Comparative Analysis of Water-Confinement Techniques in Laser Shock Peening

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Shock Peening Technology Evolution and Objectives

Laser Shock Peening (LSP) emerged in the 1960s as a surface treatment technology when researchers at Battelle Memorial Institute discovered that high-intensity laser pulses could generate shock waves capable of modifying material properties. The initial development focused on improving fatigue life of metal components, primarily for aerospace applications. Throughout the 1970s and 1980s, significant advancements were made in understanding the fundamental mechanisms of LSP, particularly how plasma-induced shock waves create beneficial compressive residual stresses in metallic materials.

Water confinement techniques represent a critical evolution in LSP technology. Initially, LSP was performed in vacuum or air environments, yielding limited effectiveness. The introduction of water as a confining medium in the late 1980s marked a pivotal advancement, dramatically enhancing shock wave intensity and material penetration depth. This innovation expanded LSP's industrial viability and application scope considerably.

The 1990s witnessed the commercialization of LSP technology, with companies like Metal Improvement Company (now Curtiss-Wright Surface Technologies) and LSP Technologies developing industrial-scale systems. During this period, water confinement techniques diversified into static water layers, flowing water systems, and water jets, each offering distinct advantages for specific applications.

Recent technological trends have focused on optimizing water confinement parameters, including layer thickness, flow dynamics, and transparency maintenance. Research indicates that water layer thickness significantly impacts shock wave propagation and intensity, with optimal ranges typically between 1-3 mm depending on laser parameters and target materials. Advanced computational models now enable precise prediction of plasma formation and shock wave propagation under various water confinement conditions.

The primary objectives of current water confinement research in LSP include enhancing process efficiency, improving treatment uniformity, and extending applicability to complex geometries. Researchers aim to develop adaptive water delivery systems that can maintain optimal confinement conditions regardless of surface orientation or complexity. Additionally, there is growing interest in environmentally sustainable approaches that minimize water consumption while maintaining or improving process effectiveness.

Future technological trajectories point toward intelligent water confinement systems that integrate real-time monitoring and adjustment capabilities. These systems would optimize water parameters based on feedback from in-process measurements, ensuring consistent treatment quality across varying material conditions and geometries. The ultimate goal is to develop water confinement techniques that enable precise, reproducible, and cost-effective LSP treatment for increasingly diverse industrial applications.

Water confinement techniques represent a critical evolution in LSP technology. Initially, LSP was performed in vacuum or air environments, yielding limited effectiveness. The introduction of water as a confining medium in the late 1980s marked a pivotal advancement, dramatically enhancing shock wave intensity and material penetration depth. This innovation expanded LSP's industrial viability and application scope considerably.

The 1990s witnessed the commercialization of LSP technology, with companies like Metal Improvement Company (now Curtiss-Wright Surface Technologies) and LSP Technologies developing industrial-scale systems. During this period, water confinement techniques diversified into static water layers, flowing water systems, and water jets, each offering distinct advantages for specific applications.

Recent technological trends have focused on optimizing water confinement parameters, including layer thickness, flow dynamics, and transparency maintenance. Research indicates that water layer thickness significantly impacts shock wave propagation and intensity, with optimal ranges typically between 1-3 mm depending on laser parameters and target materials. Advanced computational models now enable precise prediction of plasma formation and shock wave propagation under various water confinement conditions.

The primary objectives of current water confinement research in LSP include enhancing process efficiency, improving treatment uniformity, and extending applicability to complex geometries. Researchers aim to develop adaptive water delivery systems that can maintain optimal confinement conditions regardless of surface orientation or complexity. Additionally, there is growing interest in environmentally sustainable approaches that minimize water consumption while maintaining or improving process effectiveness.

Future technological trajectories point toward intelligent water confinement systems that integrate real-time monitoring and adjustment capabilities. These systems would optimize water parameters based on feedback from in-process measurements, ensuring consistent treatment quality across varying material conditions and geometries. The ultimate goal is to develop water confinement techniques that enable precise, reproducible, and cost-effective LSP treatment for increasingly diverse industrial applications.

