Laser Shock Peening for Surface Hardening of Metallic Alloys

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSP Technology Background and Objectives

Laser Shock Peening (LSP) emerged in the 1960s as a surface treatment technology initially developed for aerospace applications. The fundamental principle involves using high-energy laser pulses to generate plasma on a material surface, creating shock waves that induce compressive residual stresses in metallic components. This technology has evolved significantly over the past six decades, transitioning from laboratory experiments to industrial applications across multiple sectors.

The evolution of LSP technology has been marked by continuous improvements in laser systems, from early ruby lasers to modern high-power Nd:YAG and fiber lasers. These advancements have enabled higher processing speeds, greater treatment depths, and more precise control over the peening process. Concurrently, the understanding of material response mechanisms to shock waves has deepened, allowing for more targeted applications and optimized treatment parameters.

Current technological trends in LSP include the development of portable systems for in-situ applications, integration with digital twin technologies for real-time process monitoring, and the expansion of applicable materials beyond traditional aerospace alloys to include advanced materials such as titanium aluminides, metal matrix composites, and additive manufactured components.

The primary objective of LSP technology is to enhance the mechanical properties and performance characteristics of metallic alloys through surface modification. Specifically, LSP aims to improve fatigue life, wear resistance, and corrosion resistance without altering the bulk material properties or component dimensions. These improvements are achieved by inducing deep compressive residual stresses that inhibit crack initiation and propagation, thereby extending component service life under cyclic loading conditions.

Secondary objectives include developing cost-effective implementation strategies to broaden LSP's industrial adoption beyond high-value aerospace components. This involves optimizing process parameters, reducing equipment costs, and increasing processing speeds to make LSP economically viable for automotive, medical, and general manufacturing applications.

Long-term technological goals for LSP include achieving precise control over residual stress distributions in complex geometries, developing hybrid processes that combine LSP with other surface treatments for synergistic effects, and establishing comprehensive predictive models that accurately simulate the LSP process and resulting material properties. These advancements would enable tailored surface treatments for specific loading conditions and environmental challenges, maximizing component performance while minimizing material usage.

The evolution of LSP technology has been marked by continuous improvements in laser systems, from early ruby lasers to modern high-power Nd:YAG and fiber lasers. These advancements have enabled higher processing speeds, greater treatment depths, and more precise control over the peening process. Concurrently, the understanding of material response mechanisms to shock waves has deepened, allowing for more targeted applications and optimized treatment parameters.

Current technological trends in LSP include the development of portable systems for in-situ applications, integration with digital twin technologies for real-time process monitoring, and the expansion of applicable materials beyond traditional aerospace alloys to include advanced materials such as titanium aluminides, metal matrix composites, and additive manufactured components.

The primary objective of LSP technology is to enhance the mechanical properties and performance characteristics of metallic alloys through surface modification. Specifically, LSP aims to improve fatigue life, wear resistance, and corrosion resistance without altering the bulk material properties or component dimensions. These improvements are achieved by inducing deep compressive residual stresses that inhibit crack initiation and propagation, thereby extending component service life under cyclic loading conditions.

Secondary objectives include developing cost-effective implementation strategies to broaden LSP's industrial adoption beyond high-value aerospace components. This involves optimizing process parameters, reducing equipment costs, and increasing processing speeds to make LSP economically viable for automotive, medical, and general manufacturing applications.

Long-term technological goals for LSP include achieving precise control over residual stress distributions in complex geometries, developing hybrid processes that combine LSP with other surface treatments for synergistic effects, and establishing comprehensive predictive models that accurately simulate the LSP process and resulting material properties. These advancements would enable tailored surface treatments for specific loading conditions and environmental challenges, maximizing component performance while minimizing material usage.

Market Demand Analysis for Advanced Surface Hardening

The global market for advanced surface hardening technologies has witnessed significant growth in recent years, with Laser Shock Peening (LSP) emerging as a particularly promising technique. The demand for LSP is primarily driven by industries requiring components with enhanced fatigue life, improved wear resistance, and superior corrosion resistance properties.

Aerospace and defense sectors represent the largest market segments for LSP technology, accounting for approximately 40% of the current market share. These industries require high-performance components capable of withstanding extreme operational conditions while maintaining structural integrity over extended service periods. Commercial aviation manufacturers are increasingly adopting LSP for critical components such as turbine blades, compressor discs, and landing gear parts.

The automotive industry presents another substantial market opportunity, particularly in the premium and performance vehicle segments. As manufacturers continue to pursue lightweight design strategies while maintaining structural integrity, LSP offers an effective solution for strengthening aluminum and other lightweight alloy components without adding mass. The technology enables automakers to meet stringent fuel efficiency standards while ensuring component durability.

Medical device manufacturing represents an emerging market with significant growth potential. LSP can enhance the performance and longevity of implantable devices such as orthopedic implants and cardiovascular stents. The biomedical sector's stringent requirements for material performance and biocompatibility align well with LSP's capabilities to create precisely controlled surface properties without chemical contamination.

