Thermal Analysis of Materials Incorporating Glacial Acetic Acid

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Analysis Goals

The primary goal of thermal analysis in materials incorporating glacial acetic acid is to comprehensively understand the thermal behavior and properties of these materials under various temperature conditions. This analysis aims to provide crucial insights into the material's stability, phase transitions, decomposition patterns, and overall thermal characteristics.

One key objective is to determine the melting point and freezing point of materials containing glacial acetic acid. This information is essential for understanding the material's phase behavior and its potential applications in different temperature environments. Additionally, the analysis seeks to identify any potential polymorphic transitions that may occur during heating or cooling processes.

Another important goal is to assess the thermal stability of the material. This involves studying the decomposition temperature and the associated weight loss patterns. Understanding these factors is critical for predicting the material's performance and longevity in high-temperature applications or during prolonged exposure to elevated temperatures.

Thermal analysis also aims to investigate the heat capacity and thermal conductivity of materials incorporating glacial acetic acid. These properties are fundamental in determining the material's ability to store and transfer heat, which is crucial for applications in thermal management systems or energy storage devices.

Furthermore, the analysis seeks to evaluate the coefficient of thermal expansion for these materials. This information is vital for predicting dimensional changes in response to temperature fluctuations, which is particularly important in applications where precise dimensional stability is required.

An additional objective is to identify any potential chemical reactions or interactions that may occur within the material or between the material and its environment during thermal cycling. This includes studying the potential for acetic acid evaporation, which could affect the material's composition and properties over time.

Lastly, thermal analysis aims to provide data for the development of thermal models and simulations. These models can be used to predict the material's behavior under various thermal conditions, enabling more efficient design and optimization of products incorporating glacial acetic acid.

By achieving these goals, thermal analysis provides a comprehensive understanding of the material's thermal properties, enabling informed decision-making in material selection, product design, and process optimization across various industries utilizing glacial acetic acid-based materials.

One key objective is to determine the melting point and freezing point of materials containing glacial acetic acid. This information is essential for understanding the material's phase behavior and its potential applications in different temperature environments. Additionally, the analysis seeks to identify any potential polymorphic transitions that may occur during heating or cooling processes.

Another important goal is to assess the thermal stability of the material. This involves studying the decomposition temperature and the associated weight loss patterns. Understanding these factors is critical for predicting the material's performance and longevity in high-temperature applications or during prolonged exposure to elevated temperatures.

Thermal analysis also aims to investigate the heat capacity and thermal conductivity of materials incorporating glacial acetic acid. These properties are fundamental in determining the material's ability to store and transfer heat, which is crucial for applications in thermal management systems or energy storage devices.

Furthermore, the analysis seeks to evaluate the coefficient of thermal expansion for these materials. This information is vital for predicting dimensional changes in response to temperature fluctuations, which is particularly important in applications where precise dimensional stability is required.

An additional objective is to identify any potential chemical reactions or interactions that may occur within the material or between the material and its environment during thermal cycling. This includes studying the potential for acetic acid evaporation, which could affect the material's composition and properties over time.

Lastly, thermal analysis aims to provide data for the development of thermal models and simulations. These models can be used to predict the material's behavior under various thermal conditions, enabling more efficient design and optimization of products incorporating glacial acetic acid.

By achieving these goals, thermal analysis provides a comprehensive understanding of the material's thermal properties, enabling informed decision-making in material selection, product design, and process optimization across various industries utilizing glacial acetic acid-based materials.

Market Demand Analysis

The market demand for thermal analysis of materials incorporating glacial acetic acid has been steadily growing across various industries. This demand is primarily driven by the increasing need for precise material characterization in sectors such as pharmaceuticals, polymers, and chemical manufacturing. Glacial acetic acid, being a versatile organic compound, plays a crucial role in many industrial processes, and understanding its thermal behavior when incorporated into different materials is essential for product development and quality control.

In the pharmaceutical industry, thermal analysis techniques are extensively used for drug formulation and stability studies. The incorporation of glacial acetic acid in pharmaceutical materials necessitates thorough thermal analysis to ensure product efficacy and safety. This has led to a significant increase in demand for advanced thermal analysis equipment and expertise in this field.

The polymer industry also contributes substantially to the market demand for thermal analysis of materials containing glacial acetic acid. As polymers are widely used in various applications, from packaging to automotive components, understanding their thermal properties when combined with glacial acetic acid is crucial for optimizing performance and durability. This has resulted in a growing market for thermal analysis services and equipment tailored to polymer-acetic acid systems.

Chemical manufacturers represent another major segment driving the demand for thermal analysis in this area. The use of glacial acetic acid as a reagent or solvent in numerous chemical processes requires precise thermal characterization to optimize reaction conditions and ensure product quality. This has led to increased investments in thermal analysis capabilities within the chemical industry.

The market for thermal analysis of materials incorporating glacial acetic acid is also influenced by regulatory requirements across different industries. Stringent quality control standards and the need for comprehensive material characterization have further boosted the demand for advanced thermal analysis techniques and expertise.

