How to Assess Coil Whine in Electronic Devices?

AUG 13, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coil Whine Background

Coil whine is an audible noise produced by electromagnetic components in electronic devices, primarily caused by vibrations in inductors, transformers, or other coiled structures. This phenomenon has been a persistent issue in the electronics industry for decades, affecting a wide range of devices from personal computers to power supplies and audio equipment.

The occurrence of coil whine is closely related to the fundamental principles of electromagnetism. When alternating current flows through a coil, it generates a fluctuating magnetic field. This field can cause the coil's windings to vibrate at frequencies within the human audible range, typically between 20 Hz and 20 kHz. The intensity and frequency of the noise can vary depending on the device's power consumption, operating frequency, and the specific characteristics of the components used.

Historically, coil whine became more noticeable with the advent of switch-mode power supplies and high-frequency digital circuits. As electronic devices became more powerful and energy-efficient, the switching frequencies increased, often pushing the vibrations into the audible spectrum. This trend has been particularly evident in the evolution of personal computers, where graphics cards and power supply units are common sources of coil whine.

The impact of coil whine extends beyond mere annoyance. In professional audio environments, it can interfere with recording and playback quality. In consumer electronics, it may be perceived as a defect, leading to customer dissatisfaction and increased return rates. For manufacturers, addressing coil whine presents a significant challenge in balancing performance, cost, and user experience.

Various factors contribute to the severity of coil whine, including the quality of components, circuit design, and manufacturing processes. Environmental conditions such as temperature and humidity can also influence the intensity of the noise. As electronic devices continue to evolve, with higher processing speeds and more complex power management systems, the potential for coil whine remains a relevant concern for engineers and designers.

Assessing coil whine involves a multidisciplinary approach, combining elements of acoustics, electrical engineering, and materials science. The evaluation process typically includes both objective measurements and subjective assessments, as human perception of the noise can vary significantly. This complexity underscores the importance of developing standardized methods for quantifying and characterizing coil whine across different types of electronic devices.

The occurrence of coil whine is closely related to the fundamental principles of electromagnetism. When alternating current flows through a coil, it generates a fluctuating magnetic field. This field can cause the coil's windings to vibrate at frequencies within the human audible range, typically between 20 Hz and 20 kHz. The intensity and frequency of the noise can vary depending on the device's power consumption, operating frequency, and the specific characteristics of the components used.

Historically, coil whine became more noticeable with the advent of switch-mode power supplies and high-frequency digital circuits. As electronic devices became more powerful and energy-efficient, the switching frequencies increased, often pushing the vibrations into the audible spectrum. This trend has been particularly evident in the evolution of personal computers, where graphics cards and power supply units are common sources of coil whine.

The impact of coil whine extends beyond mere annoyance. In professional audio environments, it can interfere with recording and playback quality. In consumer electronics, it may be perceived as a defect, leading to customer dissatisfaction and increased return rates. For manufacturers, addressing coil whine presents a significant challenge in balancing performance, cost, and user experience.

Various factors contribute to the severity of coil whine, including the quality of components, circuit design, and manufacturing processes. Environmental conditions such as temperature and humidity can also influence the intensity of the noise. As electronic devices continue to evolve, with higher processing speeds and more complex power management systems, the potential for coil whine remains a relevant concern for engineers and designers.

Assessing coil whine involves a multidisciplinary approach, combining elements of acoustics, electrical engineering, and materials science. The evaluation process typically includes both objective measurements and subjective assessments, as human perception of the noise can vary significantly. This complexity underscores the importance of developing standardized methods for quantifying and characterizing coil whine across different types of electronic devices.

Market Impact Analysis

Coil whine in electronic devices has become a significant concern in the consumer electronics market, affecting both manufacturers and end-users. This issue has far-reaching implications across various sectors, particularly in high-performance computing, gaming, and audio equipment industries.

The prevalence of coil whine has led to increased customer dissatisfaction and product returns, impacting brand reputation and sales figures for affected manufacturers. Companies that can effectively address and mitigate coil whine issues gain a competitive edge in the market, potentially increasing their market share and customer loyalty.

In the gaming industry, coil whine has become a notable factor in purchasing decisions for graphics cards and gaming consoles. Manufacturers who successfully minimize or eliminate coil whine in their products often see improved sales and positive reviews, translating to better market positioning. This has sparked a race among manufacturers to develop innovative solutions and technologies to reduce coil whine, driving research and development investments in this area.

