Exploring Coil Whine in Passive Electronic Components

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coil Whine Origins and Objectives

Coil whine, a phenomenon observed in passive electronic components, has been a persistent challenge in the electronics industry for decades. This audible noise, typically emanating from inductors, transformers, and capacitors, has its roots in the fundamental principles of electromagnetism and material science. The evolution of coil whine as a recognized issue can be traced back to the early days of electronic devices, becoming more prominent with the miniaturization and increased power density of modern electronics.

The primary mechanism behind coil whine is magnetostriction, a property of ferromagnetic materials that causes them to change shape when subjected to a magnetic field. As alternating currents flow through coils and other components, the resulting fluctuating magnetic fields induce mechanical vibrations in the materials. These vibrations, often occurring at frequencies within the human audible range, manifest as the characteristic high-pitched noise known as coil whine.

Over time, the perception of coil whine has shifted from being a mere annoyance to a significant quality and performance issue. This transition is largely due to the increasing prevalence of electronic devices in both professional and personal environments, where noise pollution can impact user experience and productivity. Furthermore, the push towards higher efficiency and compact designs in power electronics has inadvertently exacerbated the coil whine problem, as components are subjected to more intense electromagnetic stresses.

The objectives of exploring coil whine in passive electronic components are multifaceted. Primarily, there is a pressing need to develop a comprehensive understanding of the physical mechanisms that contribute to this phenomenon. This includes investigating the interplay between electrical, magnetic, and mechanical properties of materials used in electronic components. By gaining deeper insights into these fundamental aspects, researchers and engineers aim to devise more effective strategies for mitigating coil whine at its source.

Another critical objective is to establish standardized methods for measuring and quantifying coil whine. The subjective nature of auditory perception has made it challenging to create universally accepted metrics for coil whine severity. Developing robust measurement techniques and criteria will enable more consistent quality control in manufacturing processes and provide a common language for discussing and addressing the issue across the industry.

Furthermore, the exploration of coil whine seeks to innovate new materials and design methodologies that inherently reduce or eliminate the problem. This includes research into novel magnetic materials with reduced magnetostriction, advanced winding techniques for inductors and transformers, and innovative encapsulation methods to dampen vibrations. The ultimate goal is to create a new generation of passive electronic components that maintain high performance while minimizing audible noise emissions.

The primary mechanism behind coil whine is magnetostriction, a property of ferromagnetic materials that causes them to change shape when subjected to a magnetic field. As alternating currents flow through coils and other components, the resulting fluctuating magnetic fields induce mechanical vibrations in the materials. These vibrations, often occurring at frequencies within the human audible range, manifest as the characteristic high-pitched noise known as coil whine.

Over time, the perception of coil whine has shifted from being a mere annoyance to a significant quality and performance issue. This transition is largely due to the increasing prevalence of electronic devices in both professional and personal environments, where noise pollution can impact user experience and productivity. Furthermore, the push towards higher efficiency and compact designs in power electronics has inadvertently exacerbated the coil whine problem, as components are subjected to more intense electromagnetic stresses.

The objectives of exploring coil whine in passive electronic components are multifaceted. Primarily, there is a pressing need to develop a comprehensive understanding of the physical mechanisms that contribute to this phenomenon. This includes investigating the interplay between electrical, magnetic, and mechanical properties of materials used in electronic components. By gaining deeper insights into these fundamental aspects, researchers and engineers aim to devise more effective strategies for mitigating coil whine at its source.

Another critical objective is to establish standardized methods for measuring and quantifying coil whine. The subjective nature of auditory perception has made it challenging to create universally accepted metrics for coil whine severity. Developing robust measurement techniques and criteria will enable more consistent quality control in manufacturing processes and provide a common language for discussing and addressing the issue across the industry.

Furthermore, the exploration of coil whine seeks to innovate new materials and design methodologies that inherently reduce or eliminate the problem. This includes research into novel magnetic materials with reduced magnetostriction, advanced winding techniques for inductors and transformers, and innovative encapsulation methods to dampen vibrations. The ultimate goal is to create a new generation of passive electronic components that maintain high performance while minimizing audible noise emissions.

Market Impact of Coil Whine

Coil whine, a phenomenon associated with passive electronic components, has emerged as a significant concern in the consumer electronics market. This high-frequency noise, often described as a buzzing or squealing sound, has far-reaching implications for product quality, user experience, and brand reputation. As consumers become increasingly aware of this issue, manufacturers are facing mounting pressure to address coil whine in their products.

The market impact of coil whine is particularly pronounced in the gaming and high-performance computing sectors. Gaming PCs, graphics cards, and power supplies are among the most affected products, with users reporting audible coil whine during intense gaming sessions or high-load scenarios. This has led to a surge in customer complaints, negative product reviews, and increased return rates for affected devices. Consequently, manufacturers are experiencing higher warranty claim costs and potential damage to their brand image.

