Laser Shock Peening-Induced Microstructural Refinement

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSP Technology Background and Objectives

Laser Shock Peening (LSP) emerged in the 1960s as a surface treatment technology initially developed for enhancing fatigue life in aircraft engine components. The fundamental principle involves generating high-amplitude shock waves through laser-induced plasma expansion, which propagates through materials causing plastic deformation and microstructural changes. Over the past six decades, LSP has evolved from a specialized aerospace application to a versatile surface modification technique applicable across multiple industries.

The technology's evolution has been marked by significant advancements in laser systems, transitioning from early ruby lasers to modern high-power Nd:YAG and fiber lasers, enabling higher processing speeds and more precise control. Concurrently, the understanding of shock wave physics and material response mechanisms has deepened substantially, allowing for more targeted microstructural modifications.

Microstructural refinement through LSP represents a particularly promising direction in this field. Unlike conventional LSP applications that primarily focus on inducing compressive residual stresses, microstructural refinement aims to deliberately alter the material's grain structure at micro and nano scales. This approach leverages the extreme strain rates (10^6-10^7 s^-1) and pressures (several GPa) generated during LSP to trigger dynamic recrystallization, grain subdivision, and dislocation density increases.

The primary technical objectives in LSP-induced microstructural refinement include achieving uniform grain refinement throughout controlled depths, optimizing process parameters to target specific microstructural features, and developing predictive models that accurately correlate LSP parameters with resultant microstructural changes. Additionally, there is growing interest in combining LSP with other processing techniques to create hierarchical microstructures with enhanced property combinations.

Recent trends indicate a shift toward precision LSP for microstructural engineering, where researchers are exploring the potential to create gradient nanostructures, manipulate phase transformations, and control crystallographic textures. The ability to selectively refine microstructures in critical component regions without affecting bulk properties presents a compelling value proposition for high-performance applications.

The technology trajectory suggests continued advancement toward multi-scale microstructural control, where LSP parameters can be precisely tailored to achieve specific grain sizes, dislocation structures, and phase distributions at different depths from the surface. This capability would enable unprecedented control over mechanical properties, particularly in applications requiring optimized combinations of strength, ductility, and fatigue resistance.

The technology's evolution has been marked by significant advancements in laser systems, transitioning from early ruby lasers to modern high-power Nd:YAG and fiber lasers, enabling higher processing speeds and more precise control. Concurrently, the understanding of shock wave physics and material response mechanisms has deepened substantially, allowing for more targeted microstructural modifications.

Microstructural refinement through LSP represents a particularly promising direction in this field. Unlike conventional LSP applications that primarily focus on inducing compressive residual stresses, microstructural refinement aims to deliberately alter the material's grain structure at micro and nano scales. This approach leverages the extreme strain rates (10^6-10^7 s^-1) and pressures (several GPa) generated during LSP to trigger dynamic recrystallization, grain subdivision, and dislocation density increases.

The primary technical objectives in LSP-induced microstructural refinement include achieving uniform grain refinement throughout controlled depths, optimizing process parameters to target specific microstructural features, and developing predictive models that accurately correlate LSP parameters with resultant microstructural changes. Additionally, there is growing interest in combining LSP with other processing techniques to create hierarchical microstructures with enhanced property combinations.

Recent trends indicate a shift toward precision LSP for microstructural engineering, where researchers are exploring the potential to create gradient nanostructures, manipulate phase transformations, and control crystallographic textures. The ability to selectively refine microstructures in critical component regions without affecting bulk properties presents a compelling value proposition for high-performance applications.

The technology trajectory suggests continued advancement toward multi-scale microstructural control, where LSP parameters can be precisely tailored to achieve specific grain sizes, dislocation structures, and phase distributions at different depths from the surface. This capability would enable unprecedented control over mechanical properties, particularly in applications requiring optimized combinations of strength, ductility, and fatigue resistance.

