Process Optimization for Laser Shock Peening of Complex Geometries

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSP Technology Background and Objectives

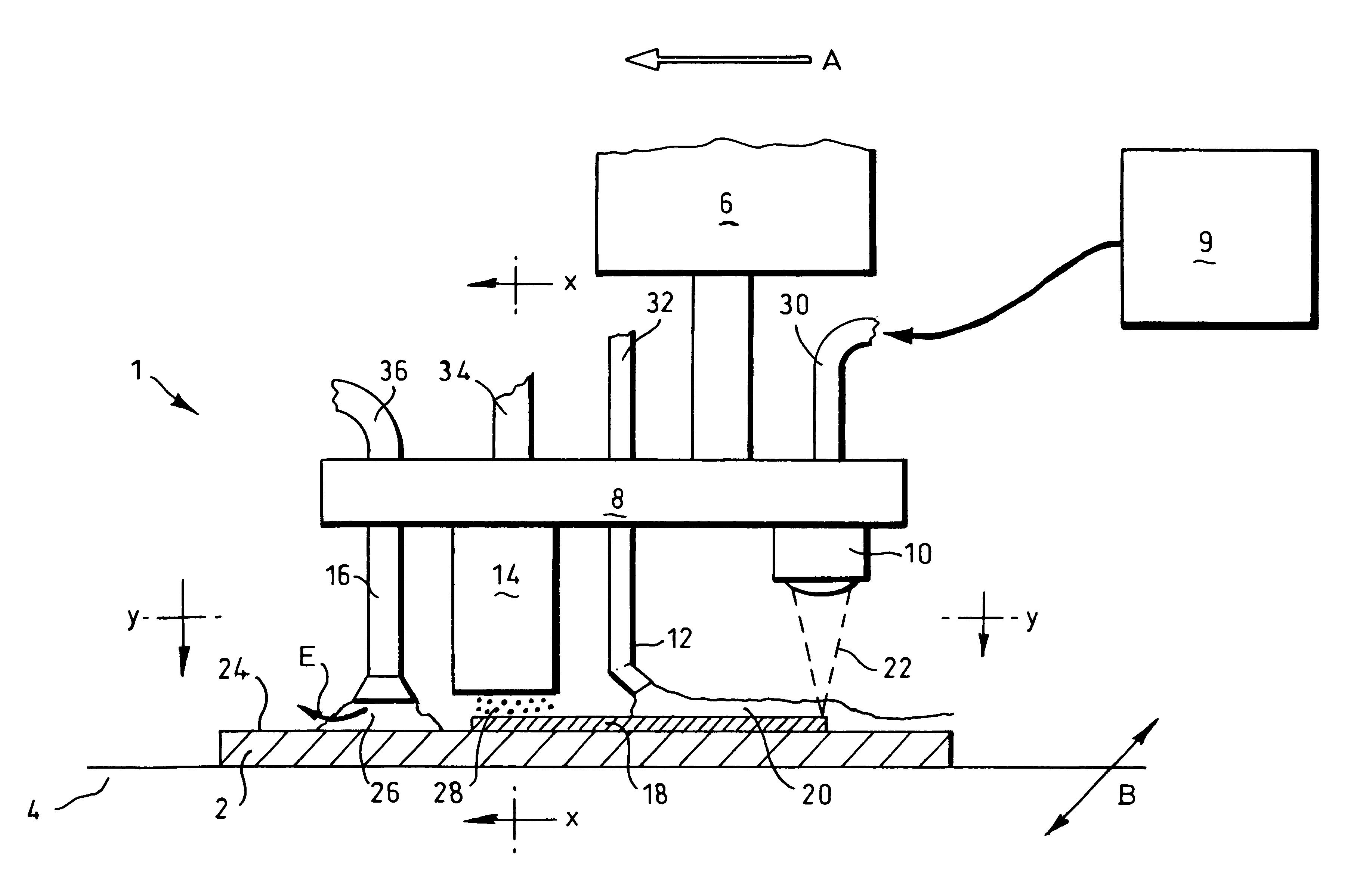

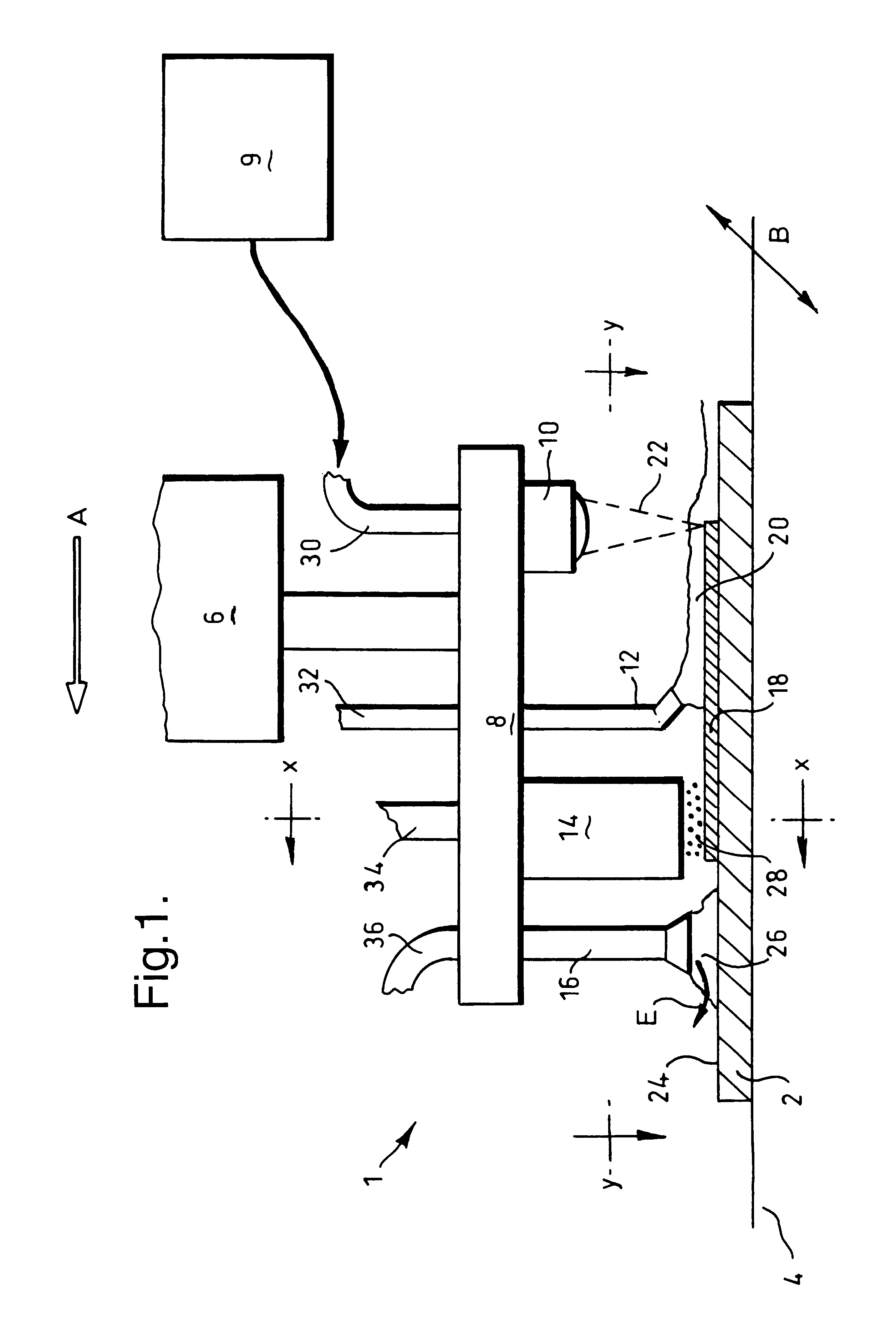

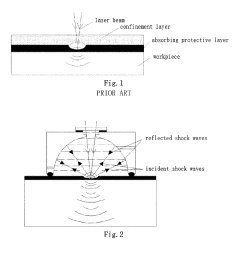

Laser Shock Peening (LSP) emerged in the 1960s as a surface treatment technology initially developed for aerospace applications. The process involves directing high-energy laser pulses at a material surface covered by an ablative layer and a transparent overlay, typically water. This generates plasma and consequently a high-amplitude pressure wave that induces compressive residual stresses in the material, significantly enhancing fatigue life, stress corrosion resistance, and overall mechanical performance.

The evolution of LSP technology has been marked by continuous improvements in laser systems, from early ruby lasers to modern high-power Nd:YAG and fiber lasers, enabling higher processing speeds and more precise applications. Initially limited to flat or simple curved surfaces, the technology now faces the challenge of treating complex geometrical components prevalent in aerospace, automotive, and medical industries.

Current objectives in LSP process optimization for complex geometries focus on several key areas. First, developing adaptive laser beam delivery systems capable of maintaining consistent peening quality across varying surface contours and angles. Second, creating sophisticated computational models that can predict residual stress distributions in complex three-dimensional structures, accounting for geometric effects on shock wave propagation and material response.

Additionally, researchers aim to establish standardized process parameters for different material-geometry combinations, as current parameters often require extensive empirical testing when applied to complex parts. The integration of real-time monitoring systems represents another critical objective, allowing for immediate process adjustments based on feedback from the treated surface.

From an industrial perspective, enhancing process efficiency while maintaining treatment quality remains paramount. This includes reducing processing time through optimized scanning patterns specific to complex geometries and minimizing the need for part repositioning during treatment. The development of more compact, flexible LSP systems that can be integrated into existing manufacturing lines or deployed for in-situ repairs also constitutes a significant technological goal.

The ultimate objective is to transform LSP from a specialized treatment requiring expert oversight to a robust, automated process capable of consistently treating components with intricate features such as internal cavities, sharp edges, and variable thicknesses. This would expand LSP applications beyond current high-value components to broader manufacturing sectors, potentially revolutionizing how industries approach surface enhancement for fatigue-critical components with complex geometries.

