Comparative Study of Laser Shock Peening and Conventional Shot Peening

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Surface Treatment Evolution and Objectives

Surface treatment technologies have evolved significantly over the past century, transforming from rudimentary mechanical processes to sophisticated engineered solutions. The earliest documented surface treatment methods date back to the 1920s when shot peening was first introduced as a means to improve fatigue resistance in metal components. This conventional technique involves bombarding a surface with small spherical media called shot to create plastic deformation and compressive residual stresses, thereby enhancing mechanical properties and fatigue life.

The evolution of surface treatment technologies accelerated during the post-World War II industrial boom, with shot peening becoming standardized across aerospace, automotive, and heavy machinery industries. By the 1970s, controlled shot peening emerged with more precise parameters and quality control measures, establishing it as the dominant surface enhancement method for critical components.

A paradigm shift occurred in the late 1960s when researchers at Battelle Memorial Institute discovered the potential of high-energy laser pulses to generate shock waves capable of inducing compressive residual stresses in metals. This discovery laid the foundation for Laser Shock Peening (LSP), though its practical implementation remained limited until the 1990s due to technological constraints in laser systems.

The development of high-power, short-pulse laser technology in the 1990s and early 2000s enabled LSP to transition from laboratory research to industrial application. Unlike conventional shot peening that relies on mechanical impact, LSP utilizes high-intensity laser pulses to generate plasma and shock waves that induce deeper and more stable compressive residual stresses without the surface roughening associated with traditional methods.

The primary objective of comparing these two surface treatment technologies is to establish a comprehensive understanding of their respective capabilities, limitations, and optimal application scenarios. Specifically, this study aims to evaluate the depth and magnitude of compressive residual stresses, surface finish characteristics, fatigue life enhancement, and process control parameters for both methods across various engineering materials.

Additionally, this comparative analysis seeks to identify the cost-effectiveness and scalability of each technology for different industrial applications, from high-volume automotive components to critical aerospace parts. The ultimate goal is to develop a decision framework that guides engineers and manufacturers in selecting the most appropriate surface treatment method based on specific performance requirements, material properties, component geometry, and economic considerations.

The evolution of surface treatment technologies accelerated during the post-World War II industrial boom, with shot peening becoming standardized across aerospace, automotive, and heavy machinery industries. By the 1970s, controlled shot peening emerged with more precise parameters and quality control measures, establishing it as the dominant surface enhancement method for critical components.

A paradigm shift occurred in the late 1960s when researchers at Battelle Memorial Institute discovered the potential of high-energy laser pulses to generate shock waves capable of inducing compressive residual stresses in metals. This discovery laid the foundation for Laser Shock Peening (LSP), though its practical implementation remained limited until the 1990s due to technological constraints in laser systems.

The development of high-power, short-pulse laser technology in the 1990s and early 2000s enabled LSP to transition from laboratory research to industrial application. Unlike conventional shot peening that relies on mechanical impact, LSP utilizes high-intensity laser pulses to generate plasma and shock waves that induce deeper and more stable compressive residual stresses without the surface roughening associated with traditional methods.

The primary objective of comparing these two surface treatment technologies is to establish a comprehensive understanding of their respective capabilities, limitations, and optimal application scenarios. Specifically, this study aims to evaluate the depth and magnitude of compressive residual stresses, surface finish characteristics, fatigue life enhancement, and process control parameters for both methods across various engineering materials.

Additionally, this comparative analysis seeks to identify the cost-effectiveness and scalability of each technology for different industrial applications, from high-volume automotive components to critical aerospace parts. The ultimate goal is to develop a decision framework that guides engineers and manufacturers in selecting the most appropriate surface treatment method based on specific performance requirements, material properties, component geometry, and economic considerations.

Market Demand Analysis for Advanced Peening Technologies

The global market for advanced surface treatment technologies has witnessed significant growth in recent years, driven by increasing demands for enhanced material performance across various industries. The peening technologies market, particularly laser shock peening (LSP) and conventional shot peening (CSP), is experiencing robust expansion with an estimated market value exceeding $2.5 billion in 2023, and projected to grow at a compound annual growth rate of 6.8% through 2030.

