Coil Whine in Audio Systems: Exploration and Solutions

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coil Whine Origins

Coil whine, a persistent issue in audio systems, originates from electromagnetic interactions within electronic components. This phenomenon primarily occurs in inductors, transformers, and other coiled structures found in power supplies and amplification circuits. The root cause lies in the magnetostriction effect, where magnetic materials physically deform under changing magnetic fields.

In audio systems, coil whine becomes particularly problematic due to the sensitivity of human hearing and the expectation of clean, noise-free sound reproduction. The issue is exacerbated by the increasing miniaturization of electronic components and the drive for higher efficiency in modern audio equipment. As power supplies and amplifiers operate at higher frequencies to improve performance, they inadvertently create conditions conducive to coil whine.

The manifestation of coil whine in audio systems can vary widely, from a barely perceptible high-pitched tone to an intrusive buzzing or whining sound. Its frequency typically ranges from a few hundred hertz to several kilohertz, falling squarely within the most sensitive range of human hearing. This makes even low-level coil whine particularly noticeable and potentially irritating to users.

Several factors contribute to the severity and prevalence of coil whine in audio equipment. The quality and design of components play a crucial role, with cheaper or poorly manufactured parts more likely to exhibit the problem. Circuit design and layout also significantly impact coil whine, as improper isolation or routing of high-frequency signals can induce vibrations in susceptible components.

Environmental factors further influence coil whine. Temperature fluctuations can alter the physical properties of materials, potentially exacerbating the issue. Additionally, the acoustic properties of the device enclosure can amplify or dampen coil whine, making it more or less noticeable to the end-user.

Understanding the origins of coil whine is crucial for developing effective mitigation strategies. By addressing the fundamental causes at the component and circuit level, engineers can work towards creating audio systems that deliver cleaner, more enjoyable listening experiences. This understanding also informs quality control processes, helping manufacturers identify and eliminate potential sources of coil whine before products reach consumers.

In audio systems, coil whine becomes particularly problematic due to the sensitivity of human hearing and the expectation of clean, noise-free sound reproduction. The issue is exacerbated by the increasing miniaturization of electronic components and the drive for higher efficiency in modern audio equipment. As power supplies and amplifiers operate at higher frequencies to improve performance, they inadvertently create conditions conducive to coil whine.

The manifestation of coil whine in audio systems can vary widely, from a barely perceptible high-pitched tone to an intrusive buzzing or whining sound. Its frequency typically ranges from a few hundred hertz to several kilohertz, falling squarely within the most sensitive range of human hearing. This makes even low-level coil whine particularly noticeable and potentially irritating to users.

Several factors contribute to the severity and prevalence of coil whine in audio equipment. The quality and design of components play a crucial role, with cheaper or poorly manufactured parts more likely to exhibit the problem. Circuit design and layout also significantly impact coil whine, as improper isolation or routing of high-frequency signals can induce vibrations in susceptible components.

Environmental factors further influence coil whine. Temperature fluctuations can alter the physical properties of materials, potentially exacerbating the issue. Additionally, the acoustic properties of the device enclosure can amplify or dampen coil whine, making it more or less noticeable to the end-user.

Understanding the origins of coil whine is crucial for developing effective mitigation strategies. By addressing the fundamental causes at the component and circuit level, engineers can work towards creating audio systems that deliver cleaner, more enjoyable listening experiences. This understanding also informs quality control processes, helping manufacturers identify and eliminate potential sources of coil whine before products reach consumers.

Audio Market Demands

The audio market has experienced significant growth and transformation in recent years, driven by technological advancements and changing consumer preferences. The global audio equipment market size was valued at $138.9 billion in 2020 and is projected to reach $207.3 billion by 2028, growing at a CAGR of 5.2% from 2021 to 2028. This growth is fueled by increasing demand for high-quality audio experiences across various sectors, including consumer electronics, automotive, and professional audio.