Energy sector applications, particularly in power generation equipment, oil and gas infrastructure, and renewable energy systems, demonstrate increasing demand for LSP technology. Components subjected to high-stress environments, corrosive conditions, or cyclic loading benefit substantially from the enhanced surface properties that LSP provides.

Market analysis indicates the global surface hardening technology market is growing at a compound annual growth rate of 6.8%, with advanced techniques like LSP experiencing even higher adoption rates. This growth trajectory is expected to continue as industries increasingly recognize the cost-benefit advantages of LSP over traditional surface treatment methods.

Regional market assessment shows North America and Europe currently leading in LSP adoption, primarily due to their established aerospace and defense industries. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization, expanding manufacturing capabilities, and increasing investment in advanced materials processing technologies.

Aerospace and defense sectors represent the largest market segments for LSP technology, accounting for approximately 40% of the current market share. These industries require high-performance components capable of withstanding extreme operational conditions while maintaining structural integrity over extended service periods. Commercial aviation manufacturers are increasingly adopting LSP for critical components such as turbine blades, compressor discs, and landing gear parts.

The automotive industry presents another substantial market opportunity, particularly in the premium and performance vehicle segments. As manufacturers continue to pursue lightweight design strategies while maintaining structural integrity, LSP offers an effective solution for strengthening aluminum and other lightweight alloy components without adding mass. The technology enables automakers to meet stringent fuel efficiency standards while ensuring component durability.

Medical device manufacturing represents an emerging market with significant growth potential. LSP can enhance the performance and longevity of implantable devices such as orthopedic implants and cardiovascular stents. The biomedical sector's stringent requirements for material performance and biocompatibility align well with LSP's capabilities to create precisely controlled surface properties without chemical contamination.

Energy sector applications, particularly in power generation equipment, oil and gas infrastructure, and renewable energy systems, demonstrate increasing demand for LSP technology. Components subjected to high-stress environments, corrosive conditions, or cyclic loading benefit substantially from the enhanced surface properties that LSP provides.

Market analysis indicates the global surface hardening technology market is growing at a compound annual growth rate of 6.8%, with advanced techniques like LSP experiencing even higher adoption rates. This growth trajectory is expected to continue as industries increasingly recognize the cost-benefit advantages of LSP over traditional surface treatment methods.

Regional market assessment shows North America and Europe currently leading in LSP adoption, primarily due to their established aerospace and defense industries. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization, expanding manufacturing capabilities, and increasing investment in advanced materials processing technologies.

Current Status and Challenges in Laser Shock Peening

Laser Shock Peening (LSP) has emerged as a revolutionary surface treatment technology for metallic alloys, with significant advancements achieved globally over the past two decades. Currently, the technology has matured from laboratory research to industrial applications, particularly in aerospace, automotive, and medical industries. Leading research institutions in the United States, China, Europe, and Japan have established comprehensive LSP research platforms, with the technology being successfully implemented in critical components such as aircraft engine blades, nuclear reactor components, and orthopedic implants.

Despite its progress, LSP faces several technical challenges that limit its broader adoption. The high-power laser systems required for effective peening remain costly, with typical industrial systems ranging from $500,000 to several million dollars, restricting accessibility for small and medium enterprises. Energy efficiency is another significant concern, as current systems convert only 10-15% of input energy into useful shock waves, with the remainder dissipated as heat.

Process control presents a substantial challenge, as the complex interaction between laser parameters, confining media, and material properties makes it difficult to achieve consistent results across different geometries and alloy compositions. Real-time monitoring systems capable of adjusting parameters during processing remain underdeveloped, leading to quality control issues in production environments.

The geographical distribution of LSP technology shows concentration in industrialized nations, with the United States and China leading in patent filings. European countries, particularly Germany and France, focus on precision applications, while Japan specializes in miniaturized systems for electronics components. Developing nations face significant barriers to entry due to the high capital investment required.

Material-specific challenges persist, as different alloy systems respond uniquely to LSP treatment. For instance, high-strength aluminum alloys show excellent response, while titanium alloys require modified parameters due to their lower thermal conductivity. The treatment of advanced materials such as metal matrix composites and additively manufactured components remains particularly challenging due to their heterogeneous microstructures.

Scale-up limitations also hinder widespread industrial adoption. Current systems typically process areas of 25-100 cm² per hour, which is insufficient for large structural components. Additionally, complex geometries with internal features remain difficult to treat effectively, limiting applications in certain industries.

Despite its progress, LSP faces several technical challenges that limit its broader adoption. The high-power laser systems required for effective peening remain costly, with typical industrial systems ranging from $500,000 to several million dollars, restricting accessibility for small and medium enterprises. Energy efficiency is another significant concern, as current systems convert only 10-15% of input energy into useful shock waves, with the remainder dissipated as heat.

Process control presents a substantial challenge, as the complex interaction between laser parameters, confining media, and material properties makes it difficult to achieve consistent results across different geometries and alloy compositions. Real-time monitoring systems capable of adjusting parameters during processing remain underdeveloped, leading to quality control issues in production environments.

The geographical distribution of LSP technology shows concentration in industrialized nations, with the United States and China leading in patent filings. European countries, particularly Germany and France, focus on precision applications, while Japan specializes in miniaturized systems for electronics components. Developing nations face significant barriers to entry due to the high capital investment required.