The evolution of LSP technology has been marked by continuous improvements in laser systems, from early ruby lasers to modern high-power Nd:YAG and fiber lasers, enabling higher processing speeds and more precise applications. Initially limited to flat or simple curved surfaces, the technology now faces the challenge of treating complex geometrical components prevalent in aerospace, automotive, and medical industries.

Current objectives in LSP process optimization for complex geometries focus on several key areas. First, developing adaptive laser beam delivery systems capable of maintaining consistent peening quality across varying surface contours and angles. Second, creating sophisticated computational models that can predict residual stress distributions in complex three-dimensional structures, accounting for geometric effects on shock wave propagation and material response.

Additionally, researchers aim to establish standardized process parameters for different material-geometry combinations, as current parameters often require extensive empirical testing when applied to complex parts. The integration of real-time monitoring systems represents another critical objective, allowing for immediate process adjustments based on feedback from the treated surface.

From an industrial perspective, enhancing process efficiency while maintaining treatment quality remains paramount. This includes reducing processing time through optimized scanning patterns specific to complex geometries and minimizing the need for part repositioning during treatment. The development of more compact, flexible LSP systems that can be integrated into existing manufacturing lines or deployed for in-situ repairs also constitutes a significant technological goal.

The ultimate objective is to transform LSP from a specialized treatment requiring expert oversight to a robust, automated process capable of consistently treating components with intricate features such as internal cavities, sharp edges, and variable thicknesses. This would expand LSP applications beyond current high-value components to broader manufacturing sectors, potentially revolutionizing how industries approach surface enhancement for fatigue-critical components with complex geometries.

Market Demand Analysis for Advanced Surface Treatment

The global market for advanced surface treatment technologies has witnessed significant growth in recent years, driven primarily by increasing demands for enhanced material performance across multiple industries. Laser Shock Peening (LSP), as a premium surface treatment method, has emerged as a critical technology for improving fatigue life, corrosion resistance, and overall durability of high-value components in aerospace, automotive, medical, and energy sectors.

Market research indicates that the global surface treatment market is projected to reach $15 billion by 2027, with advanced techniques like LSP representing the fastest-growing segment at a CAGR of 7.8%. This growth is particularly pronounced in aerospace and defense sectors, where the need for lightweight yet durable components continues to drive innovation in surface engineering technologies.

The demand for LSP specifically for complex geometries stems from industry trends toward more intricate component designs that optimize weight while maintaining structural integrity. Aerospace manufacturers report that components treated with optimized LSP processes demonstrate 30-40% improvement in fatigue life compared to conventional treatments, translating to significant operational cost savings and enhanced safety margins.

Automotive industry adoption of advanced surface treatments has accelerated with the shift toward electric vehicles, where weight reduction and durability of critical components directly impact vehicle range and performance. Market surveys indicate that 68% of automotive manufacturers are actively exploring advanced surface treatment options for next-generation vehicle platforms.

The medical device industry represents another significant growth area, with demand for precisely controlled surface properties on implantable devices growing at 9.2% annually. LSP offers unique advantages for biomedical applications due to its ability to enhance surface properties without chemical contamination or thermal effects.

Regional analysis reveals that North America currently leads the market for advanced surface treatments (38% market share), followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization and increasing aerospace and automotive manufacturing capabilities in China, Japan, and India.

Customer requirements analysis indicates five key market demands driving LSP process optimization: treatment of increasingly complex geometries, reduction in processing time, improved consistency across varying surface contours, integration with existing manufacturing workflows, and comprehensive quality verification methods. Survey data shows that 72% of potential industrial users cite "ability to effectively treat complex geometries" as their primary consideration when evaluating advanced surface treatment technologies.

Market research indicates that the global surface treatment market is projected to reach $15 billion by 2027, with advanced techniques like LSP representing the fastest-growing segment at a CAGR of 7.8%. This growth is particularly pronounced in aerospace and defense sectors, where the need for lightweight yet durable components continues to drive innovation in surface engineering technologies.

The demand for LSP specifically for complex geometries stems from industry trends toward more intricate component designs that optimize weight while maintaining structural integrity. Aerospace manufacturers report that components treated with optimized LSP processes demonstrate 30-40% improvement in fatigue life compared to conventional treatments, translating to significant operational cost savings and enhanced safety margins.

Automotive industry adoption of advanced surface treatments has accelerated with the shift toward electric vehicles, where weight reduction and durability of critical components directly impact vehicle range and performance. Market surveys indicate that 68% of automotive manufacturers are actively exploring advanced surface treatment options for next-generation vehicle platforms.

The medical device industry represents another significant growth area, with demand for precisely controlled surface properties on implantable devices growing at 9.2% annually. LSP offers unique advantages for biomedical applications due to its ability to enhance surface properties without chemical contamination or thermal effects.