The audio equipment sector has also been significantly impacted by coil whine concerns. High-end audio enthusiasts and professionals are particularly sensitive to any unwanted noise in their systems. Manufacturers who can produce audio equipment with minimal or no coil whine command premium prices and enjoy stronger brand loyalty in this niche market.

The issue of coil whine has created new market opportunities for specialized testing equipment and services. Companies offering advanced acoustic testing solutions and noise reduction technologies have seen increased demand for their products and expertise. This has led to the emergence of a niche market focused on coil whine assessment and mitigation solutions.

In the broader consumer electronics market, awareness of coil whine has increased among consumers, influencing purchasing decisions across various product categories. This has prompted manufacturers to prioritize acoustic performance in their product design and quality control processes, leading to overall improvements in product quality and user experience.

The impact of coil whine extends to the supply chain as well. Component manufacturers, particularly those producing inductors and transformers, face increased pressure to develop and supply parts that minimize coil whine. This has led to innovations in materials and manufacturing processes, potentially benefiting multiple industries beyond consumer electronics.

As environmental noise regulations become stricter in many regions, the ability to assess and control coil whine has gained importance in ensuring compliance. This regulatory aspect adds another dimension to the market impact, potentially affecting product certifications and market access for electronic devices.

The prevalence of coil whine has led to increased customer dissatisfaction and product returns, impacting brand reputation and sales figures for affected manufacturers. Companies that can effectively address and mitigate coil whine issues gain a competitive edge in the market, potentially increasing their market share and customer loyalty.

In the gaming industry, coil whine has become a notable factor in purchasing decisions for graphics cards and gaming consoles. Manufacturers who successfully minimize or eliminate coil whine in their products often see improved sales and positive reviews, translating to better market positioning. This has sparked a race among manufacturers to develop innovative solutions and technologies to reduce coil whine, driving research and development investments in this area.

The audio equipment sector has also been significantly impacted by coil whine concerns. High-end audio enthusiasts and professionals are particularly sensitive to any unwanted noise in their systems. Manufacturers who can produce audio equipment with minimal or no coil whine command premium prices and enjoy stronger brand loyalty in this niche market.

The issue of coil whine has created new market opportunities for specialized testing equipment and services. Companies offering advanced acoustic testing solutions and noise reduction technologies have seen increased demand for their products and expertise. This has led to the emergence of a niche market focused on coil whine assessment and mitigation solutions.

In the broader consumer electronics market, awareness of coil whine has increased among consumers, influencing purchasing decisions across various product categories. This has prompted manufacturers to prioritize acoustic performance in their product design and quality control processes, leading to overall improvements in product quality and user experience.

The impact of coil whine extends to the supply chain as well. Component manufacturers, particularly those producing inductors and transformers, face increased pressure to develop and supply parts that minimize coil whine. This has led to innovations in materials and manufacturing processes, potentially benefiting multiple industries beyond consumer electronics.

As environmental noise regulations become stricter in many regions, the ability to assess and control coil whine has gained importance in ensuring compliance. This regulatory aspect adds another dimension to the market impact, potentially affecting product certifications and market access for electronic devices.

Technical Challenges

Assessing coil whine in electronic devices presents several technical challenges that researchers and engineers must overcome. One of the primary difficulties lies in the subjective nature of coil whine perception. Different individuals may have varying sensitivities to the high-frequency noise, making it challenging to establish standardized assessment criteria.

The frequency range of coil whine, typically between 1 kHz and 20 kHz, poses another significant challenge. Many conventional audio measurement tools are not optimized for this specific range, requiring specialized equipment or modifications to existing systems. This can lead to inconsistencies in measurement results across different testing environments.

Environmental factors also play a crucial role in coil whine assessment. Background noise, temperature, and humidity can all affect the intensity and perception of coil whine. Creating a controlled testing environment that accurately simulates real-world usage scenarios while minimizing external influences is a complex task.

The intermittent nature of coil whine adds another layer of complexity to the assessment process. The noise may only occur under specific load conditions or during certain operations, making it difficult to consistently reproduce and measure. This unpredictability necessitates long-term testing and sophisticated monitoring systems to capture and analyze coil whine events effectively.

Identifying the exact source of coil whine within a device is often challenging due to the compact nature of modern electronics. Multiple components, such as inductors, transformers, and capacitors, can contribute to the phenomenon. Isolating individual components for assessment without altering the overall system behavior requires advanced techniques and careful consideration of the device's design.

Quantifying the impact of coil whine on user experience presents another significant challenge. While objective measurements can provide valuable data, correlating these measurements with subjective user perceptions is complex. Developing a comprehensive assessment methodology that combines both objective and subjective evaluations remains an ongoing challenge in the field.

