Comparative Analysis of Ammonium Hydroxide in Food Safety Applications

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonium Hydroxide in Food Safety: Background and Objectives

Ammonium hydroxide, a compound of nitrogen and hydrogen, has been a subject of interest in food safety applications for several decades. This alkaline solution, commonly known as ammonia water, has played a significant role in various food processing techniques, particularly in meat production. The historical use of ammonium hydroxide in food safety can be traced back to the early 20th century when it was first introduced as a cleaning agent in food processing facilities.

The evolution of ammonium hydroxide's application in food safety has been driven by the increasing demand for effective antimicrobial treatments and the need to extend the shelf life of food products. Over time, its use has expanded from cleaning to direct food treatment, particularly in the meat industry. The primary objective of utilizing ammonium hydroxide in food safety is to reduce the presence of harmful pathogens, such as E. coli and Salmonella, which pose significant risks to consumer health.

The technological progression in this field has been marked by continuous refinement of application methods and dosage control. Initially, ammonium hydroxide was applied through simple spraying techniques, but advancements have led to more sophisticated systems that ensure uniform distribution and precise concentration control. This evolution has been crucial in addressing concerns about taste alteration and potential health impacts associated with excessive use.

In recent years, the food industry has witnessed a growing trend towards natural and minimally processed foods, which has prompted a reevaluation of chemical treatments like ammonium hydroxide. This shift has spurred research into alternative antimicrobial strategies and has led to a more nuanced approach to the use of ammonium hydroxide in food safety applications.

The current technological landscape surrounding ammonium hydroxide in food safety is characterized by a balance between efficacy and consumer acceptance. Researchers and food safety experts are focusing on optimizing application methods to maximize pathogen reduction while minimizing any potential negative impacts on food quality or consumer perception. This includes exploring synergistic effects with other food safety interventions and developing more targeted application techniques.

Looking ahead, the technological goals in this field are multifaceted. There is a push towards developing more environmentally friendly and consumer-acceptable alternatives that can match or exceed the antimicrobial efficacy of ammonium hydroxide. Additionally, there is ongoing research into improving the precision of application methods, potentially through the integration of smart sensors and automated systems that can adjust treatment parameters in real-time based on product characteristics and contamination levels.

The evolution of ammonium hydroxide's application in food safety has been driven by the increasing demand for effective antimicrobial treatments and the need to extend the shelf life of food products. Over time, its use has expanded from cleaning to direct food treatment, particularly in the meat industry. The primary objective of utilizing ammonium hydroxide in food safety is to reduce the presence of harmful pathogens, such as E. coli and Salmonella, which pose significant risks to consumer health.

The technological progression in this field has been marked by continuous refinement of application methods and dosage control. Initially, ammonium hydroxide was applied through simple spraying techniques, but advancements have led to more sophisticated systems that ensure uniform distribution and precise concentration control. This evolution has been crucial in addressing concerns about taste alteration and potential health impacts associated with excessive use.

In recent years, the food industry has witnessed a growing trend towards natural and minimally processed foods, which has prompted a reevaluation of chemical treatments like ammonium hydroxide. This shift has spurred research into alternative antimicrobial strategies and has led to a more nuanced approach to the use of ammonium hydroxide in food safety applications.

The current technological landscape surrounding ammonium hydroxide in food safety is characterized by a balance between efficacy and consumer acceptance. Researchers and food safety experts are focusing on optimizing application methods to maximize pathogen reduction while minimizing any potential negative impacts on food quality or consumer perception. This includes exploring synergistic effects with other food safety interventions and developing more targeted application techniques.

Looking ahead, the technological goals in this field are multifaceted. There is a push towards developing more environmentally friendly and consumer-acceptable alternatives that can match or exceed the antimicrobial efficacy of ammonium hydroxide. Additionally, there is ongoing research into improving the precision of application methods, potentially through the integration of smart sensors and automated systems that can adjust treatment parameters in real-time based on product characteristics and contamination levels.

Market Demand Analysis for Food Safety Solutions

The global food safety solutions market has been experiencing significant growth, driven by increasing consumer awareness, stringent regulations, and the need for improved food quality assurance. The demand for effective food safety solutions, including the use of ammonium hydroxide, has been on the rise across various sectors of the food industry.

In recent years, there has been a growing concern over foodborne illnesses and contamination, leading to a surge in demand for advanced food safety technologies and solutions. The market for food safety testing and quality control measures has expanded rapidly, with a particular focus on antimicrobial agents and pH regulators like ammonium hydroxide.