Market Applications and Industry Demand for LSP

Laser Shock Peening (LSP) has witnessed significant market growth across multiple industries due to its ability to enhance material properties and extend component lifespans. The aerospace sector represents the largest market for LSP technology, with applications focused on critical components such as turbine blades, discs, and structural elements. Major aerospace manufacturers including Boeing, Airbus, GE Aviation, and Rolls-Royce have integrated LSP into their manufacturing processes to improve fatigue resistance and foreign object damage tolerance in high-value components.

The automotive industry has emerged as the second-largest market for LSP applications, particularly for high-performance vehicles and critical safety components. LSP treatment of engine components, transmission systems, and structural elements provides enhanced durability and reliability under extreme operating conditions. Premium automotive manufacturers have begun incorporating LSP into production lines for components subject to high cyclic loading.

The medical device sector represents a rapidly growing market for LSP technology, particularly for implantable devices such as orthopedic implants and cardiovascular stents. The ability of LSP to create compressive residual stresses without altering surface chemistry makes it particularly valuable for biomedical applications where material biocompatibility is paramount.

Power generation represents another significant market, with LSP being applied to turbine components in nuclear, hydroelectric, and conventional power plants. The technology's ability to extend component lifespan and improve resistance to stress corrosion cracking delivers substantial economic benefits through reduced maintenance costs and extended service intervals.

Market analysis indicates the global LSP market is experiencing compound annual growth rates exceeding traditional surface treatment technologies. This growth is driven by increasing awareness of LSP benefits, technological advancements in laser systems, and the growing emphasis on lightweight materials in transportation industries where fatigue performance is critical.

The demand for water confinement techniques specifically is driven by their superior performance in creating higher-magnitude shock waves compared to other confinement methods. Industries requiring the highest levels of residual stress induction, particularly aerospace and defense, show the strongest demand for advanced water confinement solutions that can deliver consistent results across complex geometries.

Emerging applications in additive manufacturing represent a potential high-growth market segment, as LSP offers solutions to address inherent weaknesses in 3D-printed metal components. The ability to selectively strengthen critical areas of additively manufactured parts is creating new market opportunities across multiple industries.

The automotive industry has emerged as the second-largest market for LSP applications, particularly for high-performance vehicles and critical safety components. LSP treatment of engine components, transmission systems, and structural elements provides enhanced durability and reliability under extreme operating conditions. Premium automotive manufacturers have begun incorporating LSP into production lines for components subject to high cyclic loading.

The medical device sector represents a rapidly growing market for LSP technology, particularly for implantable devices such as orthopedic implants and cardiovascular stents. The ability of LSP to create compressive residual stresses without altering surface chemistry makes it particularly valuable for biomedical applications where material biocompatibility is paramount.

Power generation represents another significant market, with LSP being applied to turbine components in nuclear, hydroelectric, and conventional power plants. The technology's ability to extend component lifespan and improve resistance to stress corrosion cracking delivers substantial economic benefits through reduced maintenance costs and extended service intervals.

Market analysis indicates the global LSP market is experiencing compound annual growth rates exceeding traditional surface treatment technologies. This growth is driven by increasing awareness of LSP benefits, technological advancements in laser systems, and the growing emphasis on lightweight materials in transportation industries where fatigue performance is critical.

The demand for water confinement techniques specifically is driven by their superior performance in creating higher-magnitude shock waves compared to other confinement methods. Industries requiring the highest levels of residual stress induction, particularly aerospace and defense, show the strongest demand for advanced water confinement solutions that can deliver consistent results across complex geometries.

Emerging applications in additive manufacturing represent a potential high-growth market segment, as LSP offers solutions to address inherent weaknesses in 3D-printed metal components. The ability to selectively strengthen critical areas of additively manufactured parts is creating new market opportunities across multiple industries.

Water-Confinement Techniques: Current Status and Challenges

Water confinement techniques represent a critical component in Laser Shock Peening (LSP) processes, serving as the medium through which shock waves are transmitted to the target material. Currently, several water confinement methodologies dominate the industrial and research landscapes, each with distinct advantages and limitations that influence their applicability across different operational contexts.

