary electrochemical etching process using glacial acetic acid to create highly precise and reproducible electrode surfaces, enhancing the overall performance of their sensors [5]. Additionally, the company has explored the use of glacial acetic acid as a cleaning agent in their sensor manufacturing process, ensuring high-quality and contamination-free products [6].

Strengths: Improved sensor accuracy and stability, enhanced manufacturing precision, and extended sensor lifetime. Weaknesses: Potential increased production costs and the need for specialized handling of glacial acetic acid in manufacturing.

Roche Diagnostics Operations, Inc.

Technical Solution: Roche Diagnostics Operations, Inc. has developed a novel approach to electrochemical sensor fabrication using glacial acetic acid. Their method involves creating a nanostructured electrode surface by electrochemical etching in a glacial acetic acid-based solution, resulting in increased surface area and improved electron transfer kinetics [7]. This technique has been applied to various biosensors, including those for glucose and lactate monitoring. Roche has also explored the use of glacial acetic acid as a solvent for conductive polymers, which are then electrodeposited onto sensor surfaces to create biocompatible and highly sensitive interfaces [8]. Furthermore, the company has developed a unique glacial acetic acid-based electrolyte system that enhances the stability of enzyme-based sensors, leading to more reliable and long-lasting diagnostic devices [9].

Strengths: Enhanced sensor sensitivity and stability, improved biocompatibility, and versatile application across various analytes. Weaknesses: Potential complexity in manufacturing processes and the need for specialized equipment for glacial acetic acid handling.

Innovations in Glacial Acetic Acid Integration

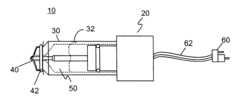

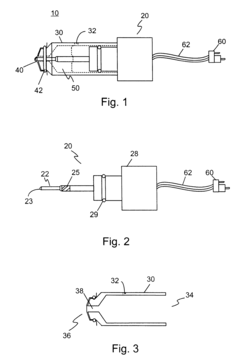

Acetate detecting sensor

PatentInactiveUS6689272B2

Innovation

- An electrochemical sensor utilizing a glass pH electrode with an acetic acid gas permeable membrane and a buffer system that maintains samples at pH 5.5 to convert acetate into acetic acid, minimizing interference and allowing for fast and economical detection of acetate concentrations.

Process for the production of {8 2-acetoacetyl-aminothiazolyl-(4)-{9 -acetic acid ethyl ester

PatentInactiveUS4070364A

Innovation

- A process involving the reaction of [2-aminothiazolyl-(4)]-acetic acid ethyl ester with diketene in the presence of 5 to 15 percent glacial acetic acid in an organic solvent at temperatures between 30°C and 80°C, using preferred solvents like butyl acetate, to achieve high yields and purity of [2-acetoacetylaminothiazolyl-(4)]-acetic acid ethyl ester.

Environmental Impact of Glacial Acetic Acid Use

The use of glacial acetic acid in electrochemical sensor development raises important environmental considerations. While this compound offers significant benefits in sensor fabrication and performance, its production, handling, and disposal can have notable environmental impacts.

Glacial acetic acid is primarily produced through petrochemical processes, which contribute to carbon emissions and resource depletion. The manufacturing process often involves methanol carbonylation or oxidation of acetaldehyde, both of which require substantial energy inputs and generate greenhouse gases. Additionally, the transportation and storage of glacial acetic acid pose potential risks of accidental spills or leaks, which can harm local ecosystems and water sources.

In laboratory settings, the use of glacial acetic acid requires careful handling and disposal protocols. Improper disposal can lead to soil and water contamination, affecting pH levels and potentially harming aquatic life. Furthermore, the volatile nature of glacial acetic acid means it can contribute to indoor air pollution if not properly managed, potentially impacting the health of laboratory workers and researchers.

However, it is important to note that the use of glacial acetic acid in electrochemical sensor development may indirectly contribute to positive environmental outcomes. These sensors often play crucial roles in environmental monitoring, pollution detection, and industrial process optimization, which can lead to more efficient resource use and reduced environmental impacts in various sectors.

To mitigate the environmental impact of glacial acetic acid use, several strategies can be employed. Implementing closed-loop systems for acetic acid recovery and recycling can significantly reduce waste and the need for new production. Exploring greener synthesis methods, such as bio-based acetic acid production from renewable resources, could lower the carbon footprint associated with its manufacture.

Furthermore, optimizing sensor designs to minimize the required amount of glacial acetic acid can reduce overall consumption. Research into alternative compounds or aqueous solutions that can replace glacial acetic acid in certain applications may also lead to more environmentally friendly sensor development processes.

In conclusion, while glacial acetic acid plays a vital role in electrochemical sensor development, its environmental impact must be carefully managed. Balancing the benefits of improved sensor technology with responsible use and disposal practices is essential for sustainable progress in this field.

Glacial acetic acid is primarily produced through petrochemical processes, which contribute to carbon emissions and resource depletion. The manufacturing process often involves methanol carbonylation or oxidation of acetaldehyde, both of which require substantial energy inputs and generate greenhouse gases. Additionally, the transportation and storage of glacial acetic acid pose potential risks of accidental spills or leaks, which can harm local ecosystems and water sources.