In the consumer electronics segment, there is a growing demand for premium audio products that offer superior sound quality and innovative features. Wireless audio devices, such as true wireless stereo (TWS) earbuds and smart speakers, have seen exponential growth. The TWS market alone is expected to grow from $69.8 billion in 2020 to $187.4 billion by 2026, with a CAGR of 17.9%.

The automotive audio market is also experiencing significant growth, driven by the increasing integration of advanced infotainment systems in vehicles. The global car audio market size was valued at $7.2 billion in 2020 and is expected to reach $9.8 billion by 2027, growing at a CAGR of 4.5% from 2021 to 2027.

Professional audio equipment, including studio monitors, mixing consoles, and digital audio workstations, continues to see steady demand from recording studios, live event venues, and broadcast facilities. The professional audio equipment market was valued at $16.1 billion in 2020 and is projected to reach $24.3 billion by 2027, with a CAGR of 6.1%.

As audio quality becomes increasingly important to consumers, there is a growing demand for solutions that address audio-related issues, including coil whine. Coil whine, a high-pitched noise produced by electronic components, can significantly impact the user experience in audio systems. Manufacturers are under pressure to develop innovative solutions to mitigate or eliminate coil whine, as consumers expect flawless audio performance from their devices.

The market demand for audio products with reduced or eliminated coil whine is particularly strong in high-end audio equipment, where discerning audiophiles are willing to pay a premium for superior sound quality. This demand extends to professional audio equipment, where even minor audio artifacts can be detrimental to the final product.

In response to these market demands, audio equipment manufacturers are investing in research and development to address coil whine and other audio quality issues. This includes exploring new materials, circuit designs, and shielding techniques to minimize electromagnetic interference and reduce unwanted noise in audio systems.

In the consumer electronics segment, there is a growing demand for premium audio products that offer superior sound quality and innovative features. Wireless audio devices, such as true wireless stereo (TWS) earbuds and smart speakers, have seen exponential growth. The TWS market alone is expected to grow from $69.8 billion in 2020 to $187.4 billion by 2026, with a CAGR of 17.9%.

The automotive audio market is also experiencing significant growth, driven by the increasing integration of advanced infotainment systems in vehicles. The global car audio market size was valued at $7.2 billion in 2020 and is expected to reach $9.8 billion by 2027, growing at a CAGR of 4.5% from 2021 to 2027.

Professional audio equipment, including studio monitors, mixing consoles, and digital audio workstations, continues to see steady demand from recording studios, live event venues, and broadcast facilities. The professional audio equipment market was valued at $16.1 billion in 2020 and is projected to reach $24.3 billion by 2027, with a CAGR of 6.1%.

As audio quality becomes increasingly important to consumers, there is a growing demand for solutions that address audio-related issues, including coil whine. Coil whine, a high-pitched noise produced by electronic components, can significantly impact the user experience in audio systems. Manufacturers are under pressure to develop innovative solutions to mitigate or eliminate coil whine, as consumers expect flawless audio performance from their devices.

The market demand for audio products with reduced or eliminated coil whine is particularly strong in high-end audio equipment, where discerning audiophiles are willing to pay a premium for superior sound quality. This demand extends to professional audio equipment, where even minor audio artifacts can be detrimental to the final product.

In response to these market demands, audio equipment manufacturers are investing in research and development to address coil whine and other audio quality issues. This includes exploring new materials, circuit designs, and shielding techniques to minimize electromagnetic interference and reduce unwanted noise in audio systems.

Coil Whine Challenges

Coil whine presents a significant challenge in audio systems, affecting both consumer electronics and professional audio equipment. This phenomenon, characterized by high-frequency electromagnetic vibrations in electronic components, can manifest as audible noise that compromises the overall sound quality and user experience.

One of the primary challenges in addressing coil whine is its unpredictable nature. The occurrence and intensity of coil whine can vary greatly between individual units of the same product model, making it difficult to implement consistent solutions across production lines. This variability stems from minor differences in component tolerances, assembly techniques, and even environmental factors.