Market Applications and Industry Demand

Laser Shock Peening-Induced Microstructural Refinement has witnessed significant market traction across multiple high-value industries where material performance and longevity are critical factors. The aerospace sector represents the largest application domain, with an estimated market value exceeding $300 million annually. Major aircraft manufacturers have integrated this technology into their production processes for critical components such as turbine blades, compressor discs, and structural elements where fatigue resistance is paramount.

The automotive industry has emerged as the second-largest adopter, particularly in high-performance and luxury vehicle segments. Applications focus on engine components, transmission systems, and safety-critical parts where enhanced material properties directly translate to improved performance and extended service life. Market analysis indicates a compound annual growth rate of 7.8% in this sector through 2025.

Medical device manufacturing represents a rapidly expanding application area, particularly for implantable devices and surgical instruments. The ability to precisely control surface properties without thermal effects makes LSP-induced microstructural refinement especially valuable for biomedical applications where material biocompatibility and mechanical integrity must coexist.

Power generation, particularly nuclear and renewable energy sectors, demonstrates growing demand for this technology. Components subjected to extreme operational conditions benefit significantly from the enhanced fatigue resistance and stress corrosion cracking prevention that refined microstructures provide. The market in this sector has grown by approximately 12% annually over the past five years.

Defense applications constitute another significant market segment, with naval and land-based military systems incorporating LSP-treated components to enhance reliability and operational lifespan. Government contracts in this sector have increased steadily, with particular emphasis on submarine and naval vessel components exposed to harsh marine environments.

Industry demand is primarily driven by three factors: increasing requirements for component longevity in critical applications, stricter safety regulations across regulated industries, and the economic benefits derived from extended maintenance intervals. The technology's ability to deliver these benefits without geometric distortion or thermal effects provides a competitive advantage over alternative surface treatment methods.

Regional market analysis reveals North America and Europe as current market leaders, though Asia-Pacific regions, particularly China, Japan, and South Korea, are investing heavily in adoption and further development of this technology across their manufacturing sectors.

The automotive industry has emerged as the second-largest adopter, particularly in high-performance and luxury vehicle segments. Applications focus on engine components, transmission systems, and safety-critical parts where enhanced material properties directly translate to improved performance and extended service life. Market analysis indicates a compound annual growth rate of 7.8% in this sector through 2025.

Medical device manufacturing represents a rapidly expanding application area, particularly for implantable devices and surgical instruments. The ability to precisely control surface properties without thermal effects makes LSP-induced microstructural refinement especially valuable for biomedical applications where material biocompatibility and mechanical integrity must coexist.

Power generation, particularly nuclear and renewable energy sectors, demonstrates growing demand for this technology. Components subjected to extreme operational conditions benefit significantly from the enhanced fatigue resistance and stress corrosion cracking prevention that refined microstructures provide. The market in this sector has grown by approximately 12% annually over the past five years.

Defense applications constitute another significant market segment, with naval and land-based military systems incorporating LSP-treated components to enhance reliability and operational lifespan. Government contracts in this sector have increased steadily, with particular emphasis on submarine and naval vessel components exposed to harsh marine environments.

Industry demand is primarily driven by three factors: increasing requirements for component longevity in critical applications, stricter safety regulations across regulated industries, and the economic benefits derived from extended maintenance intervals. The technology's ability to deliver these benefits without geometric distortion or thermal effects provides a competitive advantage over alternative surface treatment methods.

Regional market analysis reveals North America and Europe as current market leaders, though Asia-Pacific regions, particularly China, Japan, and South Korea, are investing heavily in adoption and further development of this technology across their manufacturing sectors.

Global LSP Development Status and Challenges

Laser Shock Peening (LSP) technology has experienced significant global development over the past three decades, with varying levels of maturity across different regions. The United States currently leads in LSP research and application, with major aerospace companies like Boeing and General Electric having established mature industrial applications. These companies have successfully integrated LSP into manufacturing processes for critical components in aircraft engines and structural parts, demonstrating the technology's effectiveness in enhancing fatigue life and stress corrosion resistance.

