Laser Shock Peening for Aerospace Structural Components

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSP Technology Background and Objectives

Laser Shock Peening (LSP) emerged in the 1960s as a surface treatment technology initially developed at Battelle Memorial Institute. The fundamental principle involves using high-energy laser pulses to generate plasma on a material surface, creating shock waves that induce compressive residual stresses in metallic components. This technology has evolved significantly over the past six decades, transitioning from laboratory experiments to industrial applications, particularly in aerospace manufacturing.

The evolution of LSP technology has been characterized by continuous improvements in laser systems, from early ruby lasers to modern high-power Nd:YAG and fiber lasers. These advancements have enabled higher processing speeds, greater treatment depths, and more precise control over the peening process. Concurrently, computational modeling capabilities have enhanced our understanding of the complex physics involved in LSP, allowing for more optimized treatment parameters.

In the aerospace sector, LSP has gained prominence as a superior alternative to conventional shot peening for critical structural components. The technology's ability to induce deeper compressive residual stresses without surface roughening makes it particularly valuable for high-fatigue applications such as turbine blades, wing attachments, and landing gear components. Recent research indicates that LSP-treated aerospace components can experience fatigue life improvements of 3-5 times compared to untreated parts.

The primary technical objective of LSP implementation in aerospace applications is to enhance the fatigue resistance and stress corrosion cracking resistance of structural components without compromising their dimensional integrity. Secondary objectives include improving foreign object damage resistance and extending the service life of critical components, thereby reducing maintenance costs and increasing aircraft availability.

Current research trends focus on expanding LSP applications to new aerospace alloys, including advanced aluminum alloys, titanium alloys, and high-temperature superalloys used in next-generation aircraft. Additionally, there is growing interest in developing portable LSP systems for in-situ repair and maintenance operations, which would significantly reduce aircraft downtime.

The integration of LSP with other surface enhancement technologies, such as ultrasonic impact treatment and deep rolling, represents another promising direction. These hybrid approaches aim to combine the deep compressive stresses achieved through LSP with the surface finishing capabilities of other techniques, creating a comprehensive solution for aerospace structural integrity.

As environmental regulations become more stringent, LSP also offers advantages as a "clean" technology compared to chemical surface treatments, aligning with the aerospace industry's sustainability goals and regulatory compliance requirements.

The evolution of LSP technology has been characterized by continuous improvements in laser systems, from early ruby lasers to modern high-power Nd:YAG and fiber lasers. These advancements have enabled higher processing speeds, greater treatment depths, and more precise control over the peening process. Concurrently, computational modeling capabilities have enhanced our understanding of the complex physics involved in LSP, allowing for more optimized treatment parameters.

In the aerospace sector, LSP has gained prominence as a superior alternative to conventional shot peening for critical structural components. The technology's ability to induce deeper compressive residual stresses without surface roughening makes it particularly valuable for high-fatigue applications such as turbine blades, wing attachments, and landing gear components. Recent research indicates that LSP-treated aerospace components can experience fatigue life improvements of 3-5 times compared to untreated parts.

The primary technical objective of LSP implementation in aerospace applications is to enhance the fatigue resistance and stress corrosion cracking resistance of structural components without compromising their dimensional integrity. Secondary objectives include improving foreign object damage resistance and extending the service life of critical components, thereby reducing maintenance costs and increasing aircraft availability.

Current research trends focus on expanding LSP applications to new aerospace alloys, including advanced aluminum alloys, titanium alloys, and high-temperature superalloys used in next-generation aircraft. Additionally, there is growing interest in developing portable LSP systems for in-situ repair and maintenance operations, which would significantly reduce aircraft downtime.

The integration of LSP with other surface enhancement technologies, such as ultrasonic impact treatment and deep rolling, represents another promising direction. These hybrid approaches aim to combine the deep compressive stresses achieved through LSP with the surface finishing capabilities of other techniques, creating a comprehensive solution for aerospace structural integrity.