Material-specific challenges persist, as different alloy systems respond uniquely to LSP treatment. For instance, high-strength aluminum alloys show excellent response, while titanium alloys require modified parameters due to their lower thermal conductivity. The treatment of advanced materials such as metal matrix composites and additively manufactured components remains particularly challenging due to their heterogeneous microstructures.

Scale-up limitations also hinder widespread industrial adoption. Current systems typically process areas of 25-100 cm² per hour, which is insufficient for large structural components. Additionally, complex geometries with internal features remain difficult to treat effectively, limiting applications in certain industries.

Current LSP Technical Solutions for Metallic Alloys

01 Laser shock peening process fundamentals

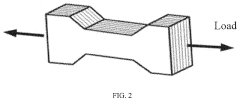

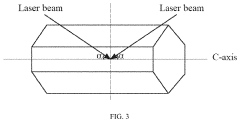

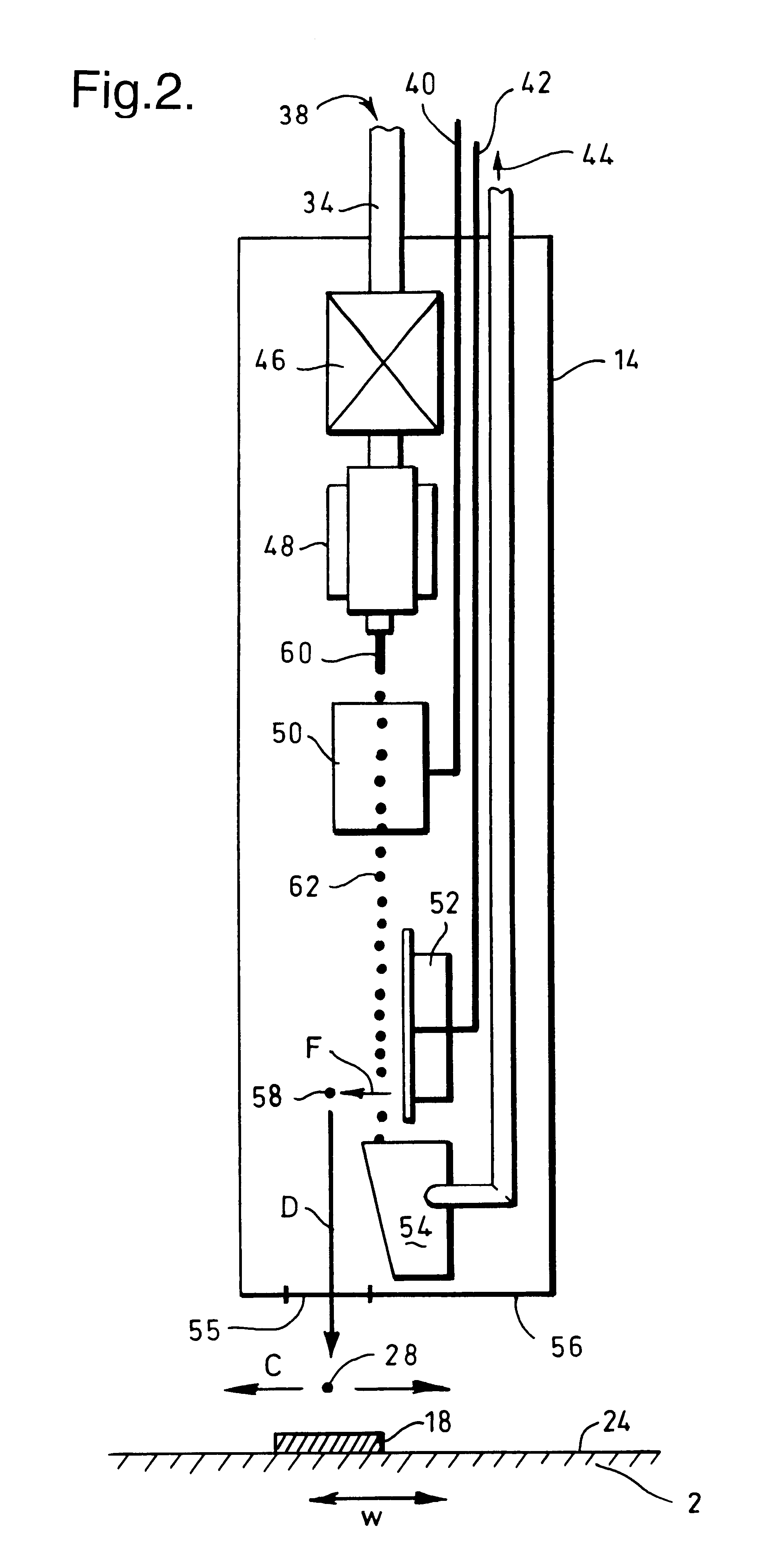

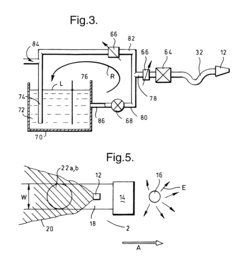

Laser shock peening (LSP) is a surface treatment process that uses high-energy laser pulses to generate shock waves on the material surface. These shock waves induce compressive residual stresses in the material, which significantly improve its fatigue life, wear resistance, and hardness. The process involves applying an opaque overlay (typically black paint) and a transparent overlay (usually water) to the material surface before laser irradiation. The confined plasma generated by the laser creates pressure waves that plastically deform the surface layers.