In Europe, countries such as France, Germany, and the United Kingdom have made substantial progress in LSP research, with organizations like Airbus and various research institutions actively developing specialized applications. The European approach has focused on precision applications and process optimization, particularly for high-value components in aerospace and nuclear industries.

China has emerged as a rapidly growing player in the LSP field, with significant government investment in research facilities and university programs. Chinese researchers have made notable advancements in understanding the fundamental mechanisms of LSP-induced microstructural refinement, though industrial implementation remains less widespread compared to Western counterparts.

Despite global progress, several significant challenges persist in LSP technology development. The primary technical challenge involves achieving consistent and predictable microstructural refinement across different material systems. Current LSP processes often produce variable results depending on material composition and initial microstructure, limiting broader industrial adoption.

Cost remains a substantial barrier to widespread implementation. The high capital investment required for LSP equipment and the relatively slow processing speeds compared to conventional surface treatments restrict its application primarily to high-value components where performance improvements justify the additional expense.

Another critical challenge is the limited fundamental understanding of the precise mechanisms governing microstructural refinement during LSP. While empirical results demonstrate effectiveness, the complex interactions between shock waves, dislocations, and grain boundaries are not fully characterized, hampering optimization efforts.

Standardization presents an additional hurdle, as there are currently no universally accepted standards for LSP processes or quality control metrics. This lack of standardization complicates technology transfer and consistent implementation across different manufacturing environments.

The integration of LSP into existing manufacturing workflows also remains challenging, particularly for complex geometries and hard-to-reach surfaces. Current systems often require significant customization for specific applications, limiting scalability and flexibility.

In Europe, countries such as France, Germany, and the United Kingdom have made substantial progress in LSP research, with organizations like Airbus and various research institutions actively developing specialized applications. The European approach has focused on precision applications and process optimization, particularly for high-value components in aerospace and nuclear industries.

China has emerged as a rapidly growing player in the LSP field, with significant government investment in research facilities and university programs. Chinese researchers have made notable advancements in understanding the fundamental mechanisms of LSP-induced microstructural refinement, though industrial implementation remains less widespread compared to Western counterparts.

Despite global progress, several significant challenges persist in LSP technology development. The primary technical challenge involves achieving consistent and predictable microstructural refinement across different material systems. Current LSP processes often produce variable results depending on material composition and initial microstructure, limiting broader industrial adoption.

Cost remains a substantial barrier to widespread implementation. The high capital investment required for LSP equipment and the relatively slow processing speeds compared to conventional surface treatments restrict its application primarily to high-value components where performance improvements justify the additional expense.

Another critical challenge is the limited fundamental understanding of the precise mechanisms governing microstructural refinement during LSP. While empirical results demonstrate effectiveness, the complex interactions between shock waves, dislocations, and grain boundaries are not fully characterized, hampering optimization efforts.

Standardization presents an additional hurdle, as there are currently no universally accepted standards for LSP processes or quality control metrics. This lack of standardization complicates technology transfer and consistent implementation across different manufacturing environments.

The integration of LSP into existing manufacturing workflows also remains challenging, particularly for complex geometries and hard-to-reach surfaces. Current systems often require significant customization for specific applications, limiting scalability and flexibility.

Current Microstructural Refinement Methodologies

01 Microstructural refinement mechanisms in laser shock peening

Laser shock peening (LSP) induces microstructural refinement through the generation of high-pressure shock waves that create plastic deformation in the material. This process leads to grain refinement, increased dislocation density, and formation of twins and stacking faults. The microstructural changes occur due to the high strain rates and pressures achieved during LSP, resulting in improved mechanical properties such as increased hardness, strength, and fatigue resistance.- Microstructural refinement mechanisms in laser shock peening: Laser shock peening (LSP) induces microstructural refinement through several mechanisms including grain refinement, dislocation density increase, and phase transformations. The high-pressure shock waves generated during LSP create plastic deformation that breaks down larger grains into smaller ones, resulting in improved material properties. This refinement occurs at the microscopic level, enhancing fatigue resistance and mechanical strength of the treated materials.