Regional analysis reveals that North America currently leads the market for advanced surface treatments (38% market share), followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization and increasing aerospace and automotive manufacturing capabilities in China, Japan, and India.

Customer requirements analysis indicates five key market demands driving LSP process optimization: treatment of increasingly complex geometries, reduction in processing time, improved consistency across varying surface contours, integration with existing manufacturing workflows, and comprehensive quality verification methods. Survey data shows that 72% of potential industrial users cite "ability to effectively treat complex geometries" as their primary consideration when evaluating advanced surface treatment technologies.

Current Challenges in Complex Geometry Processing

Laser Shock Peening (LSP) of complex geometries presents significant technical challenges that currently limit its widespread industrial application. The primary obstacle lies in the non-uniform distribution of residual stresses when processing components with intricate shapes, corners, edges, and varying thicknesses. Conventional LSP systems, originally designed for flat or simple curved surfaces, struggle to maintain consistent peening intensity across complex three-dimensional features, resulting in under-processed or over-processed areas.

The laser beam delivery system faces particular difficulties when attempting to maintain optimal incident angles on complex surfaces. When the angle deviates from perpendicular, the energy density distribution becomes distorted, leading to inconsistent shock wave generation and unpredictable residual stress profiles. Current robotic positioning systems lack the precision required for complex geometries, with positioning errors as small as 0.5mm potentially causing significant variations in treatment effectiveness.

Process monitoring presents another major challenge, as real-time feedback mechanisms for complex geometries remain underdeveloped. Unlike flat surfaces where plasma formation and expansion can be easily monitored, complex geometries create variable plasma dynamics that are difficult to interpret. This makes quality control problematic and necessitates extensive post-processing inspection, significantly increasing production costs and cycle times.

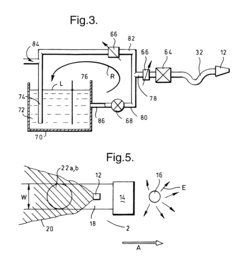

Water confinement layer management becomes exceptionally difficult on vertical surfaces, undercuts, and internal features. The water layer, critical for shock wave amplification, tends to flow unevenly on complex surfaces, creating dry spots that result in process inefficiency or even surface damage. Current water delivery systems lack the sophistication to ensure uniform coverage on intricate geometries.

Material response variability compounds these challenges, as different alloys and microstructures respond uniquely to LSP treatment. This variability becomes more pronounced in components with geometry-induced stress concentrations or pre-existing residual stress fields. The interaction between these factors creates complex mechanical responses that current simulation models struggle to predict accurately.

Computational limitations further hinder progress, as existing finite element models for LSP process optimization require enormous computational resources when applied to complex geometries. Most models make simplifying assumptions that become invalid for intricate shapes, resulting in significant discrepancies between predicted and actual residual stress distributions. The development of more efficient and accurate simulation tools remains a critical research need.

The laser beam delivery system faces particular difficulties when attempting to maintain optimal incident angles on complex surfaces. When the angle deviates from perpendicular, the energy density distribution becomes distorted, leading to inconsistent shock wave generation and unpredictable residual stress profiles. Current robotic positioning systems lack the precision required for complex geometries, with positioning errors as small as 0.5mm potentially causing significant variations in treatment effectiveness.

Process monitoring presents another major challenge, as real-time feedback mechanisms for complex geometries remain underdeveloped. Unlike flat surfaces where plasma formation and expansion can be easily monitored, complex geometries create variable plasma dynamics that are difficult to interpret. This makes quality control problematic and necessitates extensive post-processing inspection, significantly increasing production costs and cycle times.

Water confinement layer management becomes exceptionally difficult on vertical surfaces, undercuts, and internal features. The water layer, critical for shock wave amplification, tends to flow unevenly on complex surfaces, creating dry spots that result in process inefficiency or even surface damage. Current water delivery systems lack the sophistication to ensure uniform coverage on intricate geometries.

Material response variability compounds these challenges, as different alloys and microstructures respond uniquely to LSP treatment. This variability becomes more pronounced in components with geometry-induced stress concentrations or pre-existing residual stress fields. The interaction between these factors creates complex mechanical responses that current simulation models struggle to predict accurately.

Computational limitations further hinder progress, as existing finite element models for LSP process optimization require enormous computational resources when applied to complex geometries. Most models make simplifying assumptions that become invalid for intricate shapes, resulting in significant discrepancies between predicted and actual residual stress distributions. The development of more efficient and accurate simulation tools remains a critical research need.

Current Process Solutions for Complex Geometries

01 Laser parameters optimization for shock peening

Optimization of laser parameters such as power density, pulse duration, spot size, and repetition rate is crucial for effective laser shock peening. These parameters directly influence the depth and intensity of the compressive residual stresses induced in the material. Proper calibration and control of these parameters can enhance fatigue life, corrosion resistance, and overall material performance. Advanced monitoring systems can be used to ensure consistent laser output during the peening process.- Laser parameters optimization for shock peening: Optimization of laser parameters such as power density, pulse duration, spot size, and repetition rate is crucial for effective laser shock peening. These parameters directly influence the depth and intensity of the compressive residual stresses induced in the material. Proper calibration and control of these parameters can enhance fatigue life, corrosion resistance, and overall material performance. Advanced monitoring systems can be used to ensure consistent laser output during the peening process.

