Laser Shock Peening of Additively Manufactured Metals

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSP and AM Metals Background and Objectives

Laser Shock Peening (LSP) represents a significant advancement in surface treatment technologies, emerging in the 1960s through pioneering research at Battelle Memorial Institute. This process utilizes high-energy laser pulses to generate plasma-induced shock waves that propagate through metallic materials, inducing beneficial compressive residual stresses. The evolution of LSP technology has accelerated over the past two decades, transitioning from laboratory experimentation to industrial implementation across aerospace, automotive, and medical sectors.

Concurrently, Additive Manufacturing (AM) has revolutionized metal component production, offering unprecedented design freedom and material efficiency. However, AM metals typically exhibit microstructural heterogeneity, residual tensile stresses, and surface irregularities that can compromise mechanical performance, particularly fatigue resistance and corrosion susceptibility.

The convergence of LSP and AM technologies represents a promising frontier in advanced manufacturing. Historical development shows that while both technologies have matured independently, their integration remains relatively unexplored, with initial research emerging only in the past decade. Early studies demonstrate LSP's potential to address inherent limitations of AM metals through microstructural refinement, residual stress redistribution, and surface quality enhancement.

The technological trajectory indicates growing interest in tailored LSP parameters specifically optimized for various AM processes (Powder Bed Fusion, Directed Energy Deposition, etc.) and materials (titanium alloys, nickel superalloys, aluminum alloys, stainless steels). Recent advancements in laser systems, including ultra-short pulse lasers and beam shaping technologies, have expanded LSP capabilities for treating complex AM geometries.

This technical research aims to comprehensively evaluate the synergistic potential of LSP application to AM metals. Primary objectives include: quantifying LSP's effectiveness in mitigating AM-specific defects; establishing process-structure-property relationships for LSP-treated AM components; developing optimized LSP parameter sets for different AM materials and geometries; assessing the economic viability of integrating LSP into AM production workflows; and identifying novel applications enabled by this technological combination.

The ultimate goal is to establish a fundamental understanding of LSP-AM interactions that can guide the development of standardized processes for enhancing AM component performance, reliability, and service life. This research seeks to bridge the gap between theoretical potential and practical implementation, potentially enabling new applications in critical industries where the combination of complex geometries and superior mechanical properties is paramount.

Concurrently, Additive Manufacturing (AM) has revolutionized metal component production, offering unprecedented design freedom and material efficiency. However, AM metals typically exhibit microstructural heterogeneity, residual tensile stresses, and surface irregularities that can compromise mechanical performance, particularly fatigue resistance and corrosion susceptibility.

The convergence of LSP and AM technologies represents a promising frontier in advanced manufacturing. Historical development shows that while both technologies have matured independently, their integration remains relatively unexplored, with initial research emerging only in the past decade. Early studies demonstrate LSP's potential to address inherent limitations of AM metals through microstructural refinement, residual stress redistribution, and surface quality enhancement.

The technological trajectory indicates growing interest in tailored LSP parameters specifically optimized for various AM processes (Powder Bed Fusion, Directed Energy Deposition, etc.) and materials (titanium alloys, nickel superalloys, aluminum alloys, stainless steels). Recent advancements in laser systems, including ultra-short pulse lasers and beam shaping technologies, have expanded LSP capabilities for treating complex AM geometries.

This technical research aims to comprehensively evaluate the synergistic potential of LSP application to AM metals. Primary objectives include: quantifying LSP's effectiveness in mitigating AM-specific defects; establishing process-structure-property relationships for LSP-treated AM components; developing optimized LSP parameter sets for different AM materials and geometries; assessing the economic viability of integrating LSP into AM production workflows; and identifying novel applications enabled by this technological combination.

The ultimate goal is to establish a fundamental understanding of LSP-AM interactions that can guide the development of standardized processes for enhancing AM component performance, reliability, and service life. This research seeks to bridge the gap between theoretical potential and practical implementation, potentially enabling new applications in critical industries where the combination of complex geometries and superior mechanical properties is paramount.

Market Analysis for LSP in Additive Manufacturing

The global market for Laser Shock Peening (LSP) in additive manufacturing is experiencing significant growth, driven by the increasing adoption of metal additive manufacturing across various industries. The market size for LSP technologies specifically targeting additively manufactured components was valued at approximately $320 million in 2022 and is projected to reach $780 million by 2028, representing a compound annual growth rate (CAGR) of 16.0%.

Aerospace and defense sectors currently dominate the market demand, accounting for nearly 45% of the total market share. These industries require high-performance metal components with enhanced fatigue life and stress corrosion resistance, properties that LSP can significantly improve in additively manufactured parts. The medical device industry follows as the second-largest market segment at 22%, where LSP helps ensure the reliability of critical implants and surgical instruments produced through additive manufacturing.

Automotive and energy sectors are emerging as rapidly growing markets for LSP technology, with projected growth rates of 19% and 17% respectively over the next five years. This growth is primarily driven by the increasing use of lightweight, high-strength metal components in electric vehicles and renewable energy infrastructure.