The frequency range of coil whine poses another significant hurdle. Typically occurring between 1 kHz and 20 kHz, these frequencies fall within the human auditory range, making them particularly noticeable and potentially irritating to users. The high-frequency nature of coil whine also makes it challenging to isolate and suppress without affecting the desired audio signal.

Power supply design plays a crucial role in coil whine generation, presenting its own set of challenges. Switching power supplies, while efficient, can contribute to coil whine through their high-frequency operation. Balancing power efficiency with noise reduction becomes a complex task for audio system designers.

Thermal management is another critical factor in coil whine mitigation. As electronic components heat up during operation, their physical properties can change, potentially exacerbating coil whine. Designing effective cooling solutions that do not introduce additional noise becomes a delicate balancing act.

The compact nature of modern audio devices further complicates coil whine reduction efforts. Limited space within devices restricts the use of traditional noise reduction techniques such as physical isolation or extensive shielding. Engineers must develop innovative solutions that are both effective and space-efficient.

Cost considerations present an ongoing challenge in addressing coil whine. While high-end audio equipment may justify more expensive noise reduction techniques, consumer-grade devices face stricter budget constraints. Finding cost-effective solutions that can be implemented at scale without significantly impacting product pricing is a constant struggle for manufacturers.

Regulatory compliance adds another layer of complexity to coil whine mitigation. Audio systems must meet electromagnetic compatibility (EMC) standards, which can sometimes conflict with noise reduction techniques. Balancing these requirements while effectively addressing coil whine demands careful engineering and design considerations.

One of the primary challenges in addressing coil whine is its unpredictable nature. The occurrence and intensity of coil whine can vary greatly between individual units of the same product model, making it difficult to implement consistent solutions across production lines. This variability stems from minor differences in component tolerances, assembly techniques, and even environmental factors.

The frequency range of coil whine poses another significant hurdle. Typically occurring between 1 kHz and 20 kHz, these frequencies fall within the human auditory range, making them particularly noticeable and potentially irritating to users. The high-frequency nature of coil whine also makes it challenging to isolate and suppress without affecting the desired audio signal.

Power supply design plays a crucial role in coil whine generation, presenting its own set of challenges. Switching power supplies, while efficient, can contribute to coil whine through their high-frequency operation. Balancing power efficiency with noise reduction becomes a complex task for audio system designers.

Thermal management is another critical factor in coil whine mitigation. As electronic components heat up during operation, their physical properties can change, potentially exacerbating coil whine. Designing effective cooling solutions that do not introduce additional noise becomes a delicate balancing act.

The compact nature of modern audio devices further complicates coil whine reduction efforts. Limited space within devices restricts the use of traditional noise reduction techniques such as physical isolation or extensive shielding. Engineers must develop innovative solutions that are both effective and space-efficient.

Cost considerations present an ongoing challenge in addressing coil whine. While high-end audio equipment may justify more expensive noise reduction techniques, consumer-grade devices face stricter budget constraints. Finding cost-effective solutions that can be implemented at scale without significantly impacting product pricing is a constant struggle for manufacturers.

Regulatory compliance adds another layer of complexity to coil whine mitigation. Audio systems must meet electromagnetic compatibility (EMC) standards, which can sometimes conflict with noise reduction techniques. Balancing these requirements while effectively addressing coil whine demands careful engineering and design considerations.

Coil Whine Solutions

01 Noise reduction techniques for electronic devices

Various methods are employed to reduce coil whine noise in electronic devices. These techniques include using specialized materials, optimizing circuit design, and implementing noise cancellation technologies. By addressing the root causes of coil whine, such as electromagnetic vibrations, these approaches aim to minimize or eliminate the audible noise produced by electronic components.- Noise reduction techniques for electronic devices: Various methods are employed to reduce coil whine noise in electronic devices. These techniques include using specialized materials, optimizing circuit design, and implementing noise cancellation technologies. By addressing the root causes of coil whine, such as electromagnetic vibrations, these approaches aim to minimize or eliminate the audible noise produced by electronic components.

