Efficient Utilization of Glacial Acetic Acid in Fermentation Technologies

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Glacial Acetic Acid in Fermentation: Background and Objectives

Glacial acetic acid, a highly concentrated form of acetic acid, has been a cornerstone in various industrial processes for decades. In recent years, its potential in fermentation technologies has garnered significant attention from researchers and industry professionals alike. The evolution of this technology can be traced back to the early 20th century when acetic acid was first synthesized on an industrial scale.

The fermentation industry has undergone substantial transformations, driven by the need for more efficient and sustainable production methods. Glacial acetic acid, with its unique properties and high purity, has emerged as a promising candidate to address these challenges. Its role in fermentation processes spans from pH regulation to metabolic pathway modulation, offering a versatile tool for enhancing fermentation efficiency and product quality.

As we delve into the current technological landscape, it becomes evident that the efficient utilization of glacial acetic acid in fermentation technologies is at a critical juncture. The global push towards sustainable manufacturing processes and the increasing demand for bio-based products have created a fertile ground for innovation in this field. Researchers and industry leaders are now focusing on developing novel approaches to harness the full potential of glacial acetic acid in fermentation processes.

The primary objectives of this technological exploration are multifaceted. Firstly, there is a pressing need to optimize the use of glacial acetic acid to improve fermentation yields and reduce production costs. This involves fine-tuning the concentration and application methods to achieve maximum efficacy without compromising product quality or safety. Secondly, researchers aim to expand the range of fermentation products that can benefit from glacial acetic acid incorporation, potentially opening up new market opportunities.

Another crucial goal is to enhance the sustainability profile of fermentation processes by leveraging glacial acetic acid. This includes developing closed-loop systems where acetic acid can be recovered and reused, minimizing waste and environmental impact. Additionally, there is a growing interest in exploring synergies between glacial acetic acid and other fermentation additives or technologies to create more robust and efficient production systems.

As we look towards the future, the trajectory of glacial acetic acid in fermentation technologies appears promising. The convergence of advanced biotechnology, process engineering, and sustainable chemistry is expected to unlock new possibilities and drive further innovations in this field. The ultimate aim is to establish glacial acetic acid as an indispensable component in next-generation fermentation technologies, contributing to more efficient, sustainable, and economically viable production processes across various industries.

The fermentation industry has undergone substantial transformations, driven by the need for more efficient and sustainable production methods. Glacial acetic acid, with its unique properties and high purity, has emerged as a promising candidate to address these challenges. Its role in fermentation processes spans from pH regulation to metabolic pathway modulation, offering a versatile tool for enhancing fermentation efficiency and product quality.

As we delve into the current technological landscape, it becomes evident that the efficient utilization of glacial acetic acid in fermentation technologies is at a critical juncture. The global push towards sustainable manufacturing processes and the increasing demand for bio-based products have created a fertile ground for innovation in this field. Researchers and industry leaders are now focusing on developing novel approaches to harness the full potential of glacial acetic acid in fermentation processes.

The primary objectives of this technological exploration are multifaceted. Firstly, there is a pressing need to optimize the use of glacial acetic acid to improve fermentation yields and reduce production costs. This involves fine-tuning the concentration and application methods to achieve maximum efficacy without compromising product quality or safety. Secondly, researchers aim to expand the range of fermentation products that can benefit from glacial acetic acid incorporation, potentially opening up new market opportunities.

Another crucial goal is to enhance the sustainability profile of fermentation processes by leveraging glacial acetic acid. This includes developing closed-loop systems where acetic acid can be recovered and reused, minimizing waste and environmental impact. Additionally, there is a growing interest in exploring synergies between glacial acetic acid and other fermentation additives or technologies to create more robust and efficient production systems.

As we look towards the future, the trajectory of glacial acetic acid in fermentation technologies appears promising. The convergence of advanced biotechnology, process engineering, and sustainable chemistry is expected to unlock new possibilities and drive further innovations in this field. The ultimate aim is to establish glacial acetic acid as an indispensable component in next-generation fermentation technologies, contributing to more efficient, sustainable, and economically viable production processes across various industries.