Geographically, the market demand is particularly strong in regions with a high concentration of pharmaceutical, chemical, and polymer industries. North America, Europe, and Asia-Pacific are the leading markets, with emerging economies in Asia showing rapid growth in demand due to expanding industrial sectors and increasing focus on research and development.

The market is characterized by a trend towards more sophisticated and automated thermal analysis equipment, capable of handling complex material systems involving glacial acetic acid. This has created opportunities for equipment manufacturers and service providers specializing in thermal analysis solutions tailored to these specific needs.

In the pharmaceutical industry, thermal analysis techniques are extensively used for drug formulation and stability studies. The incorporation of glacial acetic acid in pharmaceutical materials necessitates thorough thermal analysis to ensure product efficacy and safety. This has led to a significant increase in demand for advanced thermal analysis equipment and expertise in this field.

The polymer industry also contributes substantially to the market demand for thermal analysis of materials containing glacial acetic acid. As polymers are widely used in various applications, from packaging to automotive components, understanding their thermal properties when combined with glacial acetic acid is crucial for optimizing performance and durability. This has resulted in a growing market for thermal analysis services and equipment tailored to polymer-acetic acid systems.

Chemical manufacturers represent another major segment driving the demand for thermal analysis in this area. The use of glacial acetic acid as a reagent or solvent in numerous chemical processes requires precise thermal characterization to optimize reaction conditions and ensure product quality. This has led to increased investments in thermal analysis capabilities within the chemical industry.

The market for thermal analysis of materials incorporating glacial acetic acid is also influenced by regulatory requirements across different industries. Stringent quality control standards and the need for comprehensive material characterization have further boosted the demand for advanced thermal analysis techniques and expertise.

Geographically, the market demand is particularly strong in regions with a high concentration of pharmaceutical, chemical, and polymer industries. North America, Europe, and Asia-Pacific are the leading markets, with emerging economies in Asia showing rapid growth in demand due to expanding industrial sectors and increasing focus on research and development.

The market is characterized by a trend towards more sophisticated and automated thermal analysis equipment, capable of handling complex material systems involving glacial acetic acid. This has created opportunities for equipment manufacturers and service providers specializing in thermal analysis solutions tailored to these specific needs.

Current Challenges

The thermal analysis of materials incorporating glacial acetic acid presents several significant challenges that researchers and industry professionals must address. One of the primary difficulties lies in the corrosive nature of glacial acetic acid, which can rapidly degrade standard laboratory equipment and sensors used in thermal analysis. This corrosion not only affects the accuracy of measurements but also poses safety risks and increases the frequency of equipment replacement.

Another challenge is the volatility of glacial acetic acid, which has a relatively low boiling point of 118°C. This characteristic makes it difficult to conduct thermal analysis at higher temperatures without significant sample loss or changes in composition. Researchers must develop specialized containment systems or modify existing techniques to prevent the escape of acetic acid vapors during analysis, which can skew results and potentially damage analytical instruments.

The hygroscopic nature of glacial acetic acid further complicates thermal analysis procedures. The material's tendency to absorb moisture from the atmosphere can lead to inconsistent results and affect the purity of samples. This necessitates stringent environmental controls and sample preparation protocols to ensure reproducibility and accuracy in thermal measurements.

Additionally, the strong hydrogen bonding capabilities of glacial acetic acid can interfere with the thermal behavior of other materials in the sample. This interaction may mask or alter the true thermal properties of the material under investigation, making it challenging to isolate and analyze specific components or phases within complex systems.

The potential for unexpected chemical reactions during thermal analysis is another significant concern. Glacial acetic acid can react with certain materials at elevated temperatures, leading to the formation of new compounds or the decomposition of existing ones. These reactions can dramatically alter the thermal profile of the sample and may lead to misinterpretation of data if not properly accounted for in the analysis.

Furthermore, the health and safety risks associated with handling glacial acetic acid require specialized training and protective measures. This adds complexity to experimental setups and may limit the accessibility of certain thermal analysis techniques to researchers without appropriate facilities or expertise.

Lastly, the development of standardized protocols for thermal analysis of materials incorporating glacial acetic acid remains a challenge. The unique properties of this compound often necessitate custom methodologies, making it difficult to compare results across different studies or laboratories. Establishing universally accepted procedures and calibration standards for such analyses is crucial for advancing research in this field and ensuring the reliability of thermal data for materials containing glacial acetic acid.

Another challenge is the volatility of glacial acetic acid, which has a relatively low boiling point of 118°C. This characteristic makes it difficult to conduct thermal analysis at higher temperatures without significant sample loss or changes in composition. Researchers must develop specialized containment systems or modify existing techniques to prevent the escape of acetic acid vapors during analysis, which can skew results and potentially damage analytical instruments.