The miniaturization trend in electronic devices further complicates coil whine assessment. As components become smaller and more densely packed, traditional measurement techniques may become less effective. Developing new methods to accurately assess coil whine in increasingly compact devices is a pressing challenge for researchers and manufacturers alike.

The frequency range of coil whine, typically between 1 kHz and 20 kHz, poses another significant challenge. Many conventional audio measurement tools are not optimized for this specific range, requiring specialized equipment or modifications to existing systems. This can lead to inconsistencies in measurement results across different testing environments.

Environmental factors also play a crucial role in coil whine assessment. Background noise, temperature, and humidity can all affect the intensity and perception of coil whine. Creating a controlled testing environment that accurately simulates real-world usage scenarios while minimizing external influences is a complex task.

The intermittent nature of coil whine adds another layer of complexity to the assessment process. The noise may only occur under specific load conditions or during certain operations, making it difficult to consistently reproduce and measure. This unpredictability necessitates long-term testing and sophisticated monitoring systems to capture and analyze coil whine events effectively.

Identifying the exact source of coil whine within a device is often challenging due to the compact nature of modern electronics. Multiple components, such as inductors, transformers, and capacitors, can contribute to the phenomenon. Isolating individual components for assessment without altering the overall system behavior requires advanced techniques and careful consideration of the device's design.

Quantifying the impact of coil whine on user experience presents another significant challenge. While objective measurements can provide valuable data, correlating these measurements with subjective user perceptions is complex. Developing a comprehensive assessment methodology that combines both objective and subjective evaluations remains an ongoing challenge in the field.

The miniaturization trend in electronic devices further complicates coil whine assessment. As components become smaller and more densely packed, traditional measurement techniques may become less effective. Developing new methods to accurately assess coil whine in increasingly compact devices is a pressing challenge for researchers and manufacturers alike.

Current Assessment Methods

01 Noise reduction techniques for electronic devices

Various methods are employed to reduce coil whine noise in electronic devices. These techniques include using specialized materials, optimizing circuit design, and implementing noise cancellation technologies. By addressing the root causes of coil whine, such as electromagnetic vibrations, these approaches aim to minimize or eliminate the audible noise produced by electronic components.- Noise reduction techniques for coil whine: Various methods are employed to reduce coil whine noise levels in electronic devices. These techniques include using specialized materials, optimizing coil design, and implementing noise cancellation technologies. By addressing the root causes of coil whine, manufacturers can significantly decrease the audible noise produced by electronic components.

- Measurement and analysis of coil whine: Accurate measurement and analysis of coil whine noise levels are crucial for developing effective solutions. Advanced sensors and signal processing techniques are used to quantify and characterize the noise produced by coils in various operating conditions. This data helps engineers identify problematic frequencies and design appropriate countermeasures.

- Electromagnetic shielding to reduce coil whine: Electromagnetic shielding is an effective method for reducing coil whine noise levels. By enclosing the coil or the entire device in materials that block electromagnetic interference, the audible noise generated by coil vibrations can be significantly attenuated. This approach is particularly useful in sensitive electronic equipment and consumer devices.

- Coil design optimization for noise reduction: Optimizing the design of coils can help minimize coil whine noise levels. This includes considerations such as coil geometry, winding techniques, and material selection. By carefully engineering these aspects, manufacturers can create coils that are less prone to producing audible vibrations during operation.

- Active noise control for coil whine suppression: Active noise control systems can be implemented to counteract coil whine. These systems use advanced signal processing and acoustic technologies to generate anti-noise that cancels out the unwanted coil whine. This approach is particularly effective for dealing with persistent noise issues in complex electronic systems.

02 Measurement and analysis of coil whine noise levels

Accurate measurement and analysis of coil whine noise levels are crucial for developing effective noise reduction solutions. Advanced sensors and signal processing techniques are used to quantify and characterize the noise produced by electronic components. This data helps engineers identify problematic frequencies and design targeted noise mitigation strategies.Expand Specific Solutions03 Electromagnetic shielding for noise reduction

Electromagnetic shielding is an effective method for reducing coil whine noise. By enclosing electronic components in specially designed materials that block electromagnetic interference, the transmission of noise-causing vibrations can be significantly reduced. This approach is particularly useful in sensitive electronic devices where minimal noise levels are crucial.Expand Specific Solutions04 Power supply design optimization for noise reduction