As environmental regulations become more stringent, LSP also offers advantages as a "clean" technology compared to chemical surface treatments, aligning with the aerospace industry's sustainability goals and regulatory compliance requirements.

Aerospace Industry Demand Analysis

The aerospace industry has demonstrated a growing demand for advanced surface treatment technologies that can enhance the fatigue life and durability of critical structural components. Laser Shock Peening (LSP) has emerged as a revolutionary technology that addresses these needs by significantly improving the mechanical properties of aerospace materials without compromising their structural integrity.

Market analysis indicates that the global aerospace industry is projected to grow at a compound annual growth rate of 3.5% over the next decade, with a particular emphasis on lightweight, high-strength materials that can withstand extreme operational conditions. This growth is driven by increasing air traffic, fleet expansion, and the replacement of aging aircraft, creating substantial demand for technologies that can extend component lifespan and reduce maintenance costs.

The military aerospace sector represents a significant market for LSP technology, with defense budgets allocating substantial resources to aircraft life extension programs. Fighter jets, military transport aircraft, and rotorcraft all contain critical components that can benefit from the enhanced fatigue resistance provided by LSP treatment, particularly in high-stress areas such as engine mounts, wing attachment points, and landing gear components.

Commercial aviation presents another major market opportunity, with manufacturers seeking to extend the service life of aircraft while reducing weight to improve fuel efficiency. The industry's push toward more electric aircraft and sustainable aviation has intensified the need for components that can withstand higher operational stresses while maintaining safety margins. LSP offers a solution by enabling the use of thinner, lighter components without sacrificing durability.

Space exploration and satellite deployment sectors are also showing increased interest in LSP technology. The extreme launch conditions and the inability to perform repairs in orbit make reliability paramount for space components. LSP's ability to enhance fatigue resistance without dimensional changes makes it particularly valuable for critical spacecraft structures and satellite components.

Regional analysis reveals that North America currently dominates the market for advanced surface treatment technologies in aerospace, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate due to expanding aerospace manufacturing capabilities in China, Japan, and India, coupled with increasing defense spending.

Customer requirements in the aerospace sector emphasize certification compliance, process repeatability, and comprehensive documentation of treatment effects. The industry demands technologies that can be integrated into existing manufacturing processes without significant disruption, while providing quantifiable improvements in component performance and lifespan.

Market analysis indicates that the global aerospace industry is projected to grow at a compound annual growth rate of 3.5% over the next decade, with a particular emphasis on lightweight, high-strength materials that can withstand extreme operational conditions. This growth is driven by increasing air traffic, fleet expansion, and the replacement of aging aircraft, creating substantial demand for technologies that can extend component lifespan and reduce maintenance costs.

The military aerospace sector represents a significant market for LSP technology, with defense budgets allocating substantial resources to aircraft life extension programs. Fighter jets, military transport aircraft, and rotorcraft all contain critical components that can benefit from the enhanced fatigue resistance provided by LSP treatment, particularly in high-stress areas such as engine mounts, wing attachment points, and landing gear components.

Commercial aviation presents another major market opportunity, with manufacturers seeking to extend the service life of aircraft while reducing weight to improve fuel efficiency. The industry's push toward more electric aircraft and sustainable aviation has intensified the need for components that can withstand higher operational stresses while maintaining safety margins. LSP offers a solution by enabling the use of thinner, lighter components without sacrificing durability.

Space exploration and satellite deployment sectors are also showing increased interest in LSP technology. The extreme launch conditions and the inability to perform repairs in orbit make reliability paramount for space components. LSP's ability to enhance fatigue resistance without dimensional changes makes it particularly valuable for critical spacecraft structures and satellite components.

Regional analysis reveals that North America currently dominates the market for advanced surface treatment technologies in aerospace, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate due to expanding aerospace manufacturing capabilities in China, Japan, and India, coupled with increasing defense spending.

Customer requirements in the aerospace sector emphasize certification compliance, process repeatability, and comprehensive documentation of treatment effects. The industry demands technologies that can be integrated into existing manufacturing processes without significant disruption, while providing quantifiable improvements in component performance and lifespan.

