Laser Shock Peening for Corrosion Fatigue Resistance

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSP Technology Background and Objectives

Laser Shock Peening (LSP) emerged in the late 1960s as a surface treatment technology initially developed for aerospace applications. The fundamental principle involves using high-energy laser pulses to generate plasma-induced shock waves that create deep compressive residual stresses in metallic materials. This technology has evolved significantly over the past five decades, transitioning from laboratory experiments to industrial applications across multiple sectors including aerospace, automotive, and medical industries.

The evolution of LSP technology has been marked by continuous improvements in laser systems, from early ruby lasers to modern high-power Nd:YAG and fiber lasers. These advancements have enabled higher processing speeds, greater treatment depths, and more precise control over the peening process. Concurrently, the understanding of material response to shock waves has deepened, allowing for more targeted applications and optimized treatment parameters.

In recent years, the focus has shifted toward enhancing corrosion fatigue resistance in critical components. Corrosion fatigue, the combined effect of cyclic loading and corrosive environments, represents a significant challenge for industries operating in harsh conditions. Traditional surface treatments such as shot peening and roller burnishing offer limited protection against this complex failure mechanism, creating a technological gap that LSP aims to address.

The primary objective of LSP technology for corrosion fatigue resistance is to develop a robust surface modification process that simultaneously enhances mechanical properties and corrosion resistance. Specifically, the technology aims to create deep compressive residual stresses (typically 1-2 mm depth compared to 0.25 mm for conventional treatments) that effectively inhibit crack initiation and propagation in corrosive environments. Additionally, LSP seeks to modify surface microstructure to reduce susceptibility to localized corrosion.

Secondary objectives include developing scalable and cost-effective LSP processes suitable for industrial implementation, optimizing treatment parameters for specific material-environment combinations, and establishing standardized testing methodologies to quantify improvements in corrosion fatigue performance. The technology also aims to extend component service life by 3-5 times in corrosive environments, thereby reducing maintenance costs and improving operational safety.

The technological trajectory suggests continued refinement of LSP parameters, development of hybrid surface treatments combining LSP with complementary technologies, and expansion into new material systems including advanced alloys and composites. As environmental regulations become more stringent and operational demands increase, LSP technology is positioned to become an essential tool in the surface engineering arsenal for combating corrosion fatigue in critical applications.

The evolution of LSP technology has been marked by continuous improvements in laser systems, from early ruby lasers to modern high-power Nd:YAG and fiber lasers. These advancements have enabled higher processing speeds, greater treatment depths, and more precise control over the peening process. Concurrently, the understanding of material response to shock waves has deepened, allowing for more targeted applications and optimized treatment parameters.

In recent years, the focus has shifted toward enhancing corrosion fatigue resistance in critical components. Corrosion fatigue, the combined effect of cyclic loading and corrosive environments, represents a significant challenge for industries operating in harsh conditions. Traditional surface treatments such as shot peening and roller burnishing offer limited protection against this complex failure mechanism, creating a technological gap that LSP aims to address.

The primary objective of LSP technology for corrosion fatigue resistance is to develop a robust surface modification process that simultaneously enhances mechanical properties and corrosion resistance. Specifically, the technology aims to create deep compressive residual stresses (typically 1-2 mm depth compared to 0.25 mm for conventional treatments) that effectively inhibit crack initiation and propagation in corrosive environments. Additionally, LSP seeks to modify surface microstructure to reduce susceptibility to localized corrosion.

Secondary objectives include developing scalable and cost-effective LSP processes suitable for industrial implementation, optimizing treatment parameters for specific material-environment combinations, and establishing standardized testing methodologies to quantify improvements in corrosion fatigue performance. The technology also aims to extend component service life by 3-5 times in corrosive environments, thereby reducing maintenance costs and improving operational safety.

The technological trajectory suggests continued refinement of LSP parameters, development of hybrid surface treatments combining LSP with complementary technologies, and expansion into new material systems including advanced alloys and composites. As environmental regulations become more stringent and operational demands increase, LSP technology is positioned to become an essential tool in the surface engineering arsenal for combating corrosion fatigue in critical applications.

Market Demand Analysis for Corrosion Fatigue Solutions

The global market for corrosion fatigue solutions has been experiencing significant growth, driven primarily by increasing concerns about infrastructure aging and the rising costs associated with corrosion-related failures. According to recent industry analyses, the annual global cost of corrosion across all sectors exceeds $2.5 trillion, representing approximately 3.4% of global GDP, with a substantial portion attributable to fatigue-accelerated corrosion damage.