In laboratory settings, the use of glacial acetic acid requires careful handling and disposal protocols. Improper disposal can lead to soil and water contamination, affecting pH levels and potentially harming aquatic life. Furthermore, the volatile nature of glacial acetic acid means it can contribute to indoor air pollution if not properly managed, potentially impacting the health of laboratory workers and researchers.

However, it is important to note that the use of glacial acetic acid in electrochemical sensor development may indirectly contribute to positive environmental outcomes. These sensors often play crucial roles in environmental monitoring, pollution detection, and industrial process optimization, which can lead to more efficient resource use and reduced environmental impacts in various sectors.

To mitigate the environmental impact of glacial acetic acid use, several strategies can be employed. Implementing closed-loop systems for acetic acid recovery and recycling can significantly reduce waste and the need for new production. Exploring greener synthesis methods, such as bio-based acetic acid production from renewable resources, could lower the carbon footprint associated with its manufacture.

Furthermore, optimizing sensor designs to minimize the required amount of glacial acetic acid can reduce overall consumption. Research into alternative compounds or aqueous solutions that can replace glacial acetic acid in certain applications may also lead to more environmentally friendly sensor development processes.

In conclusion, while glacial acetic acid plays a vital role in electrochemical sensor development, its environmental impact must be carefully managed. Balancing the benefits of improved sensor technology with responsible use and disposal practices is essential for sustainable progress in this field.

Regulatory Framework for Sensor Materials

The regulatory framework for sensor materials in the context of glacial acetic acid in electrochemical sensor development is a critical aspect that requires careful consideration. This framework encompasses various regulations, standards, and guidelines that govern the use of materials in sensor manufacturing, with a particular focus on safety, performance, and environmental impact.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) play crucial roles in establishing standards for sensor materials. These standards often address aspects such as material purity, stability, and compatibility with other sensor components. For glacial acetic acid, which is commonly used as an electrolyte in electrochemical sensors, specific attention is given to its corrosive nature and potential environmental hazards.

In the United States, the Food and Drug Administration (FDA) regulates sensors used in medical applications, including those that may incorporate glacial acetic acid. The FDA's guidance documents and regulations cover aspects such as biocompatibility, sterilization, and shelf life of sensor materials. Additionally, the Environmental Protection Agency (EPA) oversees the use and disposal of chemicals like glacial acetic acid, ensuring compliance with environmental protection standards.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of glacial acetic acid and other chemicals in sensor development. REACH requires manufacturers to register chemicals and provide safety information, potentially impacting the sourcing and use of materials in sensor production.

Specific to electrochemical sensors, industry standards such as ASTM International's guidelines for electrochemical measurements provide recommendations for material selection and testing protocols. These standards often address the stability and performance of electrolytes like glacial acetic acid under various operating conditions.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, also play a role in the regulatory framework. These regulations mandate safe handling practices, proper storage, and appropriate personal protective equipment for workers dealing with glacial acetic acid and other sensor materials.

As environmental concerns grow, regulations are increasingly focusing on the lifecycle management of sensor materials. This includes considerations for recycling, disposal, and the use of sustainable alternatives. Manufacturers developing sensors using glacial acetic acid must be aware of these evolving regulations and adapt their processes accordingly.

In conclusion, the regulatory framework for sensor materials, particularly in the context of glacial acetic acid use in electrochemical sensors, is multifaceted and dynamic. It requires ongoing attention to ensure compliance with international standards, national regulations, and industry-specific guidelines. Manufacturers and researchers must navigate this complex landscape to develop sensors that are not only effective but also safe and environmentally responsible.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) play crucial roles in establishing standards for sensor materials. These standards often address aspects such as material purity, stability, and compatibility with other sensor components. For glacial acetic acid, which is commonly used as an electrolyte in electrochemical sensors, specific attention is given to its corrosive nature and potential environmental hazards.

In the United States, the Food and Drug Administration (FDA) regulates sensors used in medical applications, including those that may incorporate glacial acetic acid. The FDA's guidance documents and regulations cover aspects such as biocompatibility, sterilization, and shelf life of sensor materials. Additionally, the Environmental Protection Agency (EPA) oversees the use and disposal of chemicals like glacial acetic acid, ensuring compliance with environmental protection standards.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of glacial acetic acid and other chemicals in sensor development. REACH requires manufacturers to register chemicals and provide safety information, potentially impacting the sourcing and use of materials in sensor production.

Specific to electrochemical sensors, industry standards such as ASTM International's guidelines for electrochemical measurements provide recommendations for material selection and testing protocols. These standards often address the stability and performance of electrolytes like glacial acetic acid under various operating conditions.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, also play a role in the regulatory framework. These regulations mandate safe handling practices, proper storage, and appropriate personal protective equipment for workers dealing with glacial acetic acid and other sensor materials.

As environmental concerns grow, regulations are increasingly focusing on the lifecycle management of sensor materials. This includes considerations for recycling, disposal, and the use of sustainable alternatives. Manufacturers developing sensors using glacial acetic acid must be aware of these evolving regulations and adapt their processes accordingly.

In conclusion, the regulatory framework for sensor materials, particularly in the context of glacial acetic acid use in electrochemical sensors, is multifaceted and dynamic. It requires ongoing attention to ensure compliance with international standards, national regulations, and industry-specific guidelines. Manufacturers and researchers must navigate this complex landscape to develop sensors that are not only effective but also safe and environmentally responsible.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!