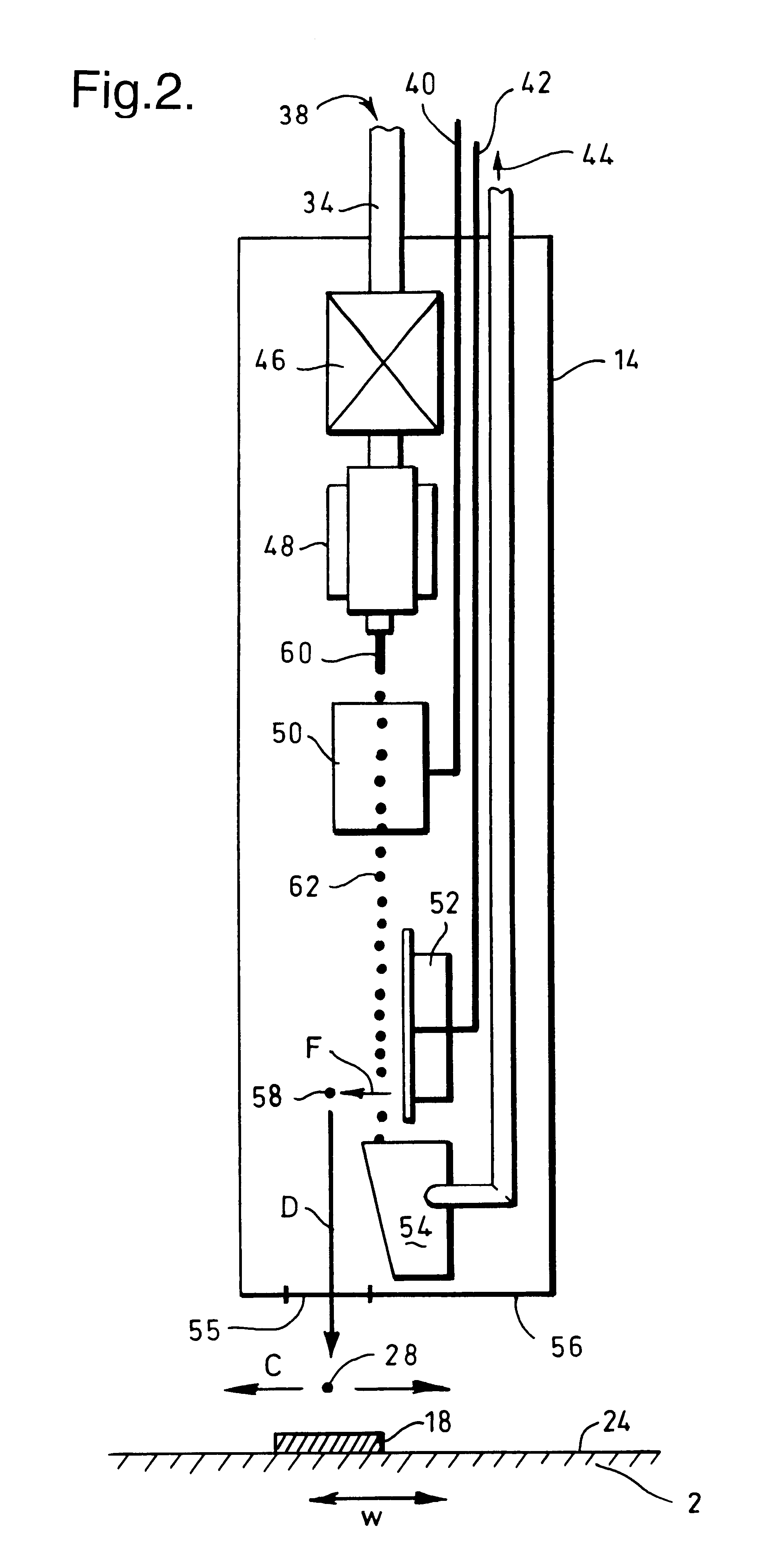

- Overlay and confinement layer configurations: The design and application of overlay and confinement layers significantly impact the effectiveness of laser shock peening. The overlay typically absorbs the laser energy and converts it to plasma, while the confinement layer constrains the plasma expansion to direct the shock wave into the material. Optimizing the thickness, composition, and application method of these layers can enhance the shock wave intensity and improve the overall peening effect on various metallic components.

- Process monitoring and quality control techniques: Implementing robust monitoring and quality control systems is essential for laser shock peening process optimization. This includes real-time monitoring of plasma formation, shock wave propagation, and material response. Advanced techniques such as interferometry, high-speed imaging, and acoustic emission analysis can be used to verify the effectiveness of the peening process. These monitoring systems help maintain consistency and ensure that the desired material properties are achieved across all treated components.

