Laser Shock Peening for Nickel-Based Superalloys

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSP Technology Background and Objectives

Laser Shock Peening (LSP) emerged in the 1960s as a surface treatment technology, initially developed at Battelle Memorial Institute. The fundamental principle involves using high-energy laser pulses to generate plasma-induced shock waves that propagate through materials, inducing beneficial compressive residual stresses. This technology has evolved significantly over the past six decades, transitioning from laboratory experiments to industrial applications, particularly in aerospace and power generation sectors.

The evolution of LSP technology has been marked by continuous improvements in laser systems, from early ruby lasers to modern high-power Nd:YAG and fiber lasers. These advancements have enabled higher processing speeds, greater treatment depths, and more precise control over the peening process. Parallel developments in computational modeling have enhanced our understanding of the complex physics involved, allowing for more accurate prediction of residual stress profiles and material behavior.

For nickel-based superalloys, which are critical materials in high-temperature applications such as gas turbine engines, LSP offers unique advantages. These alloys, including Inconel 718, Waspaloy, and Rene 95, are designed to maintain mechanical strength at elevated temperatures but are susceptible to fatigue failure and stress corrosion cracking. The harsh operating environments of these components, characterized by high temperatures, cyclic loading, and corrosive conditions, necessitate advanced surface treatment solutions.

The primary technical objective of applying LSP to nickel-based superalloys is to enhance fatigue life and resistance to stress corrosion cracking without altering the carefully engineered microstructure and properties that make these alloys valuable. Unlike conventional shot peening, LSP can introduce deeper compressive residual stresses with minimal surface roughening, which is particularly important for aerodynamic components and those operating in fluid environments.

Secondary objectives include improving the resistance to foreign object damage, enhancing thermal stability of the induced residual stresses, and developing process parameters specifically optimized for different nickel-based superalloy compositions. The technology aims to address the increasing demands for longer component lifespans, reduced maintenance costs, and improved safety margins in critical applications.

Current research trends focus on understanding the interaction between LSP-induced residual stresses and the complex precipitation-strengthened microstructures of nickel-based superalloys, particularly at elevated temperatures where stress relaxation can occur. Additionally, there is growing interest in combining LSP with other surface treatments to create synergistic effects that further enhance component performance and durability.

The evolution of LSP technology has been marked by continuous improvements in laser systems, from early ruby lasers to modern high-power Nd:YAG and fiber lasers. These advancements have enabled higher processing speeds, greater treatment depths, and more precise control over the peening process. Parallel developments in computational modeling have enhanced our understanding of the complex physics involved, allowing for more accurate prediction of residual stress profiles and material behavior.

For nickel-based superalloys, which are critical materials in high-temperature applications such as gas turbine engines, LSP offers unique advantages. These alloys, including Inconel 718, Waspaloy, and Rene 95, are designed to maintain mechanical strength at elevated temperatures but are susceptible to fatigue failure and stress corrosion cracking. The harsh operating environments of these components, characterized by high temperatures, cyclic loading, and corrosive conditions, necessitate advanced surface treatment solutions.

The primary technical objective of applying LSP to nickel-based superalloys is to enhance fatigue life and resistance to stress corrosion cracking without altering the carefully engineered microstructure and properties that make these alloys valuable. Unlike conventional shot peening, LSP can introduce deeper compressive residual stresses with minimal surface roughening, which is particularly important for aerodynamic components and those operating in fluid environments.

Secondary objectives include improving the resistance to foreign object damage, enhancing thermal stability of the induced residual stresses, and developing process parameters specifically optimized for different nickel-based superalloy compositions. The technology aims to address the increasing demands for longer component lifespans, reduced maintenance costs, and improved safety margins in critical applications.

Current research trends focus on understanding the interaction between LSP-induced residual stresses and the complex precipitation-strengthened microstructures of nickel-based superalloys, particularly at elevated temperatures where stress relaxation can occur. Additionally, there is growing interest in combining LSP with other surface treatments to create synergistic effects that further enhance component performance and durability.

