GC-MS vs High-Performance Thin Layer Chromatography

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Analytical Techniques Background and Objectives

Analytical techniques have evolved significantly over the past century, with chromatography emerging as one of the most powerful methods for separating and analyzing complex mixtures. Gas Chromatography-Mass Spectrometry (GC-MS) and High-Performance Thin Layer Chromatography (HPTLC) represent two distinct approaches that have gained prominence in various analytical fields, including pharmaceutical analysis, environmental monitoring, food safety, and forensic science.

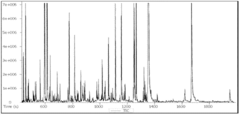

GC-MS combines the separation capabilities of gas chromatography with the detection specificity of mass spectrometry, creating a powerful tool for identifying and quantifying volatile and semi-volatile compounds. Since its commercial introduction in the 1950s, GC-MS has undergone substantial technological advancements, particularly in terms of column technology, ionization methods, and data processing capabilities. The evolution from packed columns to capillary columns significantly enhanced separation efficiency, while developments in mass analyzers improved detection limits and compound identification accuracy.

HPTLC, on the other hand, represents the modern refinement of traditional thin-layer chromatography. Emerging in the 1970s, HPTLC offers advantages in terms of smaller particle size, more uniform layer thickness, and automated sample application and detection systems. These improvements have transformed a once primarily qualitative technique into a robust quantitative analytical method with applications across multiple industries.

The technological trajectory for both techniques shows a clear trend toward increased automation, improved sensitivity, and enhanced data processing capabilities. GC-MS systems have evolved from large, complex instruments requiring specialized operators to more user-friendly benchtop systems with sophisticated software interfaces. Similarly, HPTLC has progressed from manual plate development to fully automated systems with digital imaging and analysis capabilities.

The primary objective of this comparative analysis is to evaluate the relative strengths, limitations, and complementary aspects of GC-MS and HPTLC techniques across different analytical applications. We aim to assess factors including sensitivity, selectivity, sample throughput, cost-effectiveness, ease of use, and applicability to various sample matrices. Additionally, we seek to identify emerging trends and innovations in both technologies that may influence their future adoption and application.

Understanding the fundamental principles, historical development, and current capabilities of these techniques provides essential context for evaluating their respective roles in modern analytical laboratories. This analysis will serve as a foundation for subsequent sections examining market demands, technical challenges, and potential innovation pathways for both GC-MS and HPTLC methodologies.

GC-MS combines the separation capabilities of gas chromatography with the detection specificity of mass spectrometry, creating a powerful tool for identifying and quantifying volatile and semi-volatile compounds. Since its commercial introduction in the 1950s, GC-MS has undergone substantial technological advancements, particularly in terms of column technology, ionization methods, and data processing capabilities. The evolution from packed columns to capillary columns significantly enhanced separation efficiency, while developments in mass analyzers improved detection limits and compound identification accuracy.

HPTLC, on the other hand, represents the modern refinement of traditional thin-layer chromatography. Emerging in the 1970s, HPTLC offers advantages in terms of smaller particle size, more uniform layer thickness, and automated sample application and detection systems. These improvements have transformed a once primarily qualitative technique into a robust quantitative analytical method with applications across multiple industries.

The technological trajectory for both techniques shows a clear trend toward increased automation, improved sensitivity, and enhanced data processing capabilities. GC-MS systems have evolved from large, complex instruments requiring specialized operators to more user-friendly benchtop systems with sophisticated software interfaces. Similarly, HPTLC has progressed from manual plate development to fully automated systems with digital imaging and analysis capabilities.

The primary objective of this comparative analysis is to evaluate the relative strengths, limitations, and complementary aspects of GC-MS and HPTLC techniques across different analytical applications. We aim to assess factors including sensitivity, selectivity, sample throughput, cost-effectiveness, ease of use, and applicability to various sample matrices. Additionally, we seek to identify emerging trends and innovations in both technologies that may influence their future adoption and application.

Understanding the fundamental principles, historical development, and current capabilities of these techniques provides essential context for evaluating their respective roles in modern analytical laboratories. This analysis will serve as a foundation for subsequent sections examining market demands, technical challenges, and potential innovation pathways for both GC-MS and HPTLC methodologies.

Market Applications and Demand Analysis

The analytical instrumentation market has witnessed significant growth in recent years, with GC-MS and High-Performance Thin Layer Chromatography (HPTLC) technologies playing crucial roles across various industries. The global analytical instrumentation market was valued at approximately 85 billion USD in 2022, with chromatography techniques accounting for nearly 30% of this market share.

