Laser Shock Peening for Turbine Blade Protection

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSP Technology Background and Objectives

Laser Shock Peening (LSP) emerged in the 1960s as a surface treatment technology, initially developed at Battelle Memorial Institute. The fundamental principle involves using high-energy laser pulses to generate plasma on a material surface, creating shock waves that induce compressive residual stresses. This technology has evolved significantly over the past six decades, transitioning from laboratory experiments to industrial applications, particularly in aerospace and power generation sectors.

The evolution of LSP technology has been closely tied to advancements in high-power laser systems. Early implementations utilized ruby lasers with limited power and repetition rates, while modern systems employ Nd:YAG or Nd:glass lasers capable of delivering precisely controlled energy densities exceeding 5 GW/cm². This progression has enabled more efficient and effective treatment processes, expanding the potential applications of LSP technology.

In the context of turbine blade protection, LSP addresses critical challenges in the power generation and aerospace industries. Gas turbine blades operate under extreme conditions, including high temperatures (often exceeding 1000°C), centrifugal forces, and exposure to corrosive environments. These conditions lead to various failure mechanisms such as fatigue cracking, foreign object damage, and stress corrosion cracking, significantly reducing component lifespan and system reliability.

The primary technical objective of LSP for turbine blade protection is to enhance fatigue life and damage tolerance through the introduction of deep compressive residual stresses in the material surface. Research indicates that properly applied LSP can improve fatigue life by 3-5 times compared to untreated components, representing a substantial advancement in turbine durability and operational safety.

Secondary objectives include improving resistance to foreign object damage, mitigating stress corrosion cracking, and enhancing overall component reliability without altering the carefully engineered aerodynamic profiles of turbine blades. The non-contact nature of LSP provides a significant advantage over traditional mechanical surface treatment methods, allowing for precise treatment of complex geometries characteristic of modern turbine blade designs.

The technology trend is moving toward more automated, cost-effective LSP systems with higher processing speeds and adaptability to various component geometries. Recent developments focus on process optimization through computational modeling, allowing for tailored treatment parameters based on specific material properties and component requirements. This trend aligns with the broader industry movement toward digital manufacturing and predictive maintenance strategies in high-value component production.

The evolution of LSP technology has been closely tied to advancements in high-power laser systems. Early implementations utilized ruby lasers with limited power and repetition rates, while modern systems employ Nd:YAG or Nd:glass lasers capable of delivering precisely controlled energy densities exceeding 5 GW/cm². This progression has enabled more efficient and effective treatment processes, expanding the potential applications of LSP technology.

In the context of turbine blade protection, LSP addresses critical challenges in the power generation and aerospace industries. Gas turbine blades operate under extreme conditions, including high temperatures (often exceeding 1000°C), centrifugal forces, and exposure to corrosive environments. These conditions lead to various failure mechanisms such as fatigue cracking, foreign object damage, and stress corrosion cracking, significantly reducing component lifespan and system reliability.

The primary technical objective of LSP for turbine blade protection is to enhance fatigue life and damage tolerance through the introduction of deep compressive residual stresses in the material surface. Research indicates that properly applied LSP can improve fatigue life by 3-5 times compared to untreated components, representing a substantial advancement in turbine durability and operational safety.

Secondary objectives include improving resistance to foreign object damage, mitigating stress corrosion cracking, and enhancing overall component reliability without altering the carefully engineered aerodynamic profiles of turbine blades. The non-contact nature of LSP provides a significant advantage over traditional mechanical surface treatment methods, allowing for precise treatment of complex geometries characteristic of modern turbine blade designs.

The technology trend is moving toward more automated, cost-effective LSP systems with higher processing speeds and adaptability to various component geometries. Recent developments focus on process optimization through computational modeling, allowing for tailored treatment parameters based on specific material properties and component requirements. This trend aligns with the broader industry movement toward digital manufacturing and predictive maintenance strategies in high-value component production.