Current LSP Implementation Challenges

Despite the significant advancements in Laser Shock Peening (LSP) technology for aerospace applications, several critical implementation challenges persist that limit its broader adoption across the industry. The primary challenge remains the high capital investment required for LSP equipment, with specialized high-energy laser systems, precision positioning mechanisms, and supporting infrastructure often costing millions of dollars. This substantial financial barrier restricts LSP implementation primarily to large aerospace manufacturers and specialized service providers.

Energy efficiency represents another significant challenge, as current LSP processes typically operate at low energy conversion rates (often below 10%), resulting in considerable power consumption and operational costs. The process also demands specialized consumables such as ablative layers and confining media that must be precisely applied and regularly replaced, adding to operational complexity and cost.

Quality control and process validation continue to present technical hurdles. The non-destructive evaluation of LSP-treated components remains challenging, as the beneficial compressive residual stresses induced by LSP are not directly observable through conventional inspection methods. This necessitates sophisticated measurement techniques such as X-ray diffraction or hole-drilling methods, which are time-consuming and often cannot be implemented in-line during production.

Process standardization across the aerospace industry presents another significant barrier. Unlike more established surface treatment methods, LSP lacks comprehensive industry-wide standards and specifications, creating uncertainty in qualification and certification processes. This absence of standardization complicates the integration of LSP into existing aerospace manufacturing protocols and quality assurance frameworks.

The geometric limitations of current LSP systems also restrict application versatility. Complex aerospace components with intricate geometries, internal surfaces, or limited accessibility present significant challenges for conventional LSP equipment. The laser beam delivery systems often struggle to maintain consistent processing parameters across varying surface contours, potentially resulting in non-uniform treatment quality.

Processing speed remains a bottleneck for high-volume production environments. Current LSP systems typically process surface areas at rates of only a few square centimeters per minute, significantly slower than competing surface treatment technologies. This throughput limitation impacts production schedules and increases per-component processing costs, particularly for larger aerospace structures.

Finally, the specialized expertise required for LSP implementation presents a workforce challenge. The technology demands highly trained operators and engineers with multidisciplinary knowledge spanning laser physics, materials science, and aerospace engineering—a skill set that remains relatively scarce in the industrial workforce.

Energy efficiency represents another significant challenge, as current LSP processes typically operate at low energy conversion rates (often below 10%), resulting in considerable power consumption and operational costs. The process also demands specialized consumables such as ablative layers and confining media that must be precisely applied and regularly replaced, adding to operational complexity and cost.

Quality control and process validation continue to present technical hurdles. The non-destructive evaluation of LSP-treated components remains challenging, as the beneficial compressive residual stresses induced by LSP are not directly observable through conventional inspection methods. This necessitates sophisticated measurement techniques such as X-ray diffraction or hole-drilling methods, which are time-consuming and often cannot be implemented in-line during production.

Process standardization across the aerospace industry presents another significant barrier. Unlike more established surface treatment methods, LSP lacks comprehensive industry-wide standards and specifications, creating uncertainty in qualification and certification processes. This absence of standardization complicates the integration of LSP into existing aerospace manufacturing protocols and quality assurance frameworks.

The geometric limitations of current LSP systems also restrict application versatility. Complex aerospace components with intricate geometries, internal surfaces, or limited accessibility present significant challenges for conventional LSP equipment. The laser beam delivery systems often struggle to maintain consistent processing parameters across varying surface contours, potentially resulting in non-uniform treatment quality.

Processing speed remains a bottleneck for high-volume production environments. Current LSP systems typically process surface areas at rates of only a few square centimeters per minute, significantly slower than competing surface treatment technologies. This throughput limitation impacts production schedules and increases per-component processing costs, particularly for larger aerospace structures.

Finally, the specialized expertise required for LSP implementation presents a workforce challenge. The technology demands highly trained operators and engineers with multidisciplinary knowledge spanning laser physics, materials science, and aerospace engineering—a skill set that remains relatively scarce in the industrial workforce.