- Material-specific treatment strategies: Different materials require tailored laser shock peening approaches for optimal results. Factors such as material composition, microstructure, thickness, and initial condition influence the response to shock peening. Optimization strategies include adjusting laser parameters, developing specific overlay configurations, and determining optimal treatment patterns based on the material properties. This material-specific approach ensures maximum improvement in fatigue life, stress corrosion resistance, and other mechanical properties for various aerospace, automotive, and medical components.

- Automation and processing path optimization: Automation systems and optimized processing paths significantly enhance the efficiency and consistency of laser shock peening operations. Computer-controlled robotic systems can precisely position the laser beam and maintain optimal standoff distances for complex geometries. Path planning algorithms can determine the most effective sequence and pattern of laser spots to achieve uniform coverage and avoid overprocessing or underprocessing. These automated approaches reduce processing time, minimize human error, and enable the treatment of complex components with consistent quality.

02 Overlay and confinement layer optimization

The selection and application of appropriate overlay and confinement layers significantly impact the effectiveness of laser shock peening. The overlay absorbs laser energy and creates plasma when vaporized, while the confinement layer (typically water or transparent material) contains the plasma expansion, enhancing the shock wave intensity. Optimizing the thickness, composition, and application method of these layers can maximize the pressure of the shock wave transmitted to the workpiece, resulting in deeper and more uniform compressive residual stresses.Expand Specific Solutions03 Process monitoring and quality control techniques

Advanced monitoring and quality control techniques are essential for optimizing laser shock peening processes. These include real-time plasma diagnostics, acoustic emission monitoring, laser beam profiling, and post-process residual stress measurement. Implementation of these techniques allows for immediate feedback and adjustment of process parameters, ensuring consistent treatment quality across components. Digital twins and AI-based monitoring systems can predict and prevent process deviations before they affect part quality.Expand Specific Solutions04 Material-specific peening strategies

Different materials require tailored laser shock peening strategies for optimal results. Factors such as material hardness, thermal conductivity, and microstructure influence the response to shock waves. For example, titanium alloys, aluminum alloys, and superalloys each require specific laser parameters and treatment patterns. Optimization involves adjusting spot overlap, treatment density, and processing sequence based on material properties to achieve desired residual stress profiles without causing thermal damage or unwanted microstructural changes.Expand Specific Solutions05 Automation and path planning optimization

Automation systems and optimized path planning significantly enhance the efficiency and consistency of laser shock peening processes. Computer-controlled robotic systems can precisely position the laser beam on complex geometries, ensuring uniform coverage and consistent spot overlap. Advanced algorithms can determine optimal treatment sequences to minimize residual distortion while maximizing beneficial compressive stresses. Integration with CAD/CAM systems allows for automated generation of peening paths based on component geometry and stress requirements.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The laser shock peening (LSP) for complex geometries market is in a growth phase, characterized by increasing adoption across aerospace, automotive, and energy sectors. The global market size is estimated to exceed $300 million, with projected annual growth of 7-9%. Technologically, the field shows varying maturity levels, with established players like LSP Technologies and Metal Improvement Co. leading commercial applications, while academic institutions (Jiangsu University, Beihang University, Shandong University) drive fundamental research. Major industrial players including GE, Airbus, Rolls-Royce, and United Technologies are integrating LSP into manufacturing processes for critical components. The competitive landscape features collaboration between research institutions and industry partners to overcome challenges in processing complex geometries, with emerging competition from Chinese manufacturers expanding capabilities.

General Electric Company

Technical Solution: General Electric has developed an integrated approach to Laser Shock Peening (LSP) for complex geometries, particularly focused on aircraft engine components and power generation turbines. Their technology utilizes multi-axis robotic systems combined with advanced simulation software that predicts residual stress distributions in complex parts before processing. GE's approach incorporates digital twin technology to create virtual models of components that guide the LSP process parameters in real-time. Their system employs adaptive optics that can dynamically adjust the laser beam characteristics based on the surface orientation and material properties at each specific location on complex parts. GE has also pioneered the use of conformal overlays that adapt to irregular surfaces, ensuring consistent plasma confinement even on highly curved or angular geometries. Their process optimization includes machine learning algorithms that analyze historical processing data to continuously refine parameters for similar geometric features across different components, creating a self-improving system that becomes more efficient with each application.

Strengths: Extensive experience with critical aerospace components; integration with comprehensive digital manufacturing ecosystem; ability to combine LSP with other surface treatments for optimized component performance; robust validation through actual service testing. Weaknesses: Solutions may be optimized primarily for GE's own product lines; high implementation costs; potential intellectual property restrictions limiting broader application.

LSP Technologies, Inc.