In the mobile device market, coil whine has become a growing concern as smartphones and tablets incorporate more powerful processors and faster charging technologies. The presence of coil whine in these devices can significantly detract from the user experience, especially in quiet environments or during media consumption. This issue has prompted some consumers to switch brands or delay upgrades, impacting sales and market share for affected manufacturers.

The automotive industry is also grappling with the effects of coil whine, particularly in electric and hybrid vehicles. As these vehicles rely heavily on power electronics, the presence of coil whine can detract from the perceived quality and comfort of the vehicle. This has led to increased research and development efforts to mitigate coil whine in automotive applications, driving up production costs and potentially affecting profit margins.

The market for audio equipment, including headphones, speakers, and amplifiers, is particularly sensitive to coil whine issues. In this sector, even minor acoustic disturbances can significantly impact product performance and user satisfaction. Manufacturers are investing heavily in noise reduction technologies and improved component selection to maintain their competitive edge and protect their market position.

As awareness of coil whine grows, there is an emerging market opportunity for specialized testing equipment and noise reduction solutions. Companies offering acoustic analysis tools, shielding materials, and advanced component designs are seeing increased demand for their products and services. This has led to the development of a niche market segment focused on coil whine mitigation, with potential for significant growth in the coming years.

The impact of coil whine extends beyond individual product categories, influencing broader market trends and consumer preferences. There is a growing emphasis on "silent computing" and noise-free electronics, with manufacturers highlighting low-noise operation as a key selling point. This shift in consumer expectations is driving innovation in component design and manufacturing processes across the electronics industry.

The market impact of coil whine is particularly pronounced in the gaming and high-performance computing sectors. Gaming PCs, graphics cards, and power supplies are among the most affected products, with users reporting audible coil whine during intense gaming sessions or high-load scenarios. This has led to a surge in customer complaints, negative product reviews, and increased return rates for affected devices. Consequently, manufacturers are experiencing higher warranty claim costs and potential damage to their brand image.

In the mobile device market, coil whine has become a growing concern as smartphones and tablets incorporate more powerful processors and faster charging technologies. The presence of coil whine in these devices can significantly detract from the user experience, especially in quiet environments or during media consumption. This issue has prompted some consumers to switch brands or delay upgrades, impacting sales and market share for affected manufacturers.

The automotive industry is also grappling with the effects of coil whine, particularly in electric and hybrid vehicles. As these vehicles rely heavily on power electronics, the presence of coil whine can detract from the perceived quality and comfort of the vehicle. This has led to increased research and development efforts to mitigate coil whine in automotive applications, driving up production costs and potentially affecting profit margins.

The market for audio equipment, including headphones, speakers, and amplifiers, is particularly sensitive to coil whine issues. In this sector, even minor acoustic disturbances can significantly impact product performance and user satisfaction. Manufacturers are investing heavily in noise reduction technologies and improved component selection to maintain their competitive edge and protect their market position.

As awareness of coil whine grows, there is an emerging market opportunity for specialized testing equipment and noise reduction solutions. Companies offering acoustic analysis tools, shielding materials, and advanced component designs are seeing increased demand for their products and services. This has led to the development of a niche market segment focused on coil whine mitigation, with potential for significant growth in the coming years.

The impact of coil whine extends beyond individual product categories, influencing broader market trends and consumer preferences. There is a growing emphasis on "silent computing" and noise-free electronics, with manufacturers highlighting low-noise operation as a key selling point. This shift in consumer expectations is driving innovation in component design and manufacturing processes across the electronics industry.

Current Challenges in Coil Whine Mitigation

Coil whine mitigation in passive electronic components presents several significant challenges that continue to perplex engineers and manufacturers. One of the primary obstacles is the inherent nature of electromagnetic forces in these components, particularly in inductors and transformers. The interaction between electric currents and magnetic fields inevitably produces mechanical vibrations, which are the root cause of coil whine.

The miniaturization trend in electronics exacerbates this issue. As devices become smaller and more compact, the proximity of components increases, leading to more pronounced electromagnetic interference and resonance effects. This proximity not only amplifies the coil whine but also makes it more challenging to isolate and address the problem without affecting the overall performance of the device.

Another significant challenge lies in the variability of coil whine across different units of the same product. Due to manufacturing tolerances and slight variations in material properties, the intensity and frequency of coil whine can differ substantially between seemingly identical components. This inconsistency makes it difficult to implement a standardized solution across production lines.

The dynamic nature of coil whine poses additional complications. The phenomenon often varies with the operating conditions of the device, such as load, temperature, and input voltage. This variability means that solutions effective under certain conditions may be less effective or even counterproductive under others, necessitating a more comprehensive and adaptive approach to mitigation.