The hygroscopic nature of glacial acetic acid further complicates thermal analysis procedures. The material's tendency to absorb moisture from the atmosphere can lead to inconsistent results and affect the purity of samples. This necessitates stringent environmental controls and sample preparation protocols to ensure reproducibility and accuracy in thermal measurements.

Additionally, the strong hydrogen bonding capabilities of glacial acetic acid can interfere with the thermal behavior of other materials in the sample. This interaction may mask or alter the true thermal properties of the material under investigation, making it challenging to isolate and analyze specific components or phases within complex systems.

The potential for unexpected chemical reactions during thermal analysis is another significant concern. Glacial acetic acid can react with certain materials at elevated temperatures, leading to the formation of new compounds or the decomposition of existing ones. These reactions can dramatically alter the thermal profile of the sample and may lead to misinterpretation of data if not properly accounted for in the analysis.

Furthermore, the health and safety risks associated with handling glacial acetic acid require specialized training and protective measures. This adds complexity to experimental setups and may limit the accessibility of certain thermal analysis techniques to researchers without appropriate facilities or expertise.

Lastly, the development of standardized protocols for thermal analysis of materials incorporating glacial acetic acid remains a challenge. The unique properties of this compound often necessitate custom methodologies, making it difficult to compare results across different studies or laboratories. Establishing universally accepted procedures and calibration standards for such analyses is crucial for advancing research in this field and ensuring the reliability of thermal data for materials containing glacial acetic acid.

Existing Methodologies

01 Thermal properties of glacial acetic acid in chemical processes

Glacial acetic acid exhibits unique thermal properties that are utilized in various chemical processes. Its low melting point and high boiling point make it suitable for use as a solvent and reagent in reactions requiring specific temperature conditions. The thermal behavior of glacial acetic acid influences its effectiveness in organic synthesis, esterification, and other industrial applications.- Thermal properties of glacial acetic acid in chemical processes: Glacial acetic acid exhibits unique thermal properties that are utilized in various chemical processes. Its low melting point and high boiling point make it suitable for use as a solvent and reagent in reactions requiring specific temperature conditions. The thermal behavior of glacial acetic acid affects heat transfer and energy efficiency in industrial applications.

- Materials incorporating glacial acetic acid for thermal management: Certain materials incorporate glacial acetic acid to enhance their thermal management properties. These composites can be used in heat storage, temperature regulation, and thermal insulation applications. The incorporation of glacial acetic acid can modify the heat capacity, thermal conductivity, and phase change characteristics of the base materials.

- Glacial acetic acid in phase change materials: Glacial acetic acid is used as a component in phase change materials (PCMs) for thermal energy storage. Its latent heat of fusion and specific heat capacity contribute to the overall thermal performance of PCMs. These materials find applications in building materials, textiles, and electronic cooling systems for temperature regulation and energy conservation.

- Thermal stability of materials containing glacial acetic acid: The thermal stability of materials incorporating glacial acetic acid is an important consideration in their design and application. Factors such as decomposition temperature, vapor pressure, and chemical reactivity at elevated temperatures affect the performance and safety of these materials. Understanding these properties is crucial for developing heat-resistant and thermally stable composites.

- Thermal conductivity enhancement using glacial acetic acid: Glacial acetic acid can be used to modify the thermal conductivity of certain materials. By incorporating it into polymers, ceramics, or other substrates, the overall heat transfer properties of the composite can be altered. This approach is explored in the development of advanced thermal interface materials and heat dissipation solutions for various industries.

02 Heat transfer characteristics of materials containing glacial acetic acid

Materials incorporating glacial acetic acid demonstrate distinct heat transfer characteristics. These properties are exploited in the design of heat exchange systems, thermal storage devices, and temperature-controlled processes. The presence of glacial acetic acid can enhance or modify the thermal conductivity and heat capacity of composite materials, influencing their performance in various applications.Expand Specific Solutions03 Phase change behavior of glacial acetic acid-based materials

The phase change behavior of materials containing glacial acetic acid is of particular interest in thermal management applications. These materials can undergo transitions between solid, liquid, and gaseous states within specific temperature ranges, allowing for efficient energy storage and release. This property is utilized in the development of phase change materials for thermal regulation in buildings, electronics, and other industries.Expand Specific Solutions04 Thermal stability and decomposition of glacial acetic acid compounds

Understanding the thermal stability and decomposition behavior of materials incorporating glacial acetic acid is crucial for their safe and effective use. Research focuses on determining the temperature ranges at which these materials remain stable and the conditions under which they may decompose or react. This knowledge is essential for designing processes and products that involve high temperatures or prolonged exposure to heat.Expand Specific Solutions05 Thermal insulation properties of glacial acetic acid-based composites

Composites containing glacial acetic acid can exhibit unique thermal insulation properties. These materials may be engineered to provide effective barriers against heat transfer, making them suitable for applications in construction, automotive, and aerospace industries. The incorporation of glacial acetic acid can modify the porosity, density, and thermal conductivity of the composite, resulting in improved insulation performance.Expand Specific Solutions

Key Industry Players

The thermal analysis of materials incorporating glacial acetic acid is an emerging field with growing market potential. The industry is in its early development stage, characterized by ongoing research and technological advancements. The market size is expanding as more industries recognize the importance of understanding material behavior under thermal stress. Companies like Eastman Chemical Co., Kureha Corp., and Adeka Corp. are at the forefront of this technology, leveraging their expertise in chemical manufacturing to develop innovative solutions. The involvement of major players such as Toyota Motor Corp. and Solvay Specialty Polymers USA LLC indicates the technology's cross-industry relevance. While not yet fully mature, the field is rapidly evolving, with academic institutions like Tianjin University of Science & Technology contributing to its advancement through research collaborations.