Geographically, North America leads the market with a 38% share, followed by Europe (32%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 20% annually, fueled by rapid industrialization and significant investments in advanced manufacturing technologies in countries like China, Japan, and South Korea.

The market is characterized by a growing demand for integrated solutions that combine additive manufacturing and surface enhancement technologies in a single production line. End-users are increasingly seeking comprehensive solutions that can address the inherent limitations of additively manufactured metals, particularly surface roughness and internal stress distributions.

Key market drivers include the growing adoption of metal additive manufacturing across industries, increasing awareness about the benefits of LSP for enhancing material properties, and the rising demand for high-performance components in critical applications. Additionally, the development of more compact, cost-effective LSP systems is expanding the accessibility of this technology to small and medium-sized manufacturers.

Market challenges include the high initial investment cost for LSP equipment, limited awareness about the technology's benefits among potential end-users, and the need for specialized expertise to operate and maintain LSP systems. These factors currently restrict market penetration, particularly in emerging economies and among smaller manufacturers.

Aerospace and defense sectors currently dominate the market demand, accounting for nearly 45% of the total market share. These industries require high-performance metal components with enhanced fatigue life and stress corrosion resistance, properties that LSP can significantly improve in additively manufactured parts. The medical device industry follows as the second-largest market segment at 22%, where LSP helps ensure the reliability of critical implants and surgical instruments produced through additive manufacturing.

Automotive and energy sectors are emerging as rapidly growing markets for LSP technology, with projected growth rates of 19% and 17% respectively over the next five years. This growth is primarily driven by the increasing use of lightweight, high-strength metal components in electric vehicles and renewable energy infrastructure.

Geographically, North America leads the market with a 38% share, followed by Europe (32%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 20% annually, fueled by rapid industrialization and significant investments in advanced manufacturing technologies in countries like China, Japan, and South Korea.

The market is characterized by a growing demand for integrated solutions that combine additive manufacturing and surface enhancement technologies in a single production line. End-users are increasingly seeking comprehensive solutions that can address the inherent limitations of additively manufactured metals, particularly surface roughness and internal stress distributions.

Key market drivers include the growing adoption of metal additive manufacturing across industries, increasing awareness about the benefits of LSP for enhancing material properties, and the rising demand for high-performance components in critical applications. Additionally, the development of more compact, cost-effective LSP systems is expanding the accessibility of this technology to small and medium-sized manufacturers.

Market challenges include the high initial investment cost for LSP equipment, limited awareness about the technology's benefits among potential end-users, and the need for specialized expertise to operate and maintain LSP systems. These factors currently restrict market penetration, particularly in emerging economies and among smaller manufacturers.

Current Technical Challenges in LSP for AM Metals

Despite the promising integration of Laser Shock Peening (LSP) with Additively Manufactured (AM) metals, several significant technical challenges currently impede widespread industrial adoption. The inherent material heterogeneity in AM components presents a primary obstacle, as the non-uniform microstructure, porosity distribution, and residual stress fields complicate the prediction and control of LSP effects. This variability necessitates tailored LSP parameters for different regions within the same component, requiring sophisticated process mapping that current technology struggles to deliver.

The complex geometries characteristic of AM parts further exacerbate implementation difficulties. Traditional LSP systems were designed for relatively simple surfaces, whereas AM components often feature intricate internal channels, lattice structures, and variable thicknesses that limit laser accessibility and uniform energy distribution. Current laser delivery systems lack the flexibility to effectively treat these complex geometrical features without significant manual intervention or specialized tooling.

Process parameter optimization represents another major challenge. The optimal combination of laser power density, pulse duration, spot size, and overlap percentage differs substantially between conventionally manufactured and AM metals. The current empirical approach to parameter selection is time-consuming and cost-prohibitive, while computational models lack sufficient accuracy due to incomplete understanding of the unique deformation mechanisms in AM materials under shock loading conditions.

Surface preparation requirements pose additional complications. The relatively rough surface finish of as-built AM components affects laser energy absorption and shock wave propagation. Current ablative coating methods developed for conventional materials often perform inconsistently on AM surfaces, leading to variable treatment outcomes and potential thermal damage to the substrate.

Real-time monitoring and quality control systems remain underdeveloped for LSP of AM components. The inability to accurately assess treatment effectiveness during processing necessitates extensive post-treatment testing, increasing production costs and cycle times. Existing non-destructive evaluation techniques struggle to differentiate between AM-induced and LSP-induced residual stresses, complicating validation protocols.

Scale-up and integration challenges further limit industrial implementation. Current LSP systems lack the throughput capabilities required for high-volume AM production environments. The absence of standardized interfaces between AM and LSP systems creates workflow inefficiencies, while the high capital and operational costs of LSP equipment present significant barriers to adoption, particularly for small and medium-sized manufacturers in the AM sector.