The pharmaceutical industry represents the largest application segment for both GC-MS and HPTLC technologies. With increasing regulatory requirements for drug safety and quality control, pharmaceutical companies are investing heavily in advanced analytical techniques. The pharmaceutical analytical testing outsourcing market is growing at a compound annual growth rate of 8.3% through 2028, creating substantial demand for both technologies.

Food safety testing constitutes another major market driver, particularly in developed regions where regulatory frameworks are stringent. The global food safety testing market size exceeded 21 billion USD in 2022, with chromatography-based methods being preferred for detecting contaminants, pesticides, and adulterants. GC-MS holds a dominant position in this segment due to its superior sensitivity for volatile compounds.

Environmental monitoring applications have expanded considerably, driven by increasing public awareness and governmental regulations regarding pollution control. Water quality testing, air pollution monitoring, and soil contamination analysis collectively generate substantial demand for analytical technologies. GC-MS systems are particularly valued in this sector for their ability to detect trace amounts of environmental pollutants.

The forensic science sector represents a specialized but growing market for both technologies. Law enforcement agencies worldwide are upgrading their analytical capabilities, with GC-MS being the gold standard for toxicology screening and drug analysis. HPTLC finds applications in document examination and certain types of drug analysis where visual representation offers advantages.

Academic and research institutions constitute a stable market segment, with universities and research centers regularly upgrading their analytical capabilities. This sector values versatility and cost-effectiveness, often making HPTLC an attractive option for educational purposes and preliminary research.

Regional market analysis reveals that North America and Europe currently dominate the market for advanced analytical technologies, while Asia-Pacific represents the fastest-growing region. China and India are emerging as significant markets due to their expanding pharmaceutical industries, increasing environmental concerns, and growing food safety regulations.

The market is witnessing a shift toward integrated systems that offer higher automation, reduced analysis time, and improved data management capabilities. This trend favors GC-MS systems, which have seen more rapid technological advancement in terms of automation and software integration compared to HPTLC.

The pharmaceutical industry represents the largest application segment for both GC-MS and HPTLC technologies. With increasing regulatory requirements for drug safety and quality control, pharmaceutical companies are investing heavily in advanced analytical techniques. The pharmaceutical analytical testing outsourcing market is growing at a compound annual growth rate of 8.3% through 2028, creating substantial demand for both technologies.

Food safety testing constitutes another major market driver, particularly in developed regions where regulatory frameworks are stringent. The global food safety testing market size exceeded 21 billion USD in 2022, with chromatography-based methods being preferred for detecting contaminants, pesticides, and adulterants. GC-MS holds a dominant position in this segment due to its superior sensitivity for volatile compounds.

Environmental monitoring applications have expanded considerably, driven by increasing public awareness and governmental regulations regarding pollution control. Water quality testing, air pollution monitoring, and soil contamination analysis collectively generate substantial demand for analytical technologies. GC-MS systems are particularly valued in this sector for their ability to detect trace amounts of environmental pollutants.

The forensic science sector represents a specialized but growing market for both technologies. Law enforcement agencies worldwide are upgrading their analytical capabilities, with GC-MS being the gold standard for toxicology screening and drug analysis. HPTLC finds applications in document examination and certain types of drug analysis where visual representation offers advantages.

Academic and research institutions constitute a stable market segment, with universities and research centers regularly upgrading their analytical capabilities. This sector values versatility and cost-effectiveness, often making HPTLC an attractive option for educational purposes and preliminary research.

Regional market analysis reveals that North America and Europe currently dominate the market for advanced analytical technologies, while Asia-Pacific represents the fastest-growing region. China and India are emerging as significant markets due to their expanding pharmaceutical industries, increasing environmental concerns, and growing food safety regulations.

The market is witnessing a shift toward integrated systems that offer higher automation, reduced analysis time, and improved data management capabilities. This trend favors GC-MS systems, which have seen more rapid technological advancement in terms of automation and software integration compared to HPTLC.

Current Status and Technical Challenges

Gas Chromatography-Mass Spectrometry (GC-MS) and High-Performance Thin Layer Chromatography (HPTLC) represent two distinct analytical approaches with varying levels of adoption and technical maturity across global markets. GC-MS has achieved widespread implementation in advanced analytical laboratories worldwide, with North America and Europe leading in both instrument development and application sophistication. The Asia-Pacific region, particularly China and Japan, has demonstrated rapid adoption rates in recent years, primarily driven by expanding pharmaceutical and environmental monitoring sectors.

HPTLC, while less automated than GC-MS, maintains significant relevance in pharmaceutical quality control, herbal medicine analysis, and food safety applications. Its prominence remains particularly strong in regions with developing laboratory infrastructure, including parts of South Asia, Africa, and South America, where its lower operational costs and simpler maintenance requirements provide distinct advantages.