Cost considerations present yet another hurdle in coil whine mitigation. While some effective solutions exist, such as using higher-quality materials or more sophisticated designs, these often come at a premium. Balancing the need for coil whine reduction with cost-effectiveness remains a significant challenge, especially in competitive consumer electronics markets where profit margins are tight.

The lack of standardized testing and measurement protocols for coil whine further complicates the issue. Without universally accepted methods for quantifying and characterizing coil whine, it becomes difficult to compare different mitigation techniques objectively or to set industry-wide benchmarks for acceptable levels of coil whine.

Lastly, the interdisciplinary nature of coil whine mitigation presents its own set of challenges. Effective solutions often require expertise from various fields, including electrical engineering, materials science, and acoustics. Coordinating these diverse areas of knowledge and integrating them into practical, manufacturable solutions remains a complex task for many organizations.

The miniaturization trend in electronics exacerbates this issue. As devices become smaller and more compact, the proximity of components increases, leading to more pronounced electromagnetic interference and resonance effects. This proximity not only amplifies the coil whine but also makes it more challenging to isolate and address the problem without affecting the overall performance of the device.

Another significant challenge lies in the variability of coil whine across different units of the same product. Due to manufacturing tolerances and slight variations in material properties, the intensity and frequency of coil whine can differ substantially between seemingly identical components. This inconsistency makes it difficult to implement a standardized solution across production lines.

The dynamic nature of coil whine poses additional complications. The phenomenon often varies with the operating conditions of the device, such as load, temperature, and input voltage. This variability means that solutions effective under certain conditions may be less effective or even counterproductive under others, necessitating a more comprehensive and adaptive approach to mitigation.

Cost considerations present yet another hurdle in coil whine mitigation. While some effective solutions exist, such as using higher-quality materials or more sophisticated designs, these often come at a premium. Balancing the need for coil whine reduction with cost-effectiveness remains a significant challenge, especially in competitive consumer electronics markets where profit margins are tight.

The lack of standardized testing and measurement protocols for coil whine further complicates the issue. Without universally accepted methods for quantifying and characterizing coil whine, it becomes difficult to compare different mitigation techniques objectively or to set industry-wide benchmarks for acceptable levels of coil whine.

Lastly, the interdisciplinary nature of coil whine mitigation presents its own set of challenges. Effective solutions often require expertise from various fields, including electrical engineering, materials science, and acoustics. Coordinating these diverse areas of knowledge and integrating them into practical, manufacturable solutions remains a complex task for many organizations.

Existing Coil Whine Reduction Techniques

01 Coil whine reduction in electronic devices

Various techniques are employed to reduce coil whine in electronic devices, particularly in power supplies and transformers. These methods include using specialized materials, optimizing component design, and implementing noise-cancelling technologies to minimize electromagnetic vibrations that cause audible noise.- Coil whine reduction in electronic devices: Various techniques are employed to reduce coil whine in electronic devices, including power supplies and circuit boards. These methods involve improving component design, using dampening materials, and optimizing circuit layouts to minimize electromagnetic vibrations that cause audible noise.