Optimizing power supply design is a key strategy in minimizing coil whine noise. This involves careful selection of components, improved circuit layouts, and the use of advanced power management techniques. By addressing issues such as voltage ripple and current fluctuations, engineers can significantly reduce the occurrence and intensity of coil whine in electronic devices.Expand Specific Solutions05 Acoustic treatment for coil whine suppression

Acoustic treatments are employed to suppress coil whine noise in electronic devices. This approach involves the use of sound-absorbing materials and structures designed to dampen vibrations and reduce noise propagation. By strategically placing these acoustic elements within the device, the audible impact of coil whine can be significantly diminished without affecting the device's performance.Expand Specific Solutions

Key Industry Players

The assessment of coil whine in electronic devices is a niche yet crucial aspect of the consumer electronics industry, currently in a mature stage with a growing market due to increasing demand for high-performance devices. The global market size for electronic components, including those affected by coil whine, is substantial and expanding. Technologically, companies like Samsung Electronics, Delta Electronics, and Siemens AG are at the forefront, developing advanced solutions to mitigate coil whine issues. These industry leaders, along with others like TDK Corp. and Taiyo Yuden Co., Ltd., are investing in research and development to improve component quality and reduce electromagnetic interference, demonstrating the industry's commitment to addressing this technical challenge.

Siemens AG

Technical Solution: Siemens AG has developed advanced techniques for assessing coil whine in electronic devices. Their approach involves a combination of acoustic measurement and analysis methods. They use high-precision microphones and accelerometers to capture both airborne and structure-borne noise[1]. The company employs spectral analysis techniques to identify characteristic frequencies associated with coil whine. Siemens has also developed proprietary software algorithms that can isolate coil whine from other background noises, allowing for more accurate assessment[2]. Their method includes thermal imaging to correlate coil whine with temperature variations, providing insights into the root causes of the issue[3].

Strengths: Comprehensive approach combining multiple measurement techniques. Advanced software algorithms for noise isolation. Correlation with thermal behavior for root cause analysis. Weaknesses: May require specialized equipment, potentially increasing assessment costs.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed a sophisticated approach to assess coil whine in electronic devices, particularly focusing on automotive and industrial applications. Their method combines both electrical and acoustic measurements to provide a comprehensive analysis. Bosch uses specialized current probes and high-bandwidth oscilloscopes to measure high-frequency current fluctuations that can lead to coil whine[10]. They have also developed a unique "acoustic camera" system that uses an array of microphones to create a visual map of sound sources, allowing for precise localization of coil whine within complex electronic assemblies[11]. Bosch's approach also includes vibration analysis using laser vibrometers to detect minute mechanical movements associated with coil whine[12].

Strengths: Comprehensive approach combining electrical, acoustic, and vibration analysis. Specialized equipment for precise localization of coil whine sources. Applicable to complex electronic systems in automotive and industrial settings. Weaknesses: May require significant investment in specialized measurement equipment.

Innovative Detection Techniques

Sound quality display apparatus, sound quality display method, computer readable medium on which sound quality display program is recorded and sound camera

PatentInactiveUS20080260167A1

Innovation

- A sound quality display apparatus comprising a sound detector, background photographing unit, sound source signal generator, and display that analyzes sound signals using frequency and time domain analysis to create sound quality data, overlaying image data with sound quality information, enabling precise detection and visualization of noise sources based on various factors such as loudness, sharpness, and tonality.