The primary technical challenges facing GC-MS technology include sample preparation complexity, particularly for biological matrices, which often requires extensive extraction and derivatization procedures. Additionally, the analysis of thermally labile compounds remains problematic due to the high temperatures inherent to the gas chromatography process. Instrument miniaturization efforts continue but face significant engineering hurdles related to vacuum system requirements and detector sensitivity at reduced scales.

For HPTLC, standardization across laboratories represents a persistent challenge, with variations in plate quality, mobile phase composition, and development conditions contributing to reproducibility issues. Quantification accuracy lags behind that of GC-MS, particularly for trace analysis applications. The technique also faces limitations in automation capability, though recent advancements in computer-controlled development chambers and digital imaging systems have partially addressed this constraint.

Both technologies confront challenges related to big data management and integration with artificial intelligence platforms. The volume of spectral and chromatographic data generated by modern GC-MS systems has outpaced the development of user-friendly interpretation tools, creating bottlenecks in data analysis workflows. Similarly, HPTLC image analysis and pattern recognition capabilities require further refinement to fully leverage the visual data generated by this technique.

Regulatory considerations increasingly influence the technical development trajectory of both methods. Enhanced detection limits for emerging contaminants, improved validation protocols, and greater emphasis on method transferability between laboratories represent common themes across international regulatory frameworks that impact both technologies.

HPTLC, while less automated than GC-MS, maintains significant relevance in pharmaceutical quality control, herbal medicine analysis, and food safety applications. Its prominence remains particularly strong in regions with developing laboratory infrastructure, including parts of South Asia, Africa, and South America, where its lower operational costs and simpler maintenance requirements provide distinct advantages.

The primary technical challenges facing GC-MS technology include sample preparation complexity, particularly for biological matrices, which often requires extensive extraction and derivatization procedures. Additionally, the analysis of thermally labile compounds remains problematic due to the high temperatures inherent to the gas chromatography process. Instrument miniaturization efforts continue but face significant engineering hurdles related to vacuum system requirements and detector sensitivity at reduced scales.

For HPTLC, standardization across laboratories represents a persistent challenge, with variations in plate quality, mobile phase composition, and development conditions contributing to reproducibility issues. Quantification accuracy lags behind that of GC-MS, particularly for trace analysis applications. The technique also faces limitations in automation capability, though recent advancements in computer-controlled development chambers and digital imaging systems have partially addressed this constraint.

Both technologies confront challenges related to big data management and integration with artificial intelligence platforms. The volume of spectral and chromatographic data generated by modern GC-MS systems has outpaced the development of user-friendly interpretation tools, creating bottlenecks in data analysis workflows. Similarly, HPTLC image analysis and pattern recognition capabilities require further refinement to fully leverage the visual data generated by this technique.

Regulatory considerations increasingly influence the technical development trajectory of both methods. Enhanced detection limits for emerging contaminants, improved validation protocols, and greater emphasis on method transferability between laboratories represent common themes across international regulatory frameworks that impact both technologies.

Comparative Methodology Approaches

01 Combined use of GC-MS and HPTLC for analytical applications

The integration of Gas Chromatography-Mass Spectrometry (GC-MS) and High-Performance Thin Layer Chromatography (HPTLC) provides complementary analytical capabilities for comprehensive sample analysis. GC-MS offers high sensitivity and specificity for volatile compounds, while HPTLC provides rapid, cost-effective separation for a wide range of compounds. This combination is particularly valuable for complex sample matrices where multiple analytical techniques are needed for complete characterization.- Analytical methods combining GC-MS and HPTLC for compound identification: The combination of Gas Chromatography-Mass Spectrometry (GC-MS) and High-Performance Thin Layer Chromatography (HPTLC) provides complementary analytical capabilities for comprehensive compound identification. GC-MS offers high sensitivity and specificity for volatile compounds, while HPTLC provides rapid visual results for a wide range of compounds. Together, these techniques enable more accurate identification and quantification of complex mixtures in various samples.

- Applications in pharmaceutical analysis and quality control: GC-MS and HPTLC are widely used in pharmaceutical analysis for quality control, stability testing, and impurity profiling. These techniques help in authenticating drug substances, detecting adulterants, and ensuring compliance with regulatory standards. The combination allows for both qualitative and quantitative analysis of active pharmaceutical ingredients and excipients, providing comprehensive data for pharmaceutical development and manufacturing.