Market Demand Analysis for Superalloy Surface Treatment

The global market for superalloy surface treatment technologies has experienced significant growth in recent years, driven primarily by increasing demands in aerospace, power generation, and automotive industries. Nickel-based superalloys, known for their exceptional mechanical strength, resistance to thermal creep deformation, and surface stability, represent approximately 50% of the total superalloy market. The surface treatment segment for these materials is projected to grow at a compound annual growth rate of 6.8% through 2028.

Laser Shock Peening (LSP) technology has emerged as a premium surface treatment solution that addresses critical performance requirements in high-stress applications. Market research indicates that aerospace turbine manufacturers are willing to pay premium prices for LSP treatments due to the substantial improvements in fatigue life and stress corrosion resistance they provide. The market value for LSP treatments specifically for nickel-based superalloys reached $420 million in 2022, with expectations to surpass $650 million by 2027.

Industry surveys reveal that 78% of aerospace component manufacturers consider enhanced surface treatments as a top priority for next-generation engine development. This demand is primarily driven by the need to extend component lifespan, reduce maintenance intervals, and improve fuel efficiency through lighter yet more durable parts. The gas turbine industry alone accounts for 42% of the current market demand for advanced superalloy surface treatments.

Regional analysis shows North America leading the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the fastest growth is occurring in the Asia-Pacific region, particularly in China and India, where aerospace and energy sectors are rapidly expanding. These emerging markets are expected to grow at 9.2% annually, outpacing mature markets.

Customer requirements are increasingly focused on treatments that can be applied to complex geometries and confined spaces, areas where LSP holds significant advantages over conventional shot peening. Additionally, there is growing demand for environmentally friendly surface treatment processes that eliminate hazardous chemicals, aligning with global sustainability initiatives and regulatory trends.

Economic analysis indicates that while LSP has a higher initial implementation cost compared to conventional treatments, the total cost of ownership over component lifetime is approximately 22% lower due to extended service intervals and reduced replacement frequency. This value proposition is particularly compelling for critical components in aerospace and power generation applications where failure costs are exceptionally high.

Laser Shock Peening (LSP) technology has emerged as a premium surface treatment solution that addresses critical performance requirements in high-stress applications. Market research indicates that aerospace turbine manufacturers are willing to pay premium prices for LSP treatments due to the substantial improvements in fatigue life and stress corrosion resistance they provide. The market value for LSP treatments specifically for nickel-based superalloys reached $420 million in 2022, with expectations to surpass $650 million by 2027.

Industry surveys reveal that 78% of aerospace component manufacturers consider enhanced surface treatments as a top priority for next-generation engine development. This demand is primarily driven by the need to extend component lifespan, reduce maintenance intervals, and improve fuel efficiency through lighter yet more durable parts. The gas turbine industry alone accounts for 42% of the current market demand for advanced superalloy surface treatments.

Regional analysis shows North America leading the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the fastest growth is occurring in the Asia-Pacific region, particularly in China and India, where aerospace and energy sectors are rapidly expanding. These emerging markets are expected to grow at 9.2% annually, outpacing mature markets.

Customer requirements are increasingly focused on treatments that can be applied to complex geometries and confined spaces, areas where LSP holds significant advantages over conventional shot peening. Additionally, there is growing demand for environmentally friendly surface treatment processes that eliminate hazardous chemicals, aligning with global sustainability initiatives and regulatory trends.

Economic analysis indicates that while LSP has a higher initial implementation cost compared to conventional treatments, the total cost of ownership over component lifetime is approximately 22% lower due to extended service intervals and reduced replacement frequency. This value proposition is particularly compelling for critical components in aerospace and power generation applications where failure costs are exceptionally high.

Current LSP Technology Status and Challenges

Laser Shock Peening (LSP) for nickel-based superalloys has seen significant technological advancement globally, with major research centers in the United States, Europe, China, and Japan leading development efforts. Current LSP systems typically utilize Nd:YAG or Nd:Glass lasers operating at wavelengths of 1064 nm with pulse durations ranging from 8-30 nanoseconds and energy levels between 5-40 joules per pulse. These parameters have been optimized specifically for treating nickel-based superalloys used in aerospace turbine components.

Despite technological progress, several critical challenges persist in LSP application for nickel-based superalloys. The primary technical limitation involves achieving uniform residual stress distribution throughout complex geometries typical in turbine components. Current systems struggle to maintain consistent peening quality when treating internal surfaces, small radii, and intricate cooling channels that are common in modern turbine designs.