Current LSP Application Solutions

01 Laser shock peening process fundamentals

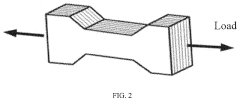

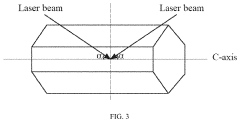

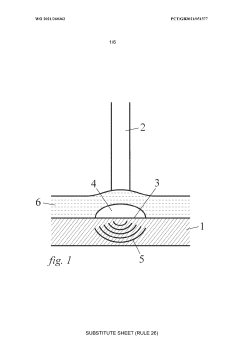

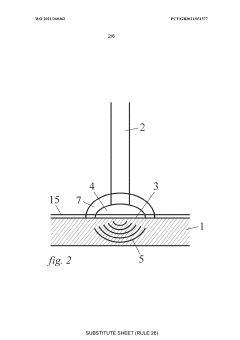

Laser shock peening (LSP) is a surface treatment process that uses high-energy laser pulses to generate shock waves on metal surfaces. When the laser beam hits the material surface (typically covered with an ablative layer and a transparent overlay), it creates a high-pressure plasma that induces compressive residual stresses in the material. This process improves fatigue life, resistance to stress corrosion cracking, and overall mechanical properties of metal components without altering their dimensional specifications.- Laser shock peening process fundamentals: Laser shock peening (LSP) is a surface treatment process that uses high-energy laser pulses to generate shock waves on the material surface. When the laser beam hits the material, it creates a plasma that expands rapidly, generating a high-pressure shock wave. This shock wave propagates into the material, causing plastic deformation and introducing compressive residual stresses that improve fatigue life, resistance to stress corrosion cracking, and overall mechanical properties of the treated components.

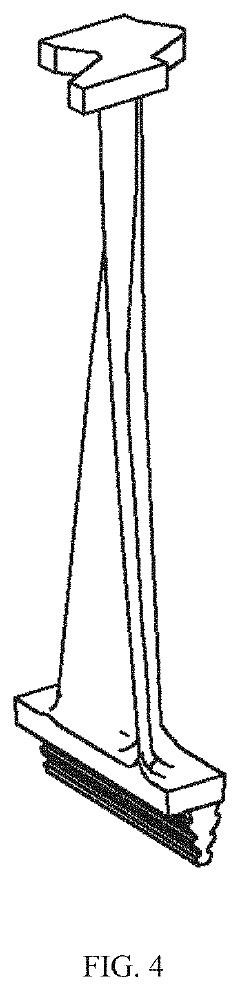

- Applications in aerospace components: Laser shock peening is widely applied to aerospace components such as turbine blades, disks, and other critical engine parts to enhance their fatigue life and durability. The process is particularly valuable for treating airfoil edges, dovetail regions, and other high-stress areas in aircraft engines. By introducing compressive residual stresses in these components, LSP significantly improves their resistance to foreign object damage, fatigue cracking, and extends their operational lifespan under extreme conditions.

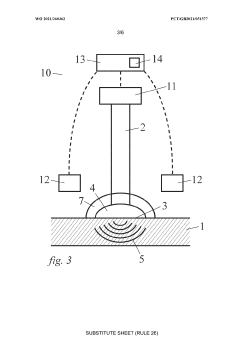

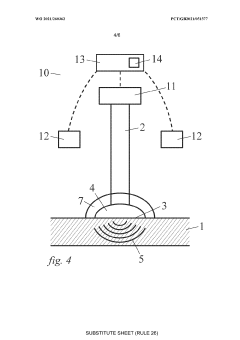

- Laser and equipment innovations: Advancements in laser technology and equipment design have significantly improved the laser shock peening process. These innovations include high-power pulsed lasers, beam delivery systems, automated processing equipment, and real-time monitoring systems. Modern LSP systems incorporate precise control of laser parameters such as pulse energy, duration, spot size, and repetition rate to optimize the treatment effect. Specialized optics and beam shaping technologies allow for treating complex geometries and ensuring uniform coverage of the treated surfaces.