- Natural product and herbal medicine analysis: For natural products and herbal medicines, GC-MS and HPTLC offer powerful tools for chemical fingerprinting and standardization. These techniques help identify bioactive compounds, authenticate herbal materials, and ensure batch-to-batch consistency. The visual nature of HPTLC combined with the molecular specificity of GC-MS enables researchers to characterize complex plant extracts and develop quality standards for traditional medicines.

- Method development and validation protocols: Specific protocols for method development and validation when using GC-MS and HPTLC in combination have been established. These include optimization of mobile phases, stationary phases, detection parameters, and sample preparation techniques. Validation parameters such as specificity, linearity, accuracy, precision, and robustness are assessed to ensure reliable and reproducible results across different laboratories and analytical conditions.

- Instrumentation and technological advancements: Recent technological advancements have improved the integration of GC-MS and HPTLC systems, enhancing their analytical capabilities. These include automated sample application, digital imaging systems for HPTLC, advanced mass detectors, and software solutions for data integration. Modern instruments offer higher resolution, better sensitivity, and more efficient workflows, allowing for faster analysis and more reliable results in various applications.

02 HPTLC and GC-MS for natural product analysis

High-Performance Thin Layer Chromatography and Gas Chromatography-Mass Spectrometry are widely employed for the analysis of natural products, including plant extracts, traditional medicines, and biological samples. HPTLC provides visual fingerprinting and semi-quantitative analysis, while GC-MS enables detailed structural identification of compounds. This combination allows for comprehensive profiling of complex natural mixtures, identification of bioactive compounds, and quality control of herbal products.Expand Specific Solutions03 Instrumentation and method development for combined chromatographic techniques

Specialized instrumentation and methodologies have been developed to enhance the capabilities of both GC-MS and HPTLC techniques. These developments include automated sample preparation systems, advanced detection methods, and integrated data analysis platforms. Innovations in column technology, mobile phase optimization, and derivatization techniques have improved separation efficiency and detection sensitivity. Method validation protocols ensure reliability and reproducibility of results across both analytical platforms.Expand Specific Solutions04 Applications in pharmaceutical analysis and quality control

GC-MS and HPTLC are extensively used in pharmaceutical analysis for drug development, quality control, and stability testing. These techniques enable identification and quantification of active pharmaceutical ingredients, detection of impurities, and monitoring of degradation products. The complementary nature of these methods provides comprehensive analytical data for regulatory submissions and ensures compliance with pharmacopoeial standards. They are particularly valuable for analyzing complex formulations and detecting counterfeit medications.Expand Specific Solutions05 Environmental and forensic applications of chromatographic techniques

GC-MS and HPTLC are powerful tools for environmental monitoring and forensic investigations. These techniques are used to detect and quantify pollutants, pesticides, and toxic substances in environmental samples. In forensic science, they help identify illicit drugs, explosives, and other evidence materials. The combination of these methods provides both screening capabilities and confirmatory analysis, essential for legal proceedings and environmental compliance monitoring.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The comparative analysis of GC-MS vs High-Performance Thin Layer Chromatography techniques reveals a mature analytical instrumentation market dominated by established players like Agilent Technologies, Waters Technology, Thermo Finnigan, and Shimadzu Corporation. The market is in a consolidation phase with an estimated global value of $5-7 billion for chromatography equipment. While GC-MS technology has reached higher technological maturity with widespread adoption in pharmaceutical, environmental, and forensic applications, HPTLC continues to evolve with innovations in automation and detection sensitivity. Academic institutions like Peking University and research organizations such as CNRS contribute significantly to method development, while companies like Seer and PureHoney Technologies represent emerging players focusing on specialized applications and technological improvements in these complementary analytical techniques.

Waters Technology Corp.

Technical Solution: Waters Technology Corporation has developed sophisticated analytical solutions for both GC-MS and HPTLC techniques. Their GC-MS systems feature innovative QuanTof technology that delivers high-resolution accurate mass data with sensitivity in the femtogram range. Their Atmospheric Pressure GC (APGC) ionization source bridges traditional GC-MS with LC-MS capabilities, expanding the range of analyzable compounds. For HPTLC applications, Waters has developed the ACQUITY QDa Mass Detector that can be coupled with HPTLC plates, creating a hybrid approach that combines the visual separation advantages of HPTLC with mass spectral confirmation. Their comparative studies demonstrate that while GC-MS provides superior detection limits (typically 10-100x lower than HPTLC) and better compound specificity through mass spectral data, their optimized HPTLC workflows offer significantly faster analysis times (approximately 75% reduction) and the ability to process multiple samples simultaneously. Waters' integrated informatics platform, Empower, allows laboratories to manage and compare data from both techniques, facilitating method selection based on specific analytical requirements.