The flowing water layer technique, widely adopted in industrial settings, enables continuous processing by maintaining a consistent water film over the target surface. While this approach facilitates high-throughput manufacturing, it faces challenges in maintaining uniform water layer thickness, particularly on complex geometries or vertical surfaces. Variations in water layer thickness directly impact shock wave intensity and distribution, potentially leading to inconsistent material treatment.

Static water confinement, conversely, offers superior control over water layer parameters but significantly reduces processing speed due to the need for containment structures and repeated setup between treatments. This method remains prevalent in laboratory research where precision outweighs production volume considerations.

Recent innovations have introduced gel-based confinement systems that combine the stability of static confinement with improved adaptability to complex geometries. These systems demonstrate promising results for treating intricate components but face scalability challenges for mass production environments.

A significant technical hurdle across all water confinement techniques involves the management of water-air interface disturbances. Laser-induced plasma formation creates explosive vapor expansion that disrupts the water layer, potentially compromising subsequent laser pulses in high-frequency applications. Current mitigation strategies include rapid water replenishment systems and optimized pulse timing sequences, though these solutions introduce additional system complexity.

The geographical distribution of water confinement technology development shows concentration in industrial nations with advanced manufacturing sectors. North American and European research institutions lead in fundamental studies, while Asian manufacturers, particularly in Japan and China, demonstrate strength in industrial implementation and process optimization.

Material compatibility presents another challenge, as certain substrates may experience adverse reactions with water exposure. This has prompted research into alternative confinement media, including transparent solid overlays and specialized liquid solutions with modified surface tension properties.

The integration of real-time monitoring systems represents an emerging focus area, with optical and acoustic sensors being developed to provide feedback on water layer conditions during processing. These systems aim to enable adaptive control of laser parameters based on confinement layer status, potentially addressing consistency challenges in dynamic processing environments.

The flowing water layer technique, widely adopted in industrial settings, enables continuous processing by maintaining a consistent water film over the target surface. While this approach facilitates high-throughput manufacturing, it faces challenges in maintaining uniform water layer thickness, particularly on complex geometries or vertical surfaces. Variations in water layer thickness directly impact shock wave intensity and distribution, potentially leading to inconsistent material treatment.

Static water confinement, conversely, offers superior control over water layer parameters but significantly reduces processing speed due to the need for containment structures and repeated setup between treatments. This method remains prevalent in laboratory research where precision outweighs production volume considerations.

Recent innovations have introduced gel-based confinement systems that combine the stability of static confinement with improved adaptability to complex geometries. These systems demonstrate promising results for treating intricate components but face scalability challenges for mass production environments.

A significant technical hurdle across all water confinement techniques involves the management of water-air interface disturbances. Laser-induced plasma formation creates explosive vapor expansion that disrupts the water layer, potentially compromising subsequent laser pulses in high-frequency applications. Current mitigation strategies include rapid water replenishment systems and optimized pulse timing sequences, though these solutions introduce additional system complexity.

The geographical distribution of water confinement technology development shows concentration in industrial nations with advanced manufacturing sectors. North American and European research institutions lead in fundamental studies, while Asian manufacturers, particularly in Japan and China, demonstrate strength in industrial implementation and process optimization.

Material compatibility presents another challenge, as certain substrates may experience adverse reactions with water exposure. This has prompted research into alternative confinement media, including transparent solid overlays and specialized liquid solutions with modified surface tension properties.

The integration of real-time monitoring systems represents an emerging focus area, with optical and acoustic sensors being developed to provide feedback on water layer conditions during processing. These systems aim to enable adaptive control of laser parameters based on confinement layer status, potentially addressing consistency challenges in dynamic processing environments.

Comparative Analysis of Existing Water-Confinement Solutions

01 Water layer thickness optimization for confinement efficiency

The thickness of the water layer used as a confinement medium in laser shock peening significantly affects the confinement efficiency. Optimal water layer thickness ensures maximum pressure generation and effective shock wave transmission to the target material. Controlling the water layer thickness through various delivery methods can enhance the overall peening effect and improve the material properties of the treated surface.- Water layer thickness optimization for confinement efficiency: The thickness of the water layer used as a confinement medium in laser shock peening significantly affects the confinement efficiency. Optimal water layer thickness ensures maximum pressure generation and effective shock wave transmission to the workpiece. Research indicates that specific thickness ranges provide better confinement of the plasma expansion, resulting in higher peak pressures and more effective material treatment. Controlling water layer parameters is essential for consistent peening results across different applications.

