Optimization of Spot Overlap in Laser Shock Peening Strategies

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Shock Peening Technology Background and Objectives

Laser Shock Peening (LSP) has emerged as a revolutionary surface treatment technology since its initial development in the 1960s at Battelle Memorial Institute. The technology has evolved significantly from its early applications in aerospace to become a versatile solution for enhancing material properties across multiple industries. LSP utilizes high-energy laser pulses to generate plasma-induced shock waves that propagate through materials, inducing beneficial compressive residual stresses and microstructural changes that dramatically improve fatigue life, corrosion resistance, and wear properties.

The evolution of LSP technology has been marked by continuous advancements in laser systems, from early ruby lasers to modern high-power Nd:YAG and fiber lasers, enabling higher processing speeds and more precise applications. Concurrently, the understanding of plasma physics and shock wave propagation mechanisms has deepened, allowing for more sophisticated treatment strategies and expanded material applications beyond traditional metals to include ceramics and composites.

Spot overlap represents a critical parameter in LSP processing that directly influences the uniformity, depth, and magnitude of induced compressive residual stresses. Historical approaches to LSP typically employed conservative overlap strategies with limited scientific basis, resulting in suboptimal processing efficiency and inconsistent material property enhancements. Recent research has begun to systematically investigate the complex relationships between spot overlap patterns, residual stress distributions, and resulting material performance.

The primary technical objective of this research is to develop optimized spot overlap strategies that maximize beneficial material property enhancements while minimizing processing time and associated costs. This involves establishing quantitative relationships between overlap parameters (percentage, pattern geometry, sequencing) and resulting residual stress profiles across different material systems and component geometries.

Secondary objectives include developing predictive models that can accurately simulate the cumulative effects of overlapping shock waves, creating standardized methodologies for determining optimal overlap parameters for specific applications, and exploring adaptive processing strategies that can dynamically adjust overlap patterns based on real-time feedback during treatment.

The significance of this research extends beyond immediate process optimization to address fundamental challenges in LSP technology adoption, including reducing processing costs, improving treatment uniformity for complex geometries, and enabling more precise tailoring of residual stress profiles for specific loading conditions. Successful optimization of spot overlap strategies represents a critical step toward broader industrial implementation of LSP technology across aerospace, automotive, energy, and medical device manufacturing sectors.

The evolution of LSP technology has been marked by continuous advancements in laser systems, from early ruby lasers to modern high-power Nd:YAG and fiber lasers, enabling higher processing speeds and more precise applications. Concurrently, the understanding of plasma physics and shock wave propagation mechanisms has deepened, allowing for more sophisticated treatment strategies and expanded material applications beyond traditional metals to include ceramics and composites.

Spot overlap represents a critical parameter in LSP processing that directly influences the uniformity, depth, and magnitude of induced compressive residual stresses. Historical approaches to LSP typically employed conservative overlap strategies with limited scientific basis, resulting in suboptimal processing efficiency and inconsistent material property enhancements. Recent research has begun to systematically investigate the complex relationships between spot overlap patterns, residual stress distributions, and resulting material performance.

The primary technical objective of this research is to develop optimized spot overlap strategies that maximize beneficial material property enhancements while minimizing processing time and associated costs. This involves establishing quantitative relationships between overlap parameters (percentage, pattern geometry, sequencing) and resulting residual stress profiles across different material systems and component geometries.

Secondary objectives include developing predictive models that can accurately simulate the cumulative effects of overlapping shock waves, creating standardized methodologies for determining optimal overlap parameters for specific applications, and exploring adaptive processing strategies that can dynamically adjust overlap patterns based on real-time feedback during treatment.

The significance of this research extends beyond immediate process optimization to address fundamental challenges in LSP technology adoption, including reducing processing costs, improving treatment uniformity for complex geometries, and enabling more precise tailoring of residual stress profiles for specific loading conditions. Successful optimization of spot overlap strategies represents a critical step toward broader industrial implementation of LSP technology across aerospace, automotive, energy, and medical device manufacturing sectors.

Market Applications and Industry Demand Analysis

Laser Shock Peening (LSP) technology has witnessed significant market growth across multiple industrial sectors, driven by increasing demands for enhanced material performance and extended component lifespans. The global market for surface treatment technologies, including LSP, currently exceeds $10 billion annually, with LSP applications specifically showing a compound annual growth rate of approximately 7-8% over the past five years.