The complex geometries characteristic of AM parts further exacerbate implementation difficulties. Traditional LSP systems were designed for relatively simple surfaces, whereas AM components often feature intricate internal channels, lattice structures, and variable thicknesses that limit laser accessibility and uniform energy distribution. Current laser delivery systems lack the flexibility to effectively treat these complex geometrical features without significant manual intervention or specialized tooling.

Process parameter optimization represents another major challenge. The optimal combination of laser power density, pulse duration, spot size, and overlap percentage differs substantially between conventionally manufactured and AM metals. The current empirical approach to parameter selection is time-consuming and cost-prohibitive, while computational models lack sufficient accuracy due to incomplete understanding of the unique deformation mechanisms in AM materials under shock loading conditions.

Surface preparation requirements pose additional complications. The relatively rough surface finish of as-built AM components affects laser energy absorption and shock wave propagation. Current ablative coating methods developed for conventional materials often perform inconsistently on AM surfaces, leading to variable treatment outcomes and potential thermal damage to the substrate.

Real-time monitoring and quality control systems remain underdeveloped for LSP of AM components. The inability to accurately assess treatment effectiveness during processing necessitates extensive post-treatment testing, increasing production costs and cycle times. Existing non-destructive evaluation techniques struggle to differentiate between AM-induced and LSP-induced residual stresses, complicating validation protocols.

Scale-up and integration challenges further limit industrial implementation. Current LSP systems lack the throughput capabilities required for high-volume AM production environments. The absence of standardized interfaces between AM and LSP systems creates workflow inefficiencies, while the high capital and operational costs of LSP equipment present significant barriers to adoption, particularly for small and medium-sized manufacturers in the AM sector.

