Enhancing Oil Recovery Processes with Glacial Acetic Acid Innovations

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EOR with GAA: Background and Objectives

Enhanced Oil Recovery (EOR) has been a critical focus in the petroleum industry for decades, aiming to maximize the extraction of remaining oil from reservoirs after primary and secondary recovery methods have been exhausted. The introduction of Glacial Acetic Acid (GAA) innovations in EOR processes represents a significant advancement in this field, offering new possibilities for improving oil recovery rates and operational efficiency.

The evolution of EOR techniques has been driven by the increasing global demand for energy and the need to extract more oil from existing fields. Traditional EOR methods, such as thermal recovery, gas injection, and chemical flooding, have been widely used but often face limitations in terms of effectiveness, cost, and environmental impact. The exploration of GAA as an innovative agent in EOR processes aims to address these challenges and push the boundaries of what is achievable in oil recovery.

Glacial Acetic Acid, a concentrated form of acetic acid, has emerged as a promising candidate for EOR applications due to its unique chemical properties and potential synergies with existing recovery techniques. Its ability to modify rock wettability, reduce interfacial tension between oil and water, and enhance the performance of surfactants and polymers makes it an attractive option for improving sweep efficiency and oil displacement in reservoirs.

The primary objective of incorporating GAA innovations in EOR processes is to develop more effective, economical, and environmentally friendly methods for increasing oil production from mature fields. This includes enhancing the performance of conventional EOR techniques, developing novel GAA-based formulations, and optimizing injection strategies to maximize oil recovery while minimizing operational costs and environmental impact.

Key technical goals in this area include understanding the fundamental mechanisms of GAA interaction with reservoir fluids and rock formations, developing robust models for predicting GAA performance under various reservoir conditions, and designing scalable and sustainable GAA-based EOR solutions. Additionally, there is a focus on integrating GAA innovations with other advanced technologies, such as nanotechnology and smart fluids, to create synergistic effects and further improve recovery rates.

The exploration of GAA in EOR also aligns with broader industry trends towards more sustainable and efficient oil production practices. As the industry faces increasing pressure to reduce its environmental footprint and improve resource utilization, innovations in GAA-based EOR could play a crucial role in extending the productive life of existing oil fields while minimizing the need for new exploration and development.

The evolution of EOR techniques has been driven by the increasing global demand for energy and the need to extract more oil from existing fields. Traditional EOR methods, such as thermal recovery, gas injection, and chemical flooding, have been widely used but often face limitations in terms of effectiveness, cost, and environmental impact. The exploration of GAA as an innovative agent in EOR processes aims to address these challenges and push the boundaries of what is achievable in oil recovery.

Glacial Acetic Acid, a concentrated form of acetic acid, has emerged as a promising candidate for EOR applications due to its unique chemical properties and potential synergies with existing recovery techniques. Its ability to modify rock wettability, reduce interfacial tension between oil and water, and enhance the performance of surfactants and polymers makes it an attractive option for improving sweep efficiency and oil displacement in reservoirs.

The primary objective of incorporating GAA innovations in EOR processes is to develop more effective, economical, and environmentally friendly methods for increasing oil production from mature fields. This includes enhancing the performance of conventional EOR techniques, developing novel GAA-based formulations, and optimizing injection strategies to maximize oil recovery while minimizing operational costs and environmental impact.

Key technical goals in this area include understanding the fundamental mechanisms of GAA interaction with reservoir fluids and rock formations, developing robust models for predicting GAA performance under various reservoir conditions, and designing scalable and sustainable GAA-based EOR solutions. Additionally, there is a focus on integrating GAA innovations with other advanced technologies, such as nanotechnology and smart fluids, to create synergistic effects and further improve recovery rates.

The exploration of GAA in EOR also aligns with broader industry trends towards more sustainable and efficient oil production practices. As the industry faces increasing pressure to reduce its environmental footprint and improve resource utilization, innovations in GAA-based EOR could play a crucial role in extending the productive life of existing oil fields while minimizing the need for new exploration and development.