Eastman Chemical Co.

Technical Solution: Eastman Chemical Co. has developed advanced thermal analysis techniques for materials incorporating glacial acetic acid. Their approach utilizes differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) to study the thermal behavior of acetic acid-based composites[1]. The company has implemented a proprietary method to analyze the thermal decomposition kinetics of these materials, allowing for precise determination of activation energies and reaction mechanisms[3]. Eastman's research also focuses on the impact of glacial acetic acid on the glass transition temperature and crystallization behavior of polymeric materials, which is crucial for applications in packaging and coatings industries[5].

Strengths: Comprehensive thermal analysis capabilities, expertise in acetic acid-based materials, and industry-specific applications. Weaknesses: Potential limitations in extreme temperature ranges and specialized equipment requirements.

Solvay Specialty Polymers USA LLC

Technical Solution: Solvay has developed a cutting-edge thermal analysis platform for materials incorporating glacial acetic acid, focusing on high-performance polymers. Their approach combines dynamic mechanical analysis (DMA) with modulated DSC to characterize the viscoelastic properties and phase transitions of acetic acid-modified materials[2]. Solvay's research has led to the development of novel polymer blends with enhanced thermal stability and chemical resistance, particularly useful in aerospace and automotive applications[4]. The company has also pioneered the use of time-temperature superposition principles to predict long-term thermal behavior of these materials under various environmental conditions[6].

Strengths: Advanced polymer science expertise, innovative material development, and broad application range. Weaknesses: Potentially higher costs associated with specialized polymer formulations and limited focus on non-polymeric materials.