Current LSP Implementation Methods for AM Metal Parts

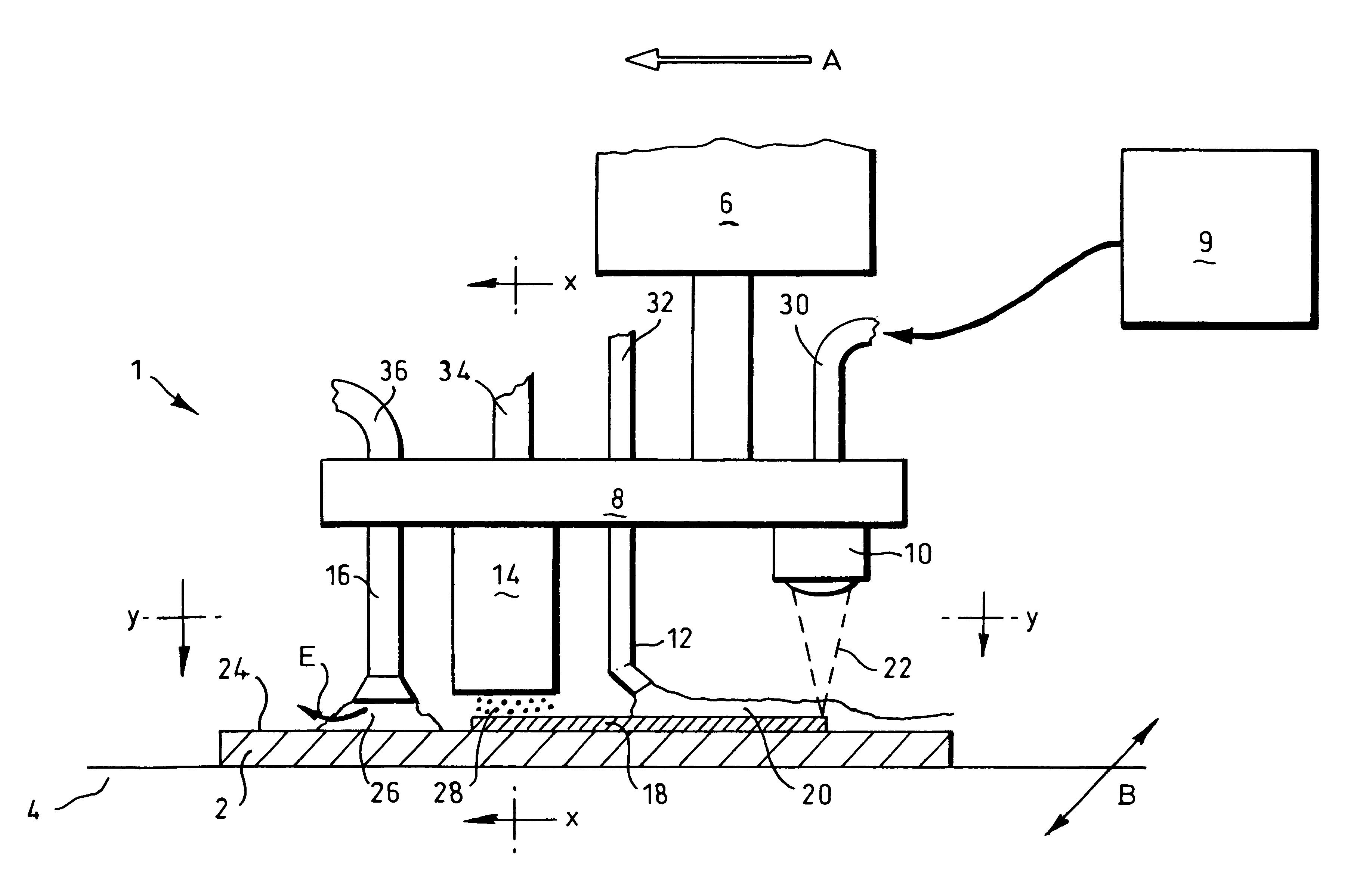

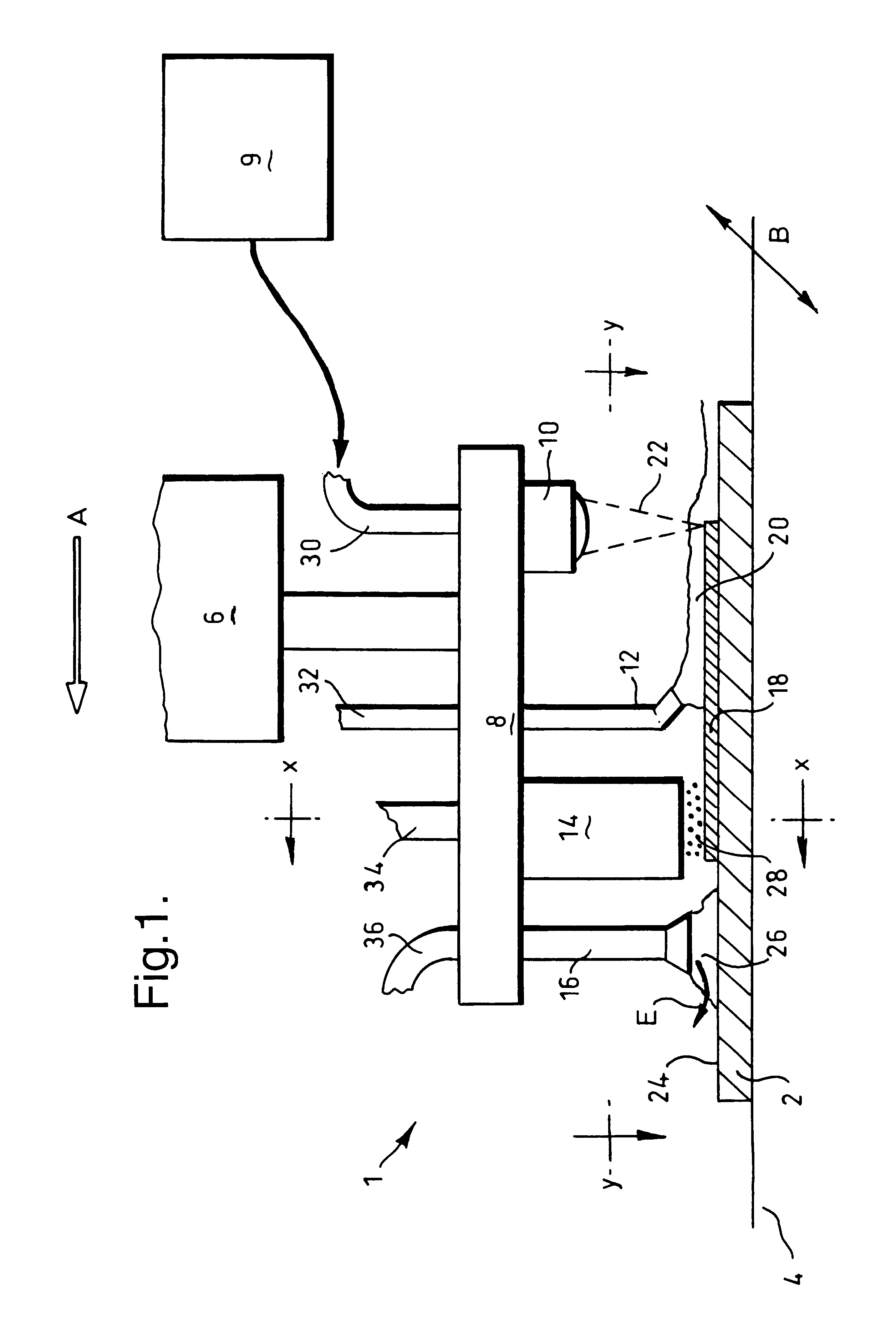

01 Laser shock peening process for additively manufactured components

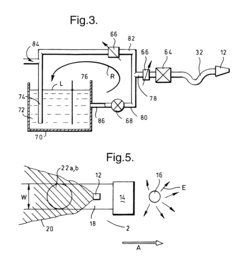

Laser shock peening (LSP) can be applied to additively manufactured metal components to improve their mechanical properties. The process involves directing high-energy laser pulses at the surface of the material, creating plasma and shock waves that induce compressive residual stresses. This treatment enhances fatigue life, stress corrosion resistance, and overall durability of additively manufactured parts that may otherwise suffer from porosity or microstructural defects inherent to the additive manufacturing process.- Laser shock peening process for additively manufactured components: Laser shock peening (LSP) can be applied to additively manufactured metal components to improve their mechanical properties. The process involves directing high-energy laser pulses at the surface of the metal, creating plasma and shock waves that induce compressive residual stresses. This treatment enhances fatigue life, stress corrosion resistance, and overall durability of additively manufactured parts that might otherwise suffer from porosity or internal defects inherent to the additive manufacturing process.