- Flow control systems for water confinement: Advanced flow control systems have been developed to maintain consistent water confinement during laser shock peening operations. These systems regulate water flow rate, direction, and pressure to ensure uniform coverage over the treatment area. Continuous flow techniques prevent water degradation from repeated laser pulses and help maintain optimal confinement conditions. Some systems incorporate sensors and feedback mechanisms to dynamically adjust water parameters based on process conditions, improving overall confinement efficiency and process reliability.

- Transparent overlay materials combined with water confinement: Hybrid confinement approaches combining water with transparent overlay materials have shown enhanced confinement efficiency in laser shock peening. These systems typically use transparent films or coatings in direct contact with the workpiece surface, with water applied as a secondary confinement layer. The combination provides better acoustic impedance matching and improved pressure transmission to the workpiece. This approach reduces water consumption while maintaining or improving confinement efficiency compared to traditional water-only methods.

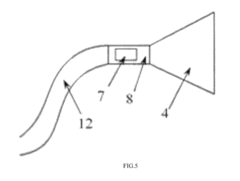

- Water delivery and containment mechanisms: Specialized water delivery and containment mechanisms have been developed to optimize water confinement in laser shock peening. These include nozzle designs that create laminar flow patterns, water curtain systems that maintain consistent coverage, and containment chambers that prevent water dispersion. Some systems incorporate water jet technologies that precisely control the water layer formation on complex geometries. Advanced designs focus on minimizing water consumption while ensuring complete coverage of the treatment area, which is critical for consistent peening results.

- Water properties modification for enhanced confinement: Modifying the properties of water used in confinement layers can significantly improve confinement efficiency in laser shock peening. Techniques include temperature control to optimize acoustic impedance, addition of soluble compounds to increase density and viscosity, and degassing to reduce bubble formation during laser interaction. Some approaches use additives that increase the absorption coefficient at specific laser wavelengths, enhancing energy coupling. These modifications can substantially increase peak pressure generation and improve the overall effectiveness of the laser shock peening process.

02 Flow control systems for water confinement

Advanced flow control systems are essential for maintaining consistent water confinement during laser shock peening. These systems regulate water flow rate, pressure, and distribution across the target surface, ensuring uniform confinement conditions. Techniques include laminar flow designs, pressurized water delivery systems, and automated flow controllers that adjust based on processing parameters to maintain optimal confinement efficiency throughout the peening process.Expand Specific Solutions03 Transparent confinement materials and water additives

The use of transparent confinement materials and water additives can significantly improve confinement efficiency in laser shock peening. These materials allow laser energy to pass through while enhancing the shock wave generation and propagation. Additives can modify water properties such as viscosity, surface tension, and acoustic impedance to optimize the confinement effect and increase the peak pressure achieved during the process.Expand Specific Solutions04 Laser-water interaction optimization techniques

Optimizing the interaction between laser pulses and the water confinement medium is crucial for efficient laser shock peening. This includes controlling laser parameters such as wavelength, pulse duration, and energy density to maximize energy coupling with the water layer. Advanced techniques involve synchronizing multiple laser pulses with water layer dynamics and managing plasma formation at the interface to enhance pressure generation and confinement efficiency.Expand Specific Solutions05 Water confinement geometry and delivery systems

The geometry of water confinement and the design of delivery systems play a vital role in laser shock peening efficiency. Specialized nozzles, water curtains, and confined flow channels can create optimal confinement conditions. Three-dimensional water confinement structures and adaptive delivery systems that conform to complex part geometries ensure consistent confinement pressure across irregular surfaces, improving the overall effectiveness of the peening process.Expand Specific Solutions

Leading Manufacturers and Research Institutions in LSP Field

The water-confinement techniques in Laser Shock Peening (LSP) market is currently in a growth phase, with increasing adoption across aerospace, automotive, and energy sectors. The global LSP market is estimated to reach approximately $700 million by 2025, growing at a CAGR of 6-8%. Technologically, water-confinement methods are evolving from traditional approaches to more sophisticated solutions. Leading academic institutions like Jiangsu University, Shandong University, and Wuhan University are advancing fundamental research, while commercial players demonstrate varying maturity levels. LSP Technologies has established commercial systems, General Electric and Rolls-Royce have integrated LSP into manufacturing processes, and newcomers like Ningbo III Lasers are developing specialized applications. Airbus, Subaru, and Toshiba are exploring implementation in critical components, indicating broadening industrial acceptance.