Technical Solution: LSP Technologies has pioneered the Laser Peening Process Optimization for Complex Geometries through their patented Procudo® Laser Peening System. This system employs advanced robotics and multi-axis positioning systems specifically designed to handle complex part geometries with precision. Their approach includes real-time monitoring and control of laser parameters (pulse energy, duration, spot size) that automatically adjust based on the specific geometry being processed. The company has developed specialized beam delivery systems that can access difficult-to-reach surfaces and internal features through sophisticated optical path manipulation. Their proprietary software creates optimized peening patterns that account for varying material thicknesses and complex curvatures, ensuring uniform residual stress distribution across irregular surfaces. LSP Technologies has also implemented in-process quality verification using optical and acoustic sensors to validate treatment effectiveness on complex parts in real-time, allowing for immediate adjustments to processing parameters when necessary.

Strengths: Industry-leading expertise specifically in laser shock peening with proprietary equipment designed for complex geometries; comprehensive process control systems that adapt to varying part geometries; extensive experience with aerospace and power generation components. Weaknesses: Their specialized equipment may require significant capital investment; process optimization may be time-consuming for entirely new geometries; limited scalability for very high-volume production environments.

Core Technical Innovations in LSP Processing

Method and apparatus for improving material properties

PatentInactiveUS6923877B1

Innovation

- Concurrently applying an opaque and a translucent laser-opaque overlay, along with laser shock peening, using a common tool head with an inkjet or bubble jet printer for rapid and precise application, eliminating the need for separate machines and reducing handling.

Laser Shock Peening Apparatus for Surface of Workpiece, and Laser Shock Peening Method

PatentActiveUS20190271059A1

Innovation

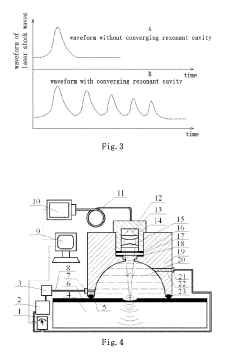

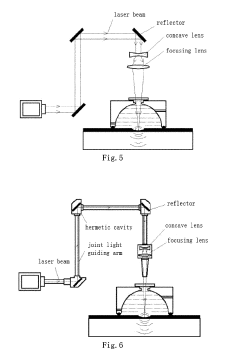

- A laser shock peening apparatus employing a resonant cavity with a fluid confinement layer that restricts the fluid inside, allowing for repeated reflection and convergence of shock waves, increasing energy utilization and improving processing efficiency and reliability.

Material-Specific Considerations for LSP Applications

The effectiveness of Laser Shock Peening (LSP) varies significantly across different material types, necessitating tailored approaches for optimal results. Metallic materials exhibit diverse responses to LSP treatment based on their crystalline structure, mechanical properties, and thermal characteristics. For instance, aluminum alloys typically require lower laser energy densities compared to titanium alloys due to their lower yield strength and higher thermal conductivity. This material-specific behavior demands precise parameter calibration to achieve the desired compressive residual stress profiles without causing surface damage.

High-strength steels present unique challenges in LSP applications, as their hardness can lead to reduced plastic deformation under shock waves. For these materials, multiple LSP impacts at the same location may be necessary to achieve sufficient residual stress depth. Conversely, nickel-based superalloys used in aerospace components respond well to LSP but require careful control of pulse overlap to prevent excessive surface roughening that could compromise fatigue performance.

The microstructural characteristics of materials significantly influence LSP outcomes. Materials with fine grain structures generally exhibit more uniform residual stress distributions compared to coarse-grained variants. Additionally, materials with high strain hardening capacity, such as austenitic stainless steels, can achieve deeper compressive residual stress layers through the LSP process. These material-specific responses must be considered when developing process parameters for complex geometries.

Surface conditions prior to LSP treatment also play a crucial role in process optimization. Materials with pre-existing surface treatments, such as coatings or chemical modifications, may require adjusted laser parameters to compensate for altered absorption characteristics. Furthermore, the presence of surface oxides or contaminants can significantly impact the efficiency of pressure wave generation and subsequent material strengthening.

Temperature sensitivity represents another critical material-specific consideration. Some alloys, particularly precipitation-hardened materials, may experience microstructural changes if excessive heating occurs during the LSP process. This necessitates careful control of pulse frequency and cooling strategies to maintain material integrity while achieving the desired surface enhancement.

For complex geometries, the anisotropic properties of certain materials add another layer of complexity. Directionally solidified or single-crystal components, common in turbine applications, exhibit orientation-dependent responses to LSP treatment. Process parameters must therefore be adjusted based on the local crystallographic orientation to ensure uniform strengthening across the entire component surface.

High-strength steels present unique challenges in LSP applications, as their hardness can lead to reduced plastic deformation under shock waves. For these materials, multiple LSP impacts at the same location may be necessary to achieve sufficient residual stress depth. Conversely, nickel-based superalloys used in aerospace components respond well to LSP but require careful control of pulse overlap to prevent excessive surface roughening that could compromise fatigue performance.

The microstructural characteristics of materials significantly influence LSP outcomes. Materials with fine grain structures generally exhibit more uniform residual stress distributions compared to coarse-grained variants. Additionally, materials with high strain hardening capacity, such as austenitic stainless steels, can achieve deeper compressive residual stress layers through the LSP process. These material-specific responses must be considered when developing process parameters for complex geometries.