Aerospace and defense sectors remain the primary demand drivers, accounting for approximately 45% of the total market share. These industries require components with superior fatigue resistance, stress corrosion cracking resistance, and extended service life—attributes that both LSP and CSP can deliver. However, the aerospace industry's stringent quality requirements and shift toward lightweight materials have created a particular demand for more precise peening technologies like LSP.

The automotive industry represents the second-largest market segment, contributing about 28% of demand. As vehicle manufacturers pursue lightweighting strategies while maintaining structural integrity, advanced peening technologies offer solutions for improving the performance of critical components such as gears, crankshafts, and suspension parts. The electric vehicle revolution has further accelerated this demand, as these vehicles require specialized components with enhanced durability characteristics.

Power generation, particularly nuclear and renewable energy sectors, has emerged as a rapidly growing market segment. The need for components that can withstand extreme operating conditions and offer extended service life has driven adoption of advanced peening technologies, with the market share in this sector increasing from 8% in 2018 to approximately 14% in 2023.

Regional analysis indicates North America and Europe currently dominate the market with combined share of 65%, primarily due to their established aerospace and automotive manufacturing bases. However, the Asia-Pacific region is witnessing the fastest growth rate at 9.2% annually, fueled by expanding industrial bases in China, India, and South Korea.

Customer demand patterns show increasing preference for technologies offering precision, repeatability, and environmental sustainability. LSP addresses these requirements more effectively than CSP, explaining its accelerated adoption despite higher implementation costs. Market surveys indicate that 72% of industrial users consider improved component lifespan as the primary benefit sought from peening technologies, followed by enhanced fatigue resistance (68%) and improved corrosion resistance (54%).

The medical device industry represents an emerging market opportunity, with demand growing at 11.3% annually as manufacturers seek surface treatment solutions for implantable devices requiring both biocompatibility and mechanical durability.

Aerospace and defense sectors remain the primary demand drivers, accounting for approximately 45% of the total market share. These industries require components with superior fatigue resistance, stress corrosion cracking resistance, and extended service life—attributes that both LSP and CSP can deliver. However, the aerospace industry's stringent quality requirements and shift toward lightweight materials have created a particular demand for more precise peening technologies like LSP.

The automotive industry represents the second-largest market segment, contributing about 28% of demand. As vehicle manufacturers pursue lightweighting strategies while maintaining structural integrity, advanced peening technologies offer solutions for improving the performance of critical components such as gears, crankshafts, and suspension parts. The electric vehicle revolution has further accelerated this demand, as these vehicles require specialized components with enhanced durability characteristics.

Power generation, particularly nuclear and renewable energy sectors, has emerged as a rapidly growing market segment. The need for components that can withstand extreme operating conditions and offer extended service life has driven adoption of advanced peening technologies, with the market share in this sector increasing from 8% in 2018 to approximately 14% in 2023.

Regional analysis indicates North America and Europe currently dominate the market with combined share of 65%, primarily due to their established aerospace and automotive manufacturing bases. However, the Asia-Pacific region is witnessing the fastest growth rate at 9.2% annually, fueled by expanding industrial bases in China, India, and South Korea.

Customer demand patterns show increasing preference for technologies offering precision, repeatability, and environmental sustainability. LSP addresses these requirements more effectively than CSP, explaining its accelerated adoption despite higher implementation costs. Market surveys indicate that 72% of industrial users consider improved component lifespan as the primary benefit sought from peening technologies, followed by enhanced fatigue resistance (68%) and improved corrosion resistance (54%).

The medical device industry represents an emerging market opportunity, with demand growing at 11.3% annually as manufacturers seek surface treatment solutions for implantable devices requiring both biocompatibility and mechanical durability.

Current Challenges in Peening Technologies

Despite significant advancements in surface treatment technologies, both Laser Shock Peening (LSP) and Conventional Shot Peening (CSP) face several critical challenges that limit their widespread industrial adoption and effectiveness. These challenges span technical, economic, and application domains, requiring innovative solutions to enhance their performance and applicability.