Market Analysis for Turbine Protection Solutions

The global market for turbine blade protection solutions has witnessed significant growth in recent years, driven primarily by the increasing demand for efficient power generation and the rising adoption of gas turbines across various industries. The market size for turbine protection technologies was valued at approximately $2.3 billion in 2022 and is projected to reach $3.5 billion by 2028, representing a compound annual growth rate (CAGR) of 7.2%.

The aerospace sector currently dominates the market share, accounting for nearly 40% of the total demand for turbine blade protection solutions. This is attributed to the stringent safety requirements and the critical need for extending the service life of aircraft engines. The power generation industry follows closely, contributing about 35% to the market, with marine and industrial applications making up the remainder.

Geographically, North America leads the market with a share of 32%, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to rapid industrialization and increasing investments in power infrastructure, particularly in China and India.

The market for Laser Shock Peening (LSP) specifically has been expanding at a faster rate than the overall turbine protection market, with a CAGR of approximately 9.5%. This accelerated growth can be attributed to LSP's superior performance in enhancing fatigue life and resistance to foreign object damage compared to traditional methods like shot peening.

Key market drivers include the growing emphasis on extending turbine component life, increasing focus on reducing maintenance costs, and stringent regulatory requirements regarding equipment safety and reliability. The aviation industry's push toward more fuel-efficient engines has also contributed significantly to the demand for advanced protection technologies like LSP.

Customer segments in this market include original equipment manufacturers (OEMs) who incorporate protection solutions during production, maintenance, repair, and overhaul (MRO) service providers, and end-users seeking aftermarket solutions. OEMs currently represent the largest customer segment, accounting for approximately 45% of the market.

Market challenges include the high initial investment required for LSP equipment, limited awareness about advanced protection technologies among potential end-users, and the technical expertise required for implementation. Additionally, the economic slowdown in certain regions and budget constraints in the defense sector have temporarily affected market growth in those areas.

The aerospace sector currently dominates the market share, accounting for nearly 40% of the total demand for turbine blade protection solutions. This is attributed to the stringent safety requirements and the critical need for extending the service life of aircraft engines. The power generation industry follows closely, contributing about 35% to the market, with marine and industrial applications making up the remainder.

Geographically, North America leads the market with a share of 32%, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to rapid industrialization and increasing investments in power infrastructure, particularly in China and India.

The market for Laser Shock Peening (LSP) specifically has been expanding at a faster rate than the overall turbine protection market, with a CAGR of approximately 9.5%. This accelerated growth can be attributed to LSP's superior performance in enhancing fatigue life and resistance to foreign object damage compared to traditional methods like shot peening.

Key market drivers include the growing emphasis on extending turbine component life, increasing focus on reducing maintenance costs, and stringent regulatory requirements regarding equipment safety and reliability. The aviation industry's push toward more fuel-efficient engines has also contributed significantly to the demand for advanced protection technologies like LSP.

Customer segments in this market include original equipment manufacturers (OEMs) who incorporate protection solutions during production, maintenance, repair, and overhaul (MRO) service providers, and end-users seeking aftermarket solutions. OEMs currently represent the largest customer segment, accounting for approximately 45% of the market.

Market challenges include the high initial investment required for LSP equipment, limited awareness about advanced protection technologies among potential end-users, and the technical expertise required for implementation. Additionally, the economic slowdown in certain regions and budget constraints in the defense sector have temporarily affected market growth in those areas.

Current LSP Implementation Challenges

Despite the proven effectiveness of Laser Shock Peening (LSP) for turbine blade protection, several significant implementation challenges currently limit its widespread adoption in industrial settings. The primary obstacle remains the high capital investment required for LSP equipment, with specialized high-energy laser systems costing between $2-5 million, making it prohibitive for smaller manufacturers and repair facilities. This financial barrier is compounded by the substantial operational costs, including maintenance of precision optical components and specialized cooling systems.

The process complexity presents another major challenge, as LSP requires precise control of multiple parameters including laser pulse energy, spot size, overlap percentage, and coverage pattern. These parameters must be carefully calibrated for different alloys and geometries, necessitating extensive expertise and experience. The development of standardized processing parameters remains incomplete across the variety of superalloys used in modern turbine blades.