Surface conditions prior to LSP treatment also play a crucial role in process optimization. Materials with pre-existing surface treatments, such as coatings or chemical modifications, may require adjusted laser parameters to compensate for altered absorption characteristics. Furthermore, the presence of surface oxides or contaminants can significantly impact the efficiency of pressure wave generation and subsequent material strengthening.

Temperature sensitivity represents another critical material-specific consideration. Some alloys, particularly precipitation-hardened materials, may experience microstructural changes if excessive heating occurs during the LSP process. This necessitates careful control of pulse frequency and cooling strategies to maintain material integrity while achieving the desired surface enhancement.

For complex geometries, the anisotropic properties of certain materials add another layer of complexity. Directionally solidified or single-crystal components, common in turbine applications, exhibit orientation-dependent responses to LSP treatment. Process parameters must therefore be adjusted based on the local crystallographic orientation to ensure uniform strengthening across the entire component surface.

Equipment and Automation Requirements for Complex Geometries

The implementation of Laser Shock Peening (LSP) for complex geometries necessitates specialized equipment and automation systems that can accommodate intricate surface contours while maintaining process precision. Conventional LSP equipment designed for flat or simple curved surfaces often proves inadequate when processing components with complex three-dimensional features, internal cavities, or variable thickness regions.

High-precision robotic manipulation systems represent a critical requirement for complex geometry processing. Six-axis industrial robots with advanced path planning capabilities enable the laser beam to maintain optimal incident angles relative to varying surface normals. These systems must achieve positioning accuracy within ±0.1mm and angular precision of ±0.5 degrees to ensure consistent peening intensity across complex surfaces. Integration of real-time surface mapping technologies further enhances adaptive positioning capabilities.

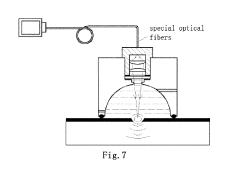

Laser delivery systems for complex geometries require significant modifications compared to conventional setups. Flexible beam delivery architectures incorporating articulated mirror arms or fiber optic systems allow the laser to access difficult-to-reach areas. For internal surfaces, specialized optical assemblies with beam-steering capabilities have been developed, though these currently face limitations in terms of energy transmission efficiency and spot size control when operating in confined spaces.

Conformal transparent overlay application presents another significant challenge. Automated systems utilizing precision spray nozzles mounted on robotic arms can apply water layers with controlled thickness even on vertical or inverted surfaces. For more complex geometries, immersion techniques or localized containment systems have been developed to maintain consistent overlay conditions regardless of surface orientation.

Monitoring systems for complex geometries must incorporate multi-sensor arrays that can track process parameters across varying surface conditions. Advanced systems integrate laser spot imaging, plasma emission spectroscopy, and acoustic monitoring to provide comprehensive process feedback. These data streams enable real-time adjustments to laser parameters based on local surface conditions, ensuring uniform residual stress profiles throughout the component.

Fixturing requirements become particularly demanding for complex parts, necessitating custom-designed workholding solutions that provide rigid support while allowing access to all treatment surfaces. Computer-aided fixture design software, coupled with rapid prototyping technologies, enables the development of geometry-specific fixturing solutions that minimize setup time while maximizing treatment coverage.

High-precision robotic manipulation systems represent a critical requirement for complex geometry processing. Six-axis industrial robots with advanced path planning capabilities enable the laser beam to maintain optimal incident angles relative to varying surface normals. These systems must achieve positioning accuracy within ±0.1mm and angular precision of ±0.5 degrees to ensure consistent peening intensity across complex surfaces. Integration of real-time surface mapping technologies further enhances adaptive positioning capabilities.

Laser delivery systems for complex geometries require significant modifications compared to conventional setups. Flexible beam delivery architectures incorporating articulated mirror arms or fiber optic systems allow the laser to access difficult-to-reach areas. For internal surfaces, specialized optical assemblies with beam-steering capabilities have been developed, though these currently face limitations in terms of energy transmission efficiency and spot size control when operating in confined spaces.

Conformal transparent overlay application presents another significant challenge. Automated systems utilizing precision spray nozzles mounted on robotic arms can apply water layers with controlled thickness even on vertical or inverted surfaces. For more complex geometries, immersion techniques or localized containment systems have been developed to maintain consistent overlay conditions regardless of surface orientation.

Monitoring systems for complex geometries must incorporate multi-sensor arrays that can track process parameters across varying surface conditions. Advanced systems integrate laser spot imaging, plasma emission spectroscopy, and acoustic monitoring to provide comprehensive process feedback. These data streams enable real-time adjustments to laser parameters based on local surface conditions, ensuring uniform residual stress profiles throughout the component.

Fixturing requirements become particularly demanding for complex parts, necessitating custom-designed workholding solutions that provide rigid support while allowing access to all treatment surfaces. Computer-aided fixture design software, coupled with rapid prototyping technologies, enables the development of geometry-specific fixturing solutions that minimize setup time while maximizing treatment coverage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!