The meat processing industry has been a key driver in the adoption of ammonium hydroxide as a food safety solution. Its application in reducing microbial contamination in meat products has gained traction, especially in countries with high meat consumption rates. The poultry and beef sectors have shown particular interest in this technology due to its effectiveness in controlling pathogens such as E. coli and Salmonella.

Furthermore, the dairy industry has also contributed to the increasing demand for ammonium hydroxide in food safety applications. Its use in cheese production and as a pH regulator in various dairy products has become more prevalent, driven by the need for extended shelf life and improved product quality.

The baking industry represents another significant market segment for ammonium hydroxide. Its application as a leavening agent and pH regulator in baked goods has seen steady growth, particularly in regions with a strong tradition of artisanal and industrial baking.

Geographically, North America and Europe have been at the forefront of adopting advanced food safety solutions, including ammonium hydroxide. These regions have stringent food safety regulations and a high level of consumer awareness, driving the demand for effective antimicrobial agents. The Asia-Pacific region, with its rapidly growing food processing industry and increasing focus on food safety, is expected to emerge as a key market for ammonium hydroxide and related food safety solutions in the coming years.

The COVID-19 pandemic has further accelerated the demand for food safety solutions, as consumers and regulatory bodies have become increasingly concerned about hygiene and contamination in the food supply chain. This has led to a renewed focus on effective antimicrobial agents and pH regulators in food processing, benefiting the market for ammonium hydroxide and similar solutions.

In recent years, there has been a growing concern over foodborne illnesses and contamination, leading to a surge in demand for advanced food safety technologies and solutions. The market for food safety testing and quality control measures has expanded rapidly, with a particular focus on antimicrobial agents and pH regulators like ammonium hydroxide.

The meat processing industry has been a key driver in the adoption of ammonium hydroxide as a food safety solution. Its application in reducing microbial contamination in meat products has gained traction, especially in countries with high meat consumption rates. The poultry and beef sectors have shown particular interest in this technology due to its effectiveness in controlling pathogens such as E. coli and Salmonella.

Furthermore, the dairy industry has also contributed to the increasing demand for ammonium hydroxide in food safety applications. Its use in cheese production and as a pH regulator in various dairy products has become more prevalent, driven by the need for extended shelf life and improved product quality.

The baking industry represents another significant market segment for ammonium hydroxide. Its application as a leavening agent and pH regulator in baked goods has seen steady growth, particularly in regions with a strong tradition of artisanal and industrial baking.

Geographically, North America and Europe have been at the forefront of adopting advanced food safety solutions, including ammonium hydroxide. These regions have stringent food safety regulations and a high level of consumer awareness, driving the demand for effective antimicrobial agents. The Asia-Pacific region, with its rapidly growing food processing industry and increasing focus on food safety, is expected to emerge as a key market for ammonium hydroxide and related food safety solutions in the coming years.

The COVID-19 pandemic has further accelerated the demand for food safety solutions, as consumers and regulatory bodies have become increasingly concerned about hygiene and contamination in the food supply chain. This has led to a renewed focus on effective antimicrobial agents and pH regulators in food processing, benefiting the market for ammonium hydroxide and similar solutions.

Current Status and Challenges in Ammonium Hydroxide Usage

The current status of ammonium hydroxide usage in food safety applications is characterized by both widespread adoption and growing scrutiny. As a versatile compound, ammonium hydroxide has found extensive use in various food processing operations, particularly in meat and poultry industries. Its primary function is as an antimicrobial agent, effectively reducing pathogenic bacteria levels and extending product shelf life.

In the United States, the Food and Drug Administration (FDA) has classified ammonium hydroxide as Generally Recognized as Safe (GRAS) for use in food production. This regulatory approval has facilitated its integration into numerous food processing systems. However, the European Food Safety Authority (EFSA) maintains a more cautious stance, permitting its use but with stricter guidelines and monitoring requirements.

Despite its widespread application, the use of ammonium hydroxide faces several challenges. One of the primary concerns is consumer perception. As public awareness of food additives grows, there has been increasing skepticism about the use of chemical compounds in food processing. This has led to a push for more natural and organic food preservation methods, challenging the industry to find alternatives or justify the continued use of ammonium hydroxide.

Another significant challenge lies in the potential health effects associated with long-term exposure to ammonium hydroxide. While current research indicates that the levels used in food processing are safe for consumption, there is ongoing debate about the cumulative effects of regular intake. This has prompted further studies and continuous monitoring of its usage in the food industry.