- Laser shock peening process fundamentals: Laser shock peening (LSP) is a surface treatment process that uses high-energy laser pulses to generate shock waves on the material surface. These shock waves induce compressive residual stresses in the material, which significantly improve its fatigue life, wear resistance, and hardness. The process involves applying an opaque overlay (typically black paint or tape) to the target surface, followed by a transparent overlay (usually water). When the laser pulse strikes the opaque overlay, it creates a high-pressure plasma that generates a shock wave, which plastically deforms the material surface and increases its hardness.

- Advanced laser configurations for shock peening: Various laser configurations have been developed to enhance the effectiveness of laser shock peening. These include pulsed lasers with specific wavelengths, energy densities, and pulse durations optimized for different materials. Advanced systems may incorporate multiple laser beams, scanning technologies, or specialized optics to treat complex geometries. Some configurations utilize fiber lasers or diode-pumped solid-state lasers that offer better control over the peening parameters, resulting in more consistent surface hardening outcomes and improved processing efficiency.

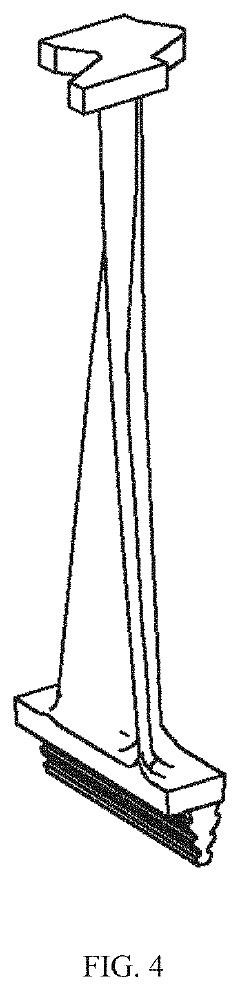

- Material-specific laser shock peening applications: Laser shock peening has been adapted for various materials including metals, alloys, and composites. The process parameters must be tailored to the specific material properties to achieve optimal hardening results. For example, titanium alloys, aluminum alloys, and steel components in aerospace applications require different laser intensities and pulse durations. The technique has been successfully applied to turbine blades, gear components, medical implants, and automotive parts. Recent developments include applications for additive manufactured components and thin-walled structures where traditional hardening methods might cause distortion.