Quality control and verification pose significant technical hurdles. Unlike conventional surface treatments, the residual stress profiles induced by LSP extend deep beneath the surface and cannot be easily measured through conventional inspection techniques. Non-destructive evaluation methods capable of accurately characterizing these subsurface stress states are still evolving, creating uncertainty in quality assurance protocols.

Processing speed limitations represent a substantial bottleneck in production environments. Current LSP systems typically operate at 1-10 Hz pulse repetition rates, resulting in treatment times of several hours for a single turbine blade. This low throughput significantly impacts production efficiency and increases per-unit processing costs, particularly challenging for high-volume manufacturing operations.

Energy efficiency concerns persist as conventional LSP systems convert only 1-3% of electrical input energy into useful mechanical work at the component surface. The remainder is lost as heat, requiring sophisticated cooling systems and contributing to high operational costs and environmental impact.

Geometric accessibility constraints limit LSP application on complex turbine blade features such as cooling holes, thin trailing edges, and intricate internal passages. The line-of-sight nature of laser delivery systems makes treating these critical areas particularly challenging, potentially leaving vulnerable regions unprotected.

Integration with existing manufacturing workflows presents logistical challenges, as LSP often requires specialized handling, preparation, and post-processing steps that may disrupt established production sequences. The development of more flexible, modular LSP systems that can be seamlessly incorporated into existing production lines remains an ongoing engineering challenge.

The process complexity presents another major challenge, as LSP requires precise control of multiple parameters including laser pulse energy, spot size, overlap percentage, and coverage pattern. These parameters must be carefully calibrated for different alloys and geometries, necessitating extensive expertise and experience. The development of standardized processing parameters remains incomplete across the variety of superalloys used in modern turbine blades.

Quality control and verification pose significant technical hurdles. Unlike conventional surface treatments, the residual stress profiles induced by LSP extend deep beneath the surface and cannot be easily measured through conventional inspection techniques. Non-destructive evaluation methods capable of accurately characterizing these subsurface stress states are still evolving, creating uncertainty in quality assurance protocols.

Processing speed limitations represent a substantial bottleneck in production environments. Current LSP systems typically operate at 1-10 Hz pulse repetition rates, resulting in treatment times of several hours for a single turbine blade. This low throughput significantly impacts production efficiency and increases per-unit processing costs, particularly challenging for high-volume manufacturing operations.

Energy efficiency concerns persist as conventional LSP systems convert only 1-3% of electrical input energy into useful mechanical work at the component surface. The remainder is lost as heat, requiring sophisticated cooling systems and contributing to high operational costs and environmental impact.

Geometric accessibility constraints limit LSP application on complex turbine blade features such as cooling holes, thin trailing edges, and intricate internal passages. The line-of-sight nature of laser delivery systems makes treating these critical areas particularly challenging, potentially leaving vulnerable regions unprotected.

Integration with existing manufacturing workflows presents logistical challenges, as LSP often requires specialized handling, preparation, and post-processing steps that may disrupt established production sequences. The development of more flexible, modular LSP systems that can be seamlessly incorporated into existing production lines remains an ongoing engineering challenge.

Current LSP Application Methods

01 Protective coatings for laser shock peening

Protective coatings are applied to workpiece surfaces before laser shock peening to prevent thermal damage and enhance the effectiveness of the process. These coatings, which may include ablative layers and transparent overlays, absorb laser energy and convert it to plasma pressure, protecting the underlying material while allowing the shock wave to propagate effectively. The coatings can be customized based on the material being treated and the desired surface properties.- Protective coatings for laser shock peening: Protective coatings are applied to workpiece surfaces before laser shock peening to prevent thermal damage and enhance the effectiveness of the process. These coatings, typically made of materials like black paint or specialized ablative layers, absorb the laser energy and convert it to a plasma pressure wave that propagates into the material. The coating protects the underlying material from thermal effects while allowing the shock wave to induce beneficial compressive stresses in the workpiece.