Market Analysis for Acetic Acid in Bioprocessing

The market for acetic acid in bioprocessing has been experiencing significant growth in recent years, driven by the increasing demand for sustainable and eco-friendly production methods. Glacial acetic acid, in particular, has emerged as a crucial component in various fermentation technologies, offering enhanced efficiency and cost-effectiveness.

The global market for acetic acid in bioprocessing is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2026. This growth is primarily attributed to the rising adoption of fermentation-based production processes across industries such as food and beverage, pharmaceuticals, and biofuels. The market value is expected to reach $2.3 billion by 2026, up from $1.7 billion in 2021.

In the food and beverage sector, acetic acid plays a crucial role in the production of vinegar, pickles, and other fermented products. The increasing consumer preference for natural and organic food products has led to a surge in demand for acetic acid derived from biological sources. This trend is particularly prominent in developed regions such as North America and Europe.

The pharmaceutical industry represents another significant market for acetic acid in bioprocessing. Acetic acid is widely used in the production of various drugs and active pharmaceutical ingredients (APIs). The growing focus on biopharmaceuticals and the shift towards green chemistry practices have further boosted the demand for acetic acid in this sector.

Geographically, Asia Pacific is expected to be the fastest-growing market for acetic acid in bioprocessing, with a CAGR of 6.5% during the forecast period. This growth is driven by the rapid industrialization in countries like China and India, coupled with increasing investments in biotechnology and pharmaceutical research.

Key players in the market include Celanese Corporation, BP plc, Eastman Chemical Company, and LyondellBasell Industries N.V. These companies are focusing on expanding their production capacities and developing innovative applications for acetic acid in bioprocessing to gain a competitive edge.

However, the market faces challenges such as fluctuating raw material prices and stringent environmental regulations. To address these issues, manufacturers are investing in research and development to improve production efficiency and explore alternative feedstocks for acetic acid production.

In conclusion, the market for acetic acid in bioprocessing presents significant opportunities for growth, driven by the increasing adoption of sustainable production methods across various industries. As technology advances and new applications emerge, the efficient utilization of glacial acetic acid in fermentation technologies is expected to play a crucial role in shaping the future of bioprocessing.

The global market for acetic acid in bioprocessing is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2026. This growth is primarily attributed to the rising adoption of fermentation-based production processes across industries such as food and beverage, pharmaceuticals, and biofuels. The market value is expected to reach $2.3 billion by 2026, up from $1.7 billion in 2021.

In the food and beverage sector, acetic acid plays a crucial role in the production of vinegar, pickles, and other fermented products. The increasing consumer preference for natural and organic food products has led to a surge in demand for acetic acid derived from biological sources. This trend is particularly prominent in developed regions such as North America and Europe.

The pharmaceutical industry represents another significant market for acetic acid in bioprocessing. Acetic acid is widely used in the production of various drugs and active pharmaceutical ingredients (APIs). The growing focus on biopharmaceuticals and the shift towards green chemistry practices have further boosted the demand for acetic acid in this sector.

Geographically, Asia Pacific is expected to be the fastest-growing market for acetic acid in bioprocessing, with a CAGR of 6.5% during the forecast period. This growth is driven by the rapid industrialization in countries like China and India, coupled with increasing investments in biotechnology and pharmaceutical research.

Key players in the market include Celanese Corporation, BP plc, Eastman Chemical Company, and LyondellBasell Industries N.V. These companies are focusing on expanding their production capacities and developing innovative applications for acetic acid in bioprocessing to gain a competitive edge.

However, the market faces challenges such as fluctuating raw material prices and stringent environmental regulations. To address these issues, manufacturers are investing in research and development to improve production efficiency and explore alternative feedstocks for acetic acid production.

In conclusion, the market for acetic acid in bioprocessing presents significant opportunities for growth, driven by the increasing adoption of sustainable production methods across various industries. As technology advances and new applications emerge, the efficient utilization of glacial acetic acid in fermentation technologies is expected to play a crucial role in shaping the future of bioprocessing.

Current Challenges in Glacial Acetic Acid Utilization

The utilization of glacial acetic acid in fermentation technologies faces several significant challenges that hinder its efficient application. One of the primary obstacles is the high cost associated with the production and purification of glacial acetic acid. The current manufacturing processes require substantial energy inputs and expensive catalysts, making it economically challenging for widespread use in fermentation processes.