- Magnetic field shielding for coil whine reduction: Magnetic field shielding is utilized to mitigate coil whine noise. This involves the use of materials and structures that can contain or redirect magnetic fields generated by coils and transformers. By reducing the interaction between these fields and surrounding components, the likelihood of coil whine occurrence is decreased, resulting in quieter operation of electronic devices.

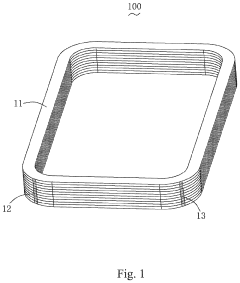

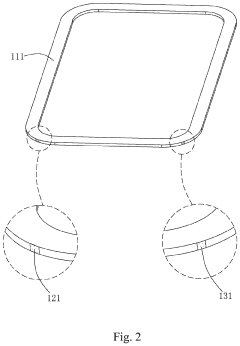

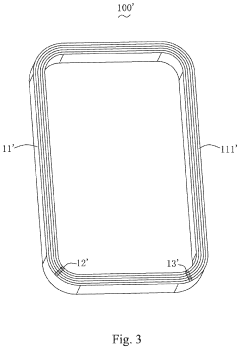

- Acoustic dampening solutions for coil whine: Acoustic dampening materials and designs are implemented to absorb and dissipate the vibrations causing coil whine. This approach involves the strategic placement of sound-absorbing materials within electronic devices, as well as the use of specialized coatings or enclosures. These solutions help to reduce the transmission of coil whine noise to the device's exterior, improving overall acoustic performance.

- Power supply design optimization to reduce coil whine: Improvements in power supply design focus on minimizing coil whine noise. This includes the use of high-quality components, optimized circuit layouts, and advanced control algorithms. By addressing factors such as voltage regulation and current ripple, these design optimizations aim to reduce the electrical conditions that contribute to coil whine, resulting in quieter operation of electronic devices.

- Frequency modulation techniques for coil whine mitigation: Frequency modulation methods are employed to reduce the perception of coil whine noise. These techniques involve altering the operating frequency of electronic components or introducing controlled frequency variations. By shifting the noise to less audible frequency ranges or distributing it across a wider spectrum, the overall perceived coil whine noise is reduced, improving user experience with electronic devices.

02 Magnetic field shielding for coil whine reduction

Magnetic field shielding is utilized to mitigate coil whine noise. This involves the use of materials and structures that can contain or redirect magnetic fields generated by coils and transformers. By reducing the interaction between these fields and surrounding components, the likelihood of coil whine occurrence is decreased, resulting in quieter operation of electronic devices.Expand Specific Solutions03 Acoustic treatment for coil whine suppression

Acoustic treatments are applied to suppress coil whine noise. This includes the use of sound-absorbing materials, acoustic enclosures, and damping techniques. These methods aim to attenuate the propagation of sound waves generated by vibrating coils, effectively reducing the perceived noise level in electronic devices and improving overall acoustic performance.Expand Specific Solutions04 Frequency modulation to minimize coil whine

Frequency modulation techniques are employed to minimize coil whine noise. By altering the operating frequency of electronic components or introducing frequency-shifting algorithms, the audible impact of coil whine can be reduced. This approach helps to distribute the noise across a wider frequency spectrum, making it less noticeable to human ears.Expand Specific Solutions05 Coil design optimization for noise reduction

Optimization of coil design is implemented to reduce coil whine noise. This involves careful consideration of coil geometry, winding techniques, and material selection. By improving the mechanical stability of coils and minimizing their susceptibility to vibration, the occurrence of coil whine can be significantly reduced, leading to quieter operation in electronic devices.Expand Specific Solutions