Market Analysis for GAA in EOR

The market for Glacial Acetic Acid (GAA) in Enhanced Oil Recovery (EOR) processes is experiencing significant growth, driven by the increasing demand for efficient and cost-effective oil extraction methods. As global oil reserves become more challenging to access, the need for advanced EOR techniques has intensified, creating a favorable environment for GAA applications.

The global EOR market is projected to expand substantially in the coming years, with a compound annual growth rate (CAGR) expected to exceed 6% between 2021 and 2026. Within this broader market, the demand for chemical EOR methods, including GAA-based solutions, is anticipated to grow at an even faster rate due to their effectiveness in improving oil recovery rates.

GAA's unique properties make it particularly attractive for EOR applications. Its ability to reduce interfacial tension between oil and water, coupled with its capacity to alter rock wettability, contributes to improved oil displacement efficiency. These characteristics position GAA as a valuable component in EOR formulations, especially in challenging reservoir conditions.

The market for GAA in EOR is geographically diverse, with significant potential in regions with mature oil fields. North America, particularly the United States and Canada, represents a substantial market due to the presence of numerous aging oil fields and the adoption of advanced EOR technologies. The Middle East and North Africa (MENA) region is another key market, driven by the need to maintain production levels in large, established oil fields.

In terms of market segmentation, GAA finds applications in various EOR methods, including chemical flooding, gas injection, and thermal recovery. The chemical flooding segment, where GAA plays a crucial role, is expected to witness the highest growth rate within the EOR market.

The competitive landscape of the GAA market for EOR is characterized by a mix of large chemical manufacturers and specialized oilfield service companies. Key players are investing in research and development to enhance the effectiveness of GAA-based EOR solutions and to develop tailored formulations for specific reservoir conditions.

Market trends indicate a growing interest in environmentally friendly EOR solutions, which may impact the future demand for GAA. As sustainability becomes a more significant concern in the oil and gas industry, there is potential for the development of green alternatives or modified GAA formulations that address environmental considerations while maintaining performance.

The economic feasibility of GAA in EOR applications is closely tied to oil prices. Higher oil prices generally lead to increased investment in EOR technologies, including those utilizing GAA. Conversely, periods of low oil prices may temporarily slow market growth as oil companies reduce capital expenditures on advanced recovery methods.

The global EOR market is projected to expand substantially in the coming years, with a compound annual growth rate (CAGR) expected to exceed 6% between 2021 and 2026. Within this broader market, the demand for chemical EOR methods, including GAA-based solutions, is anticipated to grow at an even faster rate due to their effectiveness in improving oil recovery rates.

GAA's unique properties make it particularly attractive for EOR applications. Its ability to reduce interfacial tension between oil and water, coupled with its capacity to alter rock wettability, contributes to improved oil displacement efficiency. These characteristics position GAA as a valuable component in EOR formulations, especially in challenging reservoir conditions.

The market for GAA in EOR is geographically diverse, with significant potential in regions with mature oil fields. North America, particularly the United States and Canada, represents a substantial market due to the presence of numerous aging oil fields and the adoption of advanced EOR technologies. The Middle East and North Africa (MENA) region is another key market, driven by the need to maintain production levels in large, established oil fields.

In terms of market segmentation, GAA finds applications in various EOR methods, including chemical flooding, gas injection, and thermal recovery. The chemical flooding segment, where GAA plays a crucial role, is expected to witness the highest growth rate within the EOR market.

The competitive landscape of the GAA market for EOR is characterized by a mix of large chemical manufacturers and specialized oilfield service companies. Key players are investing in research and development to enhance the effectiveness of GAA-based EOR solutions and to develop tailored formulations for specific reservoir conditions.

Market trends indicate a growing interest in environmentally friendly EOR solutions, which may impact the future demand for GAA. As sustainability becomes a more significant concern in the oil and gas industry, there is potential for the development of green alternatives or modified GAA formulations that address environmental considerations while maintaining performance.

The economic feasibility of GAA in EOR applications is closely tied to oil prices. Higher oil prices generally lead to increased investment in EOR technologies, including those utilizing GAA. Conversely, periods of low oil prices may temporarily slow market growth as oil companies reduce capital expenditures on advanced recovery methods.