The aerospace industry remains the primary adopter of LSP technology, accounting for nearly 40% of the total market share. Major aircraft manufacturers and their suppliers implement LSP for critical components such as turbine blades, discs, and structural elements where fatigue resistance and stress corrosion cracking prevention are paramount. The optimization of spot overlap in LSP processes directly addresses the aerospace industry's stringent requirements for uniform residual stress distribution and consistent surface quality.

Automotive manufacturing represents the second-largest market segment, with growing implementation in high-performance engine components, transmission systems, and safety-critical parts. The industry's shift toward lightweight materials while maintaining structural integrity has created new opportunities for advanced LSP applications with optimized processing parameters.

The power generation sector, particularly nuclear and conventional power plants, demonstrates increasing demand for LSP technologies in turbine components, pressure vessels, and structural elements subject to extreme operating conditions. The ability to precisely control spot overlap patterns enables more effective treatment of complex geometries common in these applications.

Medical device manufacturing has emerged as a rapidly expanding market for LSP, particularly for implantable devices where fatigue resistance and biocompatibility are critical. The precision offered by optimized spot overlap strategies allows for controlled surface modification without compromising dimensional tolerances or material properties.

Industry surveys indicate that manufacturing efficiency and cost reduction are primary drivers for research into spot overlap optimization. Approximately 65% of industrial users cite processing time as a critical factor in LSP implementation decisions, while 58% emphasize the importance of uniform material property enhancement. The ability to reduce processing time while maintaining or improving treatment quality through optimized overlap strategies directly addresses these market demands.

Recent market analysis reveals growing interest in automated and adaptive LSP systems capable of real-time adjustment of spot overlap parameters based on component geometry and material properties. This trend aligns with broader Industry 4.0 initiatives and represents a significant opportunity for technology developers focusing on spot overlap optimization algorithms and control systems.

The aerospace industry remains the primary adopter of LSP technology, accounting for nearly 40% of the total market share. Major aircraft manufacturers and their suppliers implement LSP for critical components such as turbine blades, discs, and structural elements where fatigue resistance and stress corrosion cracking prevention are paramount. The optimization of spot overlap in LSP processes directly addresses the aerospace industry's stringent requirements for uniform residual stress distribution and consistent surface quality.

Automotive manufacturing represents the second-largest market segment, with growing implementation in high-performance engine components, transmission systems, and safety-critical parts. The industry's shift toward lightweight materials while maintaining structural integrity has created new opportunities for advanced LSP applications with optimized processing parameters.

The power generation sector, particularly nuclear and conventional power plants, demonstrates increasing demand for LSP technologies in turbine components, pressure vessels, and structural elements subject to extreme operating conditions. The ability to precisely control spot overlap patterns enables more effective treatment of complex geometries common in these applications.

Medical device manufacturing has emerged as a rapidly expanding market for LSP, particularly for implantable devices where fatigue resistance and biocompatibility are critical. The precision offered by optimized spot overlap strategies allows for controlled surface modification without compromising dimensional tolerances or material properties.

Industry surveys indicate that manufacturing efficiency and cost reduction are primary drivers for research into spot overlap optimization. Approximately 65% of industrial users cite processing time as a critical factor in LSP implementation decisions, while 58% emphasize the importance of uniform material property enhancement. The ability to reduce processing time while maintaining or improving treatment quality through optimized overlap strategies directly addresses these market demands.

Recent market analysis reveals growing interest in automated and adaptive LSP systems capable of real-time adjustment of spot overlap parameters based on component geometry and material properties. This trend aligns with broader Industry 4.0 initiatives and represents a significant opportunity for technology developers focusing on spot overlap optimization algorithms and control systems.

Current Spot Overlap Techniques and Challenges

Laser Shock Peening (LSP) currently employs several spot overlap techniques to achieve desired surface treatment outcomes. The most prevalent approach is the square grid pattern, where laser spots are arranged in rows and columns with predetermined overlap percentages. This method provides uniform coverage but often results in uneven residual stress distribution at intersection points. Typical overlap ratios range from 30% to 70%, with 50% being the industry standard for many applications in aerospace and automotive sectors.