Strengths: Innovative hybrid approaches combining aspects of both technologies; high-resolution accurate mass capabilities; comprehensive software integration; strong application development support. Weaknesses: Complex systems require specialized training; higher initial investment costs; maintenance requirements can be significant; HPTLC-MS integration still evolving compared to standalone techniques.

Thermo Finnigan Corp.

Technical Solution: Thermo Finnigan (now part of Thermo Fisher Scientific) has developed industry-leading GC-MS technology with their TSQ series featuring Advanced Electron Ionization Source (AEI) that delivers up to 3x greater sensitivity than conventional sources. Their proprietary ExtractaBrite ion source design significantly reduces maintenance requirements while maintaining performance over extended operation periods. For comparative analysis with HPTLC, Thermo has conducted extensive research demonstrating that their GC-MS systems provide superior specificity through high-resolution accurate mass capabilities (resolving power >60,000 FWHM), enabling confident identification of compounds in complex matrices that would be challenging with HPTLC alone. Their studies show GC-MS excels in quantitative precision (typically <5% RSD versus 10-15% for HPTLC) and detection limits (typically 100-1000x lower than HPTLC), while acknowledging HPTLC advantages in sample throughput and minimal sample preparation requirements. Thermo's integrated software platforms enable laboratories to leverage both techniques complementarily, with their mass spectral libraries containing over 1 million compounds facilitating identification across both platforms.

Strengths: Industry-leading mass accuracy and resolution; robust ion source design requiring less maintenance; extensive compound libraries for identification; comprehensive software integration. Weaknesses: Higher operational costs compared to HPTLC; longer analysis times for complex samples; steeper learning curve for operators; limited parallel processing capabilities compared to HPTLC.