The environmental impact of ammonium hydroxide production and disposal is also a growing concern. As sustainability becomes a key focus in food production, manufacturers are under pressure to evaluate and mitigate the environmental footprint of their processes, including the use of chemical additives like ammonium hydroxide.

From a technical standpoint, ensuring consistent and controlled application of ammonium hydroxide in food processing remains a challenge. Variations in concentration and application methods can affect both efficacy and safety, necessitating robust quality control measures and standardized protocols across the industry.

Lastly, the regulatory landscape surrounding ammonium hydroxide usage is evolving. While it remains approved for use in many countries, there is a trend towards stricter regulations and increased transparency in food labeling. This shifting regulatory environment poses challenges for food manufacturers in terms of compliance and potential reformulation of products to meet new standards or consumer expectations.

In the United States, the Food and Drug Administration (FDA) has classified ammonium hydroxide as Generally Recognized as Safe (GRAS) for use in food production. This regulatory approval has facilitated its integration into numerous food processing systems. However, the European Food Safety Authority (EFSA) maintains a more cautious stance, permitting its use but with stricter guidelines and monitoring requirements.

Despite its widespread application, the use of ammonium hydroxide faces several challenges. One of the primary concerns is consumer perception. As public awareness of food additives grows, there has been increasing skepticism about the use of chemical compounds in food processing. This has led to a push for more natural and organic food preservation methods, challenging the industry to find alternatives or justify the continued use of ammonium hydroxide.

Another significant challenge lies in the potential health effects associated with long-term exposure to ammonium hydroxide. While current research indicates that the levels used in food processing are safe for consumption, there is ongoing debate about the cumulative effects of regular intake. This has prompted further studies and continuous monitoring of its usage in the food industry.

The environmental impact of ammonium hydroxide production and disposal is also a growing concern. As sustainability becomes a key focus in food production, manufacturers are under pressure to evaluate and mitigate the environmental footprint of their processes, including the use of chemical additives like ammonium hydroxide.

From a technical standpoint, ensuring consistent and controlled application of ammonium hydroxide in food processing remains a challenge. Variations in concentration and application methods can affect both efficacy and safety, necessitating robust quality control measures and standardized protocols across the industry.

Lastly, the regulatory landscape surrounding ammonium hydroxide usage is evolving. While it remains approved for use in many countries, there is a trend towards stricter regulations and increased transparency in food labeling. This shifting regulatory environment poses challenges for food manufacturers in terms of compliance and potential reformulation of products to meet new standards or consumer expectations.

Existing Applications of Ammonium Hydroxide in Food Safety

01 Use in chemical processes

Ammonium hydroxide is widely used in various chemical processes as a reactant, catalyst, or pH regulator. It plays a crucial role in the synthesis of organic compounds, production of fertilizers, and treatment of industrial waste. Its alkaline properties make it useful for neutralizing acids and controlling pH levels in different applications.- Use in chemical processes: Ammonium hydroxide is widely used in various chemical processes as a reactant, catalyst, or pH regulator. It plays a crucial role in the production of different compounds and materials, including polymers, pharmaceuticals, and industrial chemicals. Its alkaline properties make it useful for neutralization reactions and as a cleaning agent in industrial applications.

- Application in wastewater treatment: Ammonium hydroxide is utilized in wastewater treatment processes for pH adjustment and nitrogen removal. It can help neutralize acidic effluents and promote the growth of beneficial bacteria in biological treatment systems. Additionally, it can be used in the precipitation of heavy metals from industrial wastewater.

- Role in agricultural and fertilizer production: Ammonium hydroxide serves as a key component in the production of various fertilizers and agricultural chemicals. It provides a source of nitrogen for plant growth and can be used to adjust soil pH. In some formulations, it is combined with other nutrients to create balanced fertilizer blends for different crop requirements.

- Use in cleaning and surface treatment: Ammonium hydroxide is employed in cleaning formulations and surface treatment processes. Its alkaline nature makes it effective for removing grease, oils, and other contaminants from various surfaces. It is also used in the etching and cleaning of electronic components and in the treatment of textiles and leather products.

- Application in personal care and cosmetic products: Ammonium hydroxide finds applications in personal care and cosmetic products. It is used as a pH adjuster in hair dyes, skin care formulations, and other beauty products. Its ability to modify the pH of formulations helps in achieving desired product characteristics and stability.