General Electric Company

Technical Solution: General Electric has developed sophisticated water-confinement techniques for Laser Shock Peening (LSP) specifically optimized for critical aerospace components, particularly turbine engine parts. Their approach utilizes a dual-layer confinement system combining precisely controlled flowing water layers (typically 1-3 mm thickness) with specialized transparent overlays to enhance shock wave propagation[2]. GE's proprietary water delivery systems incorporate high-precision flow control that synchronizes with their high-energy laser systems, allowing for consistent peening quality across complex geometries. The company has implemented automated water management systems that maintain optimal water clarity, temperature, and flow characteristics throughout extended processing cycles. GE has also pioneered techniques for vertical and inverted processing orientations, overcoming gravitational challenges in water confinement through specialized nozzle designs and pressure-controlled delivery systems[5]. Their water confinement technology has been integrated into production lines for critical aircraft engine components, demonstrating scalability for high-volume manufacturing environments.

Strengths: Extensive validation on flight-critical components; integration with automated production systems; proven reliability in aerospace applications. Weaknesses: System complexity requires significant capital investment; specialized for particular component geometries; requires precise maintenance of water quality parameters.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Security (LLNS) has developed advanced water-confinement techniques for Laser Shock Peening that build upon their pioneering work in high-energy laser systems. Their approach utilizes precisely characterized water layers with controlled thickness gradients to optimize shock wave propagation for different material applications. LLNS has conducted extensive research on the plasma physics at the laser-water interface, developing models that predict confinement efficiency based on water layer properties and laser parameters[4]. Their technology incorporates high-speed imaging and diagnostics to visualize plasma formation and shock wave propagation through water confinement in real-time, enabling scientific validation of confinement effectiveness. LLNS has also explored advanced water delivery systems that maintain laminar flow characteristics even at high processing speeds, reducing optical distortions that can affect laser beam delivery. Their research has demonstrated that precisely controlled water temperature and dissolved gas content significantly impact shock wave characteristics, leading to the development of water conditioning systems that maintain optimal properties throughout extended processing[7]. LLNS continues to advance fundamental understanding of water-confinement mechanisms through computational modeling and experimental validation.

Strengths: Cutting-edge research capabilities; sophisticated diagnostic tools for process optimization; fundamental understanding of plasma-water interactions. Weaknesses: Technologies may be less mature for industrial implementation; focus on scientific advancement rather than production efficiency; systems may require specialized expertise to operate effectively.

Key Patents and Technical Innovations in LSP Water-Confinement

Method and apparatus for injecting water restraint layer of laser shock processing blade

PatentInactiveUS9909195B2

Innovation

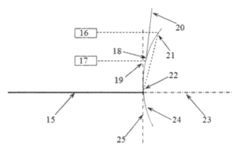

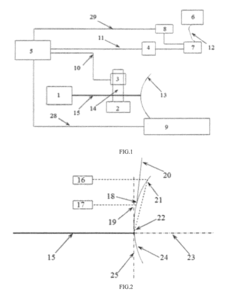

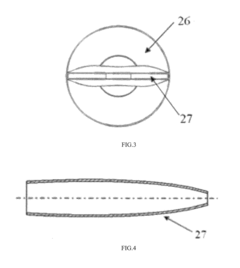

- A method and apparatus that adjust the position and angle of a water jet to form a stable and homogeneous water confinement layer by determining a theoretical curve based on probe points on the blade surface, using a diastimeter platform, controllers, and a flexible pipe system to ensure the water jet enters at an optimal 10°-15° angle, allowing for precise control of water flow velocity and thickness.