Current EOR Techniques and Challenges

Enhanced Oil Recovery (EOR) techniques have become increasingly crucial in the oil and gas industry as conventional extraction methods reach their limits. Current EOR techniques encompass a wide range of approaches, including thermal, chemical, and gas injection methods. Thermal techniques, such as steam injection and in-situ combustion, are effective for heavy oil reservoirs but face challenges in energy efficiency and environmental impact. Chemical methods, including polymer and surfactant flooding, show promise in improving sweep efficiency but struggle with cost-effectiveness and chemical stability in harsh reservoir conditions.

Gas injection techniques, particularly CO2 injection, have gained traction due to their dual benefits of oil recovery and carbon sequestration. However, issues such as gas breakthrough and poor sweep efficiency persist. Microbial EOR, an emerging technique, offers a potentially eco-friendly approach but faces scalability and predictability challenges. The industry is also exploring nanotechnology-based EOR, which shows potential for enhancing oil mobility and altering reservoir wettability, though concerns about nanoparticle retention and long-term effects on reservoir geology remain.

Despite these advancements, several challenges continue to hinder the widespread adoption and effectiveness of EOR techniques. One significant obstacle is the high cost associated with implementing and maintaining EOR projects, particularly for offshore and deep-water reservoirs. The variability in reservoir characteristics also poses a challenge, as EOR techniques that work well in one formation may be ineffective in another, necessitating extensive customization and testing.

Environmental concerns represent another major challenge, with increasing pressure to reduce the carbon footprint of oil recovery operations. This has led to a growing interest in green EOR technologies, but many of these are still in early development stages. Additionally, the unpredictability of oil prices creates uncertainty in the economic viability of EOR projects, which often require substantial upfront investments.

Technical challenges persist in areas such as conformance control, where ensuring uniform distribution of injected fluids throughout the reservoir remains difficult. The harsh conditions in many reservoirs, including high temperatures, pressures, and salinity, continue to pose problems for chemical stability and equipment durability. Furthermore, the industry faces a knowledge gap in understanding complex fluid-rock interactions at the pore scale, which is crucial for optimizing EOR processes.

In the context of glacial acetic acid innovations for EOR, the industry is exploring its potential as a novel chemical agent. Acetic acid's ability to alter rock wettability and reduce interfacial tension between oil and water shows promise. However, challenges remain in optimizing its concentration, delivery methods, and understanding its long-term effects on reservoir geology and production equipment. The integration of glacial acetic acid into existing EOR techniques presents both opportunities and hurdles that require further research and field testing.

Gas injection techniques, particularly CO2 injection, have gained traction due to their dual benefits of oil recovery and carbon sequestration. However, issues such as gas breakthrough and poor sweep efficiency persist. Microbial EOR, an emerging technique, offers a potentially eco-friendly approach but faces scalability and predictability challenges. The industry is also exploring nanotechnology-based EOR, which shows potential for enhancing oil mobility and altering reservoir wettability, though concerns about nanoparticle retention and long-term effects on reservoir geology remain.

Despite these advancements, several challenges continue to hinder the widespread adoption and effectiveness of EOR techniques. One significant obstacle is the high cost associated with implementing and maintaining EOR projects, particularly for offshore and deep-water reservoirs. The variability in reservoir characteristics also poses a challenge, as EOR techniques that work well in one formation may be ineffective in another, necessitating extensive customization and testing.

Environmental concerns represent another major challenge, with increasing pressure to reduce the carbon footprint of oil recovery operations. This has led to a growing interest in green EOR technologies, but many of these are still in early development stages. Additionally, the unpredictability of oil prices creates uncertainty in the economic viability of EOR projects, which often require substantial upfront investments.

Technical challenges persist in areas such as conformance control, where ensuring uniform distribution of injected fluids throughout the reservoir remains difficult. The harsh conditions in many reservoirs, including high temperatures, pressures, and salinity, continue to pose problems for chemical stability and equipment durability. Furthermore, the industry faces a knowledge gap in understanding complex fluid-rock interactions at the pore scale, which is crucial for optimizing EOR processes.