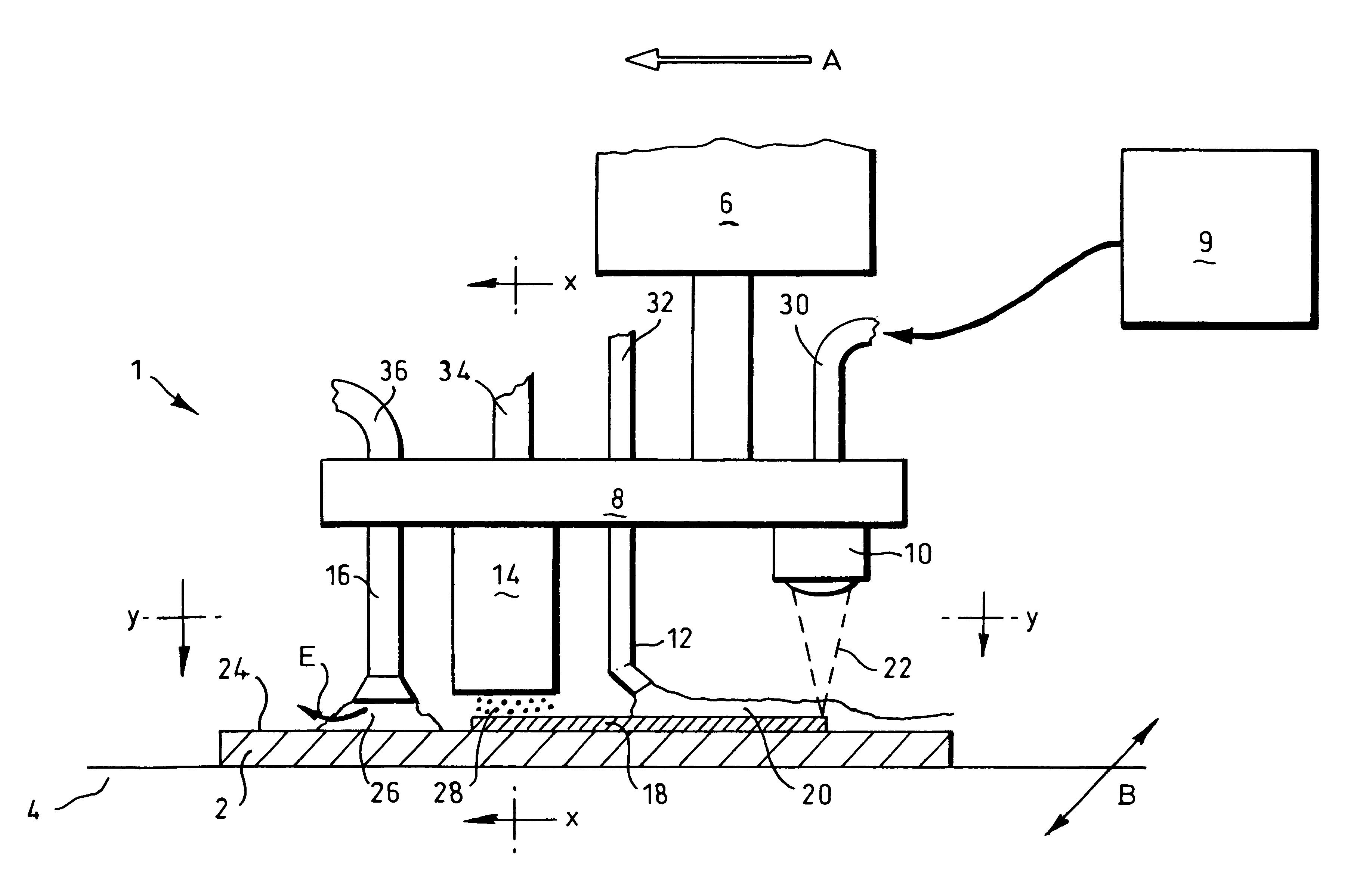

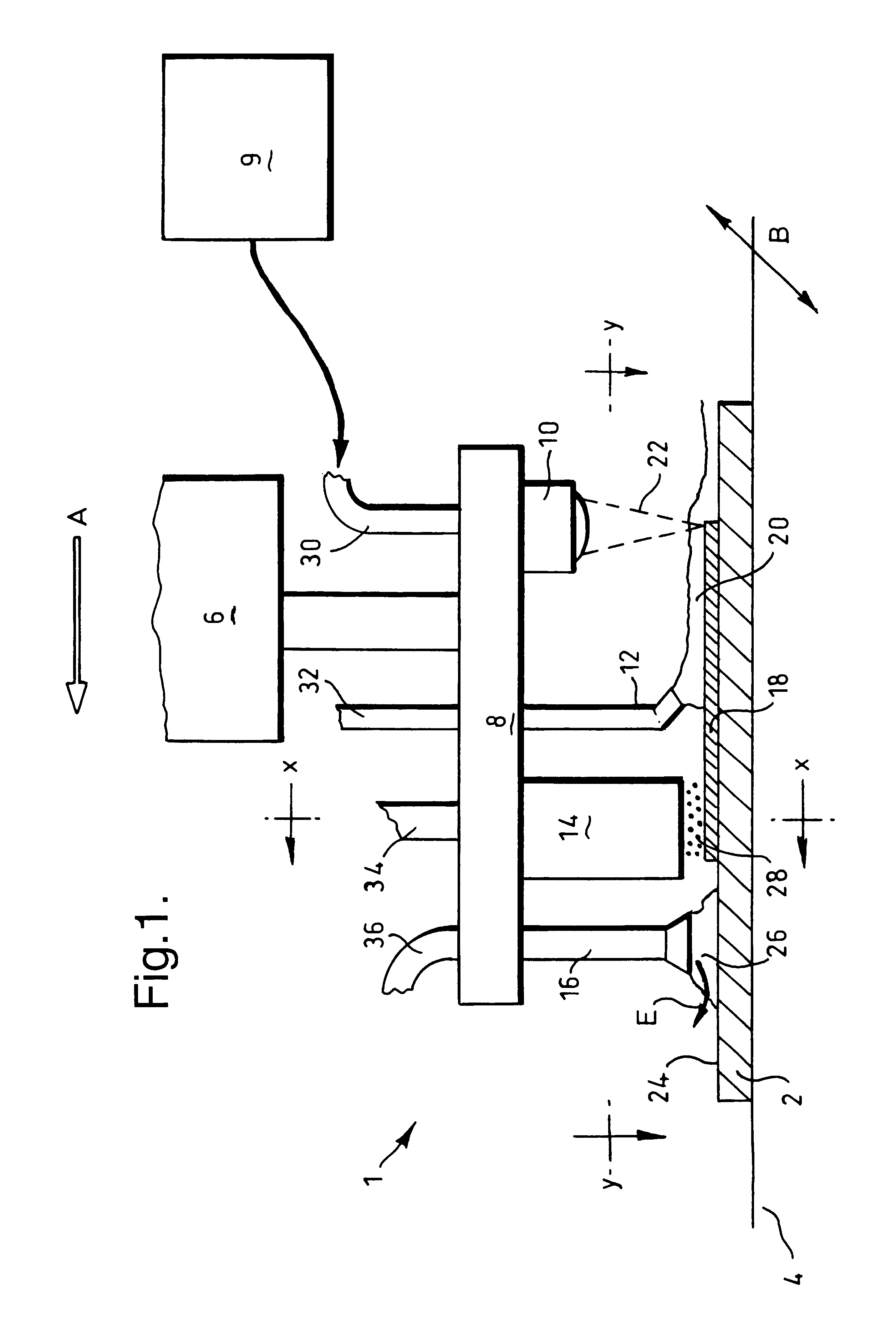

- Process optimization and control systems: Advanced control systems have been developed to optimize the laser shock peening process for surface hardening. These systems monitor and adjust parameters such as laser power, spot size, pulse duration, and overlap percentage in real-time. Computer modeling and simulation tools help predict the residual stress distribution and material response before actual processing. Some systems incorporate in-situ monitoring using sensors that measure plasma formation, shock wave propagation, and surface deformation. Automated robotic systems ensure precise positioning and movement of the laser beam relative to complex component geometries, resulting in uniform surface treatment and consistent hardening results.

- Combined surface treatment approaches: Hybrid approaches that combine laser shock peening with other surface treatment methods have been developed to enhance surface hardening effects. These combinations include laser shock peening followed by traditional heat treatment, nitriding, or coating processes. Sequential application of laser shock peening and shot peening can create deeper compressive stress layers than either process alone. Some approaches integrate laser shock peening with ultrasonic impact treatment or friction stir processing to achieve superior surface properties. These combined techniques allow for customized surface hardening solutions that address specific wear, fatigue, and corrosion requirements for high-performance components.

02 Equipment and laser parameters optimization

The effectiveness of laser shock peening depends on optimizing various parameters including laser power density, pulse duration, spot size, and repetition rate. Advanced laser systems with precise control over these parameters are essential for achieving consistent surface hardening results. The equipment typically includes high-energy pulsed lasers (Nd:YAG or Nd:glass), beam delivery systems, positioning mechanisms, and monitoring devices. Proper calibration and maintenance of these systems ensure uniform treatment and maximum hardening effect across complex geometries.Expand Specific Solutions03 Material-specific applications and enhancements

Laser shock peening can be tailored for specific materials including titanium alloys, aluminum alloys, stainless steels, and nickel-based superalloys. The process parameters need to be adjusted based on the material properties to achieve optimal hardening results. For some materials, multiple treatments or combined processes (such as laser shock peening followed by heat treatment) may be employed to further enhance surface properties. The depth of the hardened layer and the magnitude of compressive residual stress can be controlled by adjusting the process parameters according to the material characteristics.Expand Specific Solutions04 Advanced techniques and process innovations