02 Application in cleaning and surface treatment

Ammonium hydroxide is utilized in cleaning formulations and surface treatment processes. It is effective in removing grease, oils, and other contaminants from various surfaces. In the semiconductor industry, it is used for etching and cleaning silicon wafers. Its ability to dissolve certain metals and oxides makes it valuable in metal surface treatment and electroplating applications.Expand Specific Solutions03 Role in textile and leather processing

Ammonium hydroxide finds applications in the textile and leather industries. It is used in dyeing processes to adjust pH levels and improve color fastness. In leather processing, it helps in dehairing hides and skins, and in adjusting the pH during tanning. Its alkaline nature aids in breaking down proteins and fats in these materials.Expand Specific Solutions04 Environmental and agricultural uses

In environmental applications, ammonium hydroxide is used for flue gas treatment to reduce nitrogen oxide emissions. In agriculture, it serves as a source of nitrogen in fertilizers and can be used to adjust soil pH. It also plays a role in the production of certain pesticides and herbicides, contributing to crop protection and yield improvement.Expand Specific Solutions05 Use in personal care and pharmaceutical products

Ammonium hydroxide is utilized in various personal care and pharmaceutical formulations. In cosmetics, it can be found in hair dyes and perming solutions. In pharmaceuticals, it is used as a pH adjuster and in the synthesis of certain drugs. Its ability to neutralize acids and maintain specific pH levels makes it valuable in these applications.Expand Specific Solutions

Key Players in Food Safety Chemical Industry

The comparative analysis of ammonium hydroxide in food safety applications reveals a competitive landscape characterized by a mature market with established players and ongoing innovation. The industry is in a growth phase, driven by increasing food safety regulations and consumer demand for safer products. The global market size for food-grade ammonium hydroxide is estimated to be in the hundreds of millions of dollars, with steady growth projected. Technologically, the field is moderately mature, with companies like Cargill, Frito-Lay, and Ajinomoto leading in application development. These firms are investing in research to enhance the efficacy and safety of ammonium hydroxide usage, while also exploring alternative solutions to address evolving consumer preferences for natural ingredients.

Cargill, Inc.

Technical Solution: Cargill has developed an innovative approach to using ammonium hydroxide in food safety applications, particularly in meat processing. Their patented system involves applying a fine mist of ammonium hydroxide to beef trimmings, effectively reducing harmful bacteria such as E. coli O157:H7 by up to 99.9%[1]. This process, known as "pH enhancement," works by slightly raising the pH of the meat, creating an environment inhospitable to pathogenic bacteria. Cargill's method is carefully controlled to ensure that the treated meat maintains its natural flavor and nutritional profile while significantly improving its safety profile[2]. The company has also invested in advanced monitoring systems to ensure precise application and consistent quality control throughout the treatment process.

Strengths: Highly effective in reducing harmful bacteria; maintains product quality and flavor; scalable for large-scale meat processing. Weaknesses: Public perception concerns about chemical use in food; potential for overuse if not carefully monitored.

Ecolab USA, Inc.

Technical Solution: Ecolab has developed a comprehensive food safety solution that incorporates ammonium hydroxide as part of a multi-faceted approach. Their system, known as the "Antimicrobial Intervention Program," utilizes a combination of chemical treatments, including ammonium hydroxide, in conjunction with advanced application technologies and data-driven monitoring[3]. Ecolab's method involves precise application of ammonium hydroxide solutions at critical control points in food processing, particularly in poultry and produce handling. The company has engineered specialized spray systems that ensure uniform coverage and optimal concentration, maximizing antimicrobial efficacy while minimizing chemical usage[4]. Additionally, Ecolab has integrated real-time monitoring and IoT-enabled sensors to continuously assess and adjust treatment parameters, ensuring consistent food safety outcomes across various processing environments.

Strengths: Comprehensive approach combining chemical and technological solutions; adaptable to various food processing scenarios; data-driven optimization. Weaknesses: Higher initial implementation costs; requires staff training for optimal use.

Core Innovations in Ammonium Hydroxide Formulations

No rinse quaternary ammonium disinfectant composition for food contact surfaces

PatentWO2023076669A1

Innovation

- A disinfecting and sanitizing composition comprising between 10 ppm to 1000 ppm of an antimicrobial quaternary ammonium compound in combination with an acid source, maintaining a pH of less than 6, which enhances sanitizing efficacy at lower concentrations and allows for no-rinse disinfection on food contact surfaces, even at low temperatures.