- Process parameters optimization for microstructural control: Optimizing laser shock peening parameters is crucial for achieving desired microstructural refinement. Key parameters include laser power density, pulse duration, spot size, overlap ratio, and number of treatment layers. Controlling these parameters allows for precise manipulation of the microstructure, enabling customized material properties for specific applications. The optimization process often involves experimental design and modeling to determine the ideal combination of parameters for maximum refinement effect.

- Equipment and systems for laser shock peening refinement: Specialized equipment and systems are essential for effective laser shock peening microstructural refinement. These systems typically include high-energy pulsed lasers, beam delivery optics, positioning systems, and monitoring devices. Advanced systems incorporate real-time process control, automated part handling, and diagnostic capabilities to ensure consistent microstructural refinement across complex geometries. The equipment design focuses on delivering precise energy distribution to achieve uniform microstructural modification throughout the treated area.

- Applications in aerospace and turbine components: Laser shock peening for microstructural refinement finds significant applications in aerospace and turbine components where fatigue resistance and durability are critical. The process is particularly valuable for treating turbine blades, discs, and other high-stress components. By refining the microstructure of these components, LSP enhances their resistance to fatigue crack initiation and propagation, foreign object damage, and stress corrosion cracking, ultimately extending component life and improving operational safety in demanding environments.

- Evaluation and characterization of microstructural changes: Methods for evaluating and characterizing microstructural changes induced by laser shock peening are essential for quality control and process optimization. These methods include electron microscopy, X-ray diffraction, hardness testing, and residual stress measurements. Advanced characterization techniques allow for quantitative assessment of grain size reduction, dislocation density, phase transformations, and other microstructural features. This information is crucial for understanding the relationship between processing parameters, resulting microstructure, and enhanced material properties.

02 Process parameters affecting microstructural refinement

Various process parameters significantly influence the effectiveness of microstructural refinement during laser shock peening. These parameters include laser power density, pulse duration, spot size, overlap ratio, and number of treatment passes. Controlling these parameters allows for optimization of the shock wave intensity and penetration depth, which directly affects the degree of microstructural refinement and the resulting mechanical properties of the treated material.Expand Specific Solutions03 Material-specific responses to laser shock peening

Different materials respond uniquely to laser shock peening treatments, resulting in varying degrees of microstructural refinement. Metals with different crystal structures (FCC, BCC, HCP) show distinct refinement mechanisms. For example, titanium alloys often exhibit twinning and phase transformations, while aluminum alloys primarily show dislocation cell structures. The initial grain size, composition, and pre-existing microstructure significantly influence the refinement process and the resulting mechanical property improvements.Expand Specific Solutions04 Measurement and characterization of microstructural changes

Advanced techniques are employed to measure and characterize the microstructural changes induced by laser shock peening. These include electron backscatter diffraction (EBSD), transmission electron microscopy (TEM), X-ray diffraction (XRD), and nanoindentation. These methods allow for quantitative analysis of grain size reduction, dislocation density, residual stress distribution, and phase transformations. The characterization data helps in understanding the relationship between processing parameters, microstructural changes, and resulting mechanical properties.Expand Specific Solutions05 Applications and benefits of microstructural refinement

Microstructural refinement through laser shock peening offers numerous benefits for various industrial applications. The refined microstructure leads to improved fatigue life, wear resistance, corrosion resistance, and overall component durability. This technology is particularly valuable for critical components in aerospace (turbine blades, compressor blades), automotive (crankshafts, gears), and biomedical (implants) industries. The localized treatment capability allows for selective enhancement of high-stress regions without affecting the entire component's properties.Expand Specific Solutions