For Conventional Shot Peening, process control and repeatability remain persistent issues. The stochastic nature of the shot impact makes it difficult to achieve consistent coverage and intensity across complex geometries. This variability can lead to uneven residual stress profiles and potentially compromise the fatigue performance of treated components. Additionally, CSP struggles with limited penetration depth, typically reaching only 0.2-0.3 mm beneath the surface, which restricts its effectiveness for applications requiring deeper compressive residual stresses.

Surface roughness represents another significant challenge for CSP. The process inherently increases surface roughness, which can be detrimental in applications where aerodynamic or tribological properties are critical. This roughness can serve as potential crack initiation sites, partially offsetting the beneficial effects of the induced compressive stresses.

Laser Shock Peening, while offering several advantages over CSP, faces its own set of challenges. The high capital equipment cost and relatively slow processing speed compared to CSP make it economically viable only for high-value components. The complex setup requirements, including precise laser parameters, overlay materials, and confining media, demand sophisticated control systems and skilled operators.

Energy efficiency remains a concern for LSP, with only a small fraction of the laser energy effectively contributing to the plastic deformation process. The majority is lost through various mechanisms including reflection, plasma formation, and thermal dissipation. This inefficiency increases operational costs and limits throughput.

Both technologies face challenges in treating complex geometries and internal surfaces. For CSP, accessing internal features is particularly problematic, while LSP struggles with line-of-sight limitations that restrict treatment to directly accessible surfaces. Neither technology has fully resolved the challenge of treating miniaturized components or intricate features common in modern manufacturing.

Quality assurance and process monitoring represent cross-cutting challenges. Non-destructive evaluation of peening quality, particularly the measurement of residual stress profiles in-situ, remains difficult. This complicates process optimization and quality control, especially for critical components where performance verification is essential.

Environmental and sustainability concerns are emerging challenges, particularly for CSP which generates waste from spent media and can involve hazardous materials. LSP's high energy consumption also raises questions about its carbon footprint, an increasingly important consideration in industrial processes.

For Conventional Shot Peening, process control and repeatability remain persistent issues. The stochastic nature of the shot impact makes it difficult to achieve consistent coverage and intensity across complex geometries. This variability can lead to uneven residual stress profiles and potentially compromise the fatigue performance of treated components. Additionally, CSP struggles with limited penetration depth, typically reaching only 0.2-0.3 mm beneath the surface, which restricts its effectiveness for applications requiring deeper compressive residual stresses.

Surface roughness represents another significant challenge for CSP. The process inherently increases surface roughness, which can be detrimental in applications where aerodynamic or tribological properties are critical. This roughness can serve as potential crack initiation sites, partially offsetting the beneficial effects of the induced compressive stresses.

Laser Shock Peening, while offering several advantages over CSP, faces its own set of challenges. The high capital equipment cost and relatively slow processing speed compared to CSP make it economically viable only for high-value components. The complex setup requirements, including precise laser parameters, overlay materials, and confining media, demand sophisticated control systems and skilled operators.

Energy efficiency remains a concern for LSP, with only a small fraction of the laser energy effectively contributing to the plastic deformation process. The majority is lost through various mechanisms including reflection, plasma formation, and thermal dissipation. This inefficiency increases operational costs and limits throughput.

Both technologies face challenges in treating complex geometries and internal surfaces. For CSP, accessing internal features is particularly problematic, while LSP struggles with line-of-sight limitations that restrict treatment to directly accessible surfaces. Neither technology has fully resolved the challenge of treating miniaturized components or intricate features common in modern manufacturing.

Quality assurance and process monitoring represent cross-cutting challenges. Non-destructive evaluation of peening quality, particularly the measurement of residual stress profiles in-situ, remains difficult. This complicates process optimization and quality control, especially for critical components where performance verification is essential.

Environmental and sustainability concerns are emerging challenges, particularly for CSP which generates waste from spent media and can involve hazardous materials. LSP's high energy consumption also raises questions about its carbon footprint, an increasingly important consideration in industrial processes.