Dry tape covered laser shock peening

PatentInactiveEP0850321A1

Innovation

- Adhesively covering the laser shock peening surface with a dry tape containing an ablative medium and a confinement medium, allowing for localized compressive residual stresses to be imparted without a fluid flow confinement curtain, using a high-power pulsed laser to create shock waves directly on the taped surface.

Material Performance Improvements Through Different Confinement Methods

The selection of confinement methods in Laser Shock Peening (LSP) significantly impacts material performance outcomes. Water confinement, as the most widely adopted technique, creates a plasma-confining environment that enhances shock wave propagation into the target material. Experimental studies have demonstrated that water-confined LSP treatments can increase surface hardness by 15-30% in aluminum alloys and up to 40% in certain steel grades compared to unconfined laser treatments. This hardening effect directly correlates with improved wear resistance, with some aerospace-grade materials showing up to 60% reduction in wear rates after water-confined LSP.

Different water confinement configurations yield varying performance improvements. Static water layers (typically 1-3mm thick) provide consistent results with hardness improvements of approximately 20% in titanium alloys. Flowing water systems, while more complex to implement, demonstrate superior performance by preventing water breakdown between successive laser pulses, resulting in more uniform residual stress profiles and approximately 15% greater penetration depth of compressive stresses compared to static configurations.

The thickness of the water layer plays a crucial role in performance optimization. Research indicates that for 1064nm Nd:YAG lasers, water layers between 1-2mm produce optimal shock wave intensities. Thinner layers (<0.5mm) result in premature breakdown of the confinement medium, while thicker layers (>3mm) cause excessive laser energy absorption before reaching the target surface, reducing treatment effectiveness by up to 25%.

Temperature control during water confinement also influences material outcomes. Studies show that maintaining water temperature below 30°C during processing can increase the magnitude of induced compressive residual stresses by 10-15% compared to treatments performed with higher temperature water. This temperature effect becomes particularly significant during high-repetition-rate processing where water heating occurs naturally.

When comparing water confinement to alternative methods such as glass or quartz overlays, water consistently demonstrates superior adaptability to complex geometries while providing comparable performance improvements. However, transparent solid confinements can deliver more precise shock wave transmission in specific applications requiring extremely controlled energy delivery, resulting in up to 8% higher surface hardness in precision components.

The fatigue life enhancement resulting from water-confined LSP is particularly noteworthy, with treated aerospace aluminum components demonstrating 3-5 times longer fatigue life compared to untreated counterparts. This improvement significantly exceeds the 2-3 times enhancement typically achieved with conventional shot peening methods.

Different water confinement configurations yield varying performance improvements. Static water layers (typically 1-3mm thick) provide consistent results with hardness improvements of approximately 20% in titanium alloys. Flowing water systems, while more complex to implement, demonstrate superior performance by preventing water breakdown between successive laser pulses, resulting in more uniform residual stress profiles and approximately 15% greater penetration depth of compressive stresses compared to static configurations.

The thickness of the water layer plays a crucial role in performance optimization. Research indicates that for 1064nm Nd:YAG lasers, water layers between 1-2mm produce optimal shock wave intensities. Thinner layers (<0.5mm) result in premature breakdown of the confinement medium, while thicker layers (>3mm) cause excessive laser energy absorption before reaching the target surface, reducing treatment effectiveness by up to 25%.

Temperature control during water confinement also influences material outcomes. Studies show that maintaining water temperature below 30°C during processing can increase the magnitude of induced compressive residual stresses by 10-15% compared to treatments performed with higher temperature water. This temperature effect becomes particularly significant during high-repetition-rate processing where water heating occurs naturally.

When comparing water confinement to alternative methods such as glass or quartz overlays, water consistently demonstrates superior adaptability to complex geometries while providing comparable performance improvements. However, transparent solid confinements can deliver more precise shock wave transmission in specific applications requiring extremely controlled energy delivery, resulting in up to 8% higher surface hardness in precision components.

The fatigue life enhancement resulting from water-confined LSP is particularly noteworthy, with treated aerospace aluminum components demonstrating 3-5 times longer fatigue life compared to untreated counterparts. This improvement significantly exceeds the 2-3 times enhancement typically achieved with conventional shot peening methods.