Another major hurdle is the corrosive nature of glacial acetic acid, which necessitates specialized equipment and materials for handling and storage. This requirement increases the overall operational costs and poses safety concerns for workers involved in the fermentation processes. The corrosive properties also limit the types of microorganisms that can be used in fermentation, as many strains are sensitive to high concentrations of acetic acid.

The volatility of glacial acetic acid presents additional challenges in maintaining consistent concentrations during fermentation. Evaporation losses can lead to fluctuations in acidity levels, potentially affecting the growth and productivity of microorganisms. This issue is particularly problematic in large-scale industrial fermentations where precise control of environmental conditions is crucial.

Furthermore, the high concentration of glacial acetic acid can inhibit microbial growth and metabolism, limiting its direct use in many fermentation processes. Dilution is often necessary, which reduces the efficiency of space utilization in bioreactors and increases water consumption. This dilution step also adds complexity to the overall process design and control.

The recovery and recycling of glacial acetic acid from fermentation broths pose significant technical challenges. Conventional separation methods such as distillation are energy-intensive and may not be economically viable for all applications. The presence of other organic acids and metabolites in the fermentation broth further complicates the purification process.

Regulatory constraints and safety considerations also present obstacles to the widespread adoption of glacial acetic acid in fermentation technologies. Stringent guidelines for handling, storage, and disposal of acetic acid must be adhered to, which can increase operational complexity and costs for manufacturers.

Lastly, the environmental impact of glacial acetic acid production and use in fermentation processes is a growing concern. The carbon footprint associated with its synthesis and the potential for accidental releases during handling and transportation raise sustainability issues that need to be addressed for long-term viability in industrial applications.

Another major hurdle is the corrosive nature of glacial acetic acid, which necessitates specialized equipment and materials for handling and storage. This requirement increases the overall operational costs and poses safety concerns for workers involved in the fermentation processes. The corrosive properties also limit the types of microorganisms that can be used in fermentation, as many strains are sensitive to high concentrations of acetic acid.

The volatility of glacial acetic acid presents additional challenges in maintaining consistent concentrations during fermentation. Evaporation losses can lead to fluctuations in acidity levels, potentially affecting the growth and productivity of microorganisms. This issue is particularly problematic in large-scale industrial fermentations where precise control of environmental conditions is crucial.

Furthermore, the high concentration of glacial acetic acid can inhibit microbial growth and metabolism, limiting its direct use in many fermentation processes. Dilution is often necessary, which reduces the efficiency of space utilization in bioreactors and increases water consumption. This dilution step also adds complexity to the overall process design and control.

The recovery and recycling of glacial acetic acid from fermentation broths pose significant technical challenges. Conventional separation methods such as distillation are energy-intensive and may not be economically viable for all applications. The presence of other organic acids and metabolites in the fermentation broth further complicates the purification process.

Regulatory constraints and safety considerations also present obstacles to the widespread adoption of glacial acetic acid in fermentation technologies. Stringent guidelines for handling, storage, and disposal of acetic acid must be adhered to, which can increase operational complexity and costs for manufacturers.

Lastly, the environmental impact of glacial acetic acid production and use in fermentation processes is a growing concern. The carbon footprint associated with its synthesis and the potential for accidental releases during handling and transportation raise sustainability issues that need to be addressed for long-term viability in industrial applications.

Existing Methods for Efficient Acetic Acid Use in Fermentation

01 Production methods for glacial acetic acid

Various methods are employed to produce glacial acetic acid efficiently. These include oxidation of acetaldehyde, fermentation processes, and catalytic reactions. The production methods focus on optimizing yield, purity, and energy efficiency in the manufacturing process.- Production methods for glacial acetic acid: Various methods are employed to produce glacial acetic acid efficiently. These include oxidation of acetaldehyde, fermentation processes, and catalytic reactions. The production methods focus on optimizing yield, purity, and energy efficiency in the manufacturing process.

- Purification and concentration techniques: Techniques for purifying and concentrating acetic acid to achieve glacial grade are crucial for efficiency. These may involve distillation, crystallization, and membrane separation processes. The goal is to remove impurities and increase the acid concentration to near 100%.