The aerospace industry demonstrates particularly strong demand for advanced corrosion fatigue solutions, with maintenance, repair, and overhaul (MRO) expenditures reaching $76 billion annually. Within this sector, components subjected to cyclic loading in corrosive environments represent critical failure points, creating a specialized market niche for technologies like Laser Shock Peening (LSP).

Similarly, the maritime and offshore energy sectors face severe challenges from corrosion fatigue, with annual maintenance costs exceeding $50 billion globally. These industries are actively seeking solutions that can extend asset lifespans and reduce maintenance intervals, creating significant market pull for innovative surface treatment technologies.

The automotive industry presents another substantial market opportunity, particularly with the transition toward lightweight materials that often exhibit greater susceptibility to corrosion fatigue. With global automotive manufacturing approaching 80 million vehicles annually, even incremental improvements in component durability translate to considerable market value.

Defense applications represent a premium segment within this market, where performance requirements often supersede cost considerations. Military aircraft, naval vessels, and land vehicles operate under extreme conditions where corrosion fatigue can compromise mission-critical systems, creating demand for high-performance solutions regardless of price premium.

Market research indicates a growing preference for preventive rather than reactive approaches to corrosion fatigue management. This shift is evidenced by increasing adoption of advanced surface engineering solutions during initial manufacturing rather than as aftermarket treatments, suggesting evolving procurement patterns among end users.

Regional analysis reveals particularly strong demand growth in Asia-Pacific markets, where rapid industrialization combined with challenging environmental conditions (coastal humidity, industrial pollution) creates acute corrosion challenges. North American and European markets remain significant but demonstrate more modest growth rates, primarily driven by infrastructure rehabilitation projects and regulatory compliance requirements.

The competitive landscape for corrosion fatigue solutions remains fragmented, with specialized surface treatment providers competing alongside major materials science corporations and OEM-integrated solutions. This fragmentation suggests market space for technologies like LSP that can demonstrate clear performance differentiation and quantifiable economic benefits through extended component lifecycles.

The aerospace industry demonstrates particularly strong demand for advanced corrosion fatigue solutions, with maintenance, repair, and overhaul (MRO) expenditures reaching $76 billion annually. Within this sector, components subjected to cyclic loading in corrosive environments represent critical failure points, creating a specialized market niche for technologies like Laser Shock Peening (LSP).

Similarly, the maritime and offshore energy sectors face severe challenges from corrosion fatigue, with annual maintenance costs exceeding $50 billion globally. These industries are actively seeking solutions that can extend asset lifespans and reduce maintenance intervals, creating significant market pull for innovative surface treatment technologies.

The automotive industry presents another substantial market opportunity, particularly with the transition toward lightweight materials that often exhibit greater susceptibility to corrosion fatigue. With global automotive manufacturing approaching 80 million vehicles annually, even incremental improvements in component durability translate to considerable market value.

Defense applications represent a premium segment within this market, where performance requirements often supersede cost considerations. Military aircraft, naval vessels, and land vehicles operate under extreme conditions where corrosion fatigue can compromise mission-critical systems, creating demand for high-performance solutions regardless of price premium.

Market research indicates a growing preference for preventive rather than reactive approaches to corrosion fatigue management. This shift is evidenced by increasing adoption of advanced surface engineering solutions during initial manufacturing rather than as aftermarket treatments, suggesting evolving procurement patterns among end users.

Regional analysis reveals particularly strong demand growth in Asia-Pacific markets, where rapid industrialization combined with challenging environmental conditions (coastal humidity, industrial pollution) creates acute corrosion challenges. North American and European markets remain significant but demonstrate more modest growth rates, primarily driven by infrastructure rehabilitation projects and regulatory compliance requirements.

The competitive landscape for corrosion fatigue solutions remains fragmented, with specialized surface treatment providers competing alongside major materials science corporations and OEM-integrated solutions. This fragmentation suggests market space for technologies like LSP that can demonstrate clear performance differentiation and quantifiable economic benefits through extended component lifecycles.