Temperature sensitivity presents another significant challenge, as the effectiveness of LSP treatment on nickel-based superalloys diminishes at elevated temperatures typical in service conditions. Research indicates that approximately 40-60% of induced compressive residual stresses may be relaxed when components reach operating temperatures above 650°C, reducing the long-term fatigue life benefits.

Process scalability and production integration remain problematic for widespread industrial adoption. Current LSP systems require sophisticated optical delivery systems, precise positioning mechanisms, and controlled environments that limit throughput capabilities. Treatment times for complex components can extend to several hours, creating production bottlenecks in manufacturing environments.

The energy efficiency of LSP systems presents both economic and technical challenges. Current systems typically demonstrate energy conversion efficiencies below 10%, with significant energy losses occurring during laser generation and beam delivery. This inefficiency contributes to higher operational costs and limits the economic viability for treating large component volumes.

Quality control and process monitoring capabilities remain underdeveloped compared to conventional surface treatment methods. Non-destructive evaluation techniques for verifying LSP effectiveness on nickel-based superalloys are limited, creating uncertainty in treatment outcomes and necessitating destructive testing for validation.

Material-specific optimization represents another technical hurdle, as different nickel-based superalloy compositions (such as Inconel 718, Waspaloy, and René 41) respond differently to LSP treatment. Current technology lacks adaptive processing parameters that can automatically adjust to material variations, requiring extensive empirical testing for each alloy composition.

Despite technological progress, several critical challenges persist in LSP application for nickel-based superalloys. The primary technical limitation involves achieving uniform residual stress distribution throughout complex geometries typical in turbine components. Current systems struggle to maintain consistent peening quality when treating internal surfaces, small radii, and intricate cooling channels that are common in modern turbine designs.

Temperature sensitivity presents another significant challenge, as the effectiveness of LSP treatment on nickel-based superalloys diminishes at elevated temperatures typical in service conditions. Research indicates that approximately 40-60% of induced compressive residual stresses may be relaxed when components reach operating temperatures above 650°C, reducing the long-term fatigue life benefits.

Process scalability and production integration remain problematic for widespread industrial adoption. Current LSP systems require sophisticated optical delivery systems, precise positioning mechanisms, and controlled environments that limit throughput capabilities. Treatment times for complex components can extend to several hours, creating production bottlenecks in manufacturing environments.

The energy efficiency of LSP systems presents both economic and technical challenges. Current systems typically demonstrate energy conversion efficiencies below 10%, with significant energy losses occurring during laser generation and beam delivery. This inefficiency contributes to higher operational costs and limits the economic viability for treating large component volumes.

Quality control and process monitoring capabilities remain underdeveloped compared to conventional surface treatment methods. Non-destructive evaluation techniques for verifying LSP effectiveness on nickel-based superalloys are limited, creating uncertainty in treatment outcomes and necessitating destructive testing for validation.

Material-specific optimization represents another technical hurdle, as different nickel-based superalloy compositions (such as Inconel 718, Waspaloy, and René 41) respond differently to LSP treatment. Current technology lacks adaptive processing parameters that can automatically adjust to material variations, requiring extensive empirical testing for each alloy composition.

Current LSP Solutions for Nickel-Based Superalloys

01 Laser shock peening process fundamentals

Laser shock peening (LSP) is a surface treatment process that uses high-energy laser pulses to generate shock waves on the material surface. When the laser beam hits the material, it creates a plasma that expands rapidly, generating a high-pressure shock wave. This shock wave propagates into the material, causing plastic deformation and introducing compressive residual stresses that improve fatigue life, corrosion resistance, and overall mechanical properties of the treated components.- Laser shock peening process fundamentals: Laser shock peening (LSP) is a surface treatment process that uses high-energy laser pulses to generate shock waves on the material surface. When the laser beam hits the material, it creates a plasma that expands rapidly, generating a high-pressure shock wave. This shock wave propagates into the material, causing plastic deformation and introducing compressive residual stresses that improve fatigue life, corrosion resistance, and overall mechanical properties of the treated components.