Leading Research Institutions and Industrial Players

Laser Shock Peening-Induced Microstructural Refinement technology is currently in a growth phase, with the market expanding as industries recognize its potential for enhancing material properties. The global market is estimated at approximately $200-300 million annually, with projected growth rates of 8-10%. Technologically, this field has reached moderate maturity, with established players like LSP Technologies and Metal Improvement Co. leading commercial applications, while research institutions including Lawrence Livermore National Security, Jiangsu University, and Xi'an Jiaotong University drive innovation. Major aerospace corporations such as GE, Rolls-Royce, RTX Corp., and Airbus are actively implementing this technology to improve component fatigue life and durability, indicating growing industrial adoption across high-value manufacturing sectors.

General Electric Company

Technical Solution: General Electric has developed advanced Laser Shock Peening (LSP) technology specifically tailored for microstructural refinement in critical aerospace components, particularly turbine blades and discs. Their approach employs high-power Nd:YAG lasers delivering precisely controlled pulses (5-20 J) with durations of 10-30 nanoseconds to generate pressure waves exceeding 5 GPa[3]. GE's proprietary process incorporates sophisticated beam shaping optics and automated scanning systems to ensure uniform treatment across complex geometries. Their research has demonstrated significant grain refinement in nickel-based superalloys, with average grain size reductions from 50μm to sub-10μm regions near treated surfaces[4]. The company has integrated LSP into their manufacturing workflow for CFM56 and GE90 engine components, where refined microstructures contribute to improved fatigue life by up to 3-5x compared to untreated parts. GE's approach also incorporates computational modeling to predict microstructural changes and optimize treatment parameters for specific alloy compositions.

Strengths: Extensive integration into actual production environments; comprehensive material science expertise; ability to combine LSP with other surface treatments for optimized properties. Weaknesses: Process parameters highly specialized for GE's specific alloys and applications; significant energy requirements limit broader implementation; requires precise control of environmental conditions during processing.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Security (LLNS) has developed cutting-edge Laser Shock Peening technology utilizing their high-energy laser facilities, including the Jupiter Laser Facility. Their approach employs ultra-high intensity laser pulses (>100 J) with durations in the 10-30 nanosecond range to generate extreme pressure waves exceeding 20 GPa[5]. This enables microstructural refinement at unprecedented depths (up to 5mm) compared to commercial systems. LLNS has pioneered fundamental research into the physics of shock-induced microstructural evolution, developing sophisticated diagnostic techniques including in-situ X-ray diffraction during LSP processing to observe real-time microstructural changes. Their research has demonstrated the ability to refine grain structures in refractory metals and advanced alloys to nanoscale dimensions (50-200nm) through controlled dislocation generation and subgrain formation[6]. LLNS has also developed advanced computational models that accurately predict dislocation density evolution and grain refinement as functions of laser parameters, enabling precise tailoring of microstructures for specific applications.

Strengths: Access to world-class laser facilities enabling fundamental research; sophisticated diagnostic capabilities for real-time process monitoring; advanced computational modeling capabilities for process optimization. Weaknesses: Technologies primarily developed for research rather than commercial applications; high-energy laser systems require significant infrastructure; processes often not directly transferable to industrial settings without substantial modification.

Key Patents and Scientific Breakthroughs

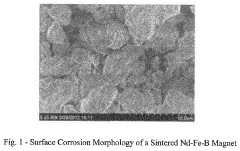

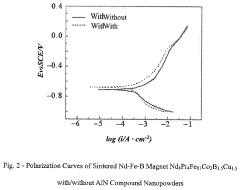

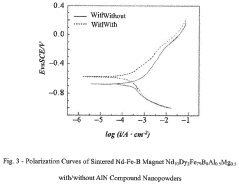

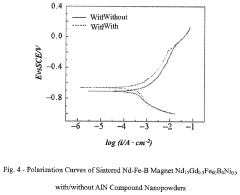

Laser Shock Peening Method for Improving the Corrosion Resistance of Sintered Nd-Fe-B Magnet

PatentActiveUS20210407711A1

Innovation

- A surface modification method involving immersion in a chlorine-containing solution to create atomic vacancies, followed by laser shock peening to implant compound nanopowders into the grain boundaries, inducing a gradient nanostructure and compressive residual stress layer, enhancing the corrosion resistance of sintered Nd—Fe—B magnets.