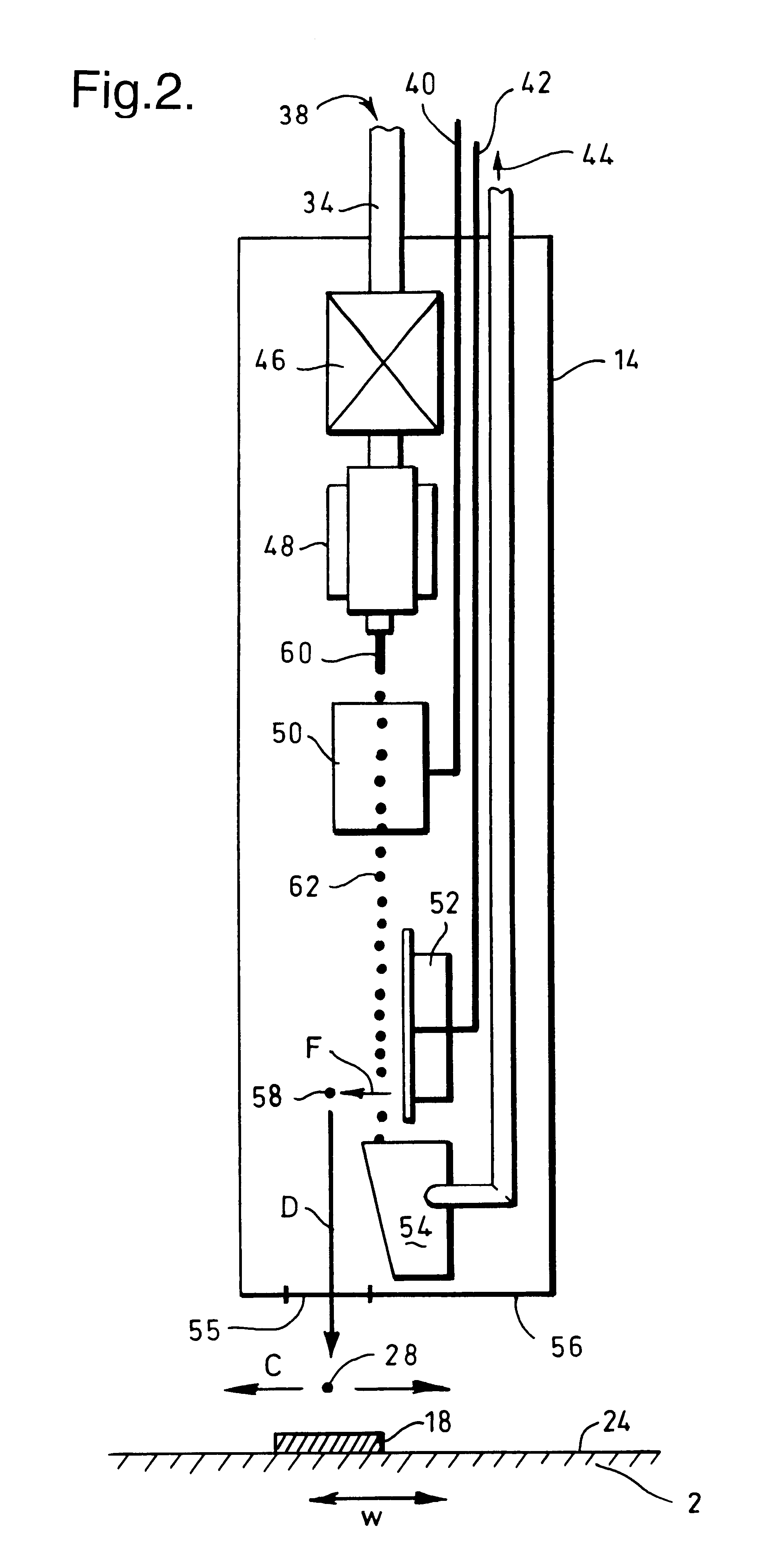

- Equipment and systems for laser shock peening: Specialized equipment and systems are used for laser shock peening of additively manufactured metals. These systems typically include high-power pulsed lasers, beam delivery optics, positioning systems, and transparent overlays (often water) that confine the plasma expansion. Advanced systems may incorporate real-time monitoring capabilities, automated part handling, and precise control of laser parameters to ensure consistent treatment across complex geometries that are common in additively manufactured parts.