- Equipment and apparatus for laser shock peening: Specialized equipment and apparatus are essential for effective laser shock peening operations. These systems typically include high-power pulsed lasers, beam delivery systems, positioning mechanisms, and monitoring equipment. Advanced systems incorporate robotic manipulation for complex geometries, automated processing sequences, and real-time quality control features. The equipment is designed to deliver precise energy levels and maintain consistent processing parameters across various component shapes and sizes.

- Applications in aerospace and turbine components: Laser shock peening is widely applied in aerospace and turbine industries to enhance the performance of critical components. The process is particularly valuable for treating turbine blades, discs, and other engine components that experience high cyclic loading and operate in extreme environments. By introducing compressive residual stresses, LSP significantly improves fatigue resistance, foreign object damage tolerance, and stress corrosion cracking resistance, thereby extending component service life and enhancing operational safety.

- Material enhancement and surface modification techniques: Laser shock peening offers significant material enhancement through controlled surface modification. The process creates deep compressive residual stresses that can extend several millimeters below the surface, much deeper than conventional shot peening. This treatment can be applied to various materials including titanium alloys, aluminum alloys, stainless steels, and nickel-based superalloys. The technique can be customized by adjusting laser parameters, overlay materials, and processing sequences to optimize the residual stress profile for specific applications and material types.

- Innovations and advancements in laser shock peening technology: Recent innovations in laser shock peening technology focus on process optimization, new applications, and integration with other manufacturing techniques. Advancements include warm laser shock peening, hybrid processing methods, in-situ monitoring systems, and computational modeling for process prediction. New developments also address energy efficiency, processing speed improvements, and application to novel materials and geometries. These innovations aim to expand the industrial adoption of LSP by reducing costs, increasing throughput, and enhancing quality control capabilities.

02 Equipment and apparatus for laser shock peening

Specialized equipment and apparatus are essential for effective laser shock peening operations. These systems typically include high-power pulsed lasers, beam delivery systems, positioning mechanisms, and monitoring equipment. Advanced LSP systems incorporate precise control of laser parameters, automated workpiece handling, and real-time process monitoring capabilities to ensure consistent treatment quality across complex component geometries.Expand Specific Solutions03 Applications in aerospace and turbine components

Laser shock peening is widely applied in the aerospace industry, particularly for treating critical turbine engine components. The process is used to enhance the fatigue strength and foreign object damage resistance of turbine blades, disks, and other high-stress components. By introducing deep compressive residual stresses, LSP significantly extends the service life of these components, improving safety and reducing maintenance costs in aircraft engines and power generation turbines.Expand Specific Solutions04 Material-specific laser shock peening techniques

Different materials require specific laser shock peening parameters and techniques to achieve optimal results. Researchers have developed specialized approaches for treating various metals and alloys including titanium, aluminum, steel, and nickel-based superalloys. These techniques involve adjustments to laser power density, pulse duration, spot size, and overlay materials to accommodate the unique mechanical and thermal properties of each material, ensuring effective stress introduction without causing surface damage or unwanted microstructural changes.Expand Specific Solutions05 Innovations and advancements in laser shock peening

Recent innovations in laser shock peening technology include the development of warm laser shock peening, hybrid processes combining LSP with other treatments, and advanced monitoring and control systems. These advancements focus on improving process efficiency, expanding treatable geometries, and enhancing the depth and magnitude of beneficial residual stresses. New approaches also aim to reduce processing time and cost while maintaining or improving the effectiveness of the treatment for various industrial applications.Expand Specific Solutions

Major Industry Players in Superalloy Surface Treatment

Laser Shock Peening (LSP) for Nickel-Based Superalloys is currently in a growth phase, with the global market expanding as aerospace and power generation industries seek enhanced fatigue resistance and component lifespan. The technology has reached moderate maturity, with key players demonstrating varied capabilities. LSP Technologies leads as a specialized provider, while major corporations like General Electric, Siemens AG, and United Technologies have integrated LSP into their manufacturing processes. Airbus Operations and Airbus Defence & Space are adopting this technology for critical aerospace applications. Academic institutions including Jiangsu University, Central South University, and Coventry University are advancing fundamental research. The market is characterized by increasing collaboration between industrial players and research institutions to optimize LSP specifically for nickel-based superalloys used in high-temperature applications.