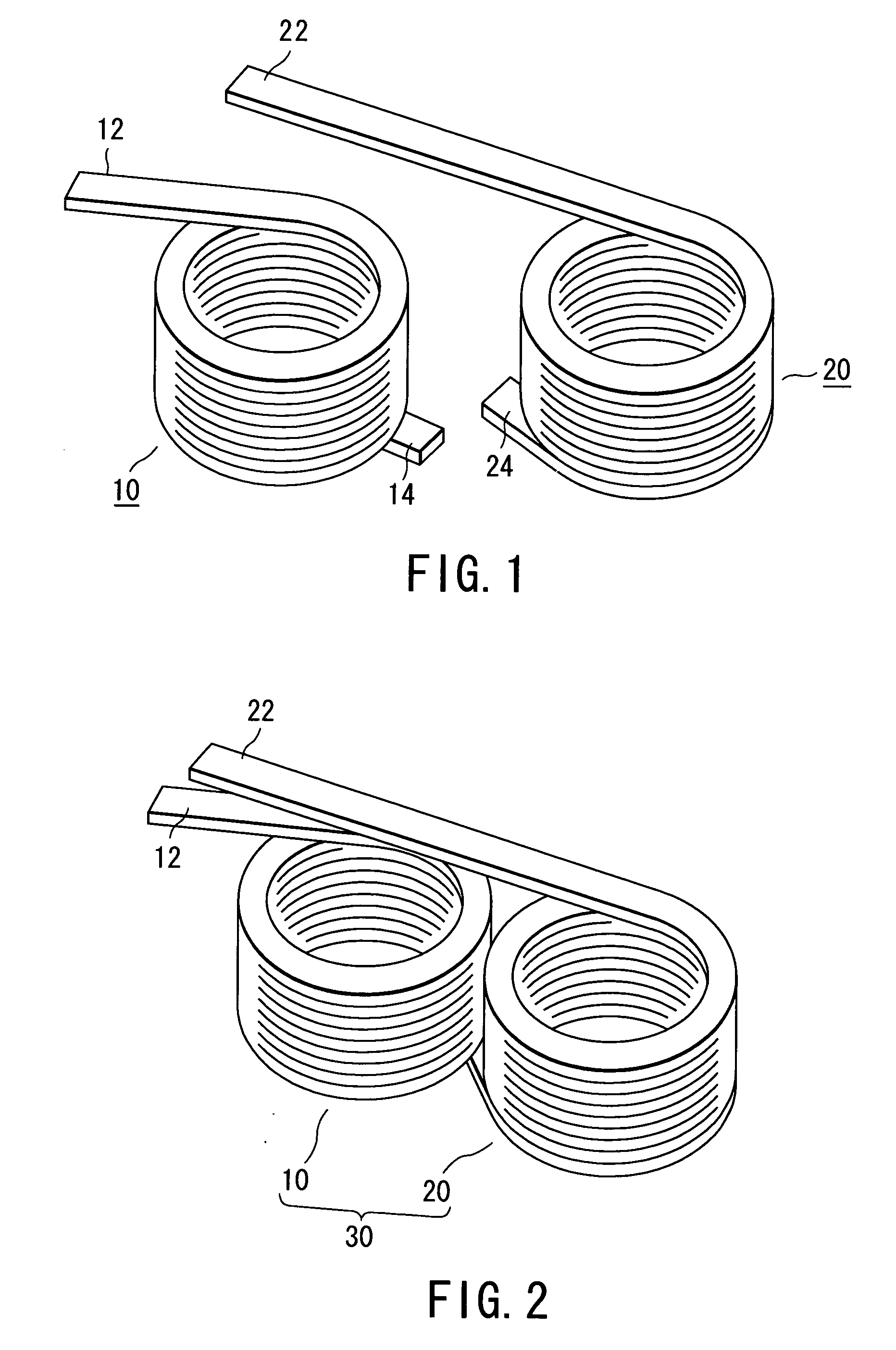

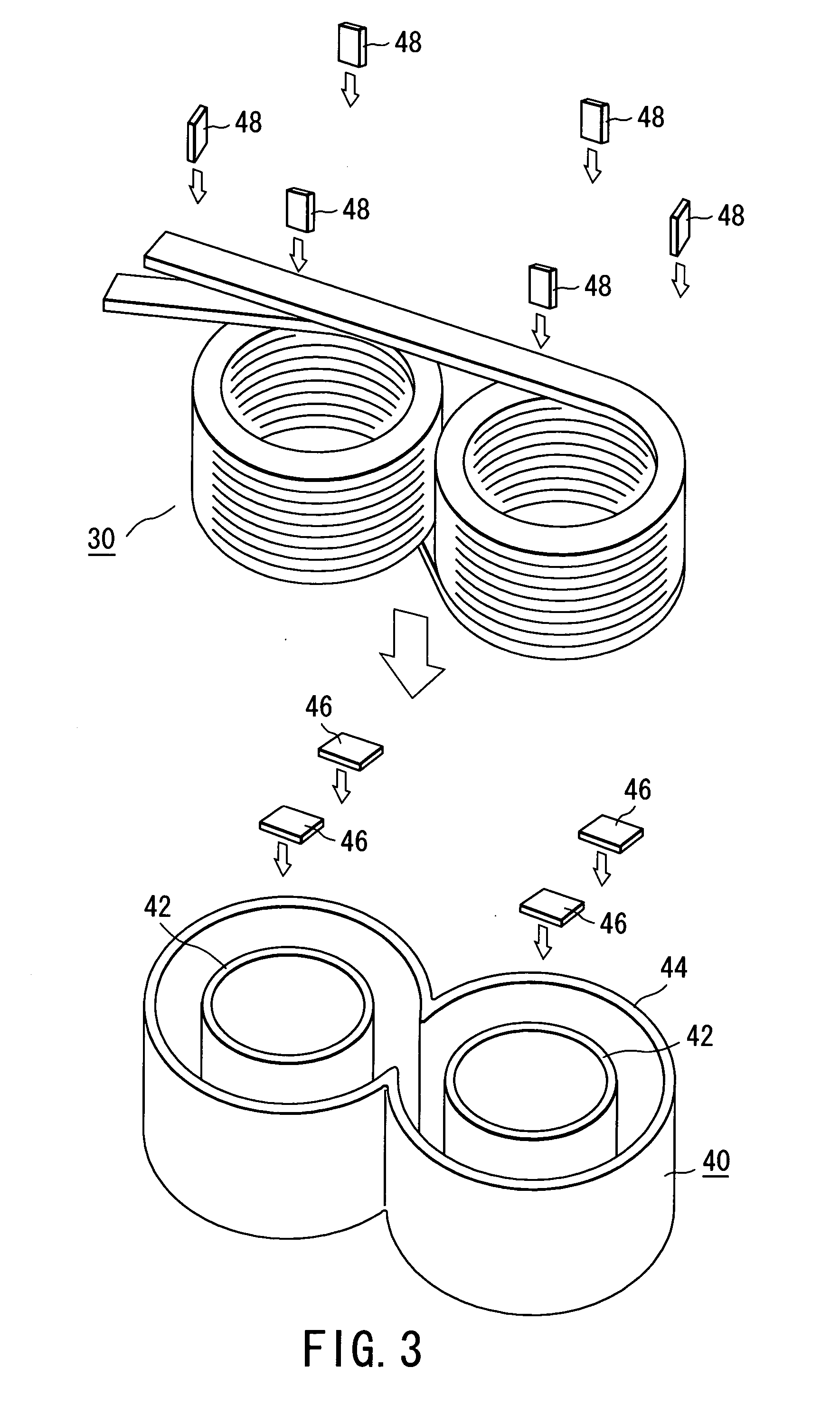

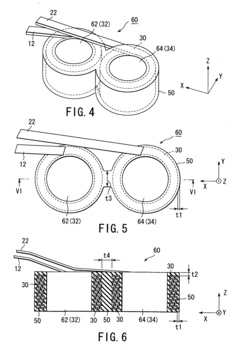

- Passive component design for noise reduction: Specific designs of passive electronic components, such as inductors and transformers, are developed to minimize coil whine. These designs may include special winding techniques, core materials, or shielding to reduce electromagnetic vibrations and acoustic noise emissions.