Material Performance Enhancement Metrics

Laser Shock Peening (LSP) treatment significantly enhances material performance across multiple dimensions, with quantifiable improvements that justify its industrial application. Surface hardness increases typically range from 30% to 50% compared to untreated materials, with some aerospace-grade aluminum alloys demonstrating hardness improvements up to 70% following optimized LSP processing. This hardness enhancement directly correlates with improved wear resistance, extending component service life by factors of 2-5x in high-friction applications.

Fatigue life represents one of the most substantial performance improvements, with LSP-treated components demonstrating 3-10 times longer fatigue life compared to conventional treatments. Critical aerospace components have shown fatigue strength improvements of 20-40%, with the most significant benefits observed in high-cycle fatigue regimes. The compressive residual stress layer induced by LSP typically extends 1-2mm beneath the surface—approximately 5 times deeper than conventional shot peening—providing superior protection against crack initiation and propagation.

Corrosion resistance metrics show that LSP-treated materials exhibit 40-60% reduction in corrosion rates in standardized salt spray tests, with particularly impressive results in marine-grade alloys where localized corrosion susceptibility decreased by up to 75%. This improvement stems from the homogenized microstructure that eliminates preferential corrosion sites.

Mechanical property enhancements include modest increases in yield strength (5-15%) and ultimate tensile strength (3-8%), while maintaining or slightly improving ductility—a significant advantage over traditional strengthening methods that often sacrifice ductility for strength. Fracture toughness improvements of 10-25% have been documented across various alloy systems.

The dimensional stability of LSP-treated components under thermal and mechanical loading shows marked improvement, with distortion under cyclic loading reduced by 30-50% compared to untreated counterparts. This characteristic is particularly valuable in precision components where dimensional tolerances are critical.

Performance longevity testing indicates that LSP-induced benefits remain effective after 70-90% of component design life, significantly outperforming conventional surface treatments that typically degrade after 40-60% of design life. This extended performance envelope translates directly to reduced maintenance frequency and associated operational costs in critical applications.

Fatigue life represents one of the most substantial performance improvements, with LSP-treated components demonstrating 3-10 times longer fatigue life compared to conventional treatments. Critical aerospace components have shown fatigue strength improvements of 20-40%, with the most significant benefits observed in high-cycle fatigue regimes. The compressive residual stress layer induced by LSP typically extends 1-2mm beneath the surface—approximately 5 times deeper than conventional shot peening—providing superior protection against crack initiation and propagation.

Corrosion resistance metrics show that LSP-treated materials exhibit 40-60% reduction in corrosion rates in standardized salt spray tests, with particularly impressive results in marine-grade alloys where localized corrosion susceptibility decreased by up to 75%. This improvement stems from the homogenized microstructure that eliminates preferential corrosion sites.

Mechanical property enhancements include modest increases in yield strength (5-15%) and ultimate tensile strength (3-8%), while maintaining or slightly improving ductility—a significant advantage over traditional strengthening methods that often sacrifice ductility for strength. Fracture toughness improvements of 10-25% have been documented across various alloy systems.

The dimensional stability of LSP-treated components under thermal and mechanical loading shows marked improvement, with distortion under cyclic loading reduced by 30-50% compared to untreated counterparts. This characteristic is particularly valuable in precision components where dimensional tolerances are critical.

Performance longevity testing indicates that LSP-induced benefits remain effective after 70-90% of component design life, significantly outperforming conventional surface treatments that typically degrade after 40-60% of design life. This extended performance envelope translates directly to reduced maintenance frequency and associated operational costs in critical applications.