Audio Industry Players

The coil whine issue in audio systems represents a niche but significant challenge in the mature audio equipment industry. The market for solutions is relatively small but growing, driven by increasing demand for high-quality audio experiences. Technologically, the problem is moderately complex, with various companies at different stages of development. Pioneer Corp. and Sony Group Corp. are leveraging their extensive audio expertise to address coil whine, while specialized acoustics firms like AAC Technologies and GoerTek are developing targeted solutions. Emerging players such as Zhuhai Jieli Technology are also entering the space with innovative approaches. The competitive landscape is diverse, with established audio giants competing alongside specialized acoustics companies and new entrants, each bringing unique strengths to tackle this persistent audio quality issue.

GoerTek Inc.

Technical Solution: GoerTek has developed a multi-pronged strategy to address coil whine in audio systems, particularly focusing on miniaturized components for portable devices. Their approach includes the use of precision-engineered micro-coils with optimized geometries to minimize mechanical resonance[2]. GoerTek has also implemented advanced damping materials and techniques, including the use of specialized viscoelastic polymers to absorb vibrations at the coil level[4]. Additionally, the company has developed a proprietary coil encapsulation process that provides both electrical insulation and mechanical stability, further reducing the potential for audible vibrations[6]. GoerTek's solutions are particularly effective in compact audio devices such as earbuds and hearing aids, where space constraints make traditional coil whine mitigation techniques challenging.

Strengths: Specialized solutions for miniaturized audio components. Advanced damping and encapsulation techniques. Effective in space-constrained applications. Weaknesses: May be less applicable to larger audio systems. Potential for increased production complexity in small-scale components.

Chinese Academy of Sciences Institute of Acoustics

Technical Solution: The Chinese Academy of Sciences Institute of Acoustics has taken a research-driven approach to addressing coil whine in audio systems. Their work focuses on understanding the fundamental physics of coil whine and developing novel mitigation strategies. The institute has conducted extensive studies on the relationship between coil geometry, material properties, and acoustic emissions, leading to the development of predictive models for coil whine behavior[1]. They have also explored innovative coil designs, including the use of non-traditional winding patterns and composite core materials to minimize mechanical resonance[3]. Additionally, the institute has investigated the use of active electronic compensation techniques, developing algorithms that can detect and cancel out coil whine in real-time across a wide frequency range[5]. While primarily focused on research, these findings have significant potential for practical applications in audio system design and manufacturing.

Strengths: Comprehensive understanding of coil whine physics. Development of predictive models and novel coil designs. Exploration of advanced electronic compensation techniques. Weaknesses: Primarily research-focused, may require further development for commercial applications. Potential challenges in scaling up solutions for mass production.

Coil Whine Innovations

Adjustment and suppression of acoustic dynamics

PatentWO2005009532A1

Innovation

- A process utilizing a series of chokes with specific winding configurations and materials, such as gold-coated copper wire, positioned in a vehicle to selectively cancel excess sound amplitudes and electromagnetic disturbances by counter-reactions, acting as an acoustic filter to regulate sound waves and electromagnetic waves in opposition, thereby modifying the acoustic environment.

Voice Coil and Sounding Device Using Same

PatentActiveUS20240064469A1

Innovation

- A voice coil design featuring at least two sub coils with incoming and outgoing wire ends welded together to form a single current path, allowing for a lighter weight wire with greater resistance, reducing the overall weight of the vibration system and enhancing mid-frequency performance.

EMI/EMC Regulations

Electromagnetic Interference (EMI) and Electromagnetic Compatibility (EMC) regulations play a crucial role in addressing coil whine issues in audio systems. These regulations are designed to ensure that electronic devices, including audio equipment, operate without causing or experiencing undue electromagnetic interference. In the context of coil whine, EMI/EMC regulations are particularly relevant as they set standards for both emissions and susceptibility to electromagnetic disturbances.