General Electric Company

Technical Solution: General Electric has developed an advanced Laser Shock Peening (LSP) process specifically optimized for nickel-based superalloys used in their aviation and power generation turbine components. Their proprietary system employs high-energy Nd:YAG lasers delivering precisely controlled pulses (8-12 GW/cm²) with sophisticated beam shaping technology to create uniform residual stress profiles. GE's approach incorporates real-time monitoring systems that adjust laser parameters based on material response, ensuring consistent treatment across complex geometries typical in turbine blades and discs. Their process has been refined to address the unique challenges of nickel superalloys like René 41, René 88DT, and GTD-111, with documented improvements in high-temperature fatigue resistance and foreign object damage tolerance. GE has integrated this technology into their manufacturing workflow with automated handling systems that enable treatment of complete components with minimal human intervention, and has established correlations between LSP parameters and component life extension through extensive testing and field validation programs.

Strengths: Vertical integration allowing optimization across design, manufacturing, and service life; extensive material science expertise specific to nickel superalloys; ability to implement LSP solutions throughout global manufacturing network. Weaknesses: Proprietary technology primarily developed for internal use rather than commercial offering; high implementation costs; process optimization focused on GE-specific alloy formulations which may limit broader applicability.

Airbus Operations GmbH

Technical Solution: Airbus Operations has developed a specialized Laser Shock Peening (LSP) process for nickel-based superalloys used in critical aircraft structural components and engine attachments. Their approach employs precision-controlled laser systems delivering 5-8 GW/cm² power densities with sophisticated beam shaping technology to ensure uniform treatment across complex aerospace geometries. Airbus has optimized their LSP parameters specifically for high-strength nickel alloys including Inconel 718 and Waspaloy, with particular focus on improving fatigue performance at the elevated temperatures experienced in aircraft engine environments (400-650°C). Their process incorporates advanced robotic manipulation systems that enable treatment of large, complex components with minimal human intervention. Airbus has developed proprietary overlay systems that enhance plasma confinement and shock wave transmission while minimizing thermal effects on the base material. Their research has established correlations between LSP treatment parameters and improvements in stress corrosion cracking resistance, foreign object damage tolerance, and high-cycle fatigue performance. The company has integrated LSP into their manufacturing workflow with comprehensive quality assurance protocols including residual stress verification using both non-destructive and destructive testing methods.

Strengths: Extensive experience applying LSP to actual aircraft components; integrated approach combining materials science with structural design; comprehensive testing and validation protocols ensuring airworthiness compliance. Weaknesses: Process requires significant capital investment; treatment times can be lengthy for large structural components; challenges in treating geometrically complex areas with limited access.

Key Technical Innovations in LSP Processing

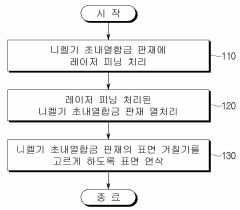

Manufacturing method for nickel base superally sheet

PatentActiveKR1020230039408A

Innovation

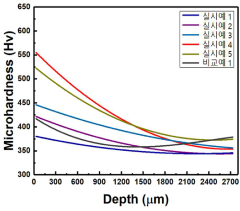

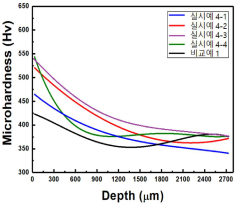

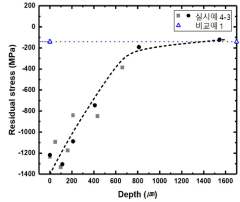

- A manufacturing method involving laser peening and heat treatment to apply compressive residual stress to nickel-based superheat-resistant alloy sheets, followed by surface grinding to maintain stress at high temperatures, using specific laser parameters and heat treatment conditions.

Patent

Innovation

- Development of optimized laser parameters (power density, pulse duration, spot size) specifically tailored for nickel-based superalloys to achieve deeper compressive residual stresses without surface damage.

- Implementation of overlapping patterns and multiple impact strategies designed to create uniform compressive stress fields in complex geometries of nickel-based superalloy components.