- Material enhancement and surface properties: Laser shock peening significantly enhances material properties by inducing deep compressive residual stresses in the surface layers. This treatment increases hardness, wear resistance, and fatigue strength while improving resistance to stress corrosion cracking. The depth of the affected layer can extend several millimeters below the surface, much deeper than conventional shot peening. LSP can be applied to various materials including aluminum alloys, titanium alloys, stainless steels, and nickel-based superalloys, with each material showing specific improvements in mechanical properties and performance characteristics.

- Process monitoring and quality control: Advanced monitoring and quality control techniques are essential for ensuring consistent and effective laser shock peening treatments. These include real-time plasma diagnostics, acoustic emission monitoring, laser beam characterization, and post-process residual stress measurements. Non-destructive testing methods such as X-ray diffraction, ultrasonic techniques, and optical interferometry are used to verify the depth and magnitude of compressive stresses. Digital twins and simulation models help predict the residual stress distribution and optimize process parameters for specific applications.

02 Equipment and laser configurations for shock peening

Specialized equipment and laser configurations are essential for effective laser shock peening. These systems typically include high-energy pulsed lasers (often Nd:glass or Nd:YAG), beam delivery systems, positioning mechanisms, and monitoring equipment. Advanced systems incorporate precise control of laser parameters such as pulse duration, energy density, and spot size. Some configurations use multiple laser beams or robotic systems to treat complex geometries, while others employ specialized optics to shape the laser beam for optimal processing conditions.Expand Specific Solutions03 Applications in aerospace and turbine components

Laser shock peening is widely applied in aerospace and turbine industries to enhance the performance of critical components. The process is particularly valuable for treating turbine blades, discs, airfoils, and other components subjected to high stress and fatigue conditions. By introducing compressive residual stresses, LSP significantly improves the fatigue life and foreign object damage resistance of these components. The treatment is especially beneficial for high-value parts in aircraft engines, power generation turbines, and other applications where component failure could have catastrophic consequences.Expand Specific Solutions04 Material-specific laser shock peening techniques

Different materials require specialized laser shock peening approaches to achieve optimal results. Techniques have been developed for treating various metals including titanium alloys, aluminum alloys, stainless steels, nickel-based superalloys, and other high-performance materials. These techniques involve adjustments to laser parameters, overlay materials, and processing conditions based on the specific material properties. Some advanced methods incorporate pre-treatments or combine LSP with other processes to enhance effectiveness for particular materials, especially those with unique microstructural characteristics or challenging geometries.Expand Specific Solutions05 Quality control and process monitoring methods

Ensuring consistent quality in laser shock peening requires sophisticated monitoring and control methods. These include real-time plasma diagnostics, acoustic emission monitoring, laser beam characterization, and post-process verification techniques. Advanced systems incorporate sensors to monitor the shock wave generation and propagation, ensuring proper energy transfer to the workpiece. Non-destructive testing methods such as X-ray diffraction, ultrasonic testing, and optical profilometry are used to verify the induced residual stress profiles and surface conditions. These quality control measures are critical for certification in aerospace and other high-reliability applications.Expand Specific Solutions

Major LSP Technology Providers

Laser Shock Peening (LSP) for aerospace structural components is in a growth phase, with the market expanding due to increasing demand for enhanced fatigue life and durability in critical aircraft parts. The global market is estimated at $200-300 million annually with projected growth of 7-9%. Technologically, LSP has reached commercial maturity but continues to evolve, with key players demonstrating varying levels of expertise. Industry leaders include LSP Technologies and Metal Improvement Co. with established commercial applications, while aerospace manufacturers like Airbus, GE, and RTX have integrated LSP into their manufacturing processes. Research institutions such as Lawrence Livermore National Security, Beihang University, and Jiangsu University are advancing the technology through fundamental research and new applications, creating a competitive landscape balanced between established commercial providers and emerging innovators.