Current State and Challenges in LSP Implementation

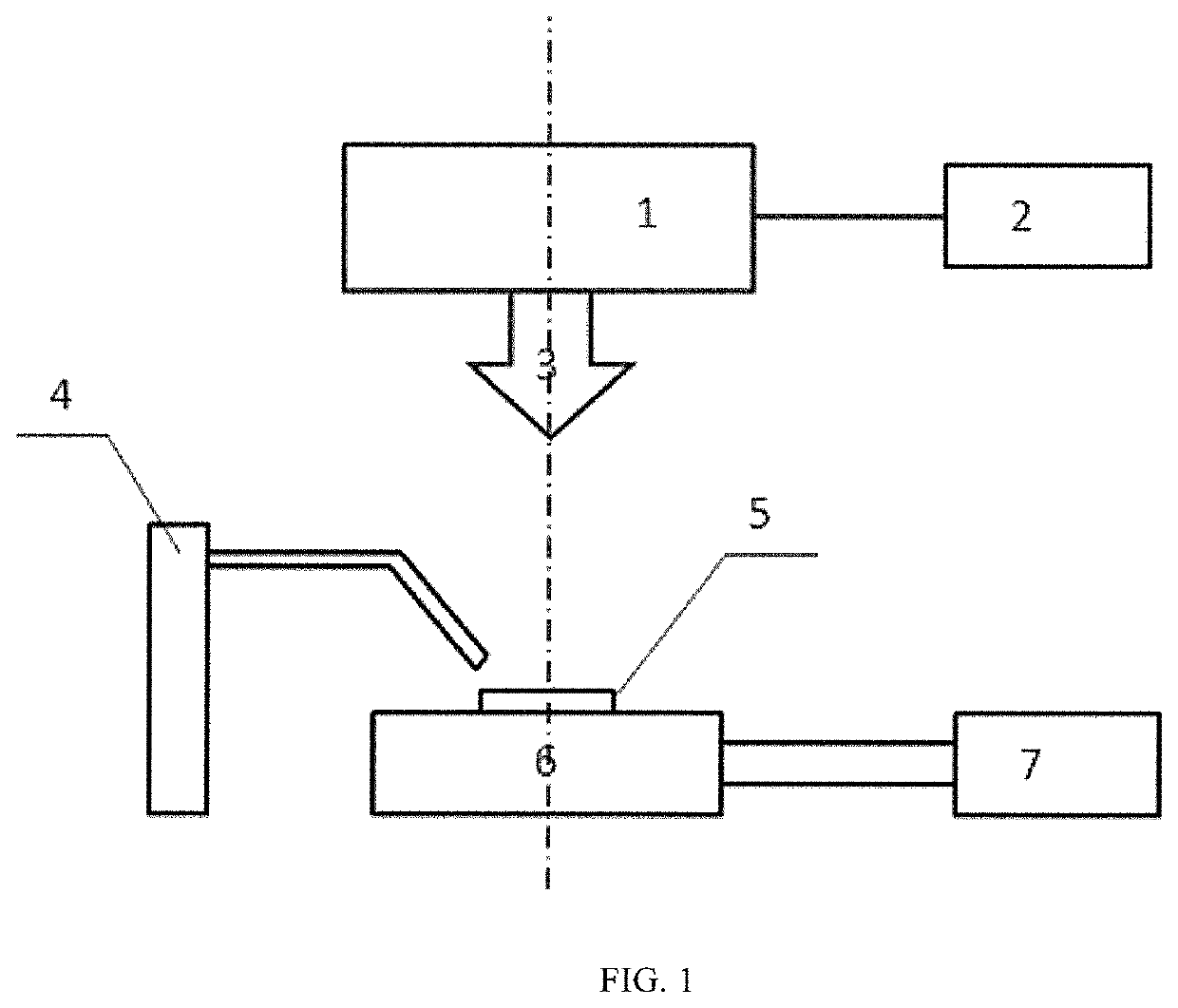

Laser Shock Peening (LSP) has reached a mature implementation stage in aerospace and power generation industries, with established commercial applications for turbine blades, discs, and other critical components. Current industrial systems typically employ Nd:YAG or Nd:glass lasers operating at 1064nm wavelength with pulse energies ranging from 10-40J and durations of 10-30ns. These systems can achieve peak power densities of 1-10 GW/cm² when properly focused, creating compressive residual stresses extending 1-2mm beneath treated surfaces.

Despite its proven effectiveness, LSP implementation faces several significant challenges. The high capital equipment cost remains a primary barrier, with industrial-scale systems requiring investments of $1-5 million, limiting adoption to high-value applications where failure costs justify the expenditure. Additionally, the process requires specialized expertise in laser physics, materials science, and precise control systems, creating a workforce development challenge for wider implementation.

Technical limitations include the relatively slow processing speed compared to conventional peening methods, with current systems typically treating only 0.1-0.5 m²/hour. This throughput constraint restricts LSP's application in mass production environments where high-volume processing is required. The need for protective ablative coatings (typically black paint or aluminum tape) in most applications adds process complexity and cost, though water-only (coating-free) LSP techniques are advancing.

Energy efficiency represents another significant challenge, as industrial LSP systems typically operate at 1-3% wall-plug efficiency, resulting in high energy consumption and cooling requirements. This inefficiency contributes to both operational costs and environmental impact considerations. Furthermore, quality control and process monitoring remain challenging due to the difficulty in non-destructively measuring residual stress distributions in treated components.