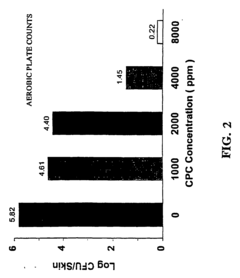

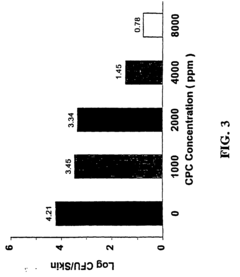

Broad spectrum prevention and removal of microbial contamination of food by quaternary ammonium compounds

PatentInactiveEP1595457A2

Innovation

- The use of quaternary ammonium compounds (QACs), specifically cetylpyridinium chloride (CPC), in an aqueous solution or formulation with solubility enhancing agents, is applied to food products to inhibit attachment, remove, and kill microorganisms, including pathogens like E. coli O157:H7 and Salmonella, through spraying or immersion, with contact times as short as 20 seconds to 90 seconds.

Regulatory Framework for Food Safety Chemicals

The regulatory framework for food safety chemicals is a complex and evolving system designed to protect public health and ensure the safety of food products. In the context of ammonium hydroxide use in food safety applications, several key regulatory bodies and guidelines play crucial roles.

The United States Food and Drug Administration (FDA) is a primary authority in regulating food safety chemicals. Under the Federal Food, Drug, and Cosmetic Act, ammonium hydroxide is classified as a Generally Recognized as Safe (GRAS) substance when used in accordance with good manufacturing practices. The FDA has established specific guidelines for its use in food processing, including maximum allowable concentrations and appropriate applications.

Internationally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides global standards for food additives and processing aids. These standards influence national regulations and facilitate international trade while ensuring food safety.

The European Food Safety Authority (EFSA) oversees food safety regulations within the European Union. EFSA has conducted risk assessments on ammonium hydroxide and established guidelines for its use in food processing. These regulations may differ from those in the United States, reflecting regional variations in risk assessment and management approaches.

Regulatory frameworks also address labeling requirements for foods treated with ammonium hydroxide. In many jurisdictions, manufacturers must disclose the use of ammonium hydroxide on product labels, ensuring transparency for consumers.

Environmental protection agencies, such as the U.S. Environmental Protection Agency (EPA), regulate the broader impacts of food safety chemicals. This includes guidelines for handling, storage, and disposal of ammonium hydroxide to minimize environmental risks.

Occupational safety regulations, enforced by agencies like the Occupational Safety and Health Administration (OSHA) in the United States, govern the safe use of ammonium hydroxide in food processing facilities. These regulations cover worker exposure limits, safety equipment requirements, and emergency response procedures.

As scientific understanding evolves, regulatory frameworks are periodically updated. Recent trends include increased scrutiny of chemical additives, emphasis on natural alternatives, and harmonization of international standards to facilitate global trade while maintaining stringent safety measures.

The United States Food and Drug Administration (FDA) is a primary authority in regulating food safety chemicals. Under the Federal Food, Drug, and Cosmetic Act, ammonium hydroxide is classified as a Generally Recognized as Safe (GRAS) substance when used in accordance with good manufacturing practices. The FDA has established specific guidelines for its use in food processing, including maximum allowable concentrations and appropriate applications.

Internationally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides global standards for food additives and processing aids. These standards influence national regulations and facilitate international trade while ensuring food safety.

The European Food Safety Authority (EFSA) oversees food safety regulations within the European Union. EFSA has conducted risk assessments on ammonium hydroxide and established guidelines for its use in food processing. These regulations may differ from those in the United States, reflecting regional variations in risk assessment and management approaches.

Regulatory frameworks also address labeling requirements for foods treated with ammonium hydroxide. In many jurisdictions, manufacturers must disclose the use of ammonium hydroxide on product labels, ensuring transparency for consumers.

Environmental protection agencies, such as the U.S. Environmental Protection Agency (EPA), regulate the broader impacts of food safety chemicals. This includes guidelines for handling, storage, and disposal of ammonium hydroxide to minimize environmental risks.

Occupational safety regulations, enforced by agencies like the Occupational Safety and Health Administration (OSHA) in the United States, govern the safe use of ammonium hydroxide in food processing facilities. These regulations cover worker exposure limits, safety equipment requirements, and emergency response procedures.

As scientific understanding evolves, regulatory frameworks are periodically updated. Recent trends include increased scrutiny of chemical additives, emphasis on natural alternatives, and harmonization of international standards to facilitate global trade while maintaining stringent safety measures.