General Electric Company

Technical Solution: General Electric has developed an advanced Laser Shock Peening (LSP) technology specifically tailored for critical aerospace engine components. Their system employs high-energy Nd:glass lasers delivering pulses of 10-50 joules with durations of 10-30 nanoseconds, creating peak power densities of 5-10 GW/cm². GE's approach incorporates robotic manipulation systems with 6-axis control to precisely treat complex geometries like turbine blades, disks, and structural components. Their proprietary process involves a dual-layer overlay system: an ablative layer (typically aluminum or black paint) and a transparent water layer that confines the plasma expansion. When the laser pulse strikes the surface, it generates pressures exceeding 1 GPa, inducing compressive residual stresses to depths of 1-2mm. GE has implemented this technology in production for CFM56 and GE90 engine components, demonstrating 3-10x improvements in fatigue life and significant enhancements in foreign object damage (FOD) resistance. Their LSP process has been certified for critical flight safety components and is integrated into their digital manufacturing ecosystem for process monitoring and quality control.

Strengths: Extensive integration with aerospace manufacturing processes; proven implementation on flight-critical components; sophisticated robotic delivery systems for complex geometries; comprehensive quality control systems. Weaknesses: Proprietary technology primarily used for in-house manufacturing rather than as commercial service; high operational costs; requires significant technical expertise to maintain and operate.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Security LLC has developed pioneering Laser Shock Peening (LSP) technology for aerospace structural applications through their work at Lawrence Livermore National Laboratory. Their approach utilizes high-energy, short-pulse laser systems capable of delivering 25-100 joule pulses with durations of 10-30 nanoseconds. The LLNL system employs neodymium-glass lasers operating at 1054nm wavelength with beam shaping optics to create uniform intensity profiles. Their process involves applying an ablative overlay (typically aluminum foil or black paint) and a transparent overlay (water) to the component surface. When the laser pulse strikes the ablative layer, it creates plasma that generates pressure waves of 1-10 GPa, inducing compressive residual stresses to depths of 1-2mm in aerospace alloys. LLNL has conducted extensive research on the fundamental physics of laser-material interactions during LSP, developing sophisticated computational models that predict residual stress distributions and material response. Their technology has been applied to aircraft structural components, demonstrating fatigue life improvements of 3-5x and enhanced resistance to stress corrosion cracking. LLNL has also pioneered warm laser peening techniques that combine LSP with controlled heating to optimize residual stress profiles in high-strength aerospace alloys.

Strengths: World-class research capabilities with deep understanding of fundamental LSP physics; sophisticated computational modeling capabilities; ability to process a wide range of materials including advanced aerospace alloys; extensive intellectual property portfolio. Weaknesses: Primary focus on research rather than production implementation; systems typically require significant technical expertise to operate; higher costs compared to conventional surface treatment methods.

Key LSP Patents and Technical Innovations

Laser shock peening method for additive manufactured component of double-phase titanium alloy

PatentActiveUS20210308767A1

Innovation

- A method combining selective laser melting with laser shock peening, where a three-dimensional digital model of a complex component is divided into slices, formed with consistent α-phase orientations using a strong magnetic field, and then subjected to laser shock peening with a shock wave angle optimized to enhance compressive residual stress and grain refinement.

Improvements in or relating to laser peening

PatentWO2021260362A1

Innovation

- A method and apparatus using a gaseous confinement medium, such as high-pressure gas, to confine the plasma generated by laser pulses, eliminating the need for a solid overlay and preventing water ingress, while allowing for controlled heat dissipation and reduced risk of localized melting.

Material Science Considerations

Laser Shock Peening (LSP) effectiveness is fundamentally dependent on the material properties of aerospace structural components. The microstructural characteristics of aerospace alloys, including grain size, phase distribution, and initial dislocation density, significantly influence the LSP-induced compressive residual stress profiles and their stability during service.

For aluminum alloys commonly used in aircraft structures (2XXX and 7XXX series), LSP creates compressive residual stresses extending to depths of 1-2mm, substantially deeper than conventional shot peening. These alloys exhibit excellent response to LSP due to their moderate yield strength and good plasticity, allowing for effective stress wave propagation and plastic deformation.