Another common technique is the hexagonal pattern arrangement, which offers more homogeneous coverage and reduces the anisotropy in material properties compared to square patterns. This approach minimizes untreated areas but requires more complex programming of laser movement paths, increasing processing time and computational requirements.

Progressive spot placement strategies have emerged recently, where overlap percentages vary throughout the treatment process based on real-time feedback or pre-calculated stress distributions. While promising, these adaptive approaches demand sophisticated control systems and accurate in-situ monitoring capabilities that are not yet widely implemented in industrial settings.

A significant challenge in current overlap techniques is the heat accumulation effect in overlapped regions. When spots overlap excessively, localized thermal effects can counteract the beneficial compressive residual stresses, potentially leading to microstructural changes that compromise material properties. Conversely, insufficient overlap creates untreated zones that become stress concentration points, undermining the treatment's effectiveness.

Edge effects present another major challenge, particularly for complex geometries. Current techniques struggle to maintain consistent overlap at component edges and corners, often resulting in under-treatment or over-treatment of these critical areas. This inconsistency can lead to premature failure in service conditions, especially under fatigue loading.

The computational modeling of spot overlap effects remains inadequate, with most current models failing to accurately predict residual stress distributions in multi-layer, multi-pass LSP treatments. The complex interaction between overlapping shock waves and their cumulative effect on material properties exceeds the capabilities of existing simulation tools, forcing practitioners to rely heavily on empirical approaches.

Material-specific optimization of overlap parameters is another challenge, as different materials respond uniquely to LSP treatment. Current one-size-fits-all approaches to overlap strategies fail to account for these variations, resulting in suboptimal surface enhancement for many advanced materials used in critical applications.

Another common technique is the hexagonal pattern arrangement, which offers more homogeneous coverage and reduces the anisotropy in material properties compared to square patterns. This approach minimizes untreated areas but requires more complex programming of laser movement paths, increasing processing time and computational requirements.

Progressive spot placement strategies have emerged recently, where overlap percentages vary throughout the treatment process based on real-time feedback or pre-calculated stress distributions. While promising, these adaptive approaches demand sophisticated control systems and accurate in-situ monitoring capabilities that are not yet widely implemented in industrial settings.

A significant challenge in current overlap techniques is the heat accumulation effect in overlapped regions. When spots overlap excessively, localized thermal effects can counteract the beneficial compressive residual stresses, potentially leading to microstructural changes that compromise material properties. Conversely, insufficient overlap creates untreated zones that become stress concentration points, undermining the treatment's effectiveness.

Edge effects present another major challenge, particularly for complex geometries. Current techniques struggle to maintain consistent overlap at component edges and corners, often resulting in under-treatment or over-treatment of these critical areas. This inconsistency can lead to premature failure in service conditions, especially under fatigue loading.

The computational modeling of spot overlap effects remains inadequate, with most current models failing to accurately predict residual stress distributions in multi-layer, multi-pass LSP treatments. The complex interaction between overlapping shock waves and their cumulative effect on material properties exceeds the capabilities of existing simulation tools, forcing practitioners to rely heavily on empirical approaches.

Material-specific optimization of overlap parameters is another challenge, as different materials respond uniquely to LSP treatment. Current one-size-fits-all approaches to overlap strategies fail to account for these variations, resulting in suboptimal surface enhancement for many advanced materials used in critical applications.

Current Spot Overlap Optimization Approaches

01 Optimization of spot overlap patterns in laser shock peening

Laser shock peening effectiveness can be enhanced by optimizing the overlap patterns of laser spots. Various patterns such as grid, spiral, or staggered arrangements can be used to ensure complete coverage of the treated surface. The degree of overlap between adjacent spots affects the uniformity of residual stress distribution and can be adjusted based on the material properties and desired mechanical improvements. Proper overlap patterns help eliminate untreated areas and ensure consistent material strengthening.- Optimization of spot overlap patterns in laser shock peening: Laser shock peening effectiveness can be enhanced by optimizing the overlap patterns of laser spots. Various patterns such as grid, hexagonal, or staggered arrangements can be used to ensure complete coverage of the treated surface. The degree of overlap between adjacent spots affects the uniformity of residual stress distribution and can be adjusted based on the material properties and desired mechanical improvements. Proper overlap patterns help eliminate untreated areas and ensure consistent material strengthening.