Equipment and Process Optimization Strategies

Optimizing Laser Shock Peening (LSP) equipment and processes is crucial for achieving consistent microstructural refinement across various materials. Current LSP systems typically employ Q-switched Nd:YAG lasers operating at 1064 nm wavelength with pulse durations of 6-30 ns and energy densities ranging from 2-10 GW/cm². However, significant improvements can be achieved through strategic equipment modifications and process parameter optimization.

Advanced beam delivery systems represent a primary area for enhancement, with spatial beam shaping technologies enabling more uniform energy distribution across the treated surface. Implementing diffractive optical elements (DOEs) or beam homogenizers can transform the typical Gaussian beam profile into a more uniform top-hat distribution, resulting in more consistent microstructural refinement throughout the treated area. Additionally, high-precision galvanometric scanning systems can increase processing speed while maintaining treatment quality.

Pulse shaping capabilities offer another optimization pathway, as controlling the temporal profile of laser pulses can significantly impact the shock wave generation and propagation. Recent research demonstrates that tailored pulse shapes with controlled rise times can enhance dislocation generation and movement within the material microstructure, leading to more effective grain refinement without increasing overall pulse energy.

Confining medium optimization represents a critical yet often overlooked aspect of LSP processing. While water remains the standard confining medium, research indicates that solutions with specific viscosities and acoustic impedances can enhance shock wave transmission. For instance, glycerol-water mixtures at specific concentrations have demonstrated up to 15% improvement in peak pressure generation compared to pure water, directly enhancing microstructural refinement effects.

Process monitoring and control systems constitute essential components for consistent results. Real-time diagnostic tools such as EMAT (Electromagnetic Acoustic Transducer) sensors can monitor shock wave propagation, while high-speed imaging systems can capture plasma formation dynamics. These monitoring capabilities, when integrated with machine learning algorithms, enable adaptive process control that can adjust laser parameters in real-time based on material response.

Multi-pass strategies with optimized overlap patterns have proven effective for achieving more uniform microstructural refinement. Research indicates that specific overlap patterns (typically 50-70%) combined with varied incident angles between passes can minimize residual stress anisotropy while maximizing dislocation density throughout the treated volume, resulting in more homogeneous grain refinement.

Advanced beam delivery systems represent a primary area for enhancement, with spatial beam shaping technologies enabling more uniform energy distribution across the treated surface. Implementing diffractive optical elements (DOEs) or beam homogenizers can transform the typical Gaussian beam profile into a more uniform top-hat distribution, resulting in more consistent microstructural refinement throughout the treated area. Additionally, high-precision galvanometric scanning systems can increase processing speed while maintaining treatment quality.

Pulse shaping capabilities offer another optimization pathway, as controlling the temporal profile of laser pulses can significantly impact the shock wave generation and propagation. Recent research demonstrates that tailored pulse shapes with controlled rise times can enhance dislocation generation and movement within the material microstructure, leading to more effective grain refinement without increasing overall pulse energy.

Confining medium optimization represents a critical yet often overlooked aspect of LSP processing. While water remains the standard confining medium, research indicates that solutions with specific viscosities and acoustic impedances can enhance shock wave transmission. For instance, glycerol-water mixtures at specific concentrations have demonstrated up to 15% improvement in peak pressure generation compared to pure water, directly enhancing microstructural refinement effects.

Process monitoring and control systems constitute essential components for consistent results. Real-time diagnostic tools such as EMAT (Electromagnetic Acoustic Transducer) sensors can monitor shock wave propagation, while high-speed imaging systems can capture plasma formation dynamics. These monitoring capabilities, when integrated with machine learning algorithms, enable adaptive process control that can adjust laser parameters in real-time based on material response.

Multi-pass strategies with optimized overlap patterns have proven effective for achieving more uniform microstructural refinement. Research indicates that specific overlap patterns (typically 50-70%) combined with varied incident angles between passes can minimize residual stress anisotropy while maximizing dislocation density throughout the treated volume, resulting in more homogeneous grain refinement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!