Comparative Analysis of LSP vs CSP Methodologies

01 Laser shock peening process and equipment

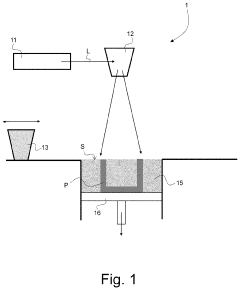

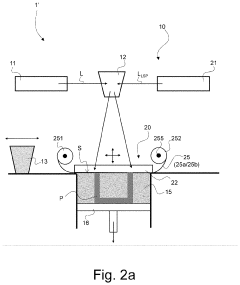

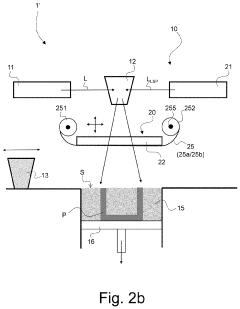

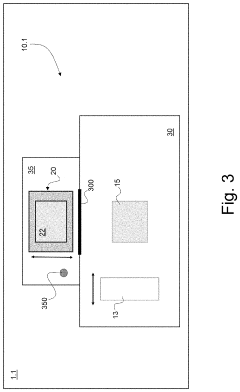

Laser shock peening (LSP) is a surface treatment process that uses high-energy laser pulses to generate shock waves on the material surface. The process involves directing laser beams onto the workpiece surface, which is typically covered with an ablative layer and a transparent overlay. The laser energy creates a plasma that generates a high-pressure shock wave, inducing compressive residual stresses in the material. This process requires specialized equipment including high-power lasers, beam delivery systems, and positioning mechanisms to ensure precise treatment of the target areas.- Comparison of Laser Shock Peening and Conventional Shot Peening: Laser shock peening (LSP) and conventional shot peening (CSP) are surface treatment methods that improve material properties. LSP uses high-energy laser pulses to create shock waves that induce compressive residual stresses deeper into the material compared to CSP. Conventional shot peening uses mechanical impact of small spherical media. The comparison shows LSP typically produces deeper compressive residual stress layers with more uniform distribution, while CSP is more cost-effective for many applications.

- Laser Shock Peening Process and Equipment: Laser shock peening involves directing high-energy laser pulses at a material surface covered with an ablative layer and a transparent overlay (typically water). The laser creates plasma that generates a shock wave, inducing compressive residual stresses in the material. The process requires specialized equipment including high-power pulsed lasers, beam delivery systems, positioning mechanisms, and monitoring devices. Various parameters such as laser power density, pulse duration, spot size, and overlap patterns can be controlled to achieve desired material properties.

- Applications and Benefits of Peening Technologies: Peening technologies are widely applied in aerospace, automotive, power generation, and medical industries. These processes enhance fatigue life, stress corrosion cracking resistance, and wear resistance of components. Specific applications include treatment of turbine blades, engine components, medical implants, and structural parts. The benefits include improved component durability, extended service life, enhanced performance under cyclic loading, and increased resistance to environmental degradation. These technologies are particularly valuable for critical components operating under high stress or in harsh environments.

- Material Response and Property Improvements: Both peening methods modify material surface properties by inducing compressive residual stresses. These stresses counteract applied tensile stresses during service, inhibiting crack initiation and propagation. The processes also cause work hardening, increasing surface hardness and wear resistance. Material response varies depending on composition, microstructure, and initial condition. Studies show improvements in fatigue strength, stress corrosion cracking resistance, and tribological properties. The depth and magnitude of compressive stresses depend on process parameters and material characteristics.

- Hybrid and Advanced Peening Techniques: Recent developments include hybrid approaches combining multiple peening methods to optimize surface properties. These techniques include warm laser peening, ultrasonic impact treatment combined with laser peening, and sequential application of different peening methods. Advanced monitoring and control systems enable real-time process adjustment and quality assurance. Computational modeling helps predict residual stress distributions and optimize process parameters. These innovations aim to enhance effectiveness, reduce processing time, and extend applications to new materials and components.