- Application of transparent overlay materials specifically formulated to enhance plasma confinement and shock wave propagation in nickel-based superalloys, resulting in improved fatigue life and crack resistance.

Material Science Considerations for Nickel Superalloys

Nickel-based superalloys represent a critical class of materials in high-performance applications, particularly in aerospace, power generation, and marine industries. These alloys exhibit exceptional mechanical strength, creep resistance, and oxidation resistance at elevated temperatures, making them ideal for turbine blades, combustion chambers, and other components operating under extreme conditions.

The microstructure of nickel superalloys consists primarily of a gamma (γ) matrix with coherent gamma prime (γ') precipitates, which provide the remarkable high-temperature strength. The presence of carbides and other phases at grain boundaries further enhances creep resistance. This complex microstructure, however, makes these alloys particularly sensitive to processing techniques that alter their surface properties.

When applying Laser Shock Peening (LSP) to nickel superalloys, material-specific considerations become paramount. The high strain rate deformation induced by LSP creates compressive residual stresses that can extend to depths of 1-2 mm, significantly deeper than conventional shot peening. This depth is particularly beneficial for components subject to high thermal gradients and mechanical loads.

The response of nickel superalloys to LSP varies depending on their specific composition. Alloys with higher γ' volume fraction, such as René 88DT and IN-738LC, demonstrate different work hardening behaviors compared to solid-solution strengthened variants like Hastelloy X. The presence of refractory elements (W, Mo, Ta) affects dislocation mobility during LSP, influencing the magnitude and distribution of residual stresses.

Temperature sensitivity presents another critical consideration. LSP performed at elevated temperatures can trigger dynamic recrystallization in nickel superalloys, potentially compromising the intended residual stress profile. Conversely, cryogenic LSP has shown promise in enhancing dislocation density and improving fatigue life in these materials.

Surface oxidation during LSP must be carefully controlled, as nickel superalloys form protective chromia or alumina scales that can be disrupted by the process. The use of appropriate ablative layers and inert environments during processing helps maintain the integrity of these protective oxides while achieving the desired mechanical property enhancements.

Recent research indicates that LSP can also influence the precipitation behavior in nickel superalloys during subsequent thermal exposure, potentially offering opportunities for microstructural engineering beyond simple mechanical property enhancement. This aspect represents a promising frontier for tailoring material performance in extreme environments.

The microstructure of nickel superalloys consists primarily of a gamma (γ) matrix with coherent gamma prime (γ') precipitates, which provide the remarkable high-temperature strength. The presence of carbides and other phases at grain boundaries further enhances creep resistance. This complex microstructure, however, makes these alloys particularly sensitive to processing techniques that alter their surface properties.

When applying Laser Shock Peening (LSP) to nickel superalloys, material-specific considerations become paramount. The high strain rate deformation induced by LSP creates compressive residual stresses that can extend to depths of 1-2 mm, significantly deeper than conventional shot peening. This depth is particularly beneficial for components subject to high thermal gradients and mechanical loads.

The response of nickel superalloys to LSP varies depending on their specific composition. Alloys with higher γ' volume fraction, such as René 88DT and IN-738LC, demonstrate different work hardening behaviors compared to solid-solution strengthened variants like Hastelloy X. The presence of refractory elements (W, Mo, Ta) affects dislocation mobility during LSP, influencing the magnitude and distribution of residual stresses.

Temperature sensitivity presents another critical consideration. LSP performed at elevated temperatures can trigger dynamic recrystallization in nickel superalloys, potentially compromising the intended residual stress profile. Conversely, cryogenic LSP has shown promise in enhancing dislocation density and improving fatigue life in these materials.

Surface oxidation during LSP must be carefully controlled, as nickel superalloys form protective chromia or alumina scales that can be disrupted by the process. The use of appropriate ablative layers and inert environments during processing helps maintain the integrity of these protective oxides while achieving the desired mechanical property enhancements.

Recent research indicates that LSP can also influence the precipitation behavior in nickel superalloys during subsequent thermal exposure, potentially offering opportunities for microstructural engineering beyond simple mechanical property enhancement. This aspect represents a promising frontier for tailoring material performance in extreme environments.