- Equipment and apparatus design: Specialized equipment and apparatus designs are developed to enhance the efficiency of glacial acetic acid production and handling. This includes reactors, distillation columns, storage tanks, and transfer systems optimized for corrosion resistance and process efficiency.

- Process control and optimization: Advanced process control systems and optimization strategies are implemented to improve the efficiency of glacial acetic acid production. This involves monitoring and adjusting parameters such as temperature, pressure, and flow rates to maximize yield and quality while minimizing energy consumption.

- Applications and utilization efficiency: Efficient utilization of glacial acetic acid in various applications is explored. This includes its use as a reagent in chemical synthesis, as a solvent in industrial processes, and in the production of vinyl acetate monomer. Improving the efficiency of these applications can lead to cost savings and reduced environmental impact.

02 Purification and concentration techniques

Techniques for purifying and concentrating acetic acid to achieve glacial quality are crucial for efficiency. These may include distillation, crystallization, and membrane separation processes. The goal is to remove impurities and increase the acid concentration to near 100%.Expand Specific Solutions03 Equipment and apparatus design

Specialized equipment and apparatus designs are developed to enhance the efficiency of glacial acetic acid production and handling. This includes reactors, distillation columns, storage tanks, and transfer systems optimized for corrosion resistance and process efficiency.Expand Specific Solutions04 Catalysts and reaction conditions

The use of specific catalysts and optimized reaction conditions plays a crucial role in improving the efficiency of glacial acetic acid production. This includes the development of novel catalysts, temperature and pressure control, and reaction kinetics optimization.Expand Specific Solutions05 Energy efficiency and waste reduction

Improving energy efficiency and reducing waste in glacial acetic acid production processes are key focus areas. This involves heat integration, recycling of byproducts, and implementation of green chemistry principles to minimize environmental impact and improve overall process efficiency.Expand Specific Solutions

Key Industry Players in Acetic Acid Production and Fermentation

The market for efficient utilization of glacial acetic acid in fermentation technologies is in a growth phase, driven by increasing demand for sustainable and bio-based products. The global market size is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, the field is advancing rapidly, with companies like Danisco US, Inc., Novozymes A/S, and DSM IP Assets BV leading in enzyme and microbial solutions. Established players such as Mizkan Holdings Co., Ltd. and Jiangsu Hengshun Vinegar Industry Co., Ltd. are leveraging their expertise in traditional fermentation processes to innovate in this space. Academic institutions like Tianjin University of Science & Technology and Hiroshima University are contributing to fundamental research, while companies like METabolic EXplorer SA are focusing on developing novel biochemical pathways for acetic acid production and utilization.

DSM IP Assets BV

Technical Solution: DSM has innovated in the field of acetic acid utilization in fermentation by developing a proprietary microbial platform technology. This platform incorporates genetically modified microorganisms capable of efficiently metabolizing acetic acid as a primary carbon source. The engineered strains are optimized for high-yield production of various bio-based chemicals and materials. DSM's technology also includes a novel fermentation process design that maintains optimal acetic acid concentrations throughout the fermentation, balancing substrate utilization and product formation[2][5]. Additionally, DSM has developed advanced separation and purification techniques specifically tailored for products derived from acetic acid fermentation, ensuring high product purity and recovery rates.

Strengths: Versatile microbial platform, high-yield production of various chemicals, integrated process design. Weaknesses: Potential regulatory challenges with GMOs, may require specialized equipment for large-scale implementation.

Novozymes A/S

Technical Solution: Novozymes has developed advanced enzyme solutions for efficient utilization of glacial acetic acid in fermentation technologies. Their approach involves engineered acetic acid-tolerant enzymes that can function optimally in high acetic acid concentrations. These enzymes are designed to catalyze key reactions in fermentation processes, such as the conversion of sugars to ethanol or other valuable products, while maintaining activity in the presence of glacial acetic acid. Novozymes' technology also includes specialized microbial strains that can metabolize acetic acid as a carbon source, effectively reducing its concentration in the fermentation medium[1][3]. This dual approach of enzyme engineering and microbial strain development allows for improved product yields and reduced process costs in various fermentation applications.

Strengths: Highly specialized enzyme solutions, reduced inhibition effects of acetic acid, improved product yields. Weaknesses: May require significant process modifications, potential high costs for enzyme production and implementation.