- Controlling overlap percentage for residual stress distribution: The percentage of overlap between laser shock peening spots significantly impacts the residual stress distribution in the treated material. Higher overlap percentages typically result in deeper and more uniform compressive residual stresses. Controlling this parameter allows for tailoring the treatment to specific component requirements. The overlap percentage can be adjusted by modifying the laser spot size, spacing, and processing parameters to achieve optimal fatigue life improvement and crack resistance in critical components.

- Multiple layer laser shock peening with spot overlap: Multiple layer laser shock peening involves applying successive layers of laser spots with controlled overlap to enhance the depth and magnitude of compressive residual stresses. Each layer can have different overlap patterns or percentages to address specific stress profiles. This technique is particularly effective for treating complex geometries and achieving deeper compressive stress layers. The process parameters for each layer, including spot size, energy density, and overlap configuration, can be optimized to maximize fatigue life improvement.

- Spot overlap techniques for specific component geometries: Laser shock peening spot overlap techniques can be tailored for specific component geometries such as airfoil edges, dovetail regions, or curved surfaces. For complex shapes, adaptive overlap patterns may be employed to ensure uniform coverage and stress distribution. The spot overlap strategy can be modified based on the local curvature, thickness, and stress concentration factors of the component. This approach ensures effective treatment of critical areas prone to fatigue failure while maintaining dimensional accuracy.

- Monitoring and control systems for laser spot overlap: Advanced monitoring and control systems can be implemented to ensure precise laser spot overlap during the peening process. These systems may include real-time imaging, position tracking, and feedback mechanisms to adjust laser parameters and positioning. Computer-controlled automation enables consistent spot placement and overlap across complex surfaces. Quality control methods can verify the achieved overlap patterns and resulting residual stress profiles, ensuring treatment effectiveness and repeatability across multiple components.

02 Control of laser parameters for effective spot overlap

Controlling laser parameters is crucial for achieving effective spot overlap in laser shock peening. Parameters such as pulse energy, duration, spot size, and repetition rate directly influence the quality of treatment. Higher pulse overlap percentages generally result in deeper compressive residual stresses. The laser power density must be carefully calibrated to ensure consistent material response across overlapping regions. Advanced control systems can be employed to maintain precise spot positioning and energy distribution.Expand Specific Solutions03 Multiple layer treatment with controlled spot overlap

Multiple layer treatments with controlled spot overlap can significantly enhance the effectiveness of laser shock peening. By applying successive layers of laser spots with specific overlap patterns, deeper and more uniform compressive residual stresses can be achieved. Each subsequent layer can be offset from the previous one to ensure complete coverage and minimize untreated areas. This technique is particularly effective for complex geometries and components subject to high fatigue stresses.Expand Specific Solutions04 Material-specific spot overlap considerations

Different materials require specific spot overlap considerations during laser shock peening. The overlap percentage must be tailored based on the material's mechanical properties, microstructure, and intended application. For instance, titanium alloys may require different overlap patterns compared to aluminum or steel alloys. The material's response to shock waves, including plastic deformation behavior and work hardening characteristics, influences the optimal spot overlap strategy. Material-specific overlap protocols help maximize fatigue life improvement while minimizing processing time.Expand Specific Solutions05 Measurement and verification of spot overlap effects

Measurement and verification techniques are essential to assess the effectiveness of spot overlap in laser shock peening. Various methods including X-ray diffraction, hole-drilling, contour method, and ultrasonic techniques can be used to measure residual stress distribution in overlapped regions. Advanced imaging and surface analysis tools help verify the consistency of treatment across the component. Real-time monitoring systems can provide feedback during processing to ensure proper spot overlap is maintained throughout the treatment process.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The laser shock peening (LSP) spot overlap optimization market is currently in a growth phase, with increasing adoption across aerospace, automotive, and energy sectors. The global LSP market is estimated to reach approximately $500 million by 2025, driven by demands for enhanced material fatigue resistance and component lifespan extension. Leading players include LSP Technologies, which has commercialized comprehensive laser peening services and systems, alongside Metal Improvement Co. LLC with its established industrial treatment capabilities. Major aerospace corporations like General Electric, Rolls-Royce, Airbus, and Safran Aircraft Engines are actively implementing and refining LSP technologies. Research institutions including Lawrence Livermore National Security, Beihang University, and Coventry University are advancing fundamental understanding of spot overlap optimization, while industrial players focus on practical applications and process efficiency improvements.