Key Technical Innovations and Patents

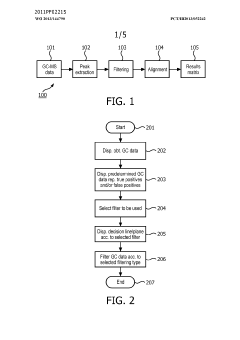

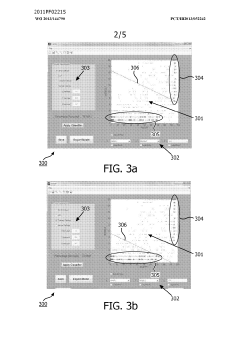

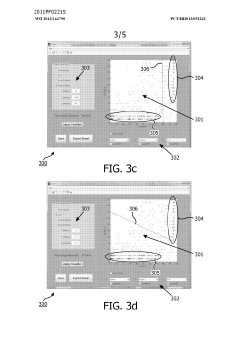

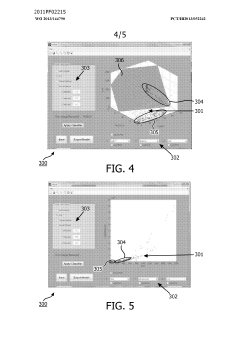

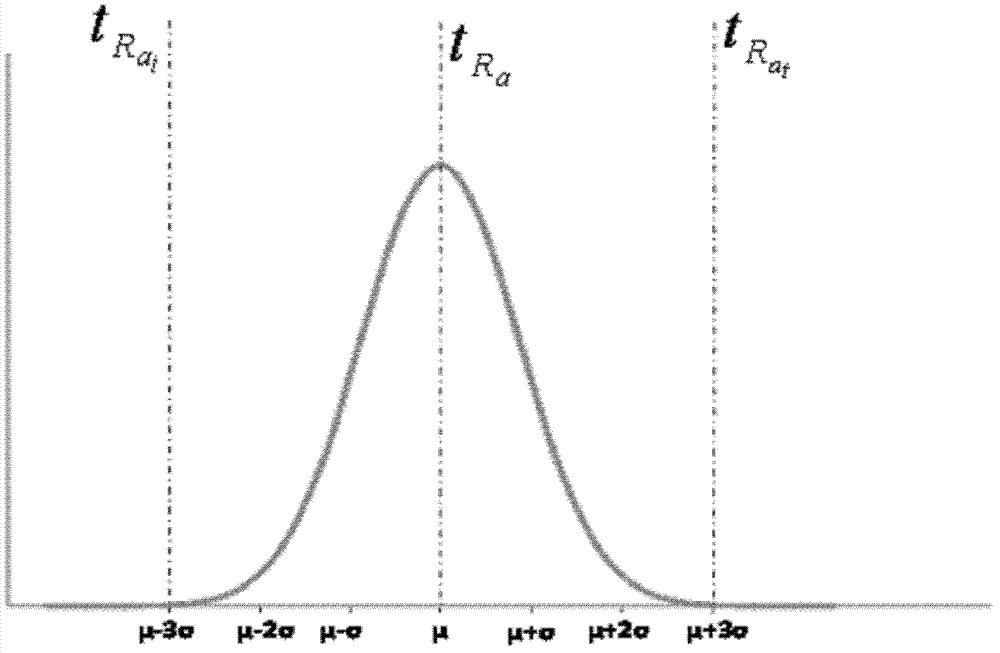

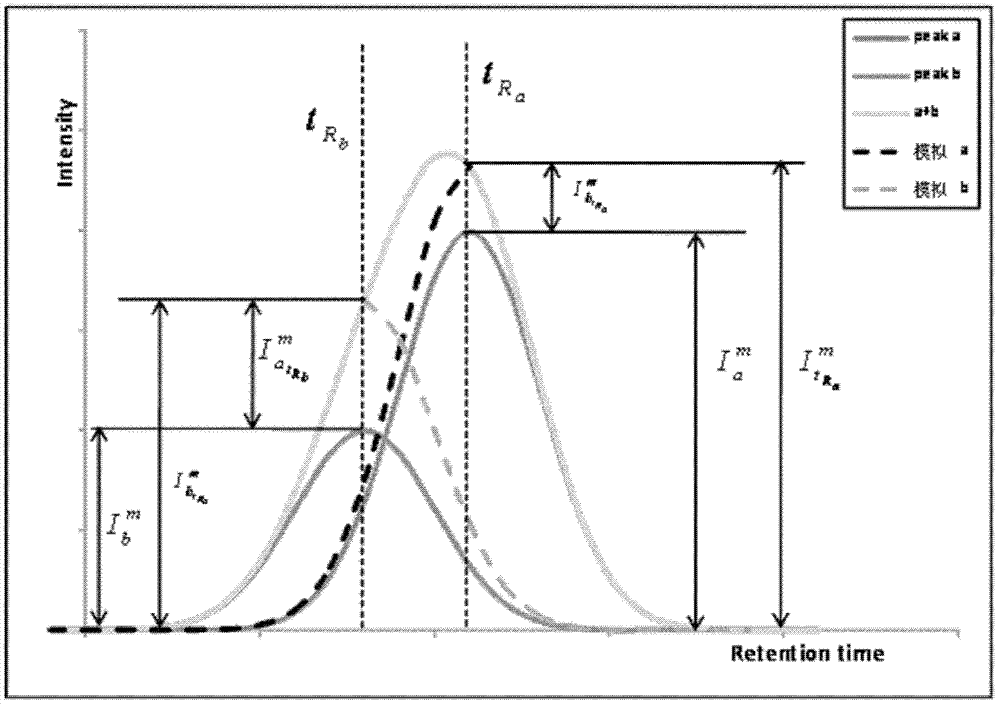

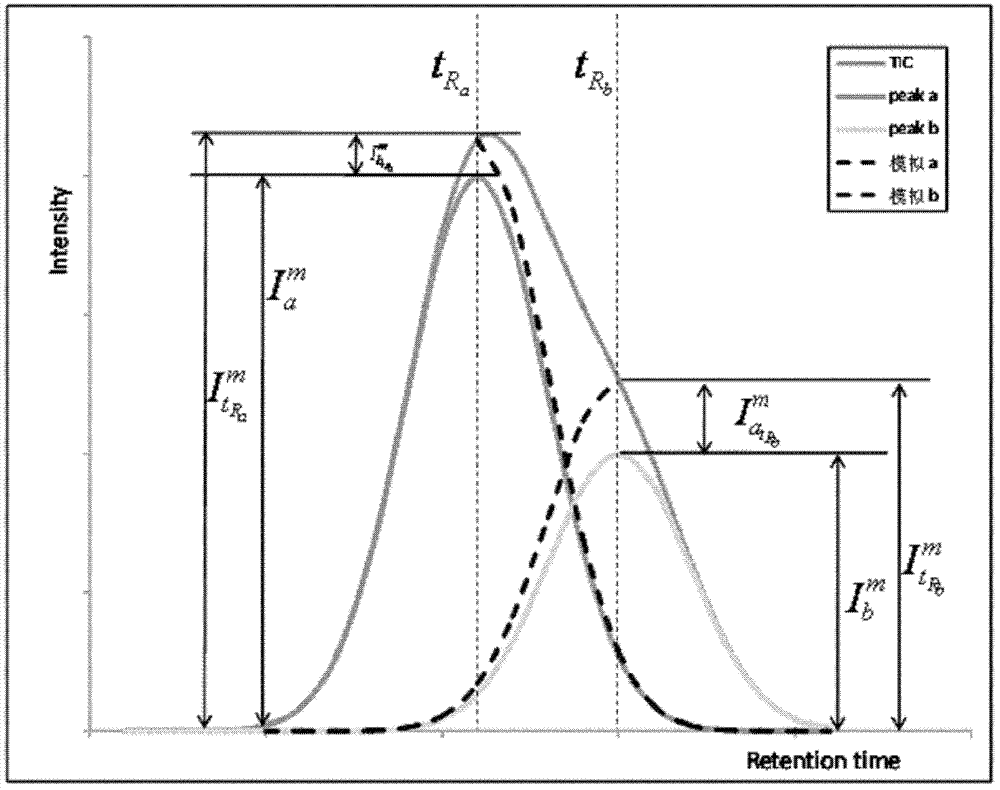

Method and system for filtering gas chromatography-mass spectrometry data

PatentWO2013144790A1

Innovation

- A method and system for filtering GC-MS data that distinguishes between true and false positives, allowing users to visually select filtering methods based on predetermined data structures and decision lines or planes, reducing data noise and improving processing efficiency.

A Universal Quantitative Analysis Method for All Components by Gas Chromatography-Mass Spectrometry

PatentInactiveCN102798683B

Innovation

- Using a full-component quantitative analysis method based on gas chromatography-mass spectrometry, AMDIS software is used to identify and group peaks on the GC-MS full scan data, calculate the characteristic values of the chromatographic peaks to screen out characteristic ions, and use them for selected ion scanning Quantitative analysis, suitable for data from different GC-MS instruments.

Cost-Benefit Analysis of Implementation

Implementing either GC-MS or High-Performance Thin Layer Chromatography (HPTLC) requires careful consideration of both initial investment and long-term operational costs against expected benefits. This cost-benefit analysis provides a comprehensive evaluation to guide decision-making processes.

Initial capital expenditure represents the most significant cost difference between these technologies. GC-MS systems typically range from $50,000 to $150,000 for standard configurations, with high-end models exceeding $300,000. In contrast, HPTLC equipment requires substantially lower initial investment, generally between $15,000 and $40,000 for a complete system including visualization components.

Operational expenses also differ markedly. GC-MS demands higher maintenance costs, approximately $5,000-$10,000 annually, including specialized service contracts and replacement parts for sensitive components like mass spectrometer filaments. HPTLC maintenance costs are considerably lower, typically $1,000-$3,000 annually, primarily for lamp replacements and general upkeep.