02 Conventional shot peening techniques

Conventional shot peening is a mechanical surface treatment process that involves bombarding the material surface with small spherical media (shots) at high velocity. The impact of these shots creates plastic deformation on the surface, inducing compressive residual stresses that improve fatigue life and resistance to stress corrosion cracking. The process parameters include shot size, hardness, velocity, coverage, and intensity. Shot peening equipment typically consists of shot propulsion systems, part handling mechanisms, and control systems to ensure consistent treatment quality.Expand Specific Solutions03 Comparative advantages of laser shock peening over conventional shot peening

Laser shock peening offers several advantages over conventional shot peening, including deeper compressive residual stress layers, more precise treatment of specific areas, better surface finish, and the ability to treat complex geometries. LSP can induce compressive stresses to depths several times greater than conventional shot peening, resulting in superior fatigue life improvement. Additionally, LSP provides better control over the treatment process, allowing for more consistent results and the ability to treat heat-sensitive components without thermal damage. These advantages make LSP particularly valuable for critical aerospace and power generation components.Expand Specific Solutions04 Applications in aerospace and turbine components

Both laser shock peening and conventional shot peening are widely used in the aerospace and power generation industries, particularly for treating turbine components such as blades, disks, and airfoils. These peening techniques enhance the fatigue life, foreign object damage resistance, and stress corrosion cracking resistance of critical components. The treatments are applied to high-stress areas of components that experience cyclic loading during operation. The improved surface properties result in extended component life, increased safety margins, and reduced maintenance costs for aircraft engines, gas turbines, and other high-performance systems.Expand Specific Solutions05 Combined and hybrid peening approaches

Researchers and industry have developed hybrid approaches that combine laser shock peening and conventional shot peening to maximize the benefits of both techniques. These combined methods can involve sequential application of both treatments or modified processes that incorporate elements of each. The hybrid approaches aim to optimize the depth and magnitude of compressive residual stresses while maintaining cost-effectiveness. Some combined methods use shot peening for broad coverage and laser shock peening for targeted treatment of critical areas, resulting in optimized component performance with balanced processing costs and time requirements.Expand Specific Solutions

Key Industry Players and Research Institutions

Laser Shock Peening (LSP) versus Conventional Shot Peening (CSP) represents a competitive landscape in advanced surface treatment technologies. The industry is in a growth phase, with the global peening market expected to reach $1.2 billion by 2027. While CSP is a mature technology with widespread adoption, LSP is emerging as a premium alternative offering superior fatigue life improvement. LSP Technologies leads commercial LSP applications, with significant research contributions from Lawrence Livermore National Laboratory and Metal Improvement Co. Major aerospace players including GE, Rolls-Royce, Airbus, and Safran are increasingly adopting LSP for critical components. Academic institutions like Beihang University, Jiangsu University, and Huazhong University are advancing fundamental research, creating a dynamic ecosystem of industrial and academic innovation in surface enhancement technologies.

General Electric Company

Technical Solution: General Electric has developed an integrated approach to laser shock peening (LSP) specifically optimized for aircraft engine components. Their technology employs high-energy Nd:glass lasers (typically 10-40J per pulse) with pulse durations of 10-30 nanoseconds to create pressure waves exceeding 1 GPa on component surfaces[1]. GE's proprietary process includes specialized beam shaping optics that allow for customized treatment patterns tailored to specific component geometries and stress profiles. For turbine airfoils, GE has implemented a dual-sided simultaneous LSP treatment that balances residual stress profiles and minimizes distortion[2]. Their system incorporates real-time monitoring with high-speed cameras and spectroscopic analysis to ensure consistent plasma formation and process quality. GE has extensively documented 3-5x improvements in fatigue life for critical engine components compared to conventional shot peening, with particular success in titanium fan and compressor blades[3].

Strengths: Highly optimized for aerospace applications; extensive validation data from field service; integrated quality control systems; demonstrated significant fatigue life improvements in critical components. Weaknesses: Proprietary system with high implementation costs; requires specialized training and facilities; process parameters must be carefully tuned for each application; slower processing speed compared to conventional methods.

LSP Technologies, Inc.

Technical Solution: LSP Technologies has pioneered commercial laser shock peening (LSP) technology with their patented Procudo® Laser Peening System. This system delivers high-energy laser pulses (up to 10J) at high repetition rates (up to 20Hz), creating pressure pulses exceeding 10 GPa when the laser hits an opaque overlay on the material surface[1]. The technology induces compressive residual stresses to depths of 1-10mm, significantly deeper than conventional shot peening (CSP) which typically reaches only 0.25-0.5mm depths[2]. Their process utilizes a transparent overlay (typically water) and an opaque overlay (often black paint or tape) to enhance plasma confinement and pressure wave generation. LSP Technologies has developed specialized robotic systems for precise control of laser positioning and has implemented digital twin technology for process optimization and validation[3].