General Electric Company

Technical Solution: General Electric has developed a sophisticated approach to laser shock peening (LSP) spot overlap optimization focused primarily on aircraft engine components. Their technology employs a variable overlap strategy that adjusts the percentage of overlap based on the specific geometry and stress requirements of different regions within a single component[1]. GE's proprietary "Adaptive Overlap Control" system uses finite element analysis to predict optimal spot patterns and automatically generates treatment paths that maintain consistent residual stress profiles while minimizing processing time. For critical turbine blade applications, they've implemented a multi-layer peening approach with precisely controlled spot overlaps between 40-60% that has been shown to increase fatigue life by up to 300%[2]. Their system incorporates real-time monitoring of plasma formation during the LSP process to verify proper spot overlap execution and maintain quality control. GE has also pioneered the use of non-uniform spot distributions with calculated overlap variations to address stress concentrations in complex geometries, particularly at the transition areas between different structural features[3].

Strengths: Extensive experience applying LSP to actual aerospace components; integrated approach combining simulation, process control and verification; demonstrated improvements in component life through optimized overlap strategies. Weaknesses: Solutions are primarily optimized for their own product lines and materials; high implementation costs; requires significant expertise to operate effectively.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Security (LLNS) has developed advanced laser shock peening (LSP) spot overlap optimization technologies through their extensive research at Lawrence Livermore National Laboratory. Their approach combines high-fidelity computational modeling with experimental validation to determine optimal spot overlap parameters for various applications. LLNS has pioneered the use of physics-based simulation tools that model the plasma formation, shock wave propagation, and material response during LSP, allowing for precise prediction of residual stress fields resulting from different overlap configurations[1]. Their research has established that optimal overlap percentages typically range from 40-60% for most aerospace materials, with specific values dependent on laser parameters, spot geometry, and material properties. LLNS has developed a unique "Progressive Overlap Strategy" where spot overlap gradually increases across a treatment area to create tailored stress gradients, particularly useful for components with varying thickness or stress requirements. Their advanced diagnostic capabilities, including high-speed imaging of plasma formation and in-situ stress measurement techniques, allow for real-time verification of spot overlap effectiveness and immediate process adjustment[2]. LLNS has also conducted groundbreaking research on the relationship between spot overlap patterns and residual stress uniformity, demonstrating that hexagonal spot arrangements with 50% overlap typically produce more isotropic stress fields compared to traditional grid patterns[3].

Strengths: Cutting-edge research capabilities with access to world-class laser facilities; sophisticated modeling tools that accurately predict process outcomes; fundamental understanding of underlying physics. Weaknesses: Technologies may be less commercially mature than industrial competitors; solutions often require significant customization for specific applications; higher implementation complexity.

Key Patents and Research in Overlap Control

Adhesive tape covered laser shock peening

PatentInactiveEP0835328A1

Innovation

- Adhesively covering the laser shock peening surfaces with tape containing an ablative medium, allowing for the use of a laser to create deep compressive residual stresses by vaporizing the medium and forming shock waves, which reduces the need for painting and paint drying, and simplifies the process by using a curtain of water to confine and redirect the shock waves.

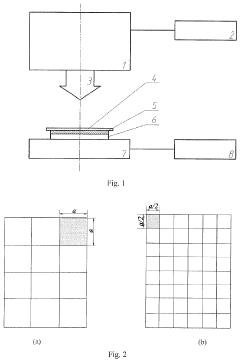

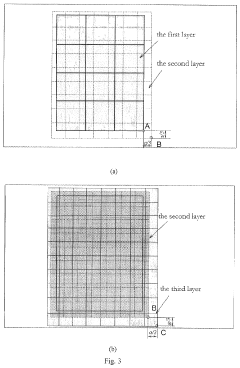

Kind of uniform strengthening methods of turbine blade subjected to varied square-spot laser shock peening with stagger multiple-layer

PatentInactiveUS10640844B2

Innovation

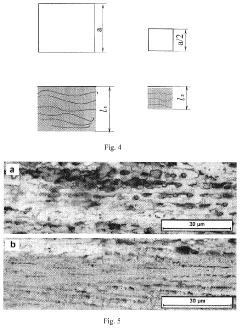

- A method involving varied square-spot LSP with stagger multiple-layer treatment, where three layers are applied with adjacent square-spots without overlap, using a latticed absorbing layer with isometric grids to position accurately, and varying square-spot lengths to reduce boundary effects and surface roughness, generating uniform compressive residual stress and refining surface grains.