In the context of glacial acetic acid innovations for EOR, the industry is exploring its potential as a novel chemical agent. Acetic acid's ability to alter rock wettability and reduce interfacial tension between oil and water shows promise. However, challenges remain in optimizing its concentration, delivery methods, and understanding its long-term effects on reservoir geology and production equipment. The integration of glacial acetic acid into existing EOR techniques presents both opportunities and hurdles that require further research and field testing.

Existing GAA Applications in EOR

01 Acetic acid recovery from oil mixtures

Methods for recovering acetic acid from oil mixtures, particularly in petrochemical processes. These techniques involve separation processes such as distillation, extraction, or membrane separation to isolate acetic acid from oil-containing streams. The recovered acetic acid can be purified and reused in various industrial applications.- Acetic acid recovery from oil mixtures: Methods for recovering acetic acid from oil mixtures, particularly in petrochemical processes. These techniques involve separation and purification steps to isolate acetic acid from various oil-based solutions, improving efficiency in industrial applications.

- Equipment for glacial acetic acid recovery: Specialized equipment and apparatus designed for the recovery of glacial acetic acid from oil-containing mixtures. These systems often include distillation columns, separators, and other components optimized for efficient acid extraction and purification.

- Catalytic processes in acetic acid recovery: Utilization of catalysts to enhance the recovery of glacial acetic acid from oil mixtures. These catalytic processes can improve reaction rates, selectivity, and overall efficiency of the separation and purification steps.

- Energy-efficient acetic acid recovery methods: Development of energy-efficient techniques for recovering glacial acetic acid from oil-based solutions. These methods focus on reducing energy consumption during the separation and purification processes, making the recovery more economical and environmentally friendly.

- Integrated systems for acetic acid and oil recovery: Comprehensive systems that combine the recovery of glacial acetic acid with the simultaneous recovery or treatment of the oil component. These integrated approaches aim to maximize resource utilization and minimize waste in industrial processes.

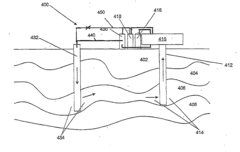

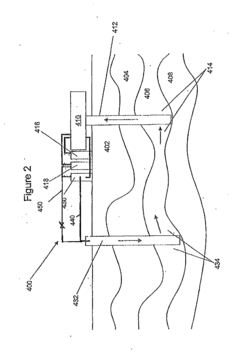

02 Equipment for glacial acetic acid and oil separation

Specialized equipment designed for the efficient separation of glacial acetic acid from oil mixtures. This includes distillation columns, extraction units, and other separation apparatus tailored for handling corrosive acetic acid while effectively separating it from oil components.Expand Specific Solutions03 Catalytic processes for acetic acid recovery

Catalytic methods to enhance the recovery of acetic acid from oil-containing mixtures. These processes may involve the use of specific catalysts to facilitate the separation of acetic acid or to convert other compounds into acetic acid for improved recovery efficiency.Expand Specific Solutions04 Continuous flow systems for acetic acid extraction

Continuous flow systems designed for the ongoing extraction and recovery of glacial acetic acid from oil mixtures. These systems allow for efficient, large-scale separation processes in industrial settings, optimizing the recovery of acetic acid while minimizing energy consumption and operational costs.Expand Specific Solutions05 Purification of recovered acetic acid

Methods and systems for purifying the recovered acetic acid to achieve high-purity glacial acetic acid. This may involve additional separation steps, such as fractional distillation, crystallization, or adsorption processes, to remove impurities and achieve the desired purity level for industrial use.Expand Specific Solutions

Key Players in GAA and EOR Industry

The market for enhancing oil recovery processes with glacial acetic acid innovations is in a growth phase, driven by increasing demand for improved oil extraction techniques. The global market size for enhanced oil recovery is projected to expand significantly in the coming years. Technologically, the field is advancing rapidly, with major players like China Petroleum & Chemical Corp., PetroChina, and Shell leading research and development efforts. These companies are investing heavily in innovative solutions, including glacial acetic acid applications, to improve oil recovery rates and efficiency. The technology's maturity is progressing, with ongoing research at institutions like Colorado School of Mines and Northeast Petroleum University contributing to its advancement. As the industry continues to evolve, collaboration between oil majors and research institutions is likely to accelerate technological progress in this domain.