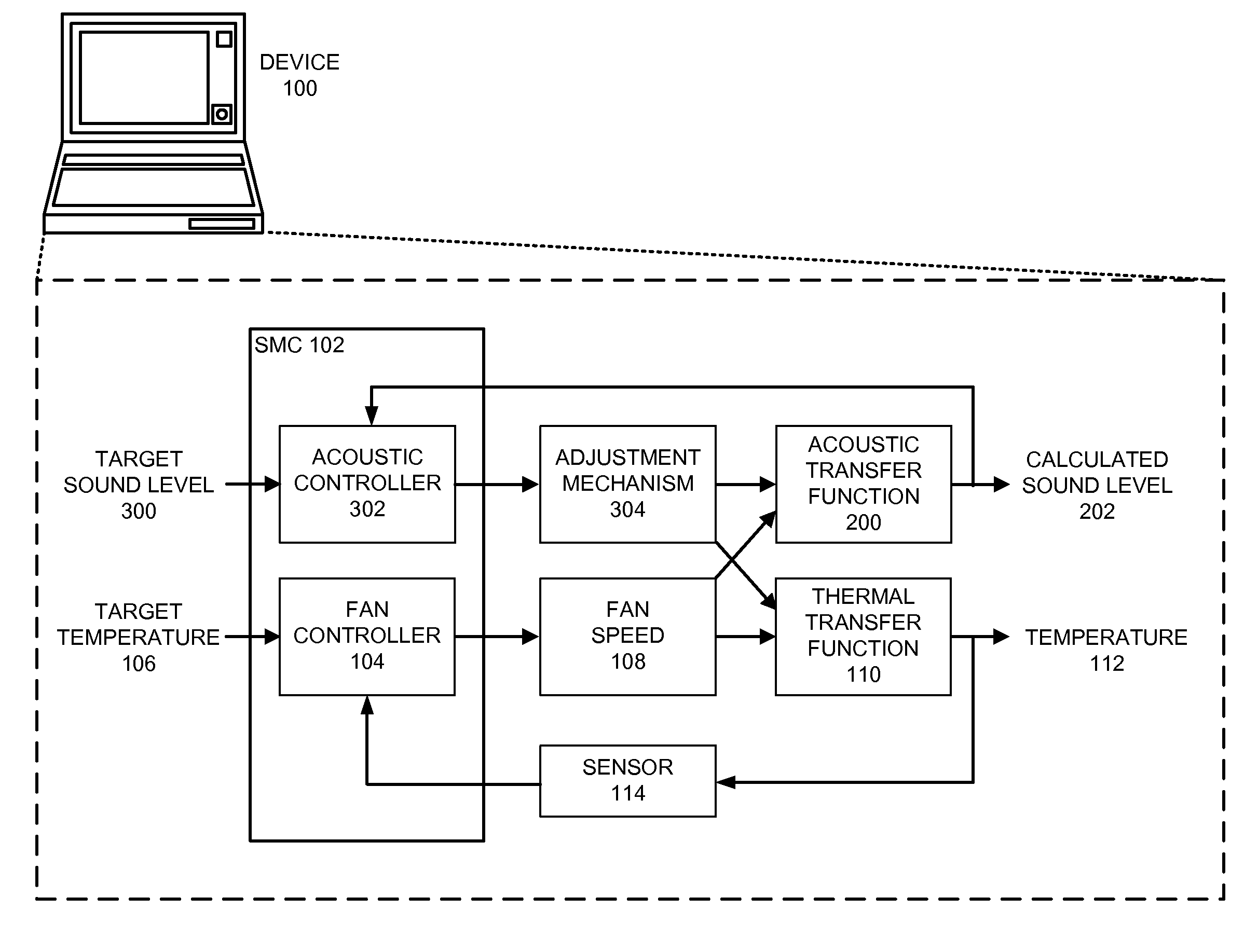

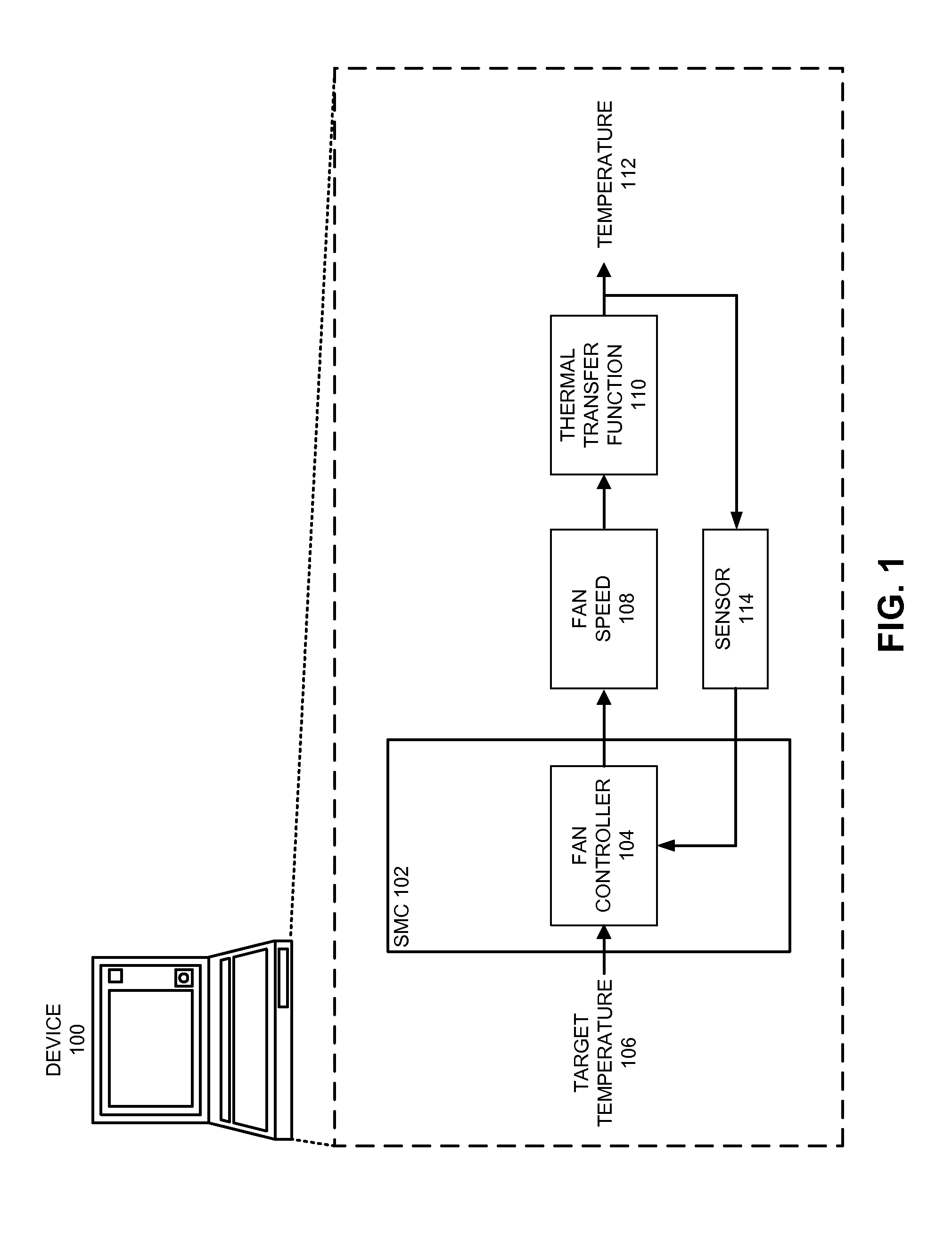

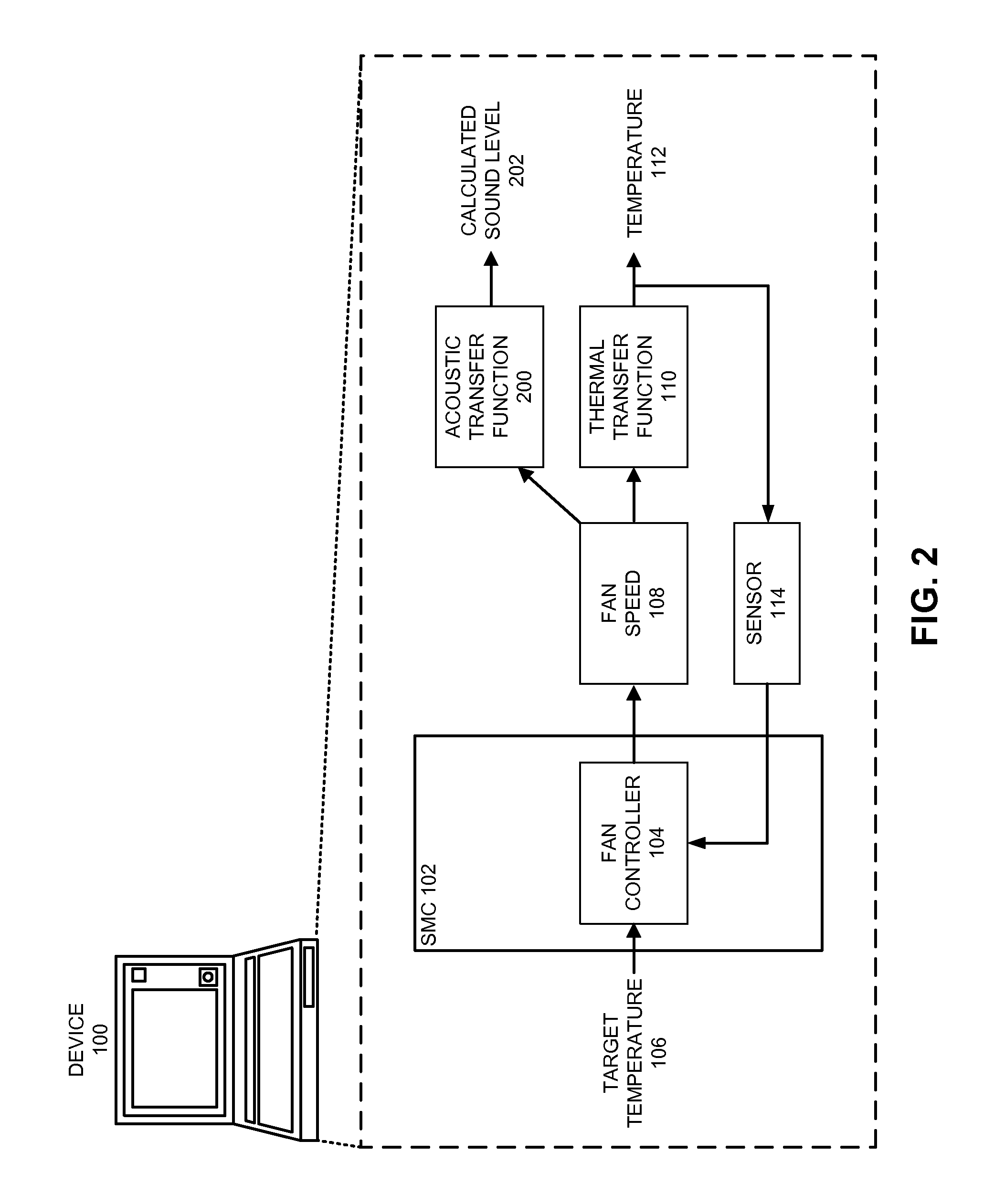

Managing acoustic noise produced by a device

PatentActiveUS20090092262A1

Innovation

- A system that monitors and manages acoustic noise by estimating noise production from individual components, using acoustic transfer functions, and dynamically adjusts power usage and performance to maintain noise levels within specified limits, while considering ambient conditions and user preferences.

Regulatory Standards

Regulatory standards play a crucial role in assessing coil whine in electronic devices, providing a framework for manufacturers and testing laboratories to evaluate and mitigate this issue. The International Electrotechnical Commission (IEC) has established several standards that address electromagnetic compatibility (EMC) and acoustic noise, which are relevant to coil whine assessment.

IEC 61000-3-2 is a key standard that sets limits for harmonic current emissions in electronic equipment. While primarily focused on power quality, this standard indirectly impacts coil whine by regulating the harmonic content of currents flowing through inductive components. Compliance with this standard can help reduce the likelihood of coil whine occurrence.