Material-Specific Considerations for Overlap Strategies

The optimization of spot overlap in Laser Shock Peening (LSP) must be carefully tailored to specific material properties to achieve optimal results. Different materials respond uniquely to LSP treatments due to variations in their mechanical and microstructural characteristics. For metals with high yield strength such as titanium alloys and hardened steels, higher overlap percentages (typically 50-70%) are often necessary to overcome the material's resistance to plastic deformation and ensure uniform residual stress distribution.

Aluminum alloys, characterized by lower yield strength, generally require moderate overlap percentages (40-60%) to prevent excessive surface deformation while still achieving desired compressive residual stress profiles. The thermal conductivity of materials also plays a crucial role in determining optimal overlap strategies. Materials with high thermal conductivity, such as copper alloys, dissipate shock wave energy more rapidly, potentially necessitating higher overlap percentages to compensate for this energy loss.

Crystallographic structure significantly influences LSP effectiveness. Face-centered cubic (FCC) materials like austenitic stainless steels typically exhibit more uniform deformation under LSP and may benefit from consistent overlap patterns. In contrast, hexagonal close-packed (HCP) materials such as titanium and magnesium alloys show anisotropic responses to LSP, requiring carefully designed directional overlap strategies to address orientation-dependent deformation behavior.

Material thickness and geometry further complicate overlap optimization. Thin sections may experience through-thickness effects where excessive overlap can lead to detrimental tensile stresses on the opposite surface. Conversely, thick sections might require higher overlap percentages to achieve sufficient depth of residual stress. For components with complex geometries, variable overlap strategies may be necessary to accommodate changing material thicknesses and stress concentrations.

Pre-existing material conditions, including heat treatment states, prior cold working, and surface conditions, significantly impact optimal overlap parameters. Previously work-hardened materials may require modified overlap strategies compared to annealed conditions. Surface coatings and treatments must also be considered, as they can alter shock wave propagation and absorption characteristics, necessitating adjustments to overlap percentages to maintain treatment effectiveness.

Recent research has demonstrated that adaptive overlap strategies—where overlap percentages are dynamically adjusted based on local material properties—show promising results for heterogeneous materials and components with varying thicknesses. This approach requires sophisticated material modeling and real-time monitoring systems but offers superior control over residual stress distribution in complex engineering components.

Aluminum alloys, characterized by lower yield strength, generally require moderate overlap percentages (40-60%) to prevent excessive surface deformation while still achieving desired compressive residual stress profiles. The thermal conductivity of materials also plays a crucial role in determining optimal overlap strategies. Materials with high thermal conductivity, such as copper alloys, dissipate shock wave energy more rapidly, potentially necessitating higher overlap percentages to compensate for this energy loss.

Crystallographic structure significantly influences LSP effectiveness. Face-centered cubic (FCC) materials like austenitic stainless steels typically exhibit more uniform deformation under LSP and may benefit from consistent overlap patterns. In contrast, hexagonal close-packed (HCP) materials such as titanium and magnesium alloys show anisotropic responses to LSP, requiring carefully designed directional overlap strategies to address orientation-dependent deformation behavior.

Material thickness and geometry further complicate overlap optimization. Thin sections may experience through-thickness effects where excessive overlap can lead to detrimental tensile stresses on the opposite surface. Conversely, thick sections might require higher overlap percentages to achieve sufficient depth of residual stress. For components with complex geometries, variable overlap strategies may be necessary to accommodate changing material thicknesses and stress concentrations.

Pre-existing material conditions, including heat treatment states, prior cold working, and surface conditions, significantly impact optimal overlap parameters. Previously work-hardened materials may require modified overlap strategies compared to annealed conditions. Surface coatings and treatments must also be considered, as they can alter shock wave propagation and absorption characteristics, necessitating adjustments to overlap percentages to maintain treatment effectiveness.