Recent innovations in laser shock peening include warm laser shock peening, which combines the process with controlled heating to enhance the depth and magnitude of compressive residual stresses. Other advancements include laser shock peening without coating (LSPwC), which eliminates the need for sacrificial coatings, and selective laser shock peening for treating specific critical areas. Computer modeling and simulation tools are increasingly used to predict the effects of laser shock peening on different materials and geometries, allowing for process optimization before actual implementation.Expand Specific Solutions05 Industrial applications and quality control

Laser shock peening is widely applied in aerospace, automotive, and power generation industries to enhance the fatigue life and durability of critical components such as turbine blades, gears, and structural elements. The process requires robust quality control measures including surface inspection, residual stress measurement, and microstructural analysis to ensure consistent hardening results. Non-destructive testing methods such as X-ray diffraction and ultrasonic techniques are commonly used to verify the effectiveness of the treatment. Automated systems with real-time monitoring capabilities help maintain process stability and repeatability in industrial settings.Expand Specific Solutions

Major Players in LSP Technology and Equipment

Laser Shock Peening (LSP) for metallic alloy surface hardening is in a growth phase, with the market expanding due to increasing demand in aerospace, automotive, and energy sectors. The global market size is estimated to reach $300-400 million by 2025, growing at 8-10% annually. Technologically, LSP has matured from experimental to commercial applications, with varying levels of implementation across key players. Companies like Metal Improvement Co. LLC and LSP Technologies lead with established commercial services, while General Electric and United Technologies have integrated LSP into their manufacturing processes. Academic institutions (Jiangsu University, Wuhan University) and research organizations (Lawrence Livermore National Security) continue advancing fundamental aspects, while aerospace companies (Airbus, Rolls-Royce) are adopting LSP for critical components, indicating industry-wide recognition of its benefits.

General Electric Company

Technical Solution: General Electric has developed advanced laser shock peening (LSP) technology primarily for aircraft engine components. Their approach utilizes high-energy laser pulses (typically 10-40 joules) with nanosecond durations to generate plasma on metal surfaces, creating pressure waves exceeding 1 GPa. GE's implementation includes proprietary overlay systems that optimize the shock wave transmission into the material while preventing thermal effects. The company has integrated robotic manipulation systems that enable precise treatment of complex geometries such as turbine blades with curved airfoils. GE's LSP process has been documented to improve fatigue life by 3-5x in critical components and has been implemented in production for CFM56 and GEnx engine fan blades. Their technology creates compressive residual stresses to depths of 1-2mm, significantly deeper than conventional shot peening (typically 0.25mm). GE has also developed specialized LSP treatments for dovetail regions of turbine disks, where stress concentration is particularly problematic, and has implemented in-situ monitoring systems to ensure process quality and consistency.