The IEC 60601 series of standards, specifically designed for medical electrical equipment, includes provisions for acoustic noise emissions. Although not exclusively targeting coil whine, these standards set maximum sound pressure levels for various device categories, which can be applied to assess the audibility of coil whine in medical devices.

For consumer electronics, the CISPR 32 standard addresses electromagnetic emissions from multimedia equipment. While not directly focused on coil whine, compliance with this standard can help identify potential sources of electromagnetic interference that may contribute to coil whine.

The ISO 7779 standard, which specifies methods for measuring and reporting noise emissions from information technology and telecommunications equipment, can be adapted for coil whine assessment. This standard provides guidelines for acoustic measurements in controlled environments, which can be valuable for quantifying coil whine levels.

In the automotive sector, the SAE J1113 series of standards addresses electromagnetic compatibility for vehicles and vehicle components. These standards include test methods and limits that can be applied to assess coil whine in automotive electronic systems.

Regulatory bodies such as the Federal Communications Commission (FCC) in the United States and the European Union's CE marking requirements also play a role in setting standards that indirectly impact coil whine assessment. While these regulations primarily focus on electromagnetic emissions, they often lead to design improvements that can reduce the likelihood of coil whine.

It is important to note that specific standards for coil whine assessment are still evolving. Many manufacturers and industry groups are working towards developing more targeted guidelines and test procedures to address this issue. As awareness of coil whine increases, it is likely that more comprehensive and specific regulatory standards will emerge in the future.

IEC 61000-3-2 is a key standard that sets limits for harmonic current emissions in electronic equipment. While primarily focused on power quality, this standard indirectly impacts coil whine by regulating the harmonic content of currents flowing through inductive components. Compliance with this standard can help reduce the likelihood of coil whine occurrence.

The IEC 60601 series of standards, specifically designed for medical electrical equipment, includes provisions for acoustic noise emissions. Although not exclusively targeting coil whine, these standards set maximum sound pressure levels for various device categories, which can be applied to assess the audibility of coil whine in medical devices.

For consumer electronics, the CISPR 32 standard addresses electromagnetic emissions from multimedia equipment. While not directly focused on coil whine, compliance with this standard can help identify potential sources of electromagnetic interference that may contribute to coil whine.