Innovative Approaches to Glacial Acetic Acid Utilization

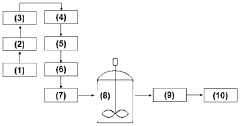

technology FOR MANUFACTURING ALCOHOLIC FERMENTED AND ACETIC ACID WITH MIXED CULTURE IN A SINGLE FERMENTATION PROCESS

PatentInactiveBR102020011157A2

Innovation

- A single fermentation process using a mixed culture of Kluyveromyces marxianus yeast and Acetobacter bacteria to produce ethanol, acetic acid, and symbiotic biomass in a single step, reducing procedural costs and time.

Microbial process for the preparation of acetic acid, as well as solvent for its extraction from the fermentation broth

PatentInactiveUS20040236149A1

Innovation

- A modified water-immiscible solvent comprising a substantially pure mixture of highly branched di-alkyl amines, combined with a selected cosolvent, is used for extraction and distillation, allowing for improved acetic acid recovery without substantial amine degradation, and eliminating the need for bacterial cell separation prior to extraction.

Environmental Impact of Glacial Acetic Acid in Bioprocessing

The environmental impact of glacial acetic acid in bioprocessing is a critical consideration for sustainable fermentation technologies. Glacial acetic acid, while an essential component in many fermentation processes, can pose significant environmental challenges if not managed properly.

One of the primary environmental concerns is the potential for acetic acid to contribute to water pollution. When released into aquatic ecosystems, even in small quantities, it can alter the pH balance and negatively affect aquatic life. This is particularly problematic in areas with sensitive water bodies or in regions where water resources are already under stress.

Air pollution is another environmental issue associated with the use of glacial acetic acid in bioprocessing. Volatile organic compounds (VOCs) can be released during handling and processing, contributing to smog formation and potentially impacting air quality in surrounding areas. Proper ventilation and emission control systems are crucial to mitigate these effects.

The production of glacial acetic acid itself has environmental implications. Traditional methods often rely on fossil fuel-based processes, contributing to greenhouse gas emissions and climate change. However, advancements in bio-based production methods offer more sustainable alternatives, potentially reducing the overall carbon footprint of acetic acid used in fermentation technologies.

Waste management is a significant challenge in bioprocessing facilities using glacial acetic acid. Improper disposal can lead to soil contamination and groundwater pollution. Implementing effective waste treatment and recycling systems is essential to minimize environmental impact and comply with increasingly stringent environmental regulations.

Energy consumption associated with the use and handling of glacial acetic acid in fermentation processes also contributes to the overall environmental footprint. Cooling and heating requirements, as well as energy-intensive purification processes, can lead to increased energy demand and associated emissions.

To address these environmental concerns, the industry is exploring various strategies. These include developing more efficient fermentation processes that require less acetic acid, implementing closed-loop systems to minimize waste and emissions, and investing in renewable energy sources to power bioprocessing facilities.

Biodegradability and eco-toxicity studies of glacial acetic acid and its byproducts in fermentation processes are ongoing. These studies aim to better understand the long-term environmental impacts and develop more environmentally friendly alternatives or mitigation strategies.

One of the primary environmental concerns is the potential for acetic acid to contribute to water pollution. When released into aquatic ecosystems, even in small quantities, it can alter the pH balance and negatively affect aquatic life. This is particularly problematic in areas with sensitive water bodies or in regions where water resources are already under stress.

Air pollution is another environmental issue associated with the use of glacial acetic acid in bioprocessing. Volatile organic compounds (VOCs) can be released during handling and processing, contributing to smog formation and potentially impacting air quality in surrounding areas. Proper ventilation and emission control systems are crucial to mitigate these effects.

The production of glacial acetic acid itself has environmental implications. Traditional methods often rely on fossil fuel-based processes, contributing to greenhouse gas emissions and climate change. However, advancements in bio-based production methods offer more sustainable alternatives, potentially reducing the overall carbon footprint of acetic acid used in fermentation technologies.

Waste management is a significant challenge in bioprocessing facilities using glacial acetic acid. Improper disposal can lead to soil contamination and groundwater pollution. Implementing effective waste treatment and recycling systems is essential to minimize environmental impact and comply with increasingly stringent environmental regulations.