Strengths: Produces deeper compressive residual stresses than CSP; offers precise control over treatment areas; leaves superior surface finish; minimal cold working; excellent fatigue life improvement for critical components. Weaknesses: Higher initial equipment cost compared to CSP; slower processing speed for large areas; requires more sophisticated setup and control systems; higher energy consumption.

Critical Patents and Research in Peening Technologies

Laser treatment systems and methods for in-situ laser shock peening (LSP) treatment of parts during production thereof by a selective laser sintering or melting (SLS/SLM) process, and additive manufacturing systems and methods implementing the same

PatentActiveUS20220395906A1

Innovation

- An in-situ Laser Shock Peening (LSP) treatment system is integrated into the SLS/SLM process, where a laser treatment system with an LSP module imparts beneficial compressive residual stresses during production, using a confining window and consumable confining material to protect against process residues and ensure effective LSP treatment.

Material Compatibility and Application Scope

Laser Shock Peening (LSP) and Conventional Shot Peening (CSP) demonstrate significant differences in their material compatibility and application scope, which directly impacts their industrial utilization. LSP exhibits superior compatibility with a wide range of materials, including high-strength alloys, superalloys, titanium alloys, and advanced composites that are commonly used in aerospace, automotive, and medical industries. The high-energy laser pulses in LSP can effectively treat materials with high hardness and complex geometries that might be challenging for conventional methods.

In contrast, CSP shows limitations when treating ultra-high-strength materials or those with complex surface geometries. However, CSP remains highly effective for traditional steel alloys, aluminum, and other common engineering materials, making it a staple in general manufacturing environments where extreme performance is not required.

The application scope of LSP extends to critical components where fatigue life and stress corrosion resistance are paramount. These include aircraft engine components, turbine blades, biomedical implants, and nuclear reactor components. The precision of LSP allows for targeted treatment of specific stress concentration areas without affecting adjacent regions, which is particularly valuable for components with intricate designs or varying thickness.

CSP's application scope is broader in general manufacturing but more limited in high-performance scenarios. It is widely used in automotive parts, springs, gears, and structural components where moderate improvement in fatigue properties is sufficient. The process is particularly suitable for batch processing of smaller components and parts with simpler geometries.

Material thickness also plays a crucial role in determining the appropriate peening method. LSP can effectively treat components with varying thicknesses, including thin sections down to 0.5mm, without causing distortion. The controlled energy delivery allows for precise depth of treatment, making it suitable for thin-walled components in aerospace applications. CSP, however, may cause excessive distortion in thin materials due to its mechanical impact nature, limiting its application in such scenarios.

Temperature sensitivity represents another differentiating factor. LSP can be applied to temperature-sensitive materials without causing thermal damage, as the process generates minimal heat. This makes it suitable for materials with specific heat treatment conditions that must be maintained. CSP does not involve significant temperature changes either, but the mechanical impact may alter the microstructure of certain heat-sensitive alloys.

In contrast, CSP shows limitations when treating ultra-high-strength materials or those with complex surface geometries. However, CSP remains highly effective for traditional steel alloys, aluminum, and other common engineering materials, making it a staple in general manufacturing environments where extreme performance is not required.

The application scope of LSP extends to critical components where fatigue life and stress corrosion resistance are paramount. These include aircraft engine components, turbine blades, biomedical implants, and nuclear reactor components. The precision of LSP allows for targeted treatment of specific stress concentration areas without affecting adjacent regions, which is particularly valuable for components with intricate designs or varying thickness.

CSP's application scope is broader in general manufacturing but more limited in high-performance scenarios. It is widely used in automotive parts, springs, gears, and structural components where moderate improvement in fatigue properties is sufficient. The process is particularly suitable for batch processing of smaller components and parts with simpler geometries.

Material thickness also plays a crucial role in determining the appropriate peening method. LSP can effectively treat components with varying thicknesses, including thin sections down to 0.5mm, without causing distortion. The controlled energy delivery allows for precise depth of treatment, making it suitable for thin-walled components in aerospace applications. CSP, however, may cause excessive distortion in thin materials due to its mechanical impact nature, limiting its application in such scenarios.