Consumable costs present another significant distinction. GC-MS requires high-purity carrier gases, specialized columns ($300-$1,000 each with 50-200 analysis lifespan), and reference standards. HPTLC utilizes plates ($5-$15 per plate for 10-20 samples), solvents, and visualization reagents, generally resulting in lower per-sample costs for routine analyses.

Personnel requirements constitute an important consideration. GC-MS operation demands highly trained specialists commanding higher salaries, while HPTLC can be performed by technicians with moderate training, reducing labor costs by approximately 30-40%.

Throughput capabilities significantly impact cost-effectiveness. While GC-MS processes samples sequentially (typically 20-30 samples daily), HPTLC allows simultaneous analysis of multiple samples (up to 30+ samples per plate), potentially reducing cost-per-sample for high-volume applications.

Return on investment timelines vary substantially. GC-MS typically requires 3-5 years to achieve ROI, depending on utilization rates and service offerings. HPTLC systems generally reach ROI within 1-2 years due to lower initial costs, despite potentially generating less revenue per analysis.

Facility requirements present additional considerations. GC-MS demands dedicated laboratory space with specialized ventilation, gas supplies, and often uninterrupted power supply systems. HPTLC requires minimal infrastructure modifications, reducing implementation costs particularly for facilities with space or utility constraints.

Initial capital expenditure represents the most significant cost difference between these technologies. GC-MS systems typically range from $50,000 to $150,000 for standard configurations, with high-end models exceeding $300,000. In contrast, HPTLC equipment requires substantially lower initial investment, generally between $15,000 and $40,000 for a complete system including visualization components.

Operational expenses also differ markedly. GC-MS demands higher maintenance costs, approximately $5,000-$10,000 annually, including specialized service contracts and replacement parts for sensitive components like mass spectrometer filaments. HPTLC maintenance costs are considerably lower, typically $1,000-$3,000 annually, primarily for lamp replacements and general upkeep.

Consumable costs present another significant distinction. GC-MS requires high-purity carrier gases, specialized columns ($300-$1,000 each with 50-200 analysis lifespan), and reference standards. HPTLC utilizes plates ($5-$15 per plate for 10-20 samples), solvents, and visualization reagents, generally resulting in lower per-sample costs for routine analyses.