- Material-specific laser shock peening techniques: Different additively manufactured metals require specific laser shock peening parameters for optimal results. Titanium alloys, aluminum alloys, nickel-based superalloys, and stainless steels each respond differently to LSP treatment. The laser energy density, pulse duration, spot size, and overlap pattern must be tailored to the specific material properties, microstructure, and intended application. Material-specific techniques have been developed to address the unique characteristics of various metals produced through additive manufacturing processes.

- Post-processing integration with additive manufacturing: Laser shock peening serves as a critical post-processing step in the additive manufacturing workflow. Integration strategies include determining the optimal timing for LSP application (either before or after heat treatment), developing part-specific peening patterns, and establishing quality control protocols. The integration of LSP into the additive manufacturing process chain helps address inherent limitations of 3D printed metals such as residual tensile stresses, anisotropic properties, and surface roughness, resulting in parts with enhanced performance characteristics.

- Performance enhancement and fatigue life improvement: Laser shock peening significantly improves the performance and fatigue life of additively manufactured metal components. The induced compressive residual stresses inhibit crack initiation and propagation, particularly in high-stress areas. Studies have shown that LSP treatment can increase fatigue life by up to several times compared to untreated additively manufactured parts. This enhancement is particularly valuable for critical applications in aerospace, medical implants, and high-performance machinery where component failure could have severe consequences.

02 Equipment and setup for laser shock peening of AM parts

Specialized equipment configurations are required for effective laser shock peening of additively manufactured metals. These setups typically include high-power pulsed lasers, beam delivery systems, positioning mechanisms, and confining media (often water layers). The equipment must be calibrated to deliver precise energy densities and pulse durations appropriate for the specific additively manufactured material being treated, considering its unique microstructure and properties that differ from traditionally manufactured metals.Expand Specific Solutions03 Material-specific considerations for AM metals under LSP

Different additively manufactured metals respond uniquely to laser shock peening treatments. Factors such as grain structure, porosity distribution, and inherent anisotropy from the layer-by-layer building process affect how these materials respond to shock waves. Tailored LSP parameters must be developed for specific AM materials like titanium alloys, nickel-based superalloys, aluminum alloys, and steel variants to optimize the induced compressive stresses while avoiding damage to the material structure.Expand Specific Solutions04 Post-processing integration of LSP in AM production workflow

Laser shock peening can be strategically integrated into the post-processing workflow for additively manufactured components. This integration requires consideration of the component's geometry, critical stress areas, and intended application. LSP may be applied selectively to high-stress regions or comprehensively across the entire component. The timing of LSP application within the overall post-processing sequence (which may include heat treatment, machining, and other surface treatments) is crucial for maximizing benefits while maintaining dimensional accuracy.Expand Specific Solutions05 Performance enhancement and validation of LSP-treated AM parts

Laser shock peened additively manufactured components show significant improvements in fatigue life, wear resistance, and stress corrosion cracking resistance. These enhancements are particularly valuable for high-performance applications in aerospace, medical, and energy sectors. Various testing methodologies including residual stress measurements, microstructural analysis, fatigue testing, and computational modeling are employed to validate the effectiveness of LSP treatments on additively manufactured metals and to predict their long-term performance under service conditions.Expand Specific Solutions

Leading Companies and Research Institutions in LSP-AM Field

Laser Shock Peening (LSP) for additively manufactured metals is currently in an early growth phase, with the market expanding as additive manufacturing adoption increases. The global market is estimated to reach significant value as industries recognize LSP's potential to enhance mechanical properties of AM parts. Technologically, the field shows varying maturity levels across players. Leading companies like Metal Improvement Co. LLC and General Electric have established commercial LSP capabilities, while Lawrence Livermore National Security and Rolls-Royce are advancing research applications. Academic institutions including Massachusetts Institute of Technology, Jiangsu University, and Beihang University are driving fundamental research. The integration of LSP with additive manufacturing represents a specialized niche where industrial-academic partnerships are accelerating technology transfer and application development.

General Electric Company

Technical Solution: General Electric has pioneered an integrated approach to Laser Shock Peening (LSP) for additively manufactured components, particularly focusing on critical aerospace applications. Their technology combines high-powered Nd:YAG lasers operating at 1064 nm wavelength with sophisticated robotic manipulation systems to achieve precise treatment of complex AM geometries. GE's process employs proprietary algorithms that account for the unique microstructural characteristics of AM parts, including their inherent porosity and directional grain structures. The company has developed specialized transparent overlays and ablative coatings optimized for different AM alloys, enhancing shock wave propagation and preventing thermal damage. Their research has demonstrated compressive residual stress depths exceeding 1.5mm in GE's additively manufactured nickel superalloys, with documented fatigue life improvements of 5-10x for critical components. GE has successfully implemented this technology in production for LEAP engine fuel nozzles and other AM components, where they've integrated LSP directly into their manufacturing workflow through automated cells that perform both the AM build and subsequent LSP treatment.