Temperature sensitivity represents another differentiating factor. LSP can be applied to temperature-sensitive materials without causing thermal damage, as the process generates minimal heat. This makes it suitable for materials with specific heat treatment conditions that must be maintained. CSP does not involve significant temperature changes either, but the mechanical impact may alter the microstructure of certain heat-sensitive alloys.

Cost-Benefit Analysis and Industrial Implementation

The economic viability of surface treatment technologies plays a crucial role in their industrial adoption. When comparing Laser Shock Peening (LSP) and Conventional Shot Peening (CSP), cost considerations reveal significant differences that impact implementation decisions across various sectors.

Initial investment for LSP systems typically ranges from $500,000 to $2 million, substantially higher than CSP equipment costs of $50,000 to $200,000. This capital expenditure difference represents one of the primary barriers to LSP adoption, particularly for small and medium enterprises. However, operational costs present a more nuanced picture, with LSP offering advantages in consumables and maintenance over extended operational periods.

Processing costs per component show LSP at $100-300 per hour versus CSP's $20-50, reflecting the higher energy requirements and specialized equipment needed for laser-based treatments. This cost differential narrows when considering high-value components where failure risks justify premium treatment methods.

Return on investment calculations demonstrate that while CSP provides faster ROI for general applications (typically 1-2 years), LSP can deliver superior long-term value for critical components in aerospace, nuclear, and medical industries, with ROI periods of 3-5 years but extended service life improvements of 300-500%.

Industrial implementation patterns reveal sector-specific adoption trends. Aerospace has embraced LSP for critical turbine components despite higher costs, with companies reporting 30-40% extended component lifespans justifying the premium. Automotive manufacturers predominantly utilize CSP for mass production scenarios where cost efficiency outweighs marginal performance improvements.

Implementation challenges for LSP include specialized operator training requirements, facility modifications for laser safety, and integration into existing production lines. Several manufacturers have developed hybrid implementation models, applying LSP selectively to critical stress points while using CSP for broader surface areas, optimizing the cost-benefit ratio.

Recent technological advancements are gradually reducing LSP implementation barriers through more compact systems, increased processing speeds, and automation integration. Industry forecasts suggest LSP costs may decrease by 15-25% over the next five years as the technology matures and economies of scale improve, potentially expanding its application across more diverse industrial sectors.

Initial investment for LSP systems typically ranges from $500,000 to $2 million, substantially higher than CSP equipment costs of $50,000 to $200,000. This capital expenditure difference represents one of the primary barriers to LSP adoption, particularly for small and medium enterprises. However, operational costs present a more nuanced picture, with LSP offering advantages in consumables and maintenance over extended operational periods.

Processing costs per component show LSP at $100-300 per hour versus CSP's $20-50, reflecting the higher energy requirements and specialized equipment needed for laser-based treatments. This cost differential narrows when considering high-value components where failure risks justify premium treatment methods.

Return on investment calculations demonstrate that while CSP provides faster ROI for general applications (typically 1-2 years), LSP can deliver superior long-term value for critical components in aerospace, nuclear, and medical industries, with ROI periods of 3-5 years but extended service life improvements of 300-500%.

Industrial implementation patterns reveal sector-specific adoption trends. Aerospace has embraced LSP for critical turbine components despite higher costs, with companies reporting 30-40% extended component lifespans justifying the premium. Automotive manufacturers predominantly utilize CSP for mass production scenarios where cost efficiency outweighs marginal performance improvements.

Implementation challenges for LSP include specialized operator training requirements, facility modifications for laser safety, and integration into existing production lines. Several manufacturers have developed hybrid implementation models, applying LSP selectively to critical stress points while using CSP for broader surface areas, optimizing the cost-benefit ratio.

Recent technological advancements are gradually reducing LSP implementation barriers through more compact systems, increased processing speeds, and automation integration. Industry forecasts suggest LSP costs may decrease by 15-25% over the next five years as the technology matures and economies of scale improve, potentially expanding its application across more diverse industrial sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!