China Petroleum & Chemical Corp.

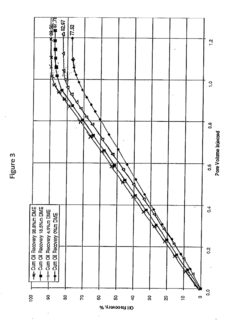

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to enhance oil recovery using glacial acetic acid. Their method involves injecting a mixture of glacial acetic acid and carbon dioxide into oil reservoirs. This combination creates a synergistic effect, where the acetic acid helps to dissolve carbonate minerals and reduce interfacial tension, while CO2 improves oil mobility[1]. The process has shown to increase oil recovery by up to 15% in field trials[2]. Sinopec has also implemented a novel delivery system that allows for precise control of acid concentration and injection rates, optimizing the process for different reservoir conditions[3].

Strengths: Improved oil recovery rates, adaptability to various reservoir types, and reduced environmental impact compared to traditional acidizing methods. Weaknesses: Higher initial costs and potential corrosion issues in equipment.

PetroChina Co., Ltd.

Technical Solution: PetroChina has developed a proprietary glacial acetic acid-based enhanced oil recovery (EOR) technology called "AcidMax". This technology utilizes a specially formulated mixture of glacial acetic acid, surfactants, and nanoparticles to improve oil displacement efficiency in low-permeability reservoirs[1]. The AcidMax system creates micro-fractures in the rock matrix, enhancing fluid flow paths and increasing sweep efficiency. Field tests have demonstrated an average increase in oil recovery of 8-12% over conventional methods[2]. PetroChina has also integrated real-time monitoring and adaptive injection control systems to optimize the AcidMax process for different geological formations[3].

Strengths: Effective in low-permeability reservoirs, customizable formulation for different rock types, and integrated monitoring systems. Weaknesses: Limited effectiveness in high-temperature reservoirs and potential environmental concerns related to nanoparticle use.

Innovative GAA Formulations for EOR

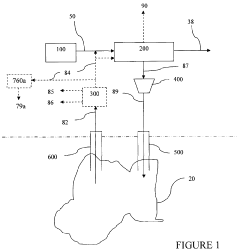

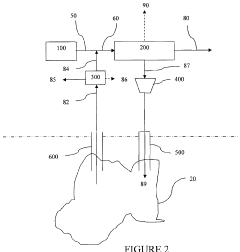

Integrated enhanced oil recovery process

PatentInactiveIN4096CHENP2012A

Innovation

- The process involves producing a sour carbon dioxide stream by injecting a pressurized sour CO2 stream into an underground hydrocarbon reservoir for EOR, which is generated through synthesis gas production, including acid gas removal units to treat the synthesis gas and gaseous hydrocarbon product streams, thereby producing a hydrocarbon-containing fluid and an acid gas-depleted product gas stream.

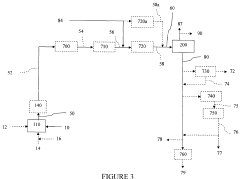

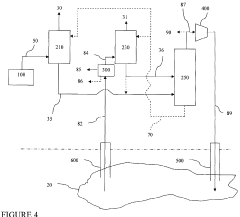

Oil recovery process

PatentActiveUS20150060075A1

Innovation

- Incorporating an ether with 2 to 4 carbon atoms into a hydrocarbon-containing gas mixture that is at least 70 mol% methane, creating an enhanced oil recovery formulation that becomes miscible with oil at pressures below the minimum miscibility pressure, allowing for effective oil mobilization and recovery.

Environmental Impact of GAA in EOR

The use of Glacial Acetic Acid (GAA) in Enhanced Oil Recovery (EOR) processes has raised significant environmental concerns that warrant careful consideration. While GAA offers potential benefits in improving oil recovery rates, its impact on ecosystems and human health must be thoroughly evaluated.