Strengths: Extensive integration with manufacturing systems for high-volume production; comprehensive material science expertise to optimize parameters for specific alloys; proven implementation in critical aerospace applications. Weaknesses: Proprietary systems limit broader industry adoption; high capital investment requirements; process optimization can be time-consuming for new applications or materials.

METAL IMPROVEMENT CO LLC

Technical Solution: Metal Improvement Company (MIC), a subsidiary of Curtiss-Wright Surface Technologies, has developed a comprehensive laser shock peening (LSP) technology platform for surface hardening of metallic alloys. Their system utilizes Nd:glass lasers delivering 10-40 joule pulses with durations of 10-30 nanoseconds at frequencies up to 10 Hz. MIC's process employs a proprietary overlay system consisting of an ablative layer (typically black paint or aluminum foil) and a transparent overlay (usually flowing water) to enhance pressure wave generation and prevent thermal effects. Their technology creates compressive residual stresses extending to depths of 1-2.5mm in titanium alloys and 0.8-1.5mm in aluminum alloys, significantly deeper than conventional shot peening. MIC has developed specialized robotic manipulation systems that enable precise treatment of complex geometries such as turbine blades, landing gear components, and medical implants. Their process has been validated to improve fatigue life by 3-10x in various aerospace components and has been implemented in production for multiple commercial and military aircraft programs. MIC also offers hybrid surface treatment solutions combining LSP with other processes like shot peening for optimized surface properties.

Strengths: Extensive industrial implementation experience across multiple sectors; comprehensive quality control systems; ability to process large and complex components; established supply chain for production-scale operations. Weaknesses: Higher processing costs compared to conventional peening methods; treatment speed limitations for high-volume applications; requires specialized facilities and expertise.

Key Technical Innovations in Laser Shock Peening

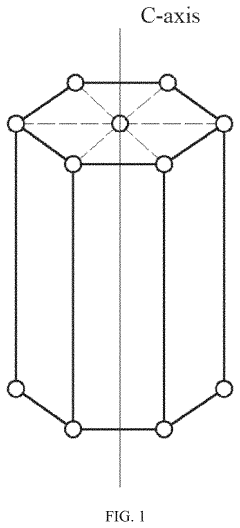

Laser shock peening method for additive manufactured component of double-phase titanium alloy

PatentActiveUS20210308767A1

Innovation

- A method combining selective laser melting with laser shock peening, where a three-dimensional digital model of a complex component is divided into slices, formed with consistent α-phase orientations using a strong magnetic field, and then subjected to laser shock peening with a shock wave angle optimized to enhance compressive residual stress and grain refinement.

Method and apparatus for improving material properties

PatentInactiveUS6923877B1

Innovation

- Concurrently applying an opaque and a translucent laser-opaque overlay, along with laser shock peening, using a common tool head with an inkjet or bubble jet printer for rapid and precise application, eliminating the need for separate machines and reducing handling.

Material Compatibility and Process Optimization

Laser Shock Peening (LSP) demonstrates varying effectiveness across different metallic alloys, necessitating comprehensive material compatibility analysis. Aluminum alloys, particularly the 2000 and 7000 series, exhibit excellent response to LSP treatment, achieving significant improvements in fatigue life and stress corrosion cracking resistance. Titanium alloys, especially Ti-6Al-4V widely used in aerospace applications, show remarkable enhancement in wear resistance and fatigue performance when properly processed with LSP.

Steel alloys present more complex behavior, with high-strength steels generally responding well but requiring careful parameter optimization to prevent excessive surface melting. Nickel-based superalloys used in turbine components demonstrate substantial improvements in high-temperature performance after LSP treatment, though they typically require higher laser energy densities compared to other alloys.

Process optimization for LSP involves several critical parameters that must be tailored to specific material characteristics. Laser pulse energy density, typically ranging from 2-10 GW/cm², must be calibrated based on material yield strength and desired penetration depth. Pulse duration, commonly between 3-30 nanoseconds, significantly affects the shock wave propagation and resulting plastic deformation depth.

Spot size and overlap percentage determine treatment uniformity, with typical overlap rates of 30-50% ensuring consistent surface coverage. The confining medium (usually water) and sacrificial overlay (typically aluminum or black paint) must be selected based on material reflectivity and desired pressure wave characteristics. Multiple LSP impacts at the same location can produce cumulative effects, with diminishing returns typically observed after 3-5 impacts.

Temperature control during processing presents a significant challenge, particularly for materials with low thermal conductivity. Excessive heat accumulation can negate the beneficial compressive stresses induced by LSP. Advanced cooling strategies, including cryogenic assistance and pulsed water jets, have demonstrated promising results in maintaining optimal processing temperatures.

Automation and process monitoring represent frontier areas in LSP optimization. Real-time monitoring of plasma formation using high-speed imaging and spectroscopy enables adaptive control of laser parameters. Machine learning algorithms are increasingly employed to predict optimal processing parameters based on material composition and desired property enhancements, reducing the extensive experimental iterations previously required for process optimization.