Strengths: Extensive integration with existing AM production lines; proven implementation in flight-critical components; comprehensive material-specific process parameters database. Weaknesses: Proprietary technology with high implementation costs; process optimization required for each new material/geometry combination; limited accessibility for smaller manufacturers.

METAL IMPROVEMENT CO LLC

Technical Solution: Metal Improvement Company (MIC) has developed a comprehensive Laser Shock Peening (LSP) technology specifically optimized for additively manufactured (AM) metals. Their approach involves using high-energy laser pulses (typically 5-20 J) with nanosecond durations to generate plasma on the material surface, creating pressure waves of 1-10 GPa that induce beneficial compressive residual stresses to depths of 1-2 mm. MIC's proprietary system incorporates specialized optics and beam delivery systems that can be precisely calibrated for the unique microstructural characteristics of AM parts, which typically exhibit anisotropic properties and process-induced defects. Their technology includes adaptive control algorithms that adjust laser parameters based on real-time feedback from the material response, ensuring optimal treatment across varying geometries and material compositions common in AM parts. MIC has demonstrated up to 300% fatigue life improvement in laser powder bed fusion (LPBF) Ti-6Al-4V components and significant enhancement of corrosion resistance in 316L stainless steel AM parts through their tailored LSP treatments.

Strengths: Industry-leading expertise in LSP with decades of experience; proprietary equipment specifically calibrated for AM materials; comprehensive process control systems. Weaknesses: Treatment process can be relatively slow for high-volume production; requires significant capital investment; may cause surface roughening that necessitates post-processing.

Key Patents and Research Breakthroughs in LSP for AM

Method and apparatus for improving material properties

PatentInactiveUS6923877B1

Innovation

- Concurrently applying an opaque and a translucent laser-opaque overlay, along with laser shock peening, using a common tool head with an inkjet or bubble jet printer for rapid and precise application, eliminating the need for separate machines and reducing handling.

Material-Specific LSP Parameters Optimization

The optimization of Laser Shock Peening (LSP) parameters for additively manufactured (AM) metals represents a critical research area due to the unique microstructural characteristics of these materials. Unlike conventionally manufactured metals, AM components exhibit distinctive grain structures, porosity distributions, and residual stress patterns that necessitate tailored LSP approaches.

For aluminum alloys produced through selective laser melting (SLM), research indicates optimal laser power densities between 5-8 GW/cm² with pulse durations of 8-12 nanoseconds. These parameters have demonstrated significant improvements in fatigue life, with increases of up to 300% compared to untreated specimens. The application of multiple LSP impacts (3-5 layers) with 50% overlap has proven most effective for addressing the anisotropic properties inherent to SLM-produced aluminum components.

Titanium alloys manufactured via electron beam melting (EBM) require more aggressive treatment parameters, with optimal results achieved at power densities of 7-10 GW/cm² and slightly longer pulse durations of 15-20 nanoseconds. The higher energy input addresses the greater strength and hardness of titanium alloys while accommodating their unique columnar grain structure resulting from the EBM process.

Nickel-based superalloys produced through direct metal laser sintering (DMLS) present particular challenges due to their high temperature resistance and complex precipitate structures. Optimization studies reveal that multiple LSP treatments with gradually increasing power densities (starting at 4 GW/cm² and increasing to 9 GW/cm²) yield superior results compared to constant-parameter approaches. This progressive treatment methodology prevents crack formation while maximizing compressive residual stress depth.

The confining medium selection also varies significantly by material type. Water overlay proves sufficient for aluminum alloys, while transparent adhesive tapes combined with water provide better acoustic impedance matching for titanium and nickel-based superalloys, enhancing shock wave transmission and resulting mechanical effects.

Spot size optimization studies demonstrate that smaller diameters (1-2 mm) are preferable for fine features in AM components, while larger spots (3-5 mm) provide more uniform treatment for bulk sections. This differentiated approach addresses the geometric complexity characteristic of additively manufactured parts.

Recent research utilizing machine learning algorithms has accelerated parameter optimization by predicting optimal LSP settings based on material composition, build parameters, and desired mechanical properties. These computational approaches have reduced experimental iterations by approximately 60%, significantly decreasing development time and material costs in LSP parameter optimization for novel AM alloys.

For aluminum alloys produced through selective laser melting (SLM), research indicates optimal laser power densities between 5-8 GW/cm² with pulse durations of 8-12 nanoseconds. These parameters have demonstrated significant improvements in fatigue life, with increases of up to 300% compared to untreated specimens. The application of multiple LSP impacts (3-5 layers) with 50% overlap has proven most effective for addressing the anisotropic properties inherent to SLM-produced aluminum components.

Titanium alloys manufactured via electron beam melting (EBM) require more aggressive treatment parameters, with optimal results achieved at power densities of 7-10 GW/cm² and slightly longer pulse durations of 15-20 nanoseconds. The higher energy input addresses the greater strength and hardness of titanium alloys while accommodating their unique columnar grain structure resulting from the EBM process.