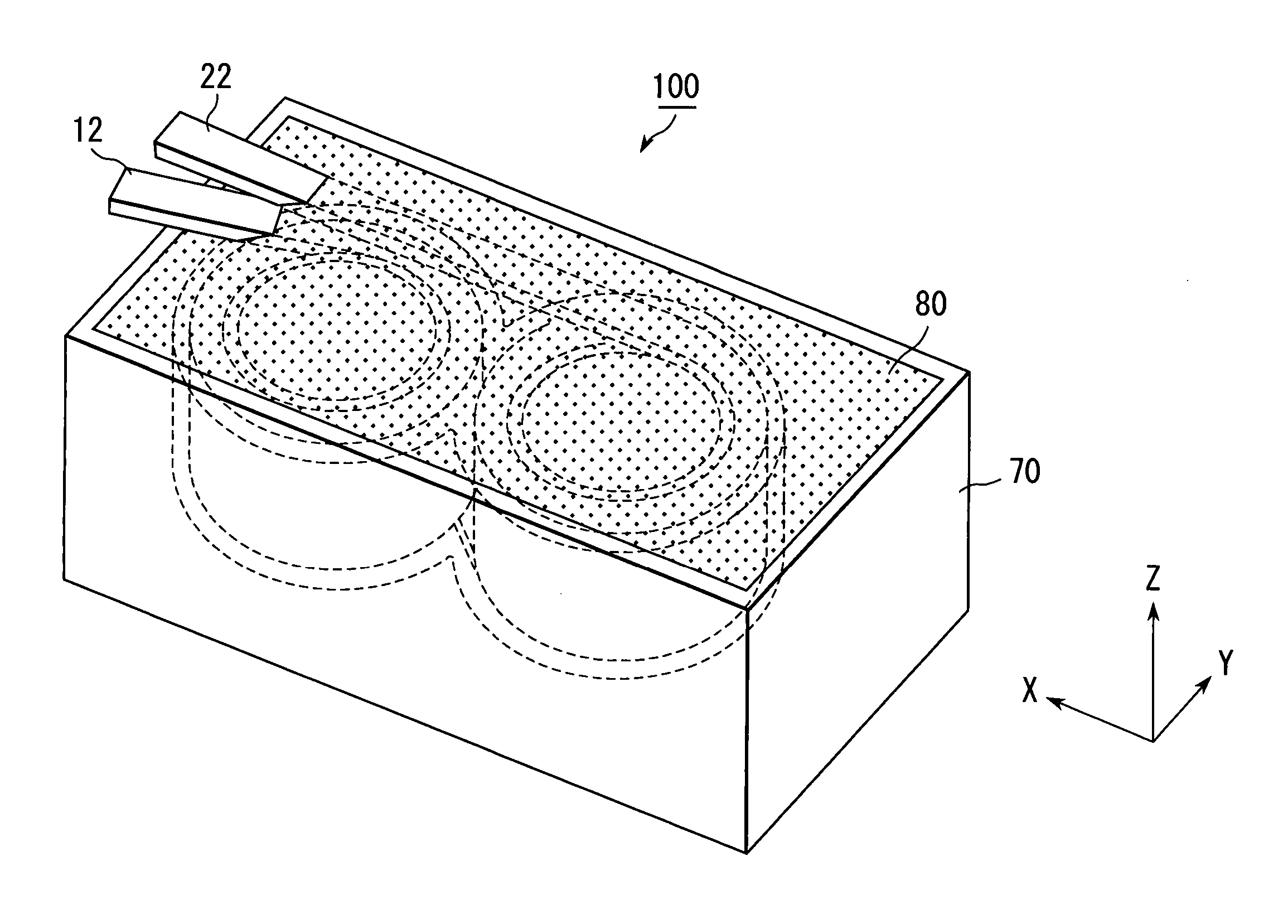

- Encapsulation and isolation techniques: Encapsulation methods and isolation techniques are used to contain and dampen coil whine in electronic components. This may involve using specialized potting compounds, vibration-absorbing materials, or physical barriers to prevent the propagation of acoustic noise from coils and transformers.

- Circuit design and layout optimization: Optimizing circuit designs and layouts to reduce coil whine involves careful placement of components, use of ground planes, and implementation of filtering techniques. These approaches aim to minimize electromagnetic interference and reduce the likelihood of audible noise generation in passive components.

- Frequency modulation and control techniques: Implementing frequency modulation and control techniques in power supply circuits and other electronic systems can help mitigate coil whine. These methods involve varying the operating frequency of switching components or implementing spread spectrum techniques to distribute the acoustic energy over a wider frequency range, making the noise less perceptible.

02 Passive component design for noise reduction

Innovative designs for passive electronic components, such as inductors and capacitors, focus on minimizing electromagnetic interference and acoustic noise. These designs incorporate advanced materials and structures to dampen vibrations and reduce the occurrence of coil whine in electronic circuits.Expand Specific Solutions03 Thermal management to mitigate coil whine

Effective thermal management strategies are implemented to reduce coil whine in electronic components. These include improved heat dissipation techniques, thermal interface materials, and cooling solutions that help maintain optimal operating temperatures, thereby reducing thermal-induced vibrations that contribute to coil whine.Expand Specific Solutions04 Encapsulation and isolation techniques

Advanced encapsulation and isolation methods are used to contain and reduce coil whine in passive electronic components. These techniques involve using specialized materials and designs to absorb vibrations, isolate noise-generating components, and prevent the propagation of acoustic emissions throughout the device.Expand Specific Solutions05 Circuit design optimization for noise reduction

Innovative circuit design approaches are employed to minimize coil whine in electronic systems. These include optimizing power delivery networks, implementing advanced filtering techniques, and using specialized circuit topologies that reduce electromagnetic emissions and acoustic noise from passive components.Expand Specific Solutions

Key Players in Electronic Component Manufacturing

The exploration of coil whine in passive electronic components is currently in a growth phase, with increasing market demand driven by the need for quieter electronic devices. The global market for passive components is substantial, estimated to reach $35 billion by 2025. Technologically, the field is advancing rapidly, with companies like Murata Manufacturing, Samsung Electro-Mechanics, and Taiyo Yuden leading innovation. These firms are developing advanced materials and manufacturing techniques to mitigate coil whine, focusing on improved component design and noise reduction technologies. Other key players such as TDK Corp. and Delta Electronics are also contributing to the field's progression, indicating a competitive and dynamic landscape in addressing this technical challenge.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed advanced ceramic capacitors with reduced acoustic noise emission. Their approach involves optimizing the internal structure of multilayer ceramic capacitors (MLCCs) to minimize mechanical stress and vibration. They have implemented a proprietary dielectric material composition and electrode design that reduces the piezoelectric effect responsible for coil whine. Additionally, Murata has introduced a damping layer within the capacitor structure to absorb vibrations[1]. Their latest X7R dielectric MLCCs have shown a significant reduction in acoustic noise levels, with some models achieving up to 30 dB lower noise compared to conventional designs[2].

Strengths: Industry-leading expertise in ceramic components, extensive R&D capabilities. Weaknesses: Higher production costs for advanced noise-reduction designs, potential trade-offs in electrical performance.

TDK Corp.