- Laser shock peening equipment protection systems: Protection systems for laser shock peening equipment are designed to shield sensitive components from damage during the peening process. These systems include protective barriers, shields, and enclosures that prevent debris, splatter, and reflected laser energy from damaging optical components, positioning systems, and other equipment. Advanced monitoring systems detect potential issues and automatically shut down operations to prevent equipment damage, ensuring consistent processing quality and extending equipment lifespan.

- Workpiece protection during laser shock peening: Methods for protecting workpieces during laser shock peening involve specialized fixtures, cooling systems, and process parameters to prevent distortion or damage. Fixtures secure the workpiece while allowing access to treatment areas and minimizing stress concentration. Cooling systems manage heat buildup during processing of sensitive materials. Process parameters such as laser power, pulse duration, and spot overlap are carefully controlled to achieve desired strengthening effects without causing thermal damage or unwanted deformation to the workpiece.

- Transparent overlay materials for laser shock peening: Transparent overlay materials are applied over the ablative coating during laser shock peening to confine the plasma expansion and increase the magnitude of the shock wave. Common transparent overlays include water, glass, quartz, and various polymers that allow the laser beam to pass through while containing the plasma expansion. The confinement provided by these overlays significantly enhances the pressure of the shock wave, resulting in deeper and more effective residual compressive stresses in the treated material, improving fatigue life and resistance to stress corrosion cracking.

- Quality control and monitoring for laser shock peening protection: Quality control and monitoring systems ensure proper protection during laser shock peening by verifying coating thickness, overlay application, and process parameters. These systems use sensors, cameras, and measurement tools to monitor the condition of protective coatings and overlays in real-time. Advanced monitoring techniques include spectroscopic analysis of the plasma plume, acoustic monitoring of the shock wave, and post-process inspection of the treated surface. These quality control measures ensure consistent protection and optimal strengthening effects across all treated components.

02 Laser shock peening equipment protection

Specialized equipment and systems are designed to protect both the laser apparatus and operators during the laser shock peening process. This includes protective enclosures, beam delivery systems, and monitoring equipment that ensure safe and efficient operation. These protective measures help maintain consistent laser parameters, prevent equipment damage from back-reflections, and shield sensitive components from debris generated during the peening process.Expand Specific Solutions03 Process parameters for optimized protection

Specific process parameters are critical for achieving optimal protection during laser shock peening. These parameters include laser power density, pulse duration, spot size, and overlap patterns. By carefully controlling these variables, the process can be tailored to provide maximum protection against fatigue, stress corrosion cracking, and other forms of material degradation. The optimization of these parameters ensures deep compressive residual stresses without causing surface damage.Expand Specific Solutions04 Environmental protection during laser shock peening

Environmental protection systems are implemented during laser shock peening to contain and manage byproducts of the process. This includes water confinement layers that not only enhance the shock wave but also contain debris, as well as ventilation and filtration systems to manage fumes and particles. These protective measures ensure that the laser shock peening process is environmentally responsible while maintaining process effectiveness.Expand Specific Solutions05 Enhanced material protection through multiple treatments

Multiple laser shock peening treatments can be applied to the same area to enhance the protective qualities of the treated material. This approach creates deeper and more uniform compressive residual stresses, providing superior protection against fatigue, corrosion, and other forms of material degradation. The layered treatment approach can be customized based on the specific requirements of the component and its operating environment.Expand Specific Solutions

Leading LSP Technology Providers

Laser Shock Peening (LSP) for turbine blade protection is in a growth phase, with the market expanding due to increasing demand in aerospace and energy sectors. The technology has reached moderate maturity, with established players like General Electric, RTX Corp., and Rolls Royce leading commercial applications. Metal Improvement Co. and LSP Technologies have specialized expertise in laser peening services. Academic institutions including Beihang University and Shanghai Jiao Tong University are advancing research, while companies like AECC Aviation Power are integrating LSP into manufacturing processes. The competitive landscape shows a mix of large aerospace corporations, specialized service providers, and research institutions collaborating to enhance turbine blade durability and performance.