Recent research has demonstrated that adaptive overlap strategies—where overlap percentages are dynamically adjusted based on local material properties—show promising results for heterogeneous materials and components with varying thicknesses. This approach requires sophisticated material modeling and real-time monitoring systems but offers superior control over residual stress distribution in complex engineering components.

Energy Efficiency and Process Sustainability

Energy efficiency and process sustainability are critical considerations in the optimization of spot overlap in Laser Shock Peening (LSP) strategies. The LSP process inherently consumes significant energy due to the high-power laser pulses required to generate plasma and shock waves. Current industrial implementations often operate with suboptimal energy utilization, with estimates suggesting that only 10-15% of input energy effectively contributes to the desired material modifications.

Spot overlap configuration directly impacts energy consumption patterns. Higher overlap percentages typically result in increased energy usage per unit area, as multiple laser pulses are delivered to the same region. Research indicates that optimizing overlap patterns can reduce energy consumption by 20-30% while maintaining or even improving treatment effectiveness. This optimization involves balancing the trade-off between comprehensive surface coverage and excessive energy input.

Recent advancements in pulse shaping technology have demonstrated promising results for energy efficiency. By tailoring the temporal profile of laser pulses specifically for overlap regions, energy delivery can be modulated to account for the residual effects from previous pulses. Studies from Lawrence Livermore National Laboratory show that adaptive pulse shaping can reduce energy requirements by up to 25% in high-overlap configurations.

Water usage represents another sustainability concern in LSP processes. Traditional LSP setups require continuous water flow as a confining medium for plasma expansion. Optimized spot patterns that minimize treatment time through efficient coverage strategies can significantly reduce water consumption. Closed-loop water recycling systems, when combined with optimized overlap strategies, have demonstrated water usage reductions of up to 40% in industrial applications.

Carbon footprint considerations are increasingly important for manufacturing processes. The energy-intensive nature of LSP contributes to substantial carbon emissions, particularly when powered by non-renewable energy sources. Life cycle assessments indicate that optimizing spot overlap patterns can reduce the carbon footprint by 15-25% through reduced processing time and energy requirements. Some manufacturers have begun implementing renewable energy sources specifically for LSP operations to further enhance sustainability metrics.

Material waste reduction represents another sustainability benefit of optimized overlap strategies. Precise control of treatment coverage minimizes over-processing, which can lead to excessive material removal during subsequent finishing operations. This precision extends component service life while reducing the environmental impact associated with premature part replacement and manufacturing of replacement components.

Spot overlap configuration directly impacts energy consumption patterns. Higher overlap percentages typically result in increased energy usage per unit area, as multiple laser pulses are delivered to the same region. Research indicates that optimizing overlap patterns can reduce energy consumption by 20-30% while maintaining or even improving treatment effectiveness. This optimization involves balancing the trade-off between comprehensive surface coverage and excessive energy input.

Recent advancements in pulse shaping technology have demonstrated promising results for energy efficiency. By tailoring the temporal profile of laser pulses specifically for overlap regions, energy delivery can be modulated to account for the residual effects from previous pulses. Studies from Lawrence Livermore National Laboratory show that adaptive pulse shaping can reduce energy requirements by up to 25% in high-overlap configurations.

Water usage represents another sustainability concern in LSP processes. Traditional LSP setups require continuous water flow as a confining medium for plasma expansion. Optimized spot patterns that minimize treatment time through efficient coverage strategies can significantly reduce water consumption. Closed-loop water recycling systems, when combined with optimized overlap strategies, have demonstrated water usage reductions of up to 40% in industrial applications.

Carbon footprint considerations are increasingly important for manufacturing processes. The energy-intensive nature of LSP contributes to substantial carbon emissions, particularly when powered by non-renewable energy sources. Life cycle assessments indicate that optimizing spot overlap patterns can reduce the carbon footprint by 15-25% through reduced processing time and energy requirements. Some manufacturers have begun implementing renewable energy sources specifically for LSP operations to further enhance sustainability metrics.

Material waste reduction represents another sustainability benefit of optimized overlap strategies. Precise control of treatment coverage minimizes over-processing, which can lead to excessive material removal during subsequent finishing operations. This precision extends component service life while reducing the environmental impact associated with premature part replacement and manufacturing of replacement components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!