Nickel-based superalloys produced through direct metal laser sintering (DMLS) present particular challenges due to their high temperature resistance and complex precipitate structures. Optimization studies reveal that multiple LSP treatments with gradually increasing power densities (starting at 4 GW/cm² and increasing to 9 GW/cm²) yield superior results compared to constant-parameter approaches. This progressive treatment methodology prevents crack formation while maximizing compressive residual stress depth.

The confining medium selection also varies significantly by material type. Water overlay proves sufficient for aluminum alloys, while transparent adhesive tapes combined with water provide better acoustic impedance matching for titanium and nickel-based superalloys, enhancing shock wave transmission and resulting mechanical effects.

Spot size optimization studies demonstrate that smaller diameters (1-2 mm) are preferable for fine features in AM components, while larger spots (3-5 mm) provide more uniform treatment for bulk sections. This differentiated approach addresses the geometric complexity characteristic of additively manufactured parts.

Recent research utilizing machine learning algorithms has accelerated parameter optimization by predicting optimal LSP settings based on material composition, build parameters, and desired mechanical properties. These computational approaches have reduced experimental iterations by approximately 60%, significantly decreasing development time and material costs in LSP parameter optimization for novel AM alloys.

Sustainability and Cost-Benefit Analysis of LSP in AM

The sustainability of Laser Shock Peening (LSP) in Additive Manufacturing (AM) processes represents a critical consideration for industrial adoption. Environmental impact assessments reveal that LSP, while energy-intensive during operation, offers significant sustainability advantages through extended component lifespans. Components treated with LSP demonstrate 3-5 times longer fatigue life compared to untreated AM parts, substantially reducing material consumption and replacement frequency in critical applications such as aerospace and medical implants.

Energy consumption analysis indicates that LSP requires approximately 2-4 kWh per square centimeter of treated surface, representing a significant initial energy investment. However, lifecycle assessments demonstrate that this energy expenditure is offset by the reduced need for replacement parts and associated manufacturing processes. For high-value components in aerospace applications, this translates to approximately 30-40% reduction in overall carbon footprint across the product lifecycle.

From a cost perspective, LSP implementation requires substantial initial capital investment, with industrial-grade systems ranging from $500,000 to $2 million. Operational costs include specialized labor ($80-120 per hour), consumables, and maintenance (approximately 5-8% of capital cost annually). However, cost-benefit analyses demonstrate positive ROI for high-value components, particularly in safety-critical applications.

Case studies from aerospace manufacturers indicate that despite adding $2,000-5,000 per component in processing costs, LSP treatment of AM titanium turbine components resulted in maintenance cost reductions exceeding $50,000 per component over their operational lifetime. Medical implant manufacturers report similar economic benefits, with LSP-treated AM implants showing 40% lower revision surgery rates.

The economic viability threshold appears at component values exceeding approximately $10,000, where the extended service life and reduced failure rates justify the additional processing costs. For lower-value components, selective application of LSP only to critical stress areas offers a more economically viable approach, reducing treatment costs by 60-70% while maintaining key performance benefits.

Future sustainability improvements may come from the development of more energy-efficient laser systems, with emerging solid-state technologies promising 30-40% reduction in energy consumption. Additionally, integration of LSP directly into AM production lines could reduce handling and transportation costs, further improving the overall sustainability profile of this technology combination.

Energy consumption analysis indicates that LSP requires approximately 2-4 kWh per square centimeter of treated surface, representing a significant initial energy investment. However, lifecycle assessments demonstrate that this energy expenditure is offset by the reduced need for replacement parts and associated manufacturing processes. For high-value components in aerospace applications, this translates to approximately 30-40% reduction in overall carbon footprint across the product lifecycle.

From a cost perspective, LSP implementation requires substantial initial capital investment, with industrial-grade systems ranging from $500,000 to $2 million. Operational costs include specialized labor ($80-120 per hour), consumables, and maintenance (approximately 5-8% of capital cost annually). However, cost-benefit analyses demonstrate positive ROI for high-value components, particularly in safety-critical applications.

Case studies from aerospace manufacturers indicate that despite adding $2,000-5,000 per component in processing costs, LSP treatment of AM titanium turbine components resulted in maintenance cost reductions exceeding $50,000 per component over their operational lifetime. Medical implant manufacturers report similar economic benefits, with LSP-treated AM implants showing 40% lower revision surgery rates.

The economic viability threshold appears at component values exceeding approximately $10,000, where the extended service life and reduced failure rates justify the additional processing costs. For lower-value components, selective application of LSP only to critical stress areas offers a more economically viable approach, reducing treatment costs by 60-70% while maintaining key performance benefits.

Future sustainability improvements may come from the development of more energy-efficient laser systems, with emerging solid-state technologies promising 30-40% reduction in energy consumption. Additionally, integration of LSP directly into AM production lines could reduce handling and transportation costs, further improving the overall sustainability profile of this technology combination.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!