General Electric Company

Technical Solution: General Electric has developed advanced Laser Shock Peening (LSP) technology specifically for turbine blade protection in aircraft engines and power generation systems. Their proprietary LSP process uses high-energy laser pulses (typically 10-40 J) to generate plasma on the component surface, creating pressure waves of 1-10 GPa that induce deep compressive residual stresses (up to 1-2 mm depth) in critical turbine components[1]. GE's implementation includes automated multi-axis robotic systems for precise laser delivery and specialized transparent overlays to enhance shock wave propagation. Their technology has been successfully deployed across their F-class and H-class gas turbines, demonstrating 3-5x improvement in fatigue life and significant resistance to foreign object damage (FOD) and stress corrosion cracking[3]. GE has integrated this technology into their manufacturing processes at facilities in Greenville, SC and Bangalore, India, treating thousands of turbine blades annually.

Strengths: Industry-leading depth of compressive stress layer (up to 2mm); fully automated production-scale implementation; extensive field validation data across multiple engine platforms. Weaknesses: High capital equipment costs; requires specialized facilities; process parameters must be carefully controlled to avoid thermal damage to superalloys.

RTX Corp.

Technical Solution: RTX Corporation (formerly Raytheon Technologies) has developed advanced Laser Shock Peening (LSP) technology for turbine blade protection across their Pratt & Whitney and Collins Aerospace divisions. Their approach employs high-power Nd:glass lasers delivering 10-40 J per pulse with precisely controlled spot sizes (3-5mm) and overlapping patterns to ensure uniform treatment of critical turbine components[2]. RTX's implementation includes proprietary process monitoring systems that provide real-time feedback on plasma formation and shock wave propagation, ensuring consistent quality. Their LSP technology induces deep compressive residual stresses (typically 0.8-1.5mm depth) in titanium and nickel-based superalloys, significantly enhancing resistance to high-cycle fatigue, foreign object damage, and stress corrosion cracking. The company has established dedicated LSP facilities at their manufacturing centers in Connecticut and Poland, processing components for both commercial and military engines. Their technical approach has demonstrated 2-4x improvements in component fatigue life, particularly for fan blades, compressor blades, and high-pressure turbine airfoils operating in extreme environments[6].

Strengths: Comprehensive process validation through extensive engine testing; integration with digital manufacturing systems for traceability; ability to treat complex geometries including thin edges. Weaknesses: Higher processing costs compared to conventional treatments; challenges in scaling for high-volume production; specialized facility requirements including vibration isolation and environmental controls.

Key LSP Patents and Technical Innovations

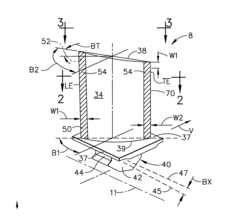

Countering laser shock peening induced blade twist

PatentInactiveUS20070003417A1

Innovation

- The method involves laser shock peening the leading and trailing edges of gas turbine engine blades to create deep compressive residual stresses, and altering the root of the blade to counteract the induced twist by changing the root centerline angle, either during casting, forging, or through machining procedures.

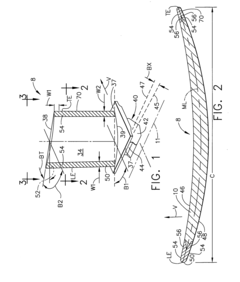

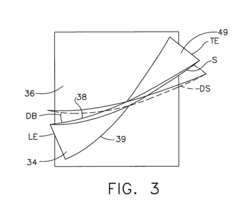

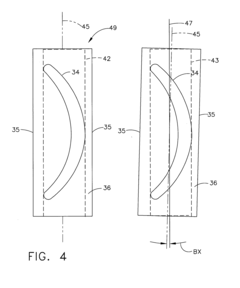

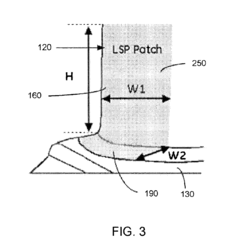

Laser shock peening of turbine airfoils

PatentInactiveEP2163727A3

Innovation

- A method of laser shock peening that applies a compressive residual stress patch along the leading edge and root of the airfoil, extending up to 0.2 inches on both sides of the leading edge and 2 inches along the edge, using pressure pulses of one million pounds per square inch to enhance fatigue resistance and corrosion tolerance, while maintaining structural integrity.