Core Innovations

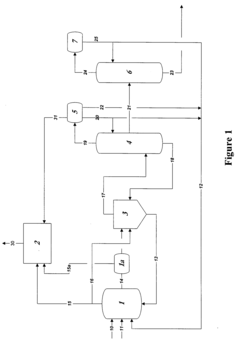

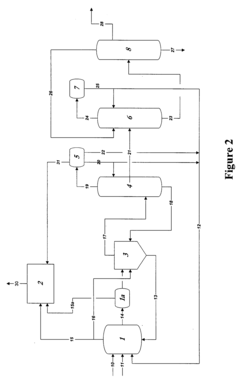

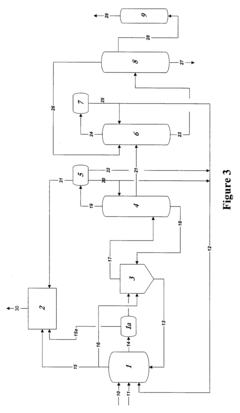

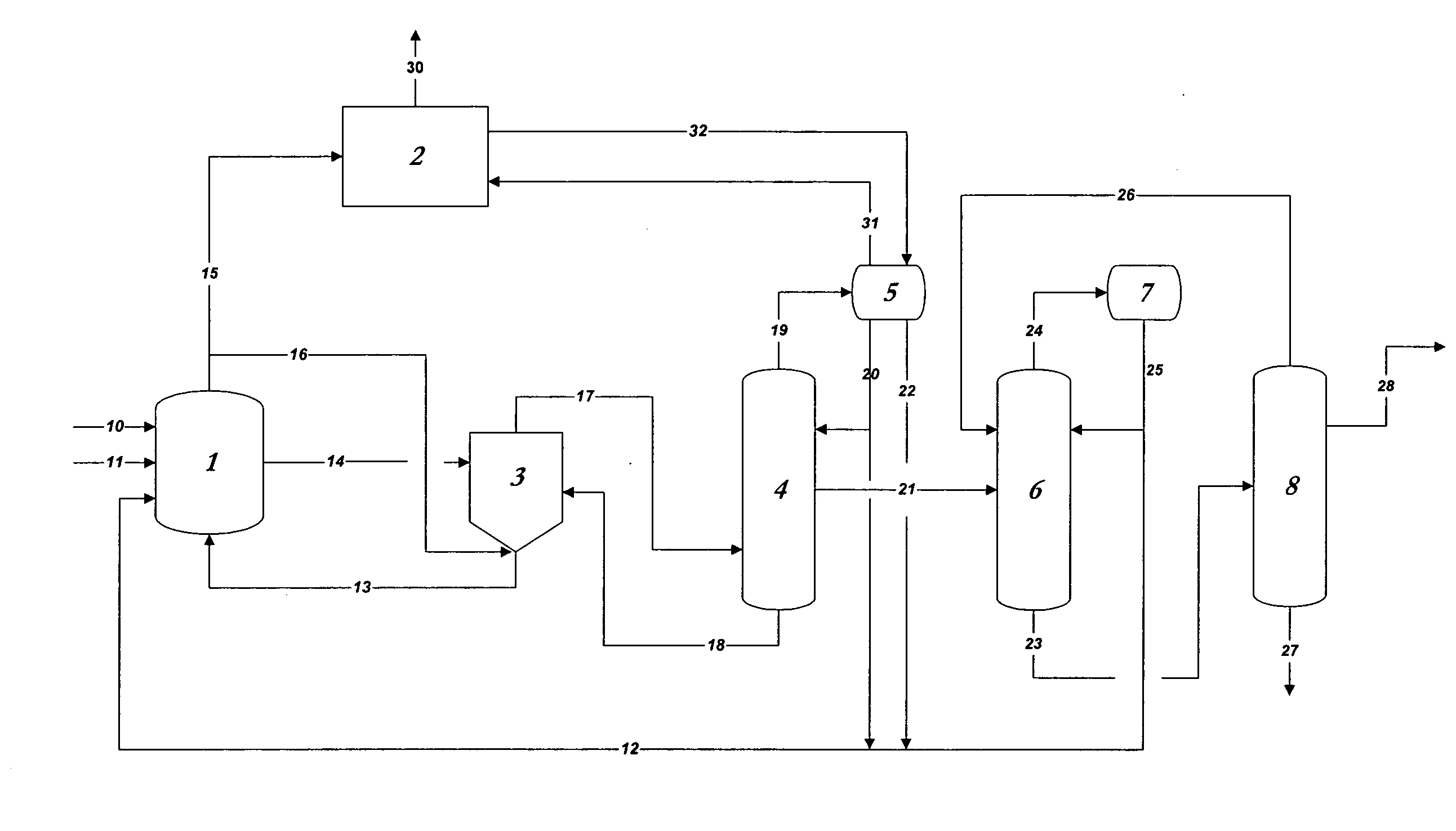