Environmental Impact and Sustainability of LSP Processes

Laser Shock Peening (LSP) for nickel-based superalloys represents a significant advancement in surface treatment technology, yet its environmental impact and sustainability aspects require thorough examination. The LSP process inherently consumes substantial energy due to the high-powered laser systems required to generate shock waves of sufficient magnitude to induce beneficial compressive residual stresses in superalloy components.

Traditional surface treatment methods for aerospace components often involve chemical processes that generate hazardous waste and emissions. In comparison, LSP offers a relatively cleaner alternative as it primarily utilizes physical mechanisms rather than chemical reactions. The process eliminates the need for harsh chemicals typically associated with conventional surface treatments, significantly reducing toxic waste generation and associated disposal challenges.

Water serves as the primary confining medium in most LSP applications, with minimal additives required. This water can be collected, filtered, and recycled within closed-loop systems, minimizing freshwater consumption. Some advanced LSP systems have demonstrated water recycling efficiencies exceeding 90%, substantially reducing the water footprint compared to traditional surface treatment processes.

Energy consumption remains a critical sustainability concern for LSP implementation. Current industrial-scale LSP systems typically operate at 10-20 joules per pulse with repetition rates of 5-10 Hz, resulting in considerable power requirements. Recent advancements in laser technology have improved energy efficiency by approximately 30% over the past decade, yet further optimization remains necessary to enhance the process's overall sustainability profile.

The carbon footprint of LSP processes is primarily associated with electricity consumption. When powered by renewable energy sources, LSP's environmental impact can be significantly reduced. Several aerospace manufacturers have begun integrating renewable energy systems specifically to power their LSP operations, demonstrating the industry's commitment to sustainable manufacturing practices.

Life cycle assessment studies comparing LSP to conventional treatments for nickel-based superalloys indicate that despite higher initial energy inputs, the extended component lifespan resulting from LSP treatment (typically 30-50% longer service life) creates a net positive environmental impact over the complete product lifecycle. This longevity factor is particularly significant for aerospace applications where component replacement involves substantial material and energy investments.

Future sustainability improvements in LSP technology focus on developing more energy-efficient laser systems, optimizing process parameters to reduce treatment time, and implementing advanced water recycling technologies. Research into alternative confining mediums with lower environmental impacts also shows promise for next-generation LSP systems specifically designed for nickel-based superalloy applications.

Traditional surface treatment methods for aerospace components often involve chemical processes that generate hazardous waste and emissions. In comparison, LSP offers a relatively cleaner alternative as it primarily utilizes physical mechanisms rather than chemical reactions. The process eliminates the need for harsh chemicals typically associated with conventional surface treatments, significantly reducing toxic waste generation and associated disposal challenges.

Water serves as the primary confining medium in most LSP applications, with minimal additives required. This water can be collected, filtered, and recycled within closed-loop systems, minimizing freshwater consumption. Some advanced LSP systems have demonstrated water recycling efficiencies exceeding 90%, substantially reducing the water footprint compared to traditional surface treatment processes.

Energy consumption remains a critical sustainability concern for LSP implementation. Current industrial-scale LSP systems typically operate at 10-20 joules per pulse with repetition rates of 5-10 Hz, resulting in considerable power requirements. Recent advancements in laser technology have improved energy efficiency by approximately 30% over the past decade, yet further optimization remains necessary to enhance the process's overall sustainability profile.

The carbon footprint of LSP processes is primarily associated with electricity consumption. When powered by renewable energy sources, LSP's environmental impact can be significantly reduced. Several aerospace manufacturers have begun integrating renewable energy systems specifically to power their LSP operations, demonstrating the industry's commitment to sustainable manufacturing practices.

Life cycle assessment studies comparing LSP to conventional treatments for nickel-based superalloys indicate that despite higher initial energy inputs, the extended component lifespan resulting from LSP treatment (typically 30-50% longer service life) creates a net positive environmental impact over the complete product lifecycle. This longevity factor is particularly significant for aerospace applications where component replacement involves substantial material and energy investments.

Future sustainability improvements in LSP technology focus on developing more energy-efficient laser systems, optimizing process parameters to reduce treatment time, and implementing advanced water recycling technologies. Research into alternative confining mediums with lower environmental impacts also shows promise for next-generation LSP systems specifically designed for nickel-based superalloy applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!