For corrosion fatigue resistance specifically, current LSP implementation faces challenges in optimizing treatment parameters for different material-environment combinations. The complex interplay between compressive stress fields, surface roughness changes, and microstructural modifications requires extensive empirical testing for each new application. Additionally, the long-term stability of LSP-induced compressive stresses in corrosive environments is not fully characterized across all relevant industrial materials and conditions.

Geographical distribution of LSP technology shows concentration in the United States, France, China, and Japan, with limited adoption in developing economies due to the aforementioned barriers. Recent research focuses on addressing these challenges through development of more energy-efficient fiber laser systems, automated process control algorithms, and hybrid treatment approaches combining LSP with other surface enhancement techniques.

Despite its proven effectiveness, LSP implementation faces several significant challenges. The high capital equipment cost remains a primary barrier, with industrial-scale systems requiring investments of $1-5 million, limiting adoption to high-value applications where failure costs justify the expenditure. Additionally, the process requires specialized expertise in laser physics, materials science, and precise control systems, creating a workforce development challenge for wider implementation.

Technical limitations include the relatively slow processing speed compared to conventional peening methods, with current systems typically treating only 0.1-0.5 m²/hour. This throughput constraint restricts LSP's application in mass production environments where high-volume processing is required. The need for protective ablative coatings (typically black paint or aluminum tape) in most applications adds process complexity and cost, though water-only (coating-free) LSP techniques are advancing.

Energy efficiency represents another significant challenge, as industrial LSP systems typically operate at 1-3% wall-plug efficiency, resulting in high energy consumption and cooling requirements. This inefficiency contributes to both operational costs and environmental impact considerations. Furthermore, quality control and process monitoring remain challenging due to the difficulty in non-destructively measuring residual stress distributions in treated components.

For corrosion fatigue resistance specifically, current LSP implementation faces challenges in optimizing treatment parameters for different material-environment combinations. The complex interplay between compressive stress fields, surface roughness changes, and microstructural modifications requires extensive empirical testing for each new application. Additionally, the long-term stability of LSP-induced compressive stresses in corrosive environments is not fully characterized across all relevant industrial materials and conditions.

Geographical distribution of LSP technology shows concentration in the United States, France, China, and Japan, with limited adoption in developing economies due to the aforementioned barriers. Recent research focuses on addressing these challenges through development of more energy-efficient fiber laser systems, automated process control algorithms, and hybrid treatment approaches combining LSP with other surface enhancement techniques.

Current LSP Technical Solutions for Corrosion Resistance

01 Laser shock peening for improved corrosion fatigue resistance

Laser shock peening (LSP) is a surface treatment technique that can significantly enhance the corrosion fatigue resistance of metallic components. The process involves applying high-intensity laser pulses to create shock waves that induce compressive residual stresses in the material surface. These compressive stresses help to inhibit crack initiation and propagation, thereby improving the material's resistance to corrosion fatigue. This technique is particularly effective for components subjected to cyclic loading in corrosive environments.- Laser shock peening to enhance fatigue resistance: Laser shock peening (LSP) is a surface treatment technique that can significantly improve the fatigue resistance of metallic components. The process involves directing high-energy laser pulses at the material surface, creating shock waves that induce compressive residual stresses in the material. These compressive stresses can effectively inhibit crack initiation and propagation, thereby enhancing the fatigue life of components exposed to cyclic loading conditions.

- Corrosion resistance improvement through LSP: Laser shock peening can significantly improve the corrosion resistance of metallic materials by creating a dense, compressive stress layer on the surface. This compressive layer helps prevent the initiation and propagation of corrosion pits and stress corrosion cracking. The treatment modifies the microstructure of the surface layer, making it more resistant to corrosive environments while simultaneously enhancing mechanical properties.

- Combined corrosion-fatigue resistance through surface modification: The dual benefits of laser shock peening address both corrosion and fatigue mechanisms, which often work synergistically to cause premature failure in components. By inducing compressive residual stresses and refining the microstructure at the surface, LSP creates a barrier that resists both corrosive attack and fatigue crack initiation. This combined protection is particularly valuable in aggressive environments where both corrosion and cyclic loading are present.

- Process parameters optimization for LSP: The effectiveness of laser shock peening in improving corrosion-fatigue resistance depends on optimizing various process parameters. These include laser power density, pulse duration, spot size, overlap rate, and number of impacts. Proper selection of these parameters is crucial to achieve the desired depth of compressive residual stress without causing thermal damage to the material. Advanced control systems and modeling techniques help in determining the optimal parameters for specific materials and applications.