The International Electrotechnical Commission (IEC) and the Federal Communications Commission (FCC) are two primary bodies that establish EMI/EMC standards globally. These standards typically define limits for radiated and conducted emissions, as well as immunity requirements for various types of equipment. For audio systems, compliance with these regulations is essential to minimize the risk of coil whine and other electromagnetic disturbances.

EMI/EMC regulations often specify frequency ranges and corresponding emission limits that audio equipment must adhere to. These limits are typically expressed in decibels relative to a reference level (dBµV/m for radiated emissions or dBµV for conducted emissions) and vary depending on the equipment class and intended operating environment. Compliance testing involves measuring emissions across a wide frequency spectrum, typically from 150 kHz to 1 GHz or higher, to ensure that the equipment does not exceed the specified limits.

In addition to emission limits, EMI/EMC regulations also address immunity requirements. These standards ensure that audio systems can operate correctly in the presence of external electromagnetic disturbances. Immunity tests may include exposure to electrostatic discharge, radiated electromagnetic fields, and electrical fast transients. For coil whine mitigation, immunity standards are particularly relevant as they help ensure that audio components are resistant to external factors that could induce or exacerbate coil vibrations.

Manufacturers of audio systems must consider EMI/EMC regulations throughout the design and development process. This involves implementing various shielding, filtering, and grounding techniques to minimize electromagnetic emissions and enhance immunity. Proper PCB layout, component selection, and system integration are critical factors in achieving compliance with these regulations while also addressing coil whine issues.

Compliance with EMI/EMC regulations often requires extensive testing in specialized laboratories. These tests simulate various electromagnetic environments and measure the equipment's performance under different conditions. For audio systems prone to coil whine, these tests can help identify potential issues early in the development process, allowing for necessary design modifications before product release.

As technology advances and audio systems become more complex, EMI/EMC regulations continue to evolve. Regulatory bodies regularly update standards to address new challenges and emerging technologies. Manufacturers must stay informed about these changes and adapt their designs accordingly to ensure ongoing compliance and optimal performance in terms of electromagnetic compatibility and coil whine reduction.

The International Electrotechnical Commission (IEC) and the Federal Communications Commission (FCC) are two primary bodies that establish EMI/EMC standards globally. These standards typically define limits for radiated and conducted emissions, as well as immunity requirements for various types of equipment. For audio systems, compliance with these regulations is essential to minimize the risk of coil whine and other electromagnetic disturbances.

EMI/EMC regulations often specify frequency ranges and corresponding emission limits that audio equipment must adhere to. These limits are typically expressed in decibels relative to a reference level (dBµV/m for radiated emissions or dBµV for conducted emissions) and vary depending on the equipment class and intended operating environment. Compliance testing involves measuring emissions across a wide frequency spectrum, typically from 150 kHz to 1 GHz or higher, to ensure that the equipment does not exceed the specified limits.

In addition to emission limits, EMI/EMC regulations also address immunity requirements. These standards ensure that audio systems can operate correctly in the presence of external electromagnetic disturbances. Immunity tests may include exposure to electrostatic discharge, radiated electromagnetic fields, and electrical fast transients. For coil whine mitigation, immunity standards are particularly relevant as they help ensure that audio components are resistant to external factors that could induce or exacerbate coil vibrations.

Manufacturers of audio systems must consider EMI/EMC regulations throughout the design and development process. This involves implementing various shielding, filtering, and grounding techniques to minimize electromagnetic emissions and enhance immunity. Proper PCB layout, component selection, and system integration are critical factors in achieving compliance with these regulations while also addressing coil whine issues.

Compliance with EMI/EMC regulations often requires extensive testing in specialized laboratories. These tests simulate various electromagnetic environments and measure the equipment's performance under different conditions. For audio systems prone to coil whine, these tests can help identify potential issues early in the development process, allowing for necessary design modifications before product release.

As technology advances and audio systems become more complex, EMI/EMC regulations continue to evolve. Regulatory bodies regularly update standards to address new challenges and emerging technologies. Manufacturers must stay informed about these changes and adapt their designs accordingly to ensure ongoing compliance and optimal performance in terms of electromagnetic compatibility and coil whine reduction.