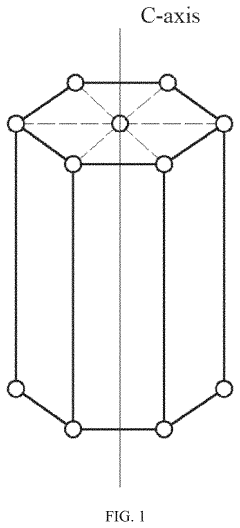

Titanium alloys (Ti-6Al-4V and other aerospace grades) present different challenges due to their higher yield strength and lower thermal conductivity. The LSP parameters must be carefully optimized for these materials to achieve desired residual stress profiles without causing surface melting or excessive thermal effects. The hexagonal close-packed (HCP) crystal structure of α-titanium phase also influences the anisotropic response to shock waves.

Nickel-based superalloys used in high-temperature applications require special consideration during LSP processing. Their precipitation-hardened microstructures and complex phase compositions necessitate tailored LSP parameters to ensure effective treatment without compromising the carefully engineered microstructures that provide their high-temperature strength.

The thermal stability of LSP-induced residual stresses varies significantly across material systems. In aluminum alloys, stress relaxation can occur at relatively low temperatures (150-200°C), while titanium and nickel-based superalloys maintain residual stress profiles at much higher operating temperatures. This thermal stability directly impacts the long-term effectiveness of LSP treatments in different aircraft components.

Surface condition prior to LSP treatment also plays a crucial role in treatment effectiveness. Pre-existing surface oxides, machining-induced residual stresses, and surface roughness can all influence the coupling efficiency of laser energy and the resulting plastic deformation. Proper surface preparation protocols must be established for each material system to ensure consistent LSP results.

The fatigue performance enhancement achieved through LSP varies across material systems, with high-strength aluminum alloys typically showing 3-5 times improvement in fatigue life, while titanium alloys may demonstrate more modest enhancements of 2-3 times, depending on loading conditions and component geometry.

For aluminum alloys commonly used in aircraft structures (2XXX and 7XXX series), LSP creates compressive residual stresses extending to depths of 1-2mm, substantially deeper than conventional shot peening. These alloys exhibit excellent response to LSP due to their moderate yield strength and good plasticity, allowing for effective stress wave propagation and plastic deformation.

Titanium alloys (Ti-6Al-4V and other aerospace grades) present different challenges due to their higher yield strength and lower thermal conductivity. The LSP parameters must be carefully optimized for these materials to achieve desired residual stress profiles without causing surface melting or excessive thermal effects. The hexagonal close-packed (HCP) crystal structure of α-titanium phase also influences the anisotropic response to shock waves.

Nickel-based superalloys used in high-temperature applications require special consideration during LSP processing. Their precipitation-hardened microstructures and complex phase compositions necessitate tailored LSP parameters to ensure effective treatment without compromising the carefully engineered microstructures that provide their high-temperature strength.

The thermal stability of LSP-induced residual stresses varies significantly across material systems. In aluminum alloys, stress relaxation can occur at relatively low temperatures (150-200°C), while titanium and nickel-based superalloys maintain residual stress profiles at much higher operating temperatures. This thermal stability directly impacts the long-term effectiveness of LSP treatments in different aircraft components.

Surface condition prior to LSP treatment also plays a crucial role in treatment effectiveness. Pre-existing surface oxides, machining-induced residual stresses, and surface roughness can all influence the coupling efficiency of laser energy and the resulting plastic deformation. Proper surface preparation protocols must be established for each material system to ensure consistent LSP results.

The fatigue performance enhancement achieved through LSP varies across material systems, with high-strength aluminum alloys typically showing 3-5 times improvement in fatigue life, while titanium alloys may demonstrate more modest enhancements of 2-3 times, depending on loading conditions and component geometry.