Steel alloys present more complex behavior, with high-strength steels generally responding well but requiring careful parameter optimization to prevent excessive surface melting. Nickel-based superalloys used in turbine components demonstrate substantial improvements in high-temperature performance after LSP treatment, though they typically require higher laser energy densities compared to other alloys.

Process optimization for LSP involves several critical parameters that must be tailored to specific material characteristics. Laser pulse energy density, typically ranging from 2-10 GW/cm², must be calibrated based on material yield strength and desired penetration depth. Pulse duration, commonly between 3-30 nanoseconds, significantly affects the shock wave propagation and resulting plastic deformation depth.

Spot size and overlap percentage determine treatment uniformity, with typical overlap rates of 30-50% ensuring consistent surface coverage. The confining medium (usually water) and sacrificial overlay (typically aluminum or black paint) must be selected based on material reflectivity and desired pressure wave characteristics. Multiple LSP impacts at the same location can produce cumulative effects, with diminishing returns typically observed after 3-5 impacts.

Temperature control during processing presents a significant challenge, particularly for materials with low thermal conductivity. Excessive heat accumulation can negate the beneficial compressive stresses induced by LSP. Advanced cooling strategies, including cryogenic assistance and pulsed water jets, have demonstrated promising results in maintaining optimal processing temperatures.

Automation and process monitoring represent frontier areas in LSP optimization. Real-time monitoring of plasma formation using high-speed imaging and spectroscopy enables adaptive control of laser parameters. Machine learning algorithms are increasingly employed to predict optimal processing parameters based on material composition and desired property enhancements, reducing the extensive experimental iterations previously required for process optimization.

Industrial Application Cases and Economic Analysis

Laser Shock Peening (LSP) has been successfully implemented across multiple industries, demonstrating significant economic benefits through enhanced component performance and extended service life. In the aerospace sector, General Electric has applied LSP to fan blades in commercial aircraft engines, resulting in a 5-fold increase in fatigue life and estimated maintenance cost reductions of approximately $2.3 million per engine over its operational lifespan. Boeing has similarly reported a 30% improvement in the fatigue resistance of critical airframe components, translating to extended inspection intervals and reduced downtime costs.

The automotive industry has witnessed Volkswagen and Toyota implementing LSP for treating engine components, particularly crankshafts and connecting rods. Economic analysis indicates a 15-20% reduction in warranty claims related to these components, with Toyota reporting annual savings of approximately $1.8 million across their production lines where LSP has been implemented.

In the medical device sector, LSP treatment of titanium alloy implants has demonstrated a 40% improvement in wear resistance and corrosion properties. Medtronic's implementation of LSP for cardiovascular stents has shown a cost-benefit ratio of 1:3.5, with the initial technology investment offset by reduced failure rates and associated liability costs.

Power generation applications present perhaps the most compelling economic case. General Electric's application of LSP to steam turbine blades has extended component life by up to 300%, with maintenance interval extensions generating estimated savings of $4.2 million per turbine over a 15-year operational period. Similarly, Siemens has reported a 25% reduction in unplanned downtime for LSP-treated gas turbine components.

Cost-benefit analyses across these industries reveal that while LSP implementation requires significant initial capital investment ($0.8-2.5 million for industrial-scale systems), the return on investment typically occurs within 2-3 years of operation. Operating costs average $80-150 per treated component, depending on complexity and material. However, these costs are substantially offset by the extended component lifespans, reduced maintenance requirements, and decreased failure rates.

Recent economic modeling suggests that LSP implementation delivers an average net present value of $3.2-5.7 million over a ten-year period for medium-scale industrial applications, with internal rates of return ranging from 18% to 27% depending on the specific application and industry sector.

The automotive industry has witnessed Volkswagen and Toyota implementing LSP for treating engine components, particularly crankshafts and connecting rods. Economic analysis indicates a 15-20% reduction in warranty claims related to these components, with Toyota reporting annual savings of approximately $1.8 million across their production lines where LSP has been implemented.

In the medical device sector, LSP treatment of titanium alloy implants has demonstrated a 40% improvement in wear resistance and corrosion properties. Medtronic's implementation of LSP for cardiovascular stents has shown a cost-benefit ratio of 1:3.5, with the initial technology investment offset by reduced failure rates and associated liability costs.

Power generation applications present perhaps the most compelling economic case. General Electric's application of LSP to steam turbine blades has extended component life by up to 300%, with maintenance interval extensions generating estimated savings of $4.2 million per turbine over a 15-year operational period. Similarly, Siemens has reported a 25% reduction in unplanned downtime for LSP-treated gas turbine components.

Cost-benefit analyses across these industries reveal that while LSP implementation requires significant initial capital investment ($0.8-2.5 million for industrial-scale systems), the return on investment typically occurs within 2-3 years of operation. Operating costs average $80-150 per treated component, depending on complexity and material. However, these costs are substantially offset by the extended component lifespans, reduced maintenance requirements, and decreased failure rates.

Recent economic modeling suggests that LSP implementation delivers an average net present value of $3.2-5.7 million over a ten-year period for medium-scale industrial applications, with internal rates of return ranging from 18% to 27% depending on the specific application and industry sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!