Psychoacoustic Impact

Coil whine in audio systems can have significant psychoacoustic impacts on listeners, affecting their perception of sound quality and overall listening experience. The high-frequency nature of coil whine often falls within the range of human hearing, typically between 1 kHz and 20 kHz, making it particularly noticeable and potentially irritating to many individuals.

The perception of coil whine is highly subjective and can vary greatly among listeners. Some individuals may be more sensitive to these high-frequency sounds, experiencing discomfort or distraction even at relatively low levels. This sensitivity can be influenced by factors such as age, hearing health, and individual auditory processing characteristics.

Psychoacoustically, coil whine can manifest as a perceived degradation in audio quality. Even when the whine itself is not consciously detected, its presence can contribute to listener fatigue and reduced enjoyment of audio content. This is particularly problematic in high-fidelity audio systems, where the goal is to reproduce sound with utmost accuracy and clarity.

The masking effect plays a crucial role in the psychoacoustic impact of coil whine. In some cases, the primary audio content may partially or completely mask the coil whine, rendering it less noticeable. However, during quieter passages or in the absence of audio playback, the whine can become more prominent, potentially disrupting the listener's focus or immersion.

Long-term exposure to coil whine in audio systems may lead to habituation, where listeners become accustomed to the sound and perceive it less acutely over time. However, this does not negate the potential for ongoing subconscious irritation or stress, which can affect overall listening satisfaction and potentially contribute to listening fatigue.

The psychoacoustic impact of coil whine extends beyond mere annoyance. It can influence the perceived quality and value of audio equipment, potentially affecting consumer satisfaction and brand reputation in the audio industry. Manufacturers must consider these psychoacoustic factors when designing and testing audio systems to ensure optimal user experience.

Addressing the psychoacoustic impact of coil whine requires a multifaceted approach. This may include implementing better shielding and isolation techniques, using components less prone to generating audible whine, and incorporating active noise cancellation technologies. Additionally, educating consumers about the nature of coil whine and its potential presence in audio systems can help manage expectations and reduce negative psychoacoustic impacts.

The perception of coil whine is highly subjective and can vary greatly among listeners. Some individuals may be more sensitive to these high-frequency sounds, experiencing discomfort or distraction even at relatively low levels. This sensitivity can be influenced by factors such as age, hearing health, and individual auditory processing characteristics.

Psychoacoustically, coil whine can manifest as a perceived degradation in audio quality. Even when the whine itself is not consciously detected, its presence can contribute to listener fatigue and reduced enjoyment of audio content. This is particularly problematic in high-fidelity audio systems, where the goal is to reproduce sound with utmost accuracy and clarity.

The masking effect plays a crucial role in the psychoacoustic impact of coil whine. In some cases, the primary audio content may partially or completely mask the coil whine, rendering it less noticeable. However, during quieter passages or in the absence of audio playback, the whine can become more prominent, potentially disrupting the listener's focus or immersion.

Long-term exposure to coil whine in audio systems may lead to habituation, where listeners become accustomed to the sound and perceive it less acutely over time. However, this does not negate the potential for ongoing subconscious irritation or stress, which can affect overall listening satisfaction and potentially contribute to listening fatigue.

The psychoacoustic impact of coil whine extends beyond mere annoyance. It can influence the perceived quality and value of audio equipment, potentially affecting consumer satisfaction and brand reputation in the audio industry. Manufacturers must consider these psychoacoustic factors when designing and testing audio systems to ensure optimal user experience.

Addressing the psychoacoustic impact of coil whine requires a multifaceted approach. This may include implementing better shielding and isolation techniques, using components less prone to generating audible whine, and incorporating active noise cancellation technologies. Additionally, educating consumers about the nature of coil whine and its potential presence in audio systems can help manage expectations and reduce negative psychoacoustic impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!