Energy consumption associated with the use and handling of glacial acetic acid in fermentation processes also contributes to the overall environmental footprint. Cooling and heating requirements, as well as energy-intensive purification processes, can lead to increased energy demand and associated emissions.

To address these environmental concerns, the industry is exploring various strategies. These include developing more efficient fermentation processes that require less acetic acid, implementing closed-loop systems to minimize waste and emissions, and investing in renewable energy sources to power bioprocessing facilities.

Biodegradability and eco-toxicity studies of glacial acetic acid and its byproducts in fermentation processes are ongoing. These studies aim to better understand the long-term environmental impacts and develop more environmentally friendly alternatives or mitigation strategies.

Economic Feasibility of Glacial Acetic Acid in Fermentation

The economic feasibility of utilizing glacial acetic acid in fermentation processes is a critical consideration for industries seeking to optimize their production methods. This analysis examines the cost-effectiveness and potential financial benefits of incorporating glacial acetic acid into fermentation technologies.

Glacial acetic acid, a highly concentrated form of acetic acid, offers several economic advantages in fermentation processes. Its purity and concentration reduce transportation and storage costs compared to diluted forms, potentially leading to significant savings in logistics and inventory management. Additionally, the high concentration allows for more precise control of acidity levels in fermentation, which can improve product quality and consistency.

The use of glacial acetic acid can also enhance process efficiency. Its rapid dissolution and uniform distribution in fermentation media can lead to faster pH adjustments and reduced processing times. This increased efficiency may translate to higher production volumes and lower energy consumption, further contributing to cost savings.

However, the economic viability of glacial acetic acid in fermentation also depends on its market price and availability. Fluctuations in raw material costs and production capacities can impact its cost-effectiveness. A comprehensive cost-benefit analysis should consider these factors alongside the potential improvements in product yield and quality.

The initial investment required for implementing glacial acetic acid in existing fermentation processes must be evaluated. This may include costs for equipment modifications, safety measures, and staff training. While these upfront expenses may be substantial, they should be weighed against the long-term operational savings and potential revenue increases from improved product quality.

Environmental regulations and sustainability goals also play a role in the economic feasibility assessment. The use of glacial acetic acid may lead to reduced waste generation and lower environmental impact compared to alternative acidifying agents. This can result in cost savings related to waste management and potential regulatory compliance benefits.

In conclusion, the economic feasibility of glacial acetic acid in fermentation technologies is multifaceted. While it offers potential benefits in terms of process efficiency, product quality, and operational costs, a thorough analysis of market conditions, implementation costs, and regulatory factors is essential to determine its overall economic viability for specific fermentation applications.

Glacial acetic acid, a highly concentrated form of acetic acid, offers several economic advantages in fermentation processes. Its purity and concentration reduce transportation and storage costs compared to diluted forms, potentially leading to significant savings in logistics and inventory management. Additionally, the high concentration allows for more precise control of acidity levels in fermentation, which can improve product quality and consistency.

The use of glacial acetic acid can also enhance process efficiency. Its rapid dissolution and uniform distribution in fermentation media can lead to faster pH adjustments and reduced processing times. This increased efficiency may translate to higher production volumes and lower energy consumption, further contributing to cost savings.

However, the economic viability of glacial acetic acid in fermentation also depends on its market price and availability. Fluctuations in raw material costs and production capacities can impact its cost-effectiveness. A comprehensive cost-benefit analysis should consider these factors alongside the potential improvements in product yield and quality.

The initial investment required for implementing glacial acetic acid in existing fermentation processes must be evaluated. This may include costs for equipment modifications, safety measures, and staff training. While these upfront expenses may be substantial, they should be weighed against the long-term operational savings and potential revenue increases from improved product quality.

Environmental regulations and sustainability goals also play a role in the economic feasibility assessment. The use of glacial acetic acid may lead to reduced waste generation and lower environmental impact compared to alternative acidifying agents. This can result in cost savings related to waste management and potential regulatory compliance benefits.

In conclusion, the economic feasibility of glacial acetic acid in fermentation technologies is multifaceted. While it offers potential benefits in terms of process efficiency, product quality, and operational costs, a thorough analysis of market conditions, implementation costs, and regulatory factors is essential to determine its overall economic viability for specific fermentation applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!