- Application-specific LSP treatments for critical components: Laser shock peening treatments can be tailored for specific applications and components that are particularly susceptible to corrosion-fatigue failure. These include aircraft components, marine structures, power generation equipment, and biomedical implants. The treatment parameters and coverage patterns are customized based on the component geometry, material properties, and expected service conditions to maximize the improvement in corrosion-fatigue resistance where it is most needed.

02 Process parameters optimization for laser shock peening

Optimizing process parameters is crucial for achieving maximum corrosion fatigue resistance through laser shock peening. Key parameters include laser power density, pulse duration, spot size, overlap rate, and number of impacts. Proper selection of these parameters can control the depth and magnitude of compressive residual stresses, which directly affects the corrosion fatigue performance. Advanced control systems can be implemented to maintain consistent processing conditions and ensure uniform treatment across complex component geometries.Expand Specific Solutions03 Material-specific laser shock peening applications

Different materials respond uniquely to laser shock peening treatments, requiring tailored approaches to maximize corrosion fatigue resistance. For aluminum alloys, specific laser parameters can enhance surface properties without causing thermal damage. Titanium alloys benefit from carefully controlled peening to create optimal compressive stress profiles. Steel components require higher energy densities to achieve sufficient penetration depth of compressive stresses. Specialized techniques have been developed for treating nickel-based superalloys used in aggressive environments where both corrosion and fatigue are concerns.Expand Specific Solutions04 Combined surface treatments with laser shock peening

Combining laser shock peening with other surface treatments can create synergistic effects that further enhance corrosion fatigue resistance. Sequential application of laser shock peening and protective coatings can provide both mechanical strengthening and chemical barrier protection. Hybrid treatments involving laser shock peening followed by shot peening can optimize the residual stress profile at different depths. Pre-treatments such as surface cleaning or chemical etching before laser shock peening can improve process effectiveness by ensuring better energy coupling and more uniform treatment results.Expand Specific Solutions05 Evaluation and testing of laser shock peened components

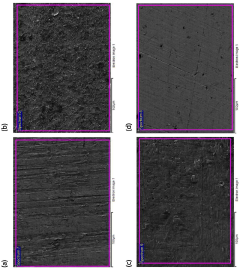

Specialized testing methodologies have been developed to evaluate the effectiveness of laser shock peening in improving corrosion fatigue resistance. These include accelerated corrosion fatigue testing in simulated service environments, residual stress measurement techniques such as X-ray diffraction and hole-drilling methods, and microstructural analysis to assess changes in surface properties. Non-destructive evaluation techniques can be employed to monitor the condition of laser shock peened components during service, allowing for timely maintenance interventions and extended component life in corrosive environments.Expand Specific Solutions

Key Industry Players in LSP Technology

Laser Shock Peening (LSP) for corrosion fatigue resistance is in the growth phase of industry development, with an expanding market driven by aerospace, automotive, and energy sectors. The technology has reached moderate maturity, with key players demonstrating varied expertise levels. Leading companies like LSP Technologies and Metal Improvement Co. have commercialized specialized services, while major corporations such as General Electric, RTX Corp. (formerly United Technologies), and Airbus are integrating LSP into manufacturing processes. Academic institutions, particularly Beihang University, Jiangsu University, and Lawrence Livermore National Security, are advancing fundamental research. The competitive landscape shows a balance between specialized service providers, large industrial adopters, and research institutions collaborating to enhance LSP applications for improved material performance.

General Electric Company

Technical Solution: General Electric has developed an advanced Laser Shock Peening (LSP) technology specifically optimized for turbine components operating in corrosive environments. Their proprietary system utilizes high-energy laser pulses (typically 10-20 J) with precisely controlled spot sizes (3-5mm) and overlapping patterns to create deep compressive residual stresses (up to 1-2mm depth) in critical components like turbine blades and discs. GE's approach incorporates sophisticated process monitoring with real-time feedback control to ensure consistent treatment quality across complex geometries. Their research has demonstrated that LSP-treated nickel-based superalloys in power generation turbines show 3-5x improvement in corrosion fatigue life when exposed to hot corrosive gases containing sulfur and sodium compounds. The technology has been successfully implemented in GE's F-class and H-class gas turbines, where components experience both high mechanical stresses and corrosive environments at elevated temperatures. GE has also developed specialized LSP treatments for steam turbine components exposed to water droplet erosion and stress corrosion cracking.

Strengths: Extensive experience applying LSP to actual production components; integrated approach combining materials science and process engineering; ability to treat complex geometries in turbomachinery. Weaknesses: Technology primarily optimized for GE's own product lines; high capital investment required; treatment process can be time-consuming for large components.

LSP Technologies, Inc.