The ISO 7779 standard, which specifies methods for measuring and reporting noise emissions from information technology and telecommunications equipment, can be adapted for coil whine assessment. This standard provides guidelines for acoustic measurements in controlled environments, which can be valuable for quantifying coil whine levels.

In the automotive sector, the SAE J1113 series of standards addresses electromagnetic compatibility for vehicles and vehicle components. These standards include test methods and limits that can be applied to assess coil whine in automotive electronic systems.

Regulatory bodies such as the Federal Communications Commission (FCC) in the United States and the European Union's CE marking requirements also play a role in setting standards that indirectly impact coil whine assessment. While these regulations primarily focus on electromagnetic emissions, they often lead to design improvements that can reduce the likelihood of coil whine.

It is important to note that specific standards for coil whine assessment are still evolving. Many manufacturers and industry groups are working towards developing more targeted guidelines and test procedures to address this issue. As awareness of coil whine increases, it is likely that more comprehensive and specific regulatory standards will emerge in the future.

Acoustic Engineering Trends

Acoustic engineering has witnessed significant advancements in recent years, particularly in the realm of electronic device noise assessment. The trend towards miniaturization and increased power density in electronic devices has led to a growing concern over coil whine and other electromagnetic noise sources. As a result, the field of acoustic engineering has evolved to address these challenges, developing new methodologies and technologies for noise detection, analysis, and mitigation.

One notable trend is the integration of advanced signal processing techniques with traditional acoustic measurement methods. Machine learning algorithms are increasingly being employed to identify and classify different types of electronic noise, including coil whine. These AI-driven approaches enable more accurate and efficient noise source identification, even in complex electronic systems with multiple potential noise generators.

Another emerging trend is the development of high-precision, multi-channel measurement systems specifically designed for electronic device noise assessment. These systems often incorporate arrays of microphones and accelerometers to capture both airborne and structure-borne noise simultaneously. By combining these measurements with advanced spatial filtering techniques, engineers can more effectively isolate and characterize coil whine and other electromagnetic noise sources within electronic devices.

The use of simulation and modeling tools in acoustic engineering has also seen significant growth. Finite element analysis (FEA) and boundary element method (BEM) simulations are increasingly being used to predict and analyze coil whine behavior in electronic components before physical prototypes are built. This trend towards virtual prototyping allows for earlier identification and mitigation of potential noise issues in the design phase, reducing development costs and time-to-market.

Furthermore, there is a growing focus on developing standardized test procedures and metrics for assessing coil whine in electronic devices. Industry organizations and regulatory bodies are working towards establishing consistent methodologies for measuring and quantifying electromagnetic noise, which will facilitate better comparison and benchmarking of different devices and technologies.

The trend towards more energy-efficient electronic devices has also influenced acoustic engineering practices. As manufacturers strive to reduce power consumption, new challenges arise in managing electromagnetic noise from switching power supplies and other high-frequency components. This has led to increased research into novel materials and design techniques that can minimize coil whine while maintaining energy efficiency.

One notable trend is the integration of advanced signal processing techniques with traditional acoustic measurement methods. Machine learning algorithms are increasingly being employed to identify and classify different types of electronic noise, including coil whine. These AI-driven approaches enable more accurate and efficient noise source identification, even in complex electronic systems with multiple potential noise generators.

Another emerging trend is the development of high-precision, multi-channel measurement systems specifically designed for electronic device noise assessment. These systems often incorporate arrays of microphones and accelerometers to capture both airborne and structure-borne noise simultaneously. By combining these measurements with advanced spatial filtering techniques, engineers can more effectively isolate and characterize coil whine and other electromagnetic noise sources within electronic devices.

The use of simulation and modeling tools in acoustic engineering has also seen significant growth. Finite element analysis (FEA) and boundary element method (BEM) simulations are increasingly being used to predict and analyze coil whine behavior in electronic components before physical prototypes are built. This trend towards virtual prototyping allows for earlier identification and mitigation of potential noise issues in the design phase, reducing development costs and time-to-market.

Furthermore, there is a growing focus on developing standardized test procedures and metrics for assessing coil whine in electronic devices. Industry organizations and regulatory bodies are working towards establishing consistent methodologies for measuring and quantifying electromagnetic noise, which will facilitate better comparison and benchmarking of different devices and technologies.

The trend towards more energy-efficient electronic devices has also influenced acoustic engineering practices. As manufacturers strive to reduce power consumption, new challenges arise in managing electromagnetic noise from switching power supplies and other high-frequency components. This has led to increased research into novel materials and design techniques that can minimize coil whine while maintaining energy efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!