Technical Solution: TDK has focused on developing noise suppression technologies for various electronic components, including capacitors and inductors. Their approach to mitigating coil whine involves a combination of material science and structural design. TDK has introduced a series of low-noise power inductors that utilize advanced core materials and winding techniques to reduce mechanical vibrations. They have also developed specialized EMI suppression filters that can attenuate high-frequency noise associated with coil whine. TDK's EPCOS brand offers ceramic capacitors with reduced microphonic effects, achieved through optimized electrode structures and the use of flexible termination materials[3]. Recent advancements include the development of polymer-based capacitors that inherently produce less acoustic noise due to their non-piezoelectric nature[4].

Strengths: Comprehensive portfolio of noise reduction solutions, strong presence in automotive and industrial markets. Weaknesses: Some solutions may be more expensive than traditional components, potential size increase in certain noise-suppressing designs.

Innovative Approaches to Coil Whine Elimination

Coil component and fabricaiton method of the same

PatentInactiveUS20050012581A1

Innovation

- A coil component design featuring a coil-containing insulator enclosure made of epoxy resin and a magnetic core composed of a mixture of resin and magnetic powder, where the insulator enclosure is embedded within the magnetic core, enhancing the component's structural integrity and noise suppression capabilities.

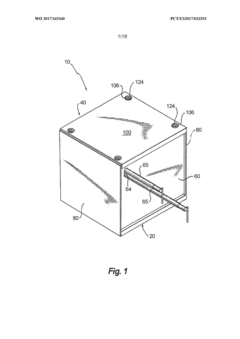

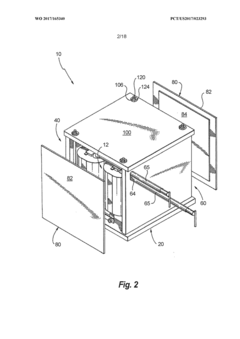

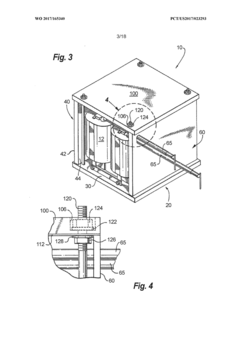

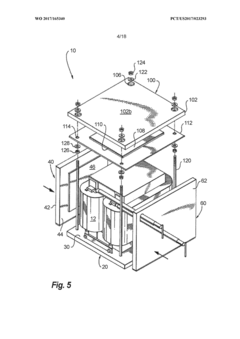

Noise reducing and cooling enclosure

PatentWO2017165340A1

Innovation

- The enclosure is constructed with multi-layered plate assemblies made of thermally conductive and acoustic quieting materials, which block and dissipate acoustic energy, using a combination of rigid acoustic blocking materials and thermally conductive materials to absorb and conduct heat away from the device.

Acoustic Testing and Quality Control

Acoustic testing and quality control play a crucial role in identifying and mitigating coil whine issues in passive electronic components. This process involves a comprehensive approach to detect, measure, and analyze the acoustic emissions produced by these components under various operating conditions.

The first step in acoustic testing is to establish a controlled environment that minimizes external noise interference. This typically involves the use of anechoic chambers or specially designed sound-isolated rooms. These facilities are equipped with high-sensitivity microphones and advanced audio recording equipment capable of capturing even the faintest sounds emitted by electronic components.

Once the testing environment is set up, components are subjected to a series of standardized tests. These tests often involve applying different voltage levels, frequencies, and load conditions to simulate real-world usage scenarios. During these tests, acoustic emissions are recorded and analyzed using specialized software that can isolate and characterize the coil whine frequencies.

Frequency spectrum analysis is a key technique used in acoustic testing. It allows engineers to identify the specific frequencies at which coil whine occurs and measure its intensity. This information is crucial for understanding the root causes of the issue and developing effective mitigation strategies.

Quality control measures based on acoustic testing results are implemented at various stages of the manufacturing process. Components that exhibit excessive coil whine are identified and either reworked or rejected. Manufacturers may also use the data collected from acoustic tests to refine their design and production processes, aiming to minimize coil whine in future batches.

Advanced quality control techniques may include the use of artificial intelligence and machine learning algorithms to detect patterns in acoustic emissions that might indicate potential coil whine issues. These systems can be trained to recognize subtle variations in sound signatures that might escape human detection, allowing for more precise and consistent quality control.

Continuous monitoring and feedback loops are essential components of an effective acoustic testing and quality control system. Regular testing of production samples helps ensure that coil whine issues are caught early and addressed promptly. This proactive approach helps maintain high product quality standards and reduces the likelihood of customer complaints related to acoustic noise.

The first step in acoustic testing is to establish a controlled environment that minimizes external noise interference. This typically involves the use of anechoic chambers or specially designed sound-isolated rooms. These facilities are equipped with high-sensitivity microphones and advanced audio recording equipment capable of capturing even the faintest sounds emitted by electronic components.