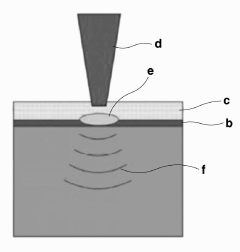

Technical Solution: LSP Technologies has pioneered commercial laser shock peening (LSP) technology specifically for corrosion fatigue resistance enhancement. Their patented Procudo® Laser Peening System delivers controlled high-energy laser pulses (5-10 J) at nanosecond durations to create deep compressive residual stresses (up to 4-5mm depth) in metal components. The process involves applying an opaque overlay (typically black tape or paint) and a transparent overlay (usually flowing water) to the metal surface before laser application. When the laser pulse strikes the opaque overlay, it creates plasma that generates a pressure wave exceeding the material's dynamic yield strength, inducing beneficial compressive stresses that significantly improve corrosion fatigue life by factors of 5-20x compared to untreated components. Their technology has been validated across aerospace, power generation, and marine applications where components face combined corrosive environments and cyclic loading.

Strengths: Industry-leading expertise with proprietary equipment specifically designed for LSP; scalable solutions for various component sizes; proven track record in aerospace and power generation sectors. Weaknesses: Higher implementation cost compared to conventional peening methods; requires specialized equipment and expertise; process parameters must be carefully controlled for optimal results.

Core Patents and Research in LSP Applications

Method of improving corrosion resistance using laser peening

PatentPendingKR1020230078251A

Innovation

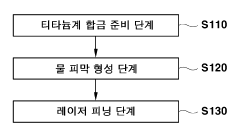

- A method involving attaching a vinyl tape to the titanium-based alloy, spraying water to form a film, and performing laser peening using a Yb:YAG laser with specific parameters to increase compressive residual stress and enhance corrosion resistance.

Combined treatment method for improving corrosion resistance of metal component in chlorine-containing solution

PatentActiveUS20210164106A1

Innovation

- The method involves large-area overlapping laser shock peening without an absorbing layer using a chlorine-containing solution as a constraining layer to form a passivation film, followed by polishing and additional laser shock peening with an absorbing layer at room temperature, inducing residual compressive stress and refining surface grains to enhance corrosion resistance.