Personnel requirements constitute an important consideration. GC-MS operation demands highly trained specialists commanding higher salaries, while HPTLC can be performed by technicians with moderate training, reducing labor costs by approximately 30-40%.

Throughput capabilities significantly impact cost-effectiveness. While GC-MS processes samples sequentially (typically 20-30 samples daily), HPTLC allows simultaneous analysis of multiple samples (up to 30+ samples per plate), potentially reducing cost-per-sample for high-volume applications.

Return on investment timelines vary substantially. GC-MS typically requires 3-5 years to achieve ROI, depending on utilization rates and service offerings. HPTLC systems generally reach ROI within 1-2 years due to lower initial costs, despite potentially generating less revenue per analysis.

Facility requirements present additional considerations. GC-MS demands dedicated laboratory space with specialized ventilation, gas supplies, and often uninterrupted power supply systems. HPTLC requires minimal infrastructure modifications, reducing implementation costs particularly for facilities with space or utility constraints.

Environmental Impact and Sustainability Considerations

The environmental impact of analytical techniques has become increasingly important in laboratory practices as sustainability considerations gain prominence in scientific research. GC-MS and High-Performance Thin Layer Chromatography (HPTLC) present distinct environmental footprints that merit careful examination. GC-MS systems typically consume significant electrical power during operation, with instruments running continuously for extended periods and requiring substantial cooling. Additionally, these systems utilize carrier gases such as helium—a non-renewable resource facing global supply challenges—or alternatives like hydrogen that present safety concerns.

Solvent consumption represents another critical environmental consideration. GC-MS methods often require extensive sample preparation involving organic solvents, many of which are environmentally hazardous. While modern systems have reduced solvent requirements through techniques like solid-phase microextraction, the cumulative environmental impact remains substantial in high-throughput laboratories.

In contrast, HPTLC demonstrates several environmentally favorable characteristics. The technique requires significantly less electricity, operating without the need for continuous power supply or extensive cooling systems. HPTLC also utilizes substantially smaller solvent volumes—typically 10-20 mL per analysis compared to the continuous flow required in GC-MS. This reduction translates to decreased waste generation and lower exposure risks for laboratory personnel.

Waste management presents different challenges for both techniques. GC-MS generates primarily gaseous waste and used consumables, while HPTLC produces solid waste in the form of used plates alongside smaller volumes of liquid waste. HPTLC plates, however, contain silica and potentially toxic visualization reagents that require proper disposal protocols to prevent environmental contamination.

Recent innovations have improved the sustainability profile of both techniques. Green chemistry principles have led to the development of bio-based solvents for HPTLC and more efficient GC-MS protocols. Additionally, manufacturers have focused on creating energy-efficient GC-MS systems with improved insulation and power management features, reducing their carbon footprint.

From a lifecycle perspective, HPTLC equipment generally requires fewer resources to manufacture and maintain than the complex instrumentation of GC-MS systems. However, comprehensive sustainability assessment must consider factors beyond operational impacts, including manufacturing processes, transportation requirements, and end-of-life disposal considerations for both technologies.

Solvent consumption represents another critical environmental consideration. GC-MS methods often require extensive sample preparation involving organic solvents, many of which are environmentally hazardous. While modern systems have reduced solvent requirements through techniques like solid-phase microextraction, the cumulative environmental impact remains substantial in high-throughput laboratories.

In contrast, HPTLC demonstrates several environmentally favorable characteristics. The technique requires significantly less electricity, operating without the need for continuous power supply or extensive cooling systems. HPTLC also utilizes substantially smaller solvent volumes—typically 10-20 mL per analysis compared to the continuous flow required in GC-MS. This reduction translates to decreased waste generation and lower exposure risks for laboratory personnel.

Waste management presents different challenges for both techniques. GC-MS generates primarily gaseous waste and used consumables, while HPTLC produces solid waste in the form of used plates alongside smaller volumes of liquid waste. HPTLC plates, however, contain silica and potentially toxic visualization reagents that require proper disposal protocols to prevent environmental contamination.

Recent innovations have improved the sustainability profile of both techniques. Green chemistry principles have led to the development of bio-based solvents for HPTLC and more efficient GC-MS protocols. Additionally, manufacturers have focused on creating energy-efficient GC-MS systems with improved insulation and power management features, reducing their carbon footprint.

From a lifecycle perspective, HPTLC equipment generally requires fewer resources to manufacture and maintain than the complex instrumentation of GC-MS systems. However, comprehensive sustainability assessment must consider factors beyond operational impacts, including manufacturing processes, transportation requirements, and end-of-life disposal considerations for both technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!