Safety and Certification Standards

The implementation of Laser Shock Peening (LSP) in aerospace structural components necessitates adherence to stringent safety protocols and certification standards to ensure airworthiness and operational reliability. Currently, the aerospace industry follows a multi-tiered regulatory framework for LSP implementation, with primary oversight from organizations such as the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and International Civil Aviation Organization (ICAO).

Material processing standards specific to LSP have evolved significantly since 2010, with SAE AMS2546 serving as the foundational specification for laser peening of metals. This standard delineates critical parameters including laser energy density, pulse duration, and coverage requirements. Complementary standards such as ASTM E837 for residual stress measurement and ASTM E647 for fatigue crack growth testing provide essential verification methodologies for LSP-treated components.

The certification pathway for LSP-treated aerospace components typically involves a comprehensive validation process. This begins with material qualification testing, followed by component-level validation, and culminates in system integration assessment. Manufacturers must demonstrate through empirical testing that LSP treatment enhances fatigue life without compromising other critical material properties. Documentation requirements include detailed process specifications, equipment calibration records, and operator qualification certifications.

Risk assessment frameworks specific to LSP applications have been developed to address potential failure modes. These frameworks incorporate Failure Mode and Effects Analysis (FMEA) methodologies tailored to laser processing technologies. Key risk factors evaluated include process parameter drift, surface preparation inconsistencies, and potential for thermal damage during processing. Mitigation strategies typically involve in-process monitoring systems and post-treatment non-destructive evaluation.

Quality assurance protocols for LSP implementation mandate comprehensive traceability systems. Each treated component must have documented evidence of process parameters, equipment configuration, and operator credentials. Non-destructive testing requirements typically include X-ray diffraction for residual stress verification and ultrasonic inspection for subsurface integrity assessment. Statistical process control methodologies are increasingly being integrated to ensure consistency across production batches.

Recent regulatory developments have focused on harmonizing international standards for LSP applications. The SAE Committee G-14 on Laser Peening has been instrumental in developing consensus standards that bridge requirements across different regulatory jurisdictions. Additionally, industry-specific guidelines have emerged for critical applications such as turbine engine components and primary structural elements, reflecting the growing acceptance of LSP as a mature technology for aerospace applications.

Material processing standards specific to LSP have evolved significantly since 2010, with SAE AMS2546 serving as the foundational specification for laser peening of metals. This standard delineates critical parameters including laser energy density, pulse duration, and coverage requirements. Complementary standards such as ASTM E837 for residual stress measurement and ASTM E647 for fatigue crack growth testing provide essential verification methodologies for LSP-treated components.

The certification pathway for LSP-treated aerospace components typically involves a comprehensive validation process. This begins with material qualification testing, followed by component-level validation, and culminates in system integration assessment. Manufacturers must demonstrate through empirical testing that LSP treatment enhances fatigue life without compromising other critical material properties. Documentation requirements include detailed process specifications, equipment calibration records, and operator qualification certifications.

Risk assessment frameworks specific to LSP applications have been developed to address potential failure modes. These frameworks incorporate Failure Mode and Effects Analysis (FMEA) methodologies tailored to laser processing technologies. Key risk factors evaluated include process parameter drift, surface preparation inconsistencies, and potential for thermal damage during processing. Mitigation strategies typically involve in-process monitoring systems and post-treatment non-destructive evaluation.

Quality assurance protocols for LSP implementation mandate comprehensive traceability systems. Each treated component must have documented evidence of process parameters, equipment configuration, and operator credentials. Non-destructive testing requirements typically include X-ray diffraction for residual stress verification and ultrasonic inspection for subsurface integrity assessment. Statistical process control methodologies are increasingly being integrated to ensure consistency across production batches.

Recent regulatory developments have focused on harmonizing international standards for LSP applications. The SAE Committee G-14 on Laser Peening has been instrumental in developing consensus standards that bridge requirements across different regulatory jurisdictions. Additionally, industry-specific guidelines have emerged for critical applications such as turbine engine components and primary structural elements, reflecting the growing acceptance of LSP as a mature technology for aerospace applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!