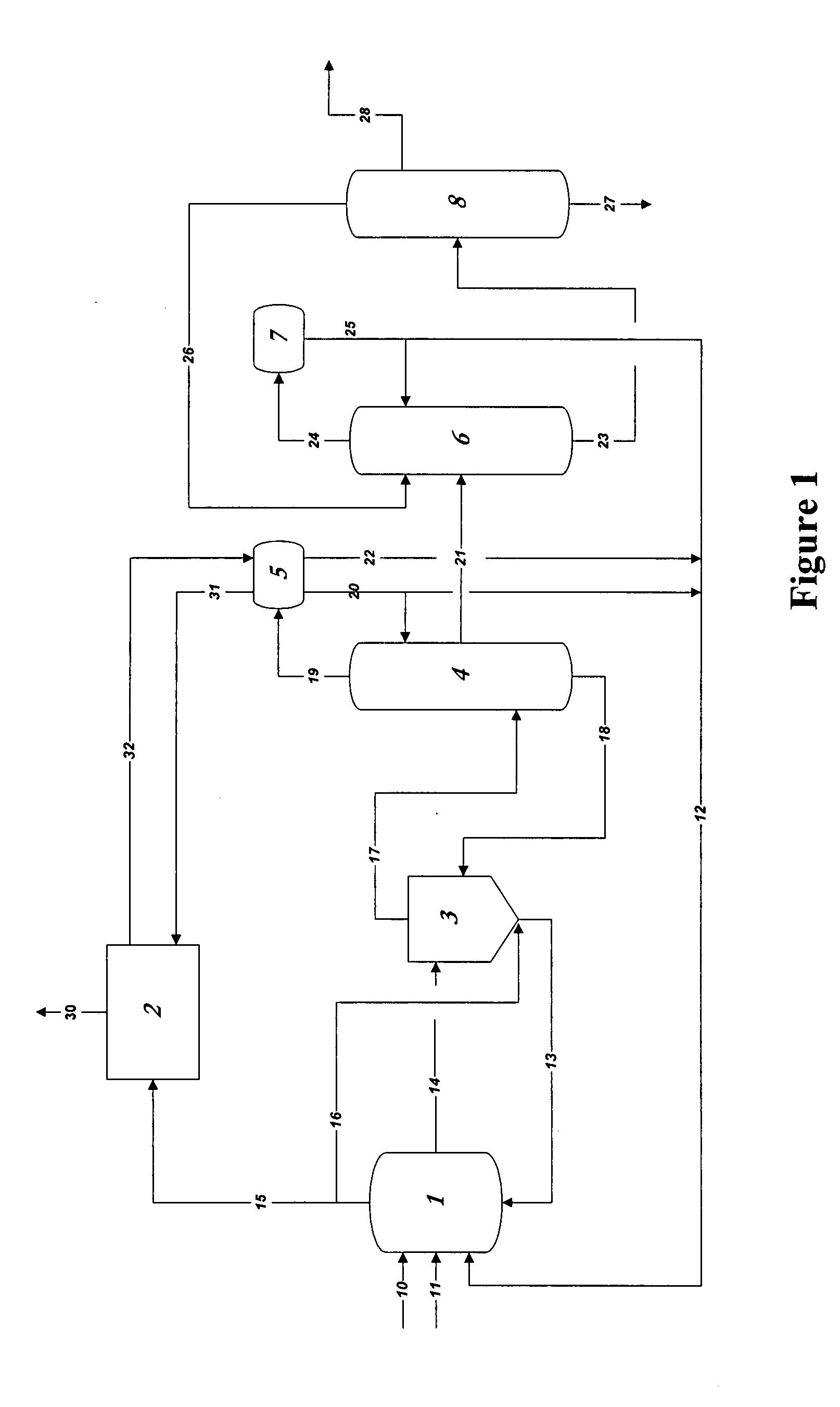

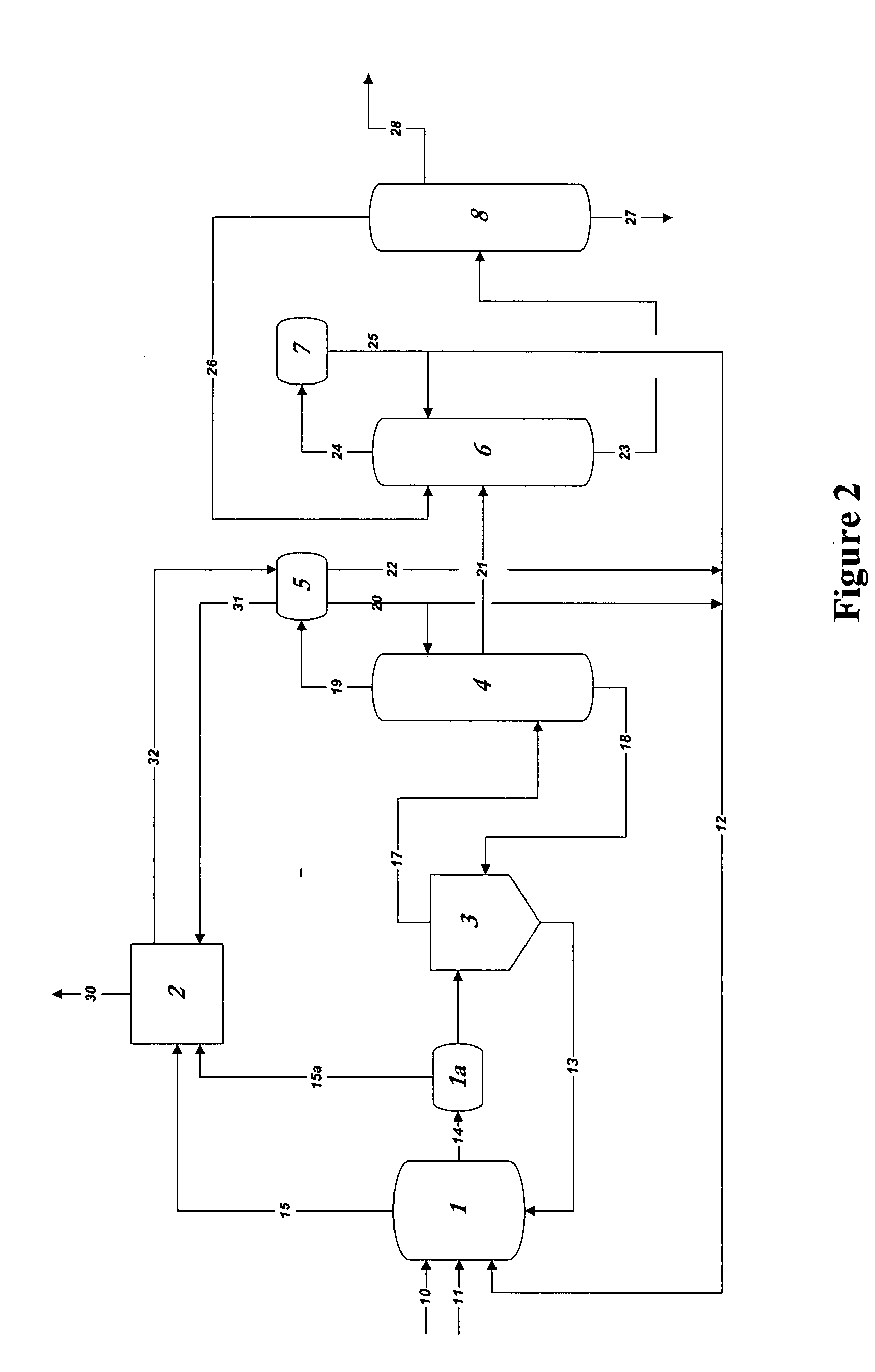

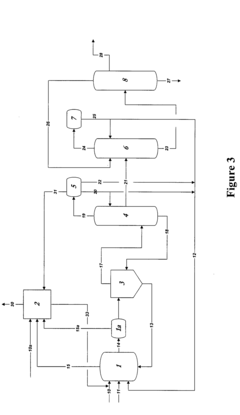

Control of impurities in product glacial acetic acid of rhodium-catalyzed methanol carbonylation