Material Compatibility and Selection Criteria

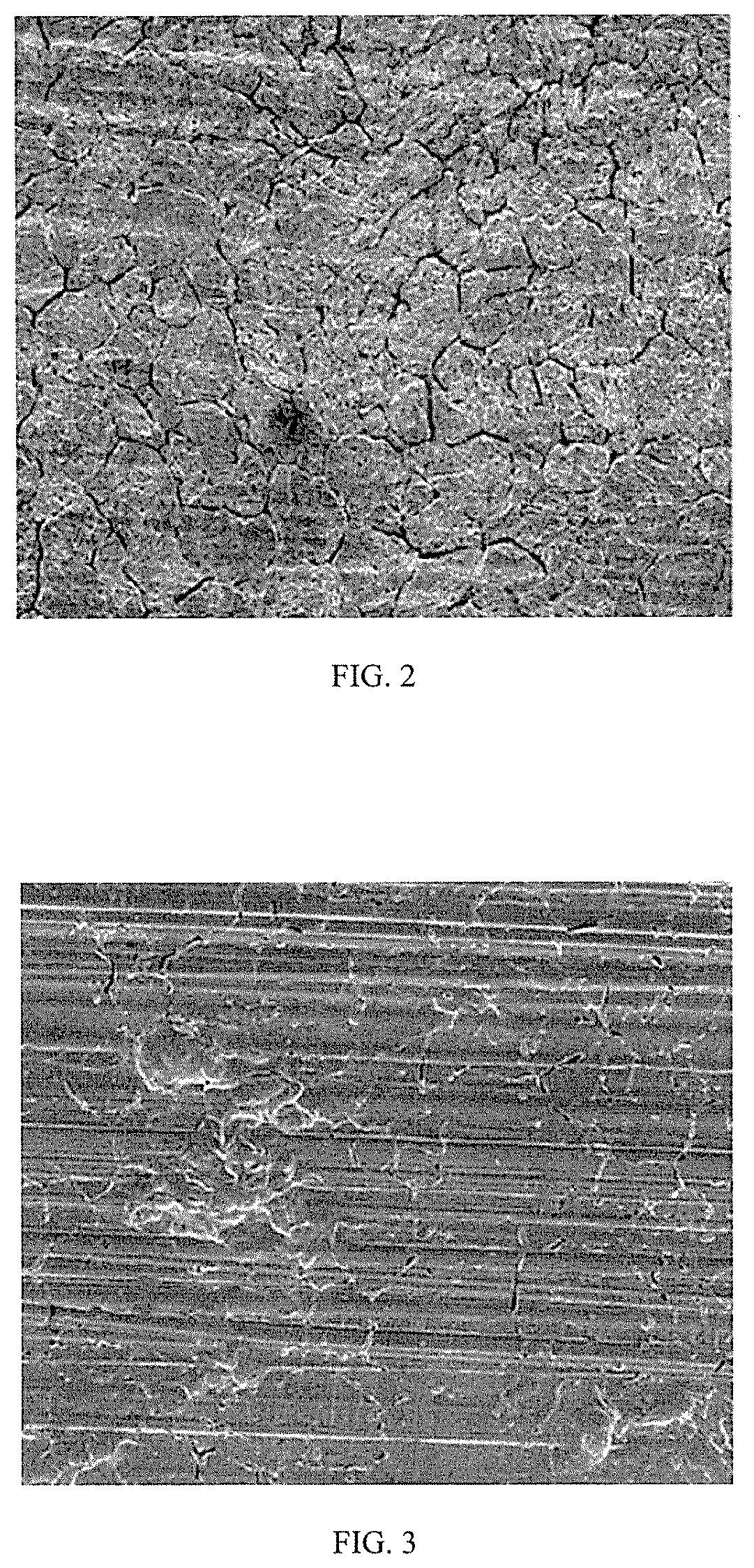

Material compatibility is a critical factor in determining the effectiveness of Laser Shock Peening (LSP) for enhancing corrosion fatigue resistance. Different materials respond uniquely to the LSP process due to variations in their mechanical properties, microstructure, and chemical composition. Metals with higher yield strength typically exhibit greater residual compressive stress after LSP treatment, resulting in superior corrosion fatigue performance.

Aluminum alloys, particularly those used in aerospace applications (2XXX and 7XXX series), demonstrate excellent compatibility with LSP. These alloys show significant improvements in corrosion fatigue life, with studies reporting up to 300% increase in fatigue performance in corrosive environments after LSP treatment. The formation of stable oxide layers combined with compressive residual stresses creates a synergistic effect that inhibits crack initiation and propagation.

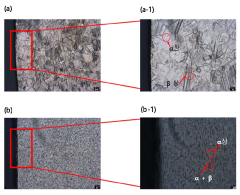

Titanium alloys, especially Ti-6Al-4V widely used in biomedical and aerospace industries, also respond favorably to LSP. The treatment induces deep compressive residual stresses without significantly altering the material's microstructure, preserving its biocompatibility while enhancing corrosion fatigue resistance in chloride-containing environments.

Selection criteria for LSP application must consider several material-specific parameters. First, the material's strain hardening capacity directly influences the magnitude and depth of compressive residual stresses achievable. Materials with higher strain hardening coefficients generally exhibit more pronounced improvements in corrosion fatigue resistance after LSP treatment.

Surface condition prior to LSP treatment significantly impacts results. Materials with pre-existing surface defects or corrosion damage may require preliminary surface preparation to maximize LSP effectiveness. The presence of coatings or surface treatments must also be evaluated, as these can either enhance or impede the LSP process depending on their properties.

Thermal stability of the induced residual stresses is another crucial selection criterion. Materials operating in elevated temperature environments must maintain the beneficial compressive stresses to ensure long-term corrosion fatigue resistance. Nickel-based superalloys demonstrate superior thermal stability of LSP-induced residual stresses compared to aluminum alloys, making them preferable for high-temperature applications.

Microstructural characteristics, including grain size, phase distribution, and inclusion content, significantly influence LSP effectiveness. Fine-grained materials typically exhibit more uniform residual stress distributions and consequently more consistent improvements in corrosion fatigue performance. Materials with high inclusion content may experience stress concentration effects that potentially diminish LSP benefits.

Aluminum alloys, particularly those used in aerospace applications (2XXX and 7XXX series), demonstrate excellent compatibility with LSP. These alloys show significant improvements in corrosion fatigue life, with studies reporting up to 300% increase in fatigue performance in corrosive environments after LSP treatment. The formation of stable oxide layers combined with compressive residual stresses creates a synergistic effect that inhibits crack initiation and propagation.

Titanium alloys, especially Ti-6Al-4V widely used in biomedical and aerospace industries, also respond favorably to LSP. The treatment induces deep compressive residual stresses without significantly altering the material's microstructure, preserving its biocompatibility while enhancing corrosion fatigue resistance in chloride-containing environments.

Selection criteria for LSP application must consider several material-specific parameters. First, the material's strain hardening capacity directly influences the magnitude and depth of compressive residual stresses achievable. Materials with higher strain hardening coefficients generally exhibit more pronounced improvements in corrosion fatigue resistance after LSP treatment.