Environmental Impact of Ammonium Hydroxide Use

The use of ammonium hydroxide in food safety applications has significant environmental implications that warrant careful consideration. While its effectiveness in controlling microbial contamination and extending shelf life is well-documented, the potential environmental impacts of its widespread use cannot be overlooked.

One of the primary environmental concerns associated with ammonium hydroxide is its contribution to air pollution. When used in food processing facilities, ammonium hydroxide can release ammonia gas into the atmosphere. Ammonia is a known air pollutant that can contribute to the formation of particulate matter and react with other pollutants to form harmful secondary compounds. These emissions can have adverse effects on local air quality and potentially contribute to regional air pollution issues.

Water pollution is another significant environmental concern. Improper disposal or accidental release of ammonium hydroxide into water systems can lead to increased ammonia levels in aquatic environments. This can result in eutrophication, a process where excess nutrients promote algal blooms, deplete oxygen levels, and disrupt aquatic ecosystems. The impact on fish and other aquatic organisms can be severe, potentially leading to fish kills and long-term ecological damage.

The production and transportation of ammonium hydroxide also contribute to its environmental footprint. The manufacturing process typically involves the reaction of ammonia with water, which requires energy and resources. Additionally, the transportation of this chemical to food processing facilities generates greenhouse gas emissions, further contributing to climate change concerns.

Soil contamination is another potential environmental risk associated with ammonium hydroxide use. Accidental spills or improper disposal practices can lead to soil alkalinization, affecting soil chemistry and potentially impacting plant growth and soil microbial communities. This can have long-term consequences for soil health and agricultural productivity in affected areas.

It is important to note that the environmental impact of ammonium hydroxide can be mitigated through proper handling, storage, and disposal practices. Many food processing facilities have implemented strict protocols to minimize environmental risks, including closed-loop systems for ammonia recovery and treatment of wastewater before discharge.

Regulatory bodies have also recognized the potential environmental hazards associated with ammonium hydroxide and have implemented guidelines for its use and disposal. Compliance with these regulations is crucial for minimizing negative environmental impacts while maintaining the benefits of its use in food safety applications.

As the food industry continues to prioritize sustainability, there is growing interest in developing alternative antimicrobial treatments that offer similar efficacy with reduced environmental impact. Research into natural antimicrobials, physical decontamination methods, and other innovative approaches may provide more environmentally friendly solutions for ensuring food safety in the future.

One of the primary environmental concerns associated with ammonium hydroxide is its contribution to air pollution. When used in food processing facilities, ammonium hydroxide can release ammonia gas into the atmosphere. Ammonia is a known air pollutant that can contribute to the formation of particulate matter and react with other pollutants to form harmful secondary compounds. These emissions can have adverse effects on local air quality and potentially contribute to regional air pollution issues.

Water pollution is another significant environmental concern. Improper disposal or accidental release of ammonium hydroxide into water systems can lead to increased ammonia levels in aquatic environments. This can result in eutrophication, a process where excess nutrients promote algal blooms, deplete oxygen levels, and disrupt aquatic ecosystems. The impact on fish and other aquatic organisms can be severe, potentially leading to fish kills and long-term ecological damage.

The production and transportation of ammonium hydroxide also contribute to its environmental footprint. The manufacturing process typically involves the reaction of ammonia with water, which requires energy and resources. Additionally, the transportation of this chemical to food processing facilities generates greenhouse gas emissions, further contributing to climate change concerns.

Soil contamination is another potential environmental risk associated with ammonium hydroxide use. Accidental spills or improper disposal practices can lead to soil alkalinization, affecting soil chemistry and potentially impacting plant growth and soil microbial communities. This can have long-term consequences for soil health and agricultural productivity in affected areas.

It is important to note that the environmental impact of ammonium hydroxide can be mitigated through proper handling, storage, and disposal practices. Many food processing facilities have implemented strict protocols to minimize environmental risks, including closed-loop systems for ammonia recovery and treatment of wastewater before discharge.

Regulatory bodies have also recognized the potential environmental hazards associated with ammonium hydroxide and have implemented guidelines for its use and disposal. Compliance with these regulations is crucial for minimizing negative environmental impacts while maintaining the benefits of its use in food safety applications.

As the food industry continues to prioritize sustainability, there is growing interest in developing alternative antimicrobial treatments that offer similar efficacy with reduced environmental impact. Research into natural antimicrobials, physical decontamination methods, and other innovative approaches may provide more environmentally friendly solutions for ensuring food safety in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!