Once the testing environment is set up, components are subjected to a series of standardized tests. These tests often involve applying different voltage levels, frequencies, and load conditions to simulate real-world usage scenarios. During these tests, acoustic emissions are recorded and analyzed using specialized software that can isolate and characterize the coil whine frequencies.

Frequency spectrum analysis is a key technique used in acoustic testing. It allows engineers to identify the specific frequencies at which coil whine occurs and measure its intensity. This information is crucial for understanding the root causes of the issue and developing effective mitigation strategies.

Quality control measures based on acoustic testing results are implemented at various stages of the manufacturing process. Components that exhibit excessive coil whine are identified and either reworked or rejected. Manufacturers may also use the data collected from acoustic tests to refine their design and production processes, aiming to minimize coil whine in future batches.

Advanced quality control techniques may include the use of artificial intelligence and machine learning algorithms to detect patterns in acoustic emissions that might indicate potential coil whine issues. These systems can be trained to recognize subtle variations in sound signatures that might escape human detection, allowing for more precise and consistent quality control.

Continuous monitoring and feedback loops are essential components of an effective acoustic testing and quality control system. Regular testing of production samples helps ensure that coil whine issues are caught early and addressed promptly. This proactive approach helps maintain high product quality standards and reduces the likelihood of customer complaints related to acoustic noise.

Environmental Factors Affecting Coil Whine

Environmental factors play a significant role in the occurrence and intensity of coil whine in passive electronic components. Temperature is one of the most critical factors affecting coil whine. As temperature increases, the physical properties of materials used in electronic components change, potentially leading to thermal expansion and contraction. This can alter the mechanical stress on coils and transformers, resulting in increased vibration and, consequently, more pronounced coil whine.

Humidity is another environmental factor that can impact coil whine. High humidity levels can lead to moisture absorption in electronic components, affecting their electrical and mechanical properties. This can change the resonant frequencies of coils and transformers, potentially exacerbating coil whine issues. Additionally, moisture can cause corrosion in metal components, further altering their vibrational characteristics.

Atmospheric pressure variations can also influence coil whine. Changes in pressure can affect the resonant frequencies of components, particularly in sealed devices. This effect is more noticeable in applications where electronic components are subjected to significant pressure changes, such as in aerospace or underwater systems.

Electromagnetic interference (EMI) from the surrounding environment can contribute to coil whine. External electromagnetic fields can induce currents in coils and transformers, causing additional vibrations that may amplify existing coil whine or create new sources of noise. This is particularly relevant in environments with high levels of electromagnetic pollution, such as industrial settings or areas with dense wireless communications infrastructure.

Mechanical vibrations from external sources can also impact coil whine. These vibrations can be transmitted through the device's housing or mounting structures, potentially resonating with the natural frequencies of coils and transformers. This can lead to increased coil whine or the manifestation of new vibrational modes.

The presence of dust and particulate matter in the environment can affect coil whine over time. Accumulation of particles on or around electronic components can alter their thermal properties and mechanical behavior. This can lead to changes in resonant frequencies and potentially increase coil whine.

Understanding these environmental factors is crucial for designing robust electronic systems that minimize coil whine across a wide range of operating conditions. Engineers must consider these factors during the design and testing phases to ensure optimal performance and reliability of passive electronic components in various environmental scenarios.

Humidity is another environmental factor that can impact coil whine. High humidity levels can lead to moisture absorption in electronic components, affecting their electrical and mechanical properties. This can change the resonant frequencies of coils and transformers, potentially exacerbating coil whine issues. Additionally, moisture can cause corrosion in metal components, further altering their vibrational characteristics.

Atmospheric pressure variations can also influence coil whine. Changes in pressure can affect the resonant frequencies of components, particularly in sealed devices. This effect is more noticeable in applications where electronic components are subjected to significant pressure changes, such as in aerospace or underwater systems.

Electromagnetic interference (EMI) from the surrounding environment can contribute to coil whine. External electromagnetic fields can induce currents in coils and transformers, causing additional vibrations that may amplify existing coil whine or create new sources of noise. This is particularly relevant in environments with high levels of electromagnetic pollution, such as industrial settings or areas with dense wireless communications infrastructure.

Mechanical vibrations from external sources can also impact coil whine. These vibrations can be transmitted through the device's housing or mounting structures, potentially resonating with the natural frequencies of coils and transformers. This can lead to increased coil whine or the manifestation of new vibrational modes.

The presence of dust and particulate matter in the environment can affect coil whine over time. Accumulation of particles on or around electronic components can alter their thermal properties and mechanical behavior. This can lead to changes in resonant frequencies and potentially increase coil whine.

Understanding these environmental factors is crucial for designing robust electronic systems that minimize coil whine across a wide range of operating conditions. Engineers must consider these factors during the design and testing phases to ensure optimal performance and reliability of passive electronic components in various environmental scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!