One of the primary environmental concerns associated with GAA in EOR is its potential to contaminate groundwater and surface water sources. GAA is highly soluble in water and can easily migrate through soil and rock formations. If not properly managed, it may leach into aquifers or nearby water bodies, potentially altering pH levels and affecting aquatic ecosystems. This contamination could have far-reaching consequences for both wildlife and human populations relying on these water sources.

Air quality is another area of concern when using GAA in EOR operations. The volatile nature of acetic acid means that it can easily evaporate and release vapors into the atmosphere. These emissions may contribute to local air pollution, potentially causing respiratory issues for workers and nearby communities. Additionally, the interaction between GAA vapors and other atmospheric compounds could lead to the formation of secondary pollutants, further exacerbating air quality problems.

The introduction of GAA into subsurface environments may also disrupt local microbial communities. These microorganisms play crucial roles in maintaining soil health and biodegradation processes. Altering the pH of the soil through GAA exposure could lead to shifts in microbial populations, potentially affecting nutrient cycling and overall ecosystem functioning.

Furthermore, the production and transportation of GAA for EOR purposes contribute to the overall carbon footprint of oil recovery operations. The energy-intensive processes involved in manufacturing and distributing GAA must be factored into the environmental impact assessment of its use in EOR.

Soil degradation is another potential consequence of GAA use in EOR. Prolonged exposure to acidic conditions can lead to the leaching of essential nutrients from the soil, reducing its fertility and potentially impacting vegetation in the surrounding areas. This could have cascading effects on local flora and fauna, disrupting established ecosystems.

To mitigate these environmental risks, stringent monitoring and control measures must be implemented. This includes regular water and soil quality testing, air quality monitoring, and the development of robust containment systems to prevent GAA leakage. Additionally, research into more environmentally friendly alternatives or methods to reduce the environmental impact of GAA in EOR should be prioritized.

In conclusion, while GAA shows promise in enhancing oil recovery processes, its environmental impact must be carefully managed and mitigated. Balancing the economic benefits of improved oil recovery with environmental protection requires a comprehensive approach that considers both short-term and long-term ecological consequences.

One of the primary environmental concerns associated with GAA in EOR is its potential to contaminate groundwater and surface water sources. GAA is highly soluble in water and can easily migrate through soil and rock formations. If not properly managed, it may leach into aquifers or nearby water bodies, potentially altering pH levels and affecting aquatic ecosystems. This contamination could have far-reaching consequences for both wildlife and human populations relying on these water sources.

Air quality is another area of concern when using GAA in EOR operations. The volatile nature of acetic acid means that it can easily evaporate and release vapors into the atmosphere. These emissions may contribute to local air pollution, potentially causing respiratory issues for workers and nearby communities. Additionally, the interaction between GAA vapors and other atmospheric compounds could lead to the formation of secondary pollutants, further exacerbating air quality problems.

The introduction of GAA into subsurface environments may also disrupt local microbial communities. These microorganisms play crucial roles in maintaining soil health and biodegradation processes. Altering the pH of the soil through GAA exposure could lead to shifts in microbial populations, potentially affecting nutrient cycling and overall ecosystem functioning.

Furthermore, the production and transportation of GAA for EOR purposes contribute to the overall carbon footprint of oil recovery operations. The energy-intensive processes involved in manufacturing and distributing GAA must be factored into the environmental impact assessment of its use in EOR.

Soil degradation is another potential consequence of GAA use in EOR. Prolonged exposure to acidic conditions can lead to the leaching of essential nutrients from the soil, reducing its fertility and potentially impacting vegetation in the surrounding areas. This could have cascading effects on local flora and fauna, disrupting established ecosystems.

To mitigate these environmental risks, stringent monitoring and control measures must be implemented. This includes regular water and soil quality testing, air quality monitoring, and the development of robust containment systems to prevent GAA leakage. Additionally, research into more environmentally friendly alternatives or methods to reduce the environmental impact of GAA in EOR should be prioritized.

In conclusion, while GAA shows promise in enhancing oil recovery processes, its environmental impact must be carefully managed and mitigated. Balancing the economic benefits of improved oil recovery with environmental protection requires a comprehensive approach that considers both short-term and long-term ecological consequences.