Environmental and Safety Considerations in LSP Water-Confinement

The implementation of water-confinement techniques in Laser Shock Peening (LSP) necessitates careful consideration of environmental impacts and safety protocols. Water, while serving as an effective confinement medium, introduces specific environmental challenges that must be addressed in industrial applications. The primary environmental concern involves water contamination from ablated material during the LSP process. When laser pulses interact with target surfaces, microscopic particles and potentially hazardous compounds can be released into the confinement water, requiring proper filtration and treatment systems before discharge.

Water consumption represents another significant environmental consideration, particularly in regions facing water scarcity. Closed-loop water systems have emerged as a sustainable solution, enabling water recycling and minimizing consumption. These systems typically incorporate filtration mechanisms to remove contaminants, allowing for extended water reuse cycles and reducing the environmental footprint of LSP operations.

Safety considerations in water-confined LSP extend beyond environmental aspects to encompass operator protection. The high-pressure plasma generated during the process can cause water splashing and potential exposure to both the laser radiation and contaminated water. Modern LSP systems incorporate protective enclosures, splash guards, and automated handling systems to minimize operator exposure and ensure workplace safety compliance.

Electrical safety presents a critical concern in water-confined LSP environments. The proximity of water to high-voltage laser equipment creates potential electrical hazards that require rigorous insulation protocols, ground-fault circuit interrupters, and regular safety inspections. Industry standards mandate specific electrical safety measures for wet environments to prevent accidents and equipment damage.

Noise pollution constitutes another safety consideration, as the shock waves generated during LSP can produce significant acoustic emissions. Proper sound insulation and hearing protection protocols must be implemented to protect operators and comply with occupational health regulations. Monitoring of noise levels should be conducted regularly to ensure compliance with workplace safety standards.

Recent advancements in water-confinement techniques have focused on developing environmentally friendly additives that enhance confinement efficiency while minimizing ecological impact. These include biodegradable surfactants and non-toxic compounds that improve plasma confinement without introducing harmful substances into wastewater streams. Such innovations represent a promising direction for reducing the environmental footprint of LSP processes while maintaining or enhancing performance.

Regulatory compliance regarding water usage and discharge represents a final critical consideration. Different regions enforce varying standards for industrial water management, necessitating customized approaches to water treatment and disposal. Companies implementing LSP technology must navigate these regulatory frameworks to ensure legal compliance while optimizing process efficiency.

Water consumption represents another significant environmental consideration, particularly in regions facing water scarcity. Closed-loop water systems have emerged as a sustainable solution, enabling water recycling and minimizing consumption. These systems typically incorporate filtration mechanisms to remove contaminants, allowing for extended water reuse cycles and reducing the environmental footprint of LSP operations.

Safety considerations in water-confined LSP extend beyond environmental aspects to encompass operator protection. The high-pressure plasma generated during the process can cause water splashing and potential exposure to both the laser radiation and contaminated water. Modern LSP systems incorporate protective enclosures, splash guards, and automated handling systems to minimize operator exposure and ensure workplace safety compliance.

Electrical safety presents a critical concern in water-confined LSP environments. The proximity of water to high-voltage laser equipment creates potential electrical hazards that require rigorous insulation protocols, ground-fault circuit interrupters, and regular safety inspections. Industry standards mandate specific electrical safety measures for wet environments to prevent accidents and equipment damage.

Noise pollution constitutes another safety consideration, as the shock waves generated during LSP can produce significant acoustic emissions. Proper sound insulation and hearing protection protocols must be implemented to protect operators and comply with occupational health regulations. Monitoring of noise levels should be conducted regularly to ensure compliance with workplace safety standards.

Recent advancements in water-confinement techniques have focused on developing environmentally friendly additives that enhance confinement efficiency while minimizing ecological impact. These include biodegradable surfactants and non-toxic compounds that improve plasma confinement without introducing harmful substances into wastewater streams. Such innovations represent a promising direction for reducing the environmental footprint of LSP processes while maintaining or enhancing performance.

Regulatory compliance regarding water usage and discharge represents a final critical consideration. Different regions enforce varying standards for industrial water management, necessitating customized approaches to water treatment and disposal. Companies implementing LSP technology must navigate these regulatory frameworks to ensure legal compliance while optimizing process efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!