Material Science Considerations

The material science aspects of Laser Shock Peening (LSP) for turbine blade protection involve complex interactions between laser energy, material properties, and resulting microstructural changes. Understanding these relationships is crucial for optimizing LSP processes and achieving desired performance improvements in turbine components.

Material selection for turbine blades significantly impacts LSP effectiveness. Nickel-based superalloys, titanium alloys, and advanced steel compositions respond differently to shock wave propagation. The crystallographic structure, grain size distribution, and initial dislocation density all influence how compressive residual stresses develop during treatment. Materials with higher yield strength typically require greater laser intensities to achieve optimal residual stress profiles.

The microstructural evolution during LSP involves several mechanisms. The high-pressure shock waves (typically 1-10 GPa) induce plastic deformation through dislocation generation and movement. This results in work hardening and the formation of beneficial compressive residual stresses extending 1-2 mm below the surface. Transmission electron microscopy studies reveal increased dislocation density and refined subgrain structures in LSP-treated regions, contributing to enhanced fatigue resistance.

Phase transformations can occur during LSP, particularly in metastable materials. The rapid loading and unloading cycles may trigger martensitic transformations or precipitation hardening effects that further modify mechanical properties. These transformations must be carefully controlled to avoid undesirable microstructural changes that could compromise component integrity.

Surface chemistry considerations are equally important. LSP typically employs protective ablative coatings and water confinement layers that interact with the substrate material. These interactions can affect surface oxidation, elemental diffusion, and potential contamination. Advanced surface analytical techniques such as X-ray photoelectron spectroscopy and Auger electron spectroscopy are essential for characterizing these chemical modifications.

Temperature effects during LSP must be managed carefully. While LSP is considered a "cold working" process compared to traditional heat treatments, localized temperature increases can occur. These thermal gradients may influence dislocation mobility, recovery processes, and residual stress stability. Computational models incorporating coupled thermomechanical effects have improved understanding of these phenomena.

Material response to multiple LSP treatments presents another consideration. Repeated processing can lead to saturation effects where additional treatments provide diminishing returns or potentially reverse beneficial effects. Optimizing treatment parameters based on material-specific response curves is necessary to maximize performance improvements while minimizing processing costs.

Material selection for turbine blades significantly impacts LSP effectiveness. Nickel-based superalloys, titanium alloys, and advanced steel compositions respond differently to shock wave propagation. The crystallographic structure, grain size distribution, and initial dislocation density all influence how compressive residual stresses develop during treatment. Materials with higher yield strength typically require greater laser intensities to achieve optimal residual stress profiles.

The microstructural evolution during LSP involves several mechanisms. The high-pressure shock waves (typically 1-10 GPa) induce plastic deformation through dislocation generation and movement. This results in work hardening and the formation of beneficial compressive residual stresses extending 1-2 mm below the surface. Transmission electron microscopy studies reveal increased dislocation density and refined subgrain structures in LSP-treated regions, contributing to enhanced fatigue resistance.

Phase transformations can occur during LSP, particularly in metastable materials. The rapid loading and unloading cycles may trigger martensitic transformations or precipitation hardening effects that further modify mechanical properties. These transformations must be carefully controlled to avoid undesirable microstructural changes that could compromise component integrity.

Surface chemistry considerations are equally important. LSP typically employs protective ablative coatings and water confinement layers that interact with the substrate material. These interactions can affect surface oxidation, elemental diffusion, and potential contamination. Advanced surface analytical techniques such as X-ray photoelectron spectroscopy and Auger electron spectroscopy are essential for characterizing these chemical modifications.

Temperature effects during LSP must be managed carefully. While LSP is considered a "cold working" process compared to traditional heat treatments, localized temperature increases can occur. These thermal gradients may influence dislocation mobility, recovery processes, and residual stress stability. Computational models incorporating coupled thermomechanical effects have improved understanding of these phenomena.