Surface condition prior to LSP treatment significantly impacts results. Materials with pre-existing surface defects or corrosion damage may require preliminary surface preparation to maximize LSP effectiveness. The presence of coatings or surface treatments must also be evaluated, as these can either enhance or impede the LSP process depending on their properties.

Thermal stability of the induced residual stresses is another crucial selection criterion. Materials operating in elevated temperature environments must maintain the beneficial compressive stresses to ensure long-term corrosion fatigue resistance. Nickel-based superalloys demonstrate superior thermal stability of LSP-induced residual stresses compared to aluminum alloys, making them preferable for high-temperature applications.

Microstructural characteristics, including grain size, phase distribution, and inclusion content, significantly influence LSP effectiveness. Fine-grained materials typically exhibit more uniform residual stress distributions and consequently more consistent improvements in corrosion fatigue performance. Materials with high inclusion content may experience stress concentration effects that potentially diminish LSP benefits.

Cost-Benefit Analysis of LSP Implementation

The implementation of Laser Shock Peening (LSP) for enhancing corrosion fatigue resistance represents a significant capital investment for manufacturing operations. Initial equipment costs typically range from $500,000 to $2 million, depending on system sophistication, power capabilities, and automation level. This substantial upfront investment necessitates careful financial analysis to justify adoption.

Operational costs must also be considered, including specialized laser maintenance ($30,000-50,000 annually), trained personnel ($80,000-120,000 per year for specialized operators), and energy consumption (approximately $15-25 per hour of operation). Additionally, the process requires consumables such as ablative layers and confining mediums, adding $10-15 per treated component.

Against these costs, LSP offers compelling long-term benefits. Component lifespan extensions of 3-5 times have been documented in aerospace applications, representing potential savings of millions in replacement parts and maintenance. For example, turbine blade life extension through LSP can reduce replacement frequency by 60-70%, with corresponding reductions in maintenance downtime.

Risk mitigation represents another significant value proposition. LSP-treated components demonstrate 30-40% improved resistance to stress corrosion cracking in marine environments, reducing catastrophic failure risks. This translates to reduced liability exposure and insurance premiums, particularly in critical infrastructure applications.

Return on investment (ROI) analysis indicates break-even periods of 2-4 years for high-value components in aerospace and power generation sectors. For automotive applications, the economics become favorable primarily in high-performance or safety-critical components where failure costs are substantial.

Comparative analysis with alternative surface treatments reveals LSP's superior cost-effectiveness for specific applications. While shot peening costs approximately $0.05-0.10 per square inch, compared to LSP's $0.50-2.00, the deeper residual stress profile and superior fatigue life improvements often justify the premium for critical components.

Implementation strategies can optimize cost-benefit ratios. Selective application of LSP only to high-stress regions rather than entire components can reduce processing costs by 40-60% while maintaining most performance benefits. Additionally, integration into existing production lines rather than standalone processing can significantly reduce handling costs and improve throughput economics.

Operational costs must also be considered, including specialized laser maintenance ($30,000-50,000 annually), trained personnel ($80,000-120,000 per year for specialized operators), and energy consumption (approximately $15-25 per hour of operation). Additionally, the process requires consumables such as ablative layers and confining mediums, adding $10-15 per treated component.

Against these costs, LSP offers compelling long-term benefits. Component lifespan extensions of 3-5 times have been documented in aerospace applications, representing potential savings of millions in replacement parts and maintenance. For example, turbine blade life extension through LSP can reduce replacement frequency by 60-70%, with corresponding reductions in maintenance downtime.

Risk mitigation represents another significant value proposition. LSP-treated components demonstrate 30-40% improved resistance to stress corrosion cracking in marine environments, reducing catastrophic failure risks. This translates to reduced liability exposure and insurance premiums, particularly in critical infrastructure applications.

Return on investment (ROI) analysis indicates break-even periods of 2-4 years for high-value components in aerospace and power generation sectors. For automotive applications, the economics become favorable primarily in high-performance or safety-critical components where failure costs are substantial.

Comparative analysis with alternative surface treatments reveals LSP's superior cost-effectiveness for specific applications. While shot peening costs approximately $0.05-0.10 per square inch, compared to LSP's $0.50-2.00, the deeper residual stress profile and superior fatigue life improvements often justify the premium for critical components.

Implementation strategies can optimize cost-benefit ratios. Selective application of LSP only to high-stress regions rather than entire components can reduce processing costs by 40-60% while maintaining most performance benefits. Additionally, integration into existing production lines rather than standalone processing can significantly reduce handling costs and improve throughput economics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!