PatentInactiveUS20090187043A1

Innovation

- A method involving a rhodium-catalyzed carbonylation process with controlled water and iodide concentrations, combined with the use of a macroreticular strong-acid cation exchange resin and silver or mercury exchanged cation exchange substrates to manage impurities, ensuring high purity glacial acetic acid production.

Control of formic acid impurities in industrial glacial acetic acid

PatentInactiveUS20080293967A1

Innovation

- Controlling the water concentration in the reaction medium during rhodium-catalyzed methanol carbonylation to specific ranges (0.5 to 14 weight percent) effectively inhibits the formation of formic acid impurities in the glacial acetic acid product, achieving low formic acid content below 160 ppm.

Safety Considerations

When conducting thermal analysis of materials incorporating glacial acetic acid, safety considerations are paramount due to the hazardous nature of this chemical. Glacial acetic acid is highly corrosive and flammable, posing significant risks to researchers and laboratory equipment. Proper personal protective equipment (PPE) is essential, including chemical-resistant gloves, safety goggles, and a lab coat. A well-ventilated fume hood should be used to prevent inhalation of vapors, which can cause respiratory irritation and damage.

The flammability of glacial acetic acid necessitates strict fire safety protocols. Open flames and sources of ignition must be eliminated from the testing area. Fire extinguishers suitable for chemical fires should be readily accessible. Additionally, the storage and handling of glacial acetic acid require special attention. It should be kept in tightly sealed containers made of compatible materials, such as glass or certain plastics, and stored in a cool, dry place away from heat sources and oxidizing agents.

Thermal analysis equipment must be carefully selected and maintained to withstand the corrosive nature of glacial acetic acid. Regular inspections and calibrations are crucial to ensure the integrity of the apparatus and the accuracy of results. Researchers should be trained in the proper use of thermal analysis instruments and the specific hazards associated with glacial acetic acid.

Emergency response procedures must be established and communicated to all personnel involved in the thermal analysis. This includes protocols for chemical spills, fires, and personal exposure. Eye wash stations and safety showers should be easily accessible in case of accidental contact with the acid. A comprehensive safety data sheet (SDS) for glacial acetic acid must be available and reviewed by all researchers prior to conducting experiments.

Waste disposal is another critical safety consideration. Glacial acetic acid and any materials contaminated with it must be disposed of as hazardous waste according to local regulations. Neutralization may be required before disposal, and this process should only be performed by trained personnel following established procedures.

Temperature control during thermal analysis is crucial not only for accurate results but also for safety. Overheating can lead to rapid decomposition or vaporization of glacial acetic acid, potentially causing pressure build-up in sealed systems. Careful monitoring and control of temperature ramps and maximum temperatures are essential to prevent accidents.

Lastly, a risk assessment should be conducted before initiating any thermal analysis involving glacial acetic acid. This assessment should identify potential hazards, evaluate the likelihood and severity of risks, and establish appropriate control measures. Regular safety audits and reviews of experimental procedures can help ensure ongoing compliance with safety protocols and identify areas for improvement in handling this hazardous material during thermal analysis.

The flammability of glacial acetic acid necessitates strict fire safety protocols. Open flames and sources of ignition must be eliminated from the testing area. Fire extinguishers suitable for chemical fires should be readily accessible. Additionally, the storage and handling of glacial acetic acid require special attention. It should be kept in tightly sealed containers made of compatible materials, such as glass or certain plastics, and stored in a cool, dry place away from heat sources and oxidizing agents.

Thermal analysis equipment must be carefully selected and maintained to withstand the corrosive nature of glacial acetic acid. Regular inspections and calibrations are crucial to ensure the integrity of the apparatus and the accuracy of results. Researchers should be trained in the proper use of thermal analysis instruments and the specific hazards associated with glacial acetic acid.

Emergency response procedures must be established and communicated to all personnel involved in the thermal analysis. This includes protocols for chemical spills, fires, and personal exposure. Eye wash stations and safety showers should be easily accessible in case of accidental contact with the acid. A comprehensive safety data sheet (SDS) for glacial acetic acid must be available and reviewed by all researchers prior to conducting experiments.

Waste disposal is another critical safety consideration. Glacial acetic acid and any materials contaminated with it must be disposed of as hazardous waste according to local regulations. Neutralization may be required before disposal, and this process should only be performed by trained personnel following established procedures.