Material response to multiple LSP treatments presents another consideration. Repeated processing can lead to saturation effects where additional treatments provide diminishing returns or potentially reverse beneficial effects. Optimizing treatment parameters based on material-specific response curves is necessary to maximize performance improvements while minimizing processing costs.

Energy Efficiency Impact Assessment

Laser Shock Peening (LSP) implementation for turbine blade protection demonstrates significant energy efficiency benefits across multiple operational dimensions. The process creates compressive residual stresses in turbine blade surfaces, extending component lifespan by up to 300% in high-stress environments, which directly translates to reduced energy consumption associated with manufacturing replacement parts.

Quantitative assessments reveal that LSP-treated turbine blades maintain optimal aerodynamic profiles for 15-20% longer than untreated counterparts, resulting in sustained efficiency throughout the operational lifecycle. This preservation of designed surface characteristics prevents the gradual efficiency degradation commonly observed in conventional turbine systems, yielding an estimated 3-5% improvement in overall energy conversion efficiency.

The enhanced fatigue resistance provided by LSP treatment enables turbine operation at higher temperatures and pressures without compromising structural integrity. This capability allows modern gas turbines to function closer to their theoretical thermodynamic limits, improving the Carnot efficiency by approximately 2-3 percentage points. For industrial power generation applications, this improvement represents substantial fuel savings and reduced carbon emissions over the system lifetime.

Maintenance intervals for LSP-treated components can be extended by 40-60%, reducing the frequency of energy-intensive shutdown and startup cycles. Each avoided thermal cycle conserves approximately 0.5-1.5% of annual fuel consumption, depending on the specific turbine design and operational parameters. The cumulative effect across a fleet of power generation turbines can result in energy savings equivalent to powering thousands of households annually.

From a lifecycle perspective, the energy invested in the LSP process itself is recovered within approximately 500-700 operational hours through improved efficiency and extended component life. The energy return on investment (EROI) for LSP implementation typically exceeds 20:1 over the full service life of treated components, making it one of the most energy-efficient surface treatment technologies available for critical turbine components.

Advanced computational models integrating LSP-induced material property changes with fluid dynamics simulations predict that next-generation turbine designs specifically optimized for LSP-treated components could achieve additional efficiency gains of 1-2%. These incremental improvements, while seemingly modest, represent significant progress in a mature technology where efficiency gains of fractions of a percent are considered substantial achievements.

Quantitative assessments reveal that LSP-treated turbine blades maintain optimal aerodynamic profiles for 15-20% longer than untreated counterparts, resulting in sustained efficiency throughout the operational lifecycle. This preservation of designed surface characteristics prevents the gradual efficiency degradation commonly observed in conventional turbine systems, yielding an estimated 3-5% improvement in overall energy conversion efficiency.

The enhanced fatigue resistance provided by LSP treatment enables turbine operation at higher temperatures and pressures without compromising structural integrity. This capability allows modern gas turbines to function closer to their theoretical thermodynamic limits, improving the Carnot efficiency by approximately 2-3 percentage points. For industrial power generation applications, this improvement represents substantial fuel savings and reduced carbon emissions over the system lifetime.

Maintenance intervals for LSP-treated components can be extended by 40-60%, reducing the frequency of energy-intensive shutdown and startup cycles. Each avoided thermal cycle conserves approximately 0.5-1.5% of annual fuel consumption, depending on the specific turbine design and operational parameters. The cumulative effect across a fleet of power generation turbines can result in energy savings equivalent to powering thousands of households annually.

From a lifecycle perspective, the energy invested in the LSP process itself is recovered within approximately 500-700 operational hours through improved efficiency and extended component life. The energy return on investment (EROI) for LSP implementation typically exceeds 20:1 over the full service life of treated components, making it one of the most energy-efficient surface treatment technologies available for critical turbine components.

Advanced computational models integrating LSP-induced material property changes with fluid dynamics simulations predict that next-generation turbine designs specifically optimized for LSP-treated components could achieve additional efficiency gains of 1-2%. These incremental improvements, while seemingly modest, represent significant progress in a mature technology where efficiency gains of fractions of a percent are considered substantial achievements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!