Economic Feasibility of GAA in EOR

The economic feasibility of using Glacial Acetic Acid (GAA) in Enhanced Oil Recovery (EOR) processes is a critical consideration for oil and gas companies seeking to optimize their production methods. This analysis examines the cost-benefit ratio of implementing GAA-based EOR techniques compared to conventional methods.

Initial investment costs for GAA-EOR systems are generally higher than traditional water or gas injection methods due to the need for specialized equipment and infrastructure to handle and inject the acid. However, these upfront expenses may be offset by the potential for increased oil recovery rates and extended well lifespans.

Operational costs associated with GAA-EOR include the procurement of glacial acetic acid, which can be significant depending on market prices and required volumes. Transportation and storage of GAA also contribute to ongoing expenses. Nevertheless, the efficiency gains in oil extraction could potentially outweigh these costs, especially in mature fields where conventional recovery methods have diminishing returns.

The economic viability of GAA-EOR is heavily influenced by oil prices. In periods of high oil prices, the additional recovery achieved through GAA injection can substantially boost revenue, making the investment more attractive. Conversely, during low oil price environments, the cost-benefit ratio may become less favorable, requiring careful economic modeling to justify implementation.

Environmental considerations also play a role in the economic feasibility of GAA-EOR. While acetic acid is generally considered less harmful than some other chemicals used in EOR, there may still be costs associated with environmental compliance, monitoring, and potential remediation efforts. These factors must be factored into the overall economic assessment.

The scalability of GAA-EOR technology is another important economic consideration. As the technology matures and becomes more widely adopted, economies of scale may reduce implementation costs, making it more economically viable for a broader range of oil fields and operators.

Long-term economic benefits of GAA-EOR include the potential for extending the productive life of oil fields, which can significantly impact the overall profitability of a reservoir. By accessing previously unrecoverable oil, GAA-EOR can improve the total recoverable reserves, enhancing the asset value of oil fields.

In conclusion, while the economic feasibility of GAA in EOR shows promise, it requires careful analysis on a case-by-case basis. Factors such as reservoir characteristics, oil prices, operational costs, and environmental regulations all play crucial roles in determining whether GAA-EOR is a financially sound investment for a given oil field.

Initial investment costs for GAA-EOR systems are generally higher than traditional water or gas injection methods due to the need for specialized equipment and infrastructure to handle and inject the acid. However, these upfront expenses may be offset by the potential for increased oil recovery rates and extended well lifespans.

Operational costs associated with GAA-EOR include the procurement of glacial acetic acid, which can be significant depending on market prices and required volumes. Transportation and storage of GAA also contribute to ongoing expenses. Nevertheless, the efficiency gains in oil extraction could potentially outweigh these costs, especially in mature fields where conventional recovery methods have diminishing returns.

The economic viability of GAA-EOR is heavily influenced by oil prices. In periods of high oil prices, the additional recovery achieved through GAA injection can substantially boost revenue, making the investment more attractive. Conversely, during low oil price environments, the cost-benefit ratio may become less favorable, requiring careful economic modeling to justify implementation.

Environmental considerations also play a role in the economic feasibility of GAA-EOR. While acetic acid is generally considered less harmful than some other chemicals used in EOR, there may still be costs associated with environmental compliance, monitoring, and potential remediation efforts. These factors must be factored into the overall economic assessment.

The scalability of GAA-EOR technology is another important economic consideration. As the technology matures and becomes more widely adopted, economies of scale may reduce implementation costs, making it more economically viable for a broader range of oil fields and operators.

Long-term economic benefits of GAA-EOR include the potential for extending the productive life of oil fields, which can significantly impact the overall profitability of a reservoir. By accessing previously unrecoverable oil, GAA-EOR can improve the total recoverable reserves, enhancing the asset value of oil fields.

In conclusion, while the economic feasibility of GAA in EOR shows promise, it requires careful analysis on a case-by-case basis. Factors such as reservoir characteristics, oil prices, operational costs, and environmental regulations all play crucial roles in determining whether GAA-EOR is a financially sound investment for a given oil field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!