Temperature control during thermal analysis is crucial not only for accurate results but also for safety. Overheating can lead to rapid decomposition or vaporization of glacial acetic acid, potentially causing pressure build-up in sealed systems. Careful monitoring and control of temperature ramps and maximum temperatures are essential to prevent accidents.

Lastly, a risk assessment should be conducted before initiating any thermal analysis involving glacial acetic acid. This assessment should identify potential hazards, evaluate the likelihood and severity of risks, and establish appropriate control measures. Regular safety audits and reviews of experimental procedures can help ensure ongoing compliance with safety protocols and identify areas for improvement in handling this hazardous material during thermal analysis.

Environmental Impact

The incorporation of glacial acetic acid in materials for thermal analysis raises significant environmental concerns that warrant careful consideration. The production, use, and disposal of glacial acetic acid can have far-reaching impacts on ecosystems, air quality, and water resources. During the manufacturing process of glacial acetic acid, emissions of volatile organic compounds (VOCs) and greenhouse gases contribute to air pollution and climate change. These emissions may include methanol, carbon monoxide, and acetic acid vapors, which can lead to the formation of ground-level ozone and smog.

When materials containing glacial acetic acid are subjected to thermal analysis, the potential for environmental contamination increases. High temperatures can cause the release of acetic acid vapors, which are corrosive and can harm both terrestrial and aquatic ecosystems if not properly contained. The acidification of soil and water bodies due to acetic acid exposure can disrupt pH-sensitive organisms and alter ecosystem dynamics. Furthermore, the disposal of waste materials from thermal analysis experiments presents challenges, as improper handling can lead to soil and groundwater contamination.

The environmental impact extends to human health as well. Exposure to acetic acid vapors can cause respiratory irritation, eye damage, and skin burns. In industrial settings, stringent safety measures are necessary to protect workers and surrounding communities from accidental releases. The transportation of glacial acetic acid also poses risks, as spills during transit can have immediate and long-lasting effects on local environments.

From a lifecycle perspective, the environmental footprint of materials incorporating glacial acetic acid must be considered. The extraction of raw materials for acetic acid production, typically through the carbonylation of methanol or oxidation of acetaldehyde, consumes significant energy and resources. The energy-intensive nature of these processes contributes to indirect environmental impacts through increased carbon emissions from power generation.

To mitigate these environmental concerns, researchers and industries are exploring alternatives and implementing more sustainable practices. Green chemistry initiatives aim to develop less hazardous substitutes for glacial acetic acid in thermal analysis applications. Closed-loop systems and improved containment technologies are being employed to minimize emissions and reduce the risk of environmental contamination. Additionally, advancements in waste treatment and recycling methods are helping to minimize the environmental burden associated with the disposal of acetic acid-containing materials.

As environmental regulations become more stringent, there is a growing emphasis on life cycle assessments and environmental impact studies for materials and processes involving glacial acetic acid. These assessments help identify areas for improvement and guide the development of more environmentally friendly alternatives. The push towards sustainability in thermal analysis techniques is driving innovation in both materials science and analytical methodologies, with the goal of reducing the overall environmental footprint of scientific and industrial processes.

When materials containing glacial acetic acid are subjected to thermal analysis, the potential for environmental contamination increases. High temperatures can cause the release of acetic acid vapors, which are corrosive and can harm both terrestrial and aquatic ecosystems if not properly contained. The acidification of soil and water bodies due to acetic acid exposure can disrupt pH-sensitive organisms and alter ecosystem dynamics. Furthermore, the disposal of waste materials from thermal analysis experiments presents challenges, as improper handling can lead to soil and groundwater contamination.

The environmental impact extends to human health as well. Exposure to acetic acid vapors can cause respiratory irritation, eye damage, and skin burns. In industrial settings, stringent safety measures are necessary to protect workers and surrounding communities from accidental releases. The transportation of glacial acetic acid also poses risks, as spills during transit can have immediate and long-lasting effects on local environments.

From a lifecycle perspective, the environmental footprint of materials incorporating glacial acetic acid must be considered. The extraction of raw materials for acetic acid production, typically through the carbonylation of methanol or oxidation of acetaldehyde, consumes significant energy and resources. The energy-intensive nature of these processes contributes to indirect environmental impacts through increased carbon emissions from power generation.

To mitigate these environmental concerns, researchers and industries are exploring alternatives and implementing more sustainable practices. Green chemistry initiatives aim to develop less hazardous substitutes for glacial acetic acid in thermal analysis applications. Closed-loop systems and improved containment technologies are being employed to minimize emissions and reduce the risk of environmental contamination. Additionally, advancements in waste treatment and recycling methods are helping to minimize the environmental burden associated with the disposal of acetic acid-containing materials.

As environmental regulations become more stringent, there is a growing emphasis on life cycle assessments and environmental impact studies for materials and processes involving glacial acetic acid. These assessments help identify areas for improvement and guide the development of more environmentally friendly alternatives. The push towards sustainability in thermal analysis techniques is driving innovation in both materials science and analytical methodologies, with the goal of reducing